Abstract

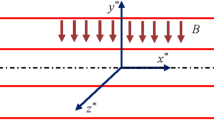

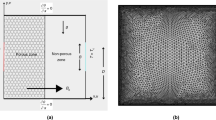

In this paper, a 3D model of magnetohydrodynamic (MHD) micropump with a rectangular channel was modeled and numerically simulated based on the finite volume method. Effects of geometrical parameters such as depth, width, and length of the side electrodes were studied on the maximum flow rate, maximum pressure, and energy rate of the rectangular MHD channels in constant electric current and constant power supply modes. The multiple attributes decision-making method was used in order to identify the most effective geometrical parameters on the performance of the micropump. Wider channels with long electrodes are identified to be in favor of high performance for high flow rate, high pressure, and energy-efficient demands. A case study of new profile with a widened channel in the pumping section was proposed, and its new geometrical parameters are introduced. Studies at constant energy rate of 1 mW showed that the extension of the channel width (electrode walls) can increase the flow rate up to 1.23 μl/min (34% increase in comparison with non-extended channel). Additionally, it was found that when the extension parameter is set to 3.5 (D/w = 3.5), the flow rate is independent of the elongation parameter (r/R).

Similar content being viewed by others

References

Rapp R, Schomburg W, Maas D, Schulz J, Stark W (1994) LIGA micropump for gases and liquids. Sens Actuators A Phys 40(1):57–61

Jeong OC, Yang SS (2000) Fabrication and test of a thermopneumatic micropump with a corrugated p+ diaphragm. Sens Actuators A Phys 83(1–3):249–255

Nguyen N, Schubert S, Richter S, Dötzel W (1998) Hybrid-assembled micro dosing system using silicon-based micropump/valve and mass flow sensor. Sens Actuators A Phys 69(1):85–91

Zengerle R, Ulrich J, Kluge S, Richter M, Richter A (1995) A bidirectional silicon micropump. Sens Actuators A Phys 50(1–2):81–86

Olsson A, Enoksson P, Stemme G, Stemme EJ (1997) Micromachined flat-walled valveless diffuser pumps. J Microelectromech Syst 6(2):161–166

Bart SF, Tavrow LS, Mehregany M, Lang JH (1990) Microfabricated electrohydrodynamic pumps. Sens Actuators A Phys 21(1–3):193–197

Vazquez-Pinon M, Pramanick B, Ortega-Gama FG, Perez-Gonzalez VH, Kulinsky L, Madou MJ, Hwang H, Martinez-Chapa SO (2019) Hydrodynamic channeling as a controlled flow reversal mechanism for bidirectional AC electroosmotic pumping using glassy carbon microelectrode arrays. J Micromech Microeng 29(7):075007

Aeinehvand M, Sánchez ER, Benítez BC, Martínez-Chapa SO (2018) Carbon iso-dielectric separation (CIDS) on centrifugal microfluidic platforms. In: Meeting abstracts, vol 39. The Electrochemical Society, pp 1307–1307

Soto FOR, Aeinehvand M, Moreno MFJ, Mager D, Madou MJ, Martínez-Chapa SO (2018) Electrolysis pumping on centrifugal microfluidic platforms for automation of bioanalytical Assays. In: Meeting Abstracts, vol 39. The Electrochemical Society, pp 1304–1304

Torniainen ED, Govyadinov AN, Markel DP, Kornilovitch PE (2012) Bubble-driven inertial micropump. Phys Fluids 24(12):122003

McNamara S, Gianchandani YB (2005) On-chip vacuum generated by a micromachined Knudsen pump. J Microelectromech Syst 14(4):741–746

Ritchie W (1837) Experimental researches in voltaic electricity. In: Abstracts of the papers printed in the philosophical transactions of the Royal Society of London. The Royal Society, pp 98–101

Williams EJ (1930) The induction of electromotive forces in a moving liquid by a magnetic field, and its application to an investigation of the flow of liquids. Proc Phys Soc 42(5):466

Asai S (1989) Birth and recent activities of electromagnetic processing of materials. ISIJ Int 29(12):981–992

Winowich N, Hughes W, Ramos J (1987) Numerical simulation of electromagnetic pump flow. Numer Methods Laminar Turbul Flow 5:1228–1240

Ramos J, Winowich N (1990) Finite difference and finite element methods for MHD channel flows. Int J Numer Methods Fluids 11(6):907–934

Han J, Zuo C, Wang W (2019) Numerical investigation of the MHD flow under the influence of heat transfer in rectangular ducts. IEEE Trans Plasma Sci 47(2):1399–1404

Fendoğlu H, Bozkaya C, Tezer-Sezgin M (2019) MHD flow in a rectangular duct with a perturbed boundary. Comput Math Appl 77(2):374–388

Wang P-J, Chang C-Y, Chang M-L (2004) Simulation of two-dimensional fully developed laminar flow for a magneto-hydrodynamic (MHD) pump. Biosens Bioelectron 20(1):115–121

Ho J-E (2007) Characteristic study of MHD pump with channel in rectangular ducts. J Mar Sci Technol 15(4):315–321

Lim S, Choi B (2009) A study on the MHD (magnetohydrodynamic) micropump with side-walled electrodes. J Mech Sci Technol 23(3):739–749

Shamloo A, Madadelahi M, Akbari A (2016) Numerical simulation of centrifugal serpentine micromixers and analyzing mixing quality parameters. Chem Eng Process Process Intensif 104:243–252

Kang H-J, Choi B (2011) Development of the MHD micropump with mixing function. Sens Actuators A Phys 165(2):439–445

Farahbakhsh I, Paknejad A, Ghassemi H (2012) Numerical simulation of 2-D laminar flow subjected to the Lorentz force effect in a channel with backward-facing step. J Mech Sci Technol 26(10):3111–3117

Shahidian A, Ghassemi M, Khorasanizade S, Abdollahzade M, Ahmadi G (2009) Flow analysis of non-Newtonian blood in a magnetohydrodynamic pump. IEEE Trans Magn 45(6):2667–2670

Moghaddam S (2013) MHD micropumping of power-law fluids: a numerical solution. Korea Aust Rheol J 25(1):29–37

Ni M-J, Munipalli R, Morley NB, Huang P, Abdou MA (2007) A current density conservative scheme for incompressible MHD flows at a low magnetic Reynolds number. Part I: on a rectangular collocated grid system. J Comput Phys 227(1):174–204

Nowruzi H, Ghassemi H (2018) Effects of nano-nozzles cross-sectional geometry on fluid flow: molecular dynamic simulation. J Mech 34(5):667–678

Saaty TL (1980) The analytic hierarchy process. McGrawHill, New York

Ciarlet PG (2002) The finite element method for elliptic problems, vol 40. Society for Industrial and Applied Mathematics, Philadelphia, pp 1–511

Azimi J, Zakeri M, Javidfard M (2015) A numerical study on characteristics of the magnetohydrodynamic micropumps. In: 2015 3rd RSI international conference on robotics and mechatronics (ICROM). IEEE, pp 401–405

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Edson José Soares, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azimi-Boulali, J., Zakeri, M. & Shoaran, M. A study on the 3D fluid flow of MHD micropump. J Braz. Soc. Mech. Sci. Eng. 41, 478 (2019). https://doi.org/10.1007/s40430-019-1979-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1979-1