Abstract

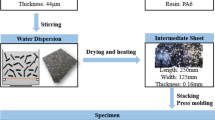

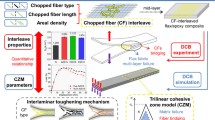

A common industrial production process for composites is filament winding, widely used for the production of axially symmetric components. In these composite components, delamination is a predominant failure mechanism. The current work focuses on investigating experimentally the effect of the initial crack and fiber bridging length on the mode-I delamination resistance curve (R-curve) behavior of various double cantilever beam (DCB) specimens. For this purpose, the magnitudes of initiation and propagation fracture toughness (GIC-init and GIC-prop) and the compliance C are calculated. DCB specimens with a stacking sequence of [± 50]6 and various initial crack lengths of a0 = 33, 37, 59 and 70 mm are manufactured from a real composite pipe using filament winding process. In order to evaluate the critical energy release rate in mode-I, various fracture tests are conducted on these specimens. The greatest bridging zone length dues to good penetration of two adjacent layers of the delamination interface. Moreover, the results indicate that the fiber bridging length has a significant effect on the GIC and the largest value of fiber bridging causes a large fracture toughness value. Finally, numerical simulations are performed using finite element (FE) method and GIC-init measurements obtained experimentally are compared to the numerical findings. The numerical displacements and GIC-init, calculated from the numerical displacements, are found to be in good agreement compared to the experimental results.

Similar content being viewed by others

References

Peters ST (2011) Composite filament winding. ASM International, Russell Township

Ainsworth L (1981) Fibre-reinforced plastic pipes and applications. Composites 12(3):185–190

Babu MS, Srikanth G, Biswas S (2005) Composite fabrication by filament winding-an insight. http://www.tifac.org.in/news/acfil.htm

Buarque E, d’Almeida J (2007) The effect of cylindrical defects on the tensile strength of glass fiber/vinyl-ester matrix reinforced composite pipes. Compos Struct 79(2):270–279

Perillo G, Echtermeyer A (2012) Evaluation of mode I interlaminar fracture toughness of filament-wound GFRE composite pipe. In: 15th European conference on composite materials, ECCM, Venice, Italy, 24–28 June 2012

Kormaníková E (2014) Delamination of laminate plates. Adv Mater Res 969:97–100

Davies P, Rannou F (1994) The effect of defects in tubes: part 1. Mode-I delamination resistance. Appl Compos Mater 1(5):333–349

Ozdil F, Carlsson L, Li X (2000) Characterization of mode-II delamination growth in glass/epoxy composite cylinders. J Compos Mater 34(4):274–298

Ozdil F, Carlsson L (2000) Characterization of mode-I delamination growth in glass/epoxy composite cylinders. J Compos Mater 34(5):398–419

Ozdil F, Carlsson L (2000) Characterization of mixed mode delamination growth in glass/epoxy composite cylinders. J Compos Mater 34(5):420–441

Hutchinson JW, Suo Z (1991) Mixed mode cracking in layered materials. Adv Appl Mech 29:63–191

Lauke B, Friedrich K (1993) Evaluation of processing parameters of thermoplastic composites fabricated by filament winding. Compos Manuf 4(2):93–101

Beckert W, Lauke B, Friedrich K (1994) Delamination toughness computation for curved thermoplastic composites. Appl Compos Mater 1(5):395–400

Andersons J, König M (2004) Dependence of fracture toughness of composite laminates on interface ply orientations and delamination growth direction. Compos Sci Technol 64(13):2139–2152

Ozdil F, Carlsson L (1999) Beam analysis of angle-ply laminate DCB specimens. Compos Sci Technol 59(2):305–315

Huimin F, Yongbo Z (2011) On the distribution of delamination in composite structures and compressive strength prediction for laminates with embedded delaminations. Appl Compos Mater 18(3):253–269

Naini JK (2016) Impact analysis of embedded delamination location in hybrid curved laminated composite stiffened panel. Appl Compos Mater 23(4):639–658

Kuboki T et al (2005) A new method to quantify delamination resistance of fibre reinforced polymers (FRP) under transverse loading. Appl Compos Mater 12(2):93–108

Dalmas D, Laksimi A (1999) On the method of determination of strain energy release rate during fatigue delamination in composite materials. Appl Compos Mater 6(5):327–340

Davies P, Blackman B, Brunner A (1998) Standard test methods for delamination resistance of composite materials: current status. Appl Compos Mater 5(6):345–364

Li F et al (2015) Experimental tests on the composite foam sandwich pipes subjected to axial load. Appl Compos Mater 22(6):669–691

De Morais A et al (2002) Mode-II interlaminar fracture of filament wound angle-ply specimens. Appl Compos Mater 9(2):117–129

Rekbi FML, Hecini M (2015) Etude expérimentale du délaminage en mode I des tubes fabriqués par enroulement filamentaire. Revue des Composites et des Matériaux Avancés 25(3–4):373–384

ASTM (2007) Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. ASTM, Conshohocken

Shokrieh M, Heidari-Rarani M, Ayatollahi M (2012) Delamination R-curve as a material property of unidirectional glass/epoxy composites. Mater Des 34:211–218

Benzeggagh ML (1980) Application de la mécanique de la rupture aux matériaux composites Exemple de la rupture par délaminage d’un stratifié. Thèse de Doctorat, Université de Technologie de Compiègne France

Haugen DJ (1998) Fracture of skin–stiffener intersections in composite wind turbine blade structures. Montana State University, Bozeman

De Moura M et al (2010) Interlaminar and intralaminar fracture characterization of composites under mode-I loading. Compos Struct 92(1):144–149

Daelemans L et al (2015) Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils. Compos Sci Technol 117:244–256

Zhou J et al (1992) A study of mode I delamination resistance of a thermoplastic composite. Compos Sci Technol 45(2):173–179

Acknowledgements

The authors would like to express their thanks for the management of the company MAGHREB PIPE M’Sila, Algeria, on their positive cooperation by providing the necessary quantity and the decent quality of material used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Fernando Antonio Forcellini.

Rights and permissions

About this article

Cite this article

Rekbi, F.M.L., Hecini, M. & Khechai, A. Experimental and numerical analysis of mode-I interlaminar fracture of composite pipes. J Braz. Soc. Mech. Sci. Eng. 40, 502 (2018). https://doi.org/10.1007/s40430-018-1423-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1423-y