Abstract

The synthesis of δ-MnO2, δ-MnO2 carbon dots nanocomposite, and Fe/Cu-doped δ-MnO2 carbon dots nanocomposite has been successfully carried out through a stirring process at room temperature and 80 °C. The synthesized powder shows a low crystallization determined through XRD and TEM analysis. Furthermore, the carbon dots are well attached to MnO2 performing a core–shell composite material, while the doping ions Fe and Cu were incorporated into the matrix substitute Mn in the MnO6 octahedron, although potassium ions were also detected. The manganese possess an oxidation state of + 3 and + 4, which promotes the oxygen vacancy creation \({V}_{\mathrm{O}}^{\cdot\cdot}\) denoting the conductivity decrease.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of fossil energy nowadays is being worked on to minimize its utilization due to causing a problem, i.e., is a limited source and the root of an environmental issue. The use of alternate energy becomes intriguing. Correspondingly, the need for adequate energy storage in the sense of highly possessing power and energy density becomes imperative, such as batteries and supercapacitors. In supercapacitors, the charge–discharge cycle mechanism and charge stored are reversible. Metallic oxide is an alternative for an electrode material that holds high specific capacitance and low resistivity. Typical metal oxide materials were reported, RuO2, MnO2, NiO, Co3O4, and NiCo2O4 [1]. Manganese oxide is among the most interesting due to its high theoretical specific capacitance (1370 F gr−1), low cost, and environmentally friendly [2].

Given the structure, manganese oxide behaves in polymorph structures α, β, γ, δ, and λ-type MnO2. The polymorphism can be described by the number of octahedral sub-units (n × m), where n and m stand for the dimensions of the tunnels in the two directions perpendicular to the chains of the edge-sharing octahedral MnO6. The α-type structure is characteristic of (2 × 2) and (1 × 1) of MnO6 octahedra units aligned along the c-axis. The β-MnO2 is characterized by one-dimensional chains of MnO6 octahedra aligned along the c-axis to form (1 × 1) size vacant tunnels. γ-MnO2 type structure is an intergrowth structure consisting of (2 × 1) and (1 × 1) tunnels. The δ-type MnO2 has a layered structure; each layer is composed of edge-sharing MnO6 octahedra. Finally, the λ-type MnO2 has a defective spinel structure [3]. It was reported that these structures possess thermal stability order β > α > γ > δ ≈ λ [4].

The use of MnO2 as charge storage was involved in the capability of the manganese oxidation state alteration Mn3+ and Mn4+ inside the octahedron MnO6 presenting defect [5], and hence, the storage capacity can be improved through doping creating defects. Metallic ions, such as V, Ru, Ag, Co, Ni, Sn, Cu, and Fe, were reported as successful dopants for Mn [16, 17, 22, 23]. Previous studies revealed that Fe- and Cu-doped α-MnO2 [6, 7], both Fe and Cu present a mixed oxidation state Fe+3, Fe4+, and Cu2+, Cu3+, while Mn3+, Mn4+. This creates defects \({\mathrm{Fe}}_{\mathrm{Mn}}^{\prime}\), \({\mathrm{Cu}}_{\mathrm{Mn}}^{\prime}\), \({\mathrm{Mn}}_{\mathrm{Mn}}^{\prime}\), and \({V}_{\mathrm{O}}^{\cdot\cdot}\). The Cu2+ has large size, may filled tunnel (2 × 2) otherwise substitute Mn creating \({\mathrm{Cu}}_{\mathrm{Mn}}^{{\prime\prime}}\). Given the dopant percentage, 5% of dopant Cu and Fe is the plausible characteristics in view of conductivity and permittivity.

Moreover, decreases in the average crystallite size have two effects, reduce the appearance of lattice strain, increase the effective surface area, and finally facilitate the charge transfer during the charging and discharging processes. In parallel, to increase the conductivity, carbon-based material was usually used as an improver [8]. Several types of supercapacitors were reported, among them was a carbon base supercapacitor developed through an electric double-layer capacitor (EDLC) to include carbon nanotubes (CNTs), activated carbon, carbon black, and carbon fiber [9,10,11]. On the other hand, carbon dots (CDs) have a small dimension (≈ 10 nm) which is considerable attribute including enhanced electron transferability, long-term chemical stability, negligible toxicity, and acquaintance of large effective surface area-to-volume ratio [12]. Nanostructures and composite material engineering are effective methods for improving electrode capacitive performance. The core–shell structure has been shown to be an effective technique for improving the electrochemical performances of nanocomposites, resulting in improved electrical conductivity, shorter ionic transport, and stronger bonds [13]. Given the good sense above, the material composed of MnO2-doped containing carbon should be expected to give an exceptional characteristic.

Various synthesis methods have been reported, i.e., sol–gel [14], coprecipitation [15], electrodeposition [16], hydrothermal reaction [17], and oxidation–reduction (Redox) method [18]. The redox reaction is a simple method for producing selective MnO2 with high specific capacitance. The production of MnO2 by such a process has the benefit of being a very rapid, one-pot reaction that is performed at a low temperature and takes shorter, and the technique is fulfilled by basic laboratory equipment [19]. Given the previous synthesis methods, it is intriguing to pursue the synthesis of doped MnO2/CDs nanocomposites at low temperatures to simplify synthesis suitable to electrochemical storage such as supercapacitors. To discover the description of the synthesized powder, MnO2/CDs’ nanocomposite that will be synthesized based on a redox reaction between Mn2+ and Mn4+, mixed with CDs and further 5% of the metal transition Fe3+ and Cu2+ as dopants.

Materials and methods

Materials’ preparation

Synthesis of carbon dots (CDs)

The CDs were completed using a one-step hydrothermal process with glucose, and 6 g of glucose were dissolved in 60 ml of deionized water by stirring for 30 min. The solution was then transferred to a 100-ml stainless-steel autoclave with a Teflon lining, which was subsequently put in a 180 °C oven for 2 h. The autoclave was naturally cooled to room temperature, and the CD solvent was acquired. After the hydrothermal treatment, the translucent suspension turns brown. The produced brown suspension was centrifuged at 4500 rpm for 15 min and filtered through a 0.22-μm filter.

Synthesis of δ-MnO2

In this study, we applied a mixed oxidation–reduction process using MnCl2 and KMnO4 to synthesize δ-MnO2, following the redox reaction:

In a typical MnO2 synthesis, 0.712 g of MnCl2.4H2O was ultrasonically dissolved in 60 ml of distilled water for 1 h. Following that, 0.948 g of KMnO4 was added to this solution, which was then stirred for about 10 min at room temperature and continued for 1 h at 80 °C, and the pink color of permanganate changed to brownish-black. The product was washed several times with deionized water and ethanol until the filtrate became neutral, then dried at 80 °C for 2 h. The sample δ-MnO2 was referred to as M-0 and MS for stirring at room temperature and 80 °C, respectively.

Synthesis of δ-MnO2/CDs nanocomposites and doped samples

Because of the thin-layered structure of graphene [20], almost all of the carbon atoms are reactive; thus, it can be oxidized by MnO4− ions in an acid solution via the following chemical reaction:

Given the thin carbon dot (CDs) size, it is expected that the above reaction will occur in the case of MnO2/CDs (MnO2 + xC). In this procedure, 7.12 ml CDs solution was added to a solution of MnCl2.4H2O, followed by a similar preparation as above. MnO2/CDs nanocomposites were made using the stirring method at low temperatures (room temperature and 80 °C). The products are abbreviated as MC-0 and MCS. The schematic of this process is shown in Fig. 1. To synthesize Fe- and Cu-doped nanocomposite samples, FeCl3·6H2O and CuCl2·2H2O (5 mol%) were used as dopant reagents and added to the above solution and proceeded similarly.

Characterization

The phase and crystal structure of MnO2 were investigated using X-ray diffraction (XRD Philips X'Pert) with Cu–K radiation at 30 mA and 40 kV, step scan 0.02°, and Bragg angle range of 5°–60°. Through the match, phase identification was accomplished! Software. Fast Fourier transform infrared (FTIR) measurements were used to determine the chemical structure of MnO2 and nanocomposites.

Field emission scanning electron microscope (FESEM) images and other element maps involving energy-dispersive X-ray (EDX) analysis were used to determine the morphology. Using ImageJ software, the numerical dimension of each sample was obtained by averaging the diameters of nanorods from different samples.

X-ray photoelectron spectroscopy (XPS) analysis data were obtained with an Axis Ultra DLD system equipped with an Al monochromatic was carried out to analyze the oxidation state of Mn and other elements in the sample.

Electrical measurements were taken on powder that was inserted between two copper electrodes and then uniaxially pressed with a 13 mm diameter. The data were collected using a Solartron Impedance Analyzer SI 1260 at room temperature with a frequency range of 0.1 Hz to 32 MHz and an applied voltage of 1 V.

Results and discussion

Powder assessment using X-ray diffraction and FTIR

X-ray diffraction (XRD) studies have been used to identify the presence of the different phases/purity of synthesized MnO2 and MnO2/CD nanocomposites. The X-ray diffraction spectra of the MnO2 and MnO2/CDs composite mixed at room temperature are presented in Fig. 2a. It is noted that diffraction peaks show broad peaks at 2θ around 37°, which can be indexed to δ-type MnO2 (JCPDS 42-1317). Further analysis, the γ-type MnO2 (JCPDS 14-0644) [21] seems to be matched with the spectra MC0. It was reported that in processing at low temperatures [3], either γ-phase or δ-phase was formed. Therefore, it can be considered as a mixed phase of δ and γ-MnO2. Broad peaks are related to a coincidence of diffraction peaks of (110) of the δ phase and (131) of the γ phase, besides, a poorly crystallized compound originating from the small grain size and approximately amorphous state of the powder. The δ-phased MnO2 is a 2D layered structure with an interlayer separation of ~ 7 Å between the MnO6 octahedra, in which a large number of stabilizing cations, such as K+ and H+, were considered to fill those spaces. While the γ-MnO2 contains octahedrons chain corner and edge-sharing producing (2 × 1) and (1 × 1) tunnel. In another disparity treatment, the sample was then stirred at a temperature of 80 °C for an hour. The spectra of X-ray diffraction on MnO2 samples, MnO2/CDs’ nanocomposites, and Cu- and Fe-doped samples are shown.

XRD patterns confirm MnO2/CDs with mixed crystalline and amorphous parts, δ-MnO2 and γ-MnO2 exhibited low intensity and broad diffraction peaks at 37°, which is typical of hexagonal randomly stacked and single-phased Birnessite-type MnO2 [23]. The diffraction peaks of MCS had not changed when compared to MnO2. The MnO2/CDs were no longer pure MnO2 phases, but the contours of the peaks were nearly identical. Therefore, it can be concluded that the presence of CDs does not change the crystal structure of MnO2.

Further investigation was conducted by FTIR measurements to characterize the chemical structure of MnO2 and nanocomposites. Figure 2b shows the FTIR spectra of MnO2 and MnO2/CDs with different methods of preparation, i.e., stirred at room temperature and 80 °C. The peaks presented at 518 cm−1 and 524 cm−1 are attributed to the stretching vibrations of Mn–O–Mn. A broad peak centered at 3444 cm−1 and a shoulder peak at 1645 cm−1 reveal the existence of hydroxyl groups on the surfaces of materials. The existence of CDs was demonstrated by the characteristic absorption at 1200 cm−1 in which the former was signed to the C=C vibrational stretch. The undetected signal of Cu and Fe dopants should be considered that its low concentration and substitute Mn in BO6 octahedron makes it signal covered by Mn–O–Mn-stretching vibration.

Microstructure and structure analysis through FESEM/TEM

Field emission scanning electron microscope (FESEM) analysis is used to decipher the surface morphology of the as-obtained δ-MnO2 and composites material (Fig. 3a). All sample shows spherical morphology with a flower-like type of nanostructures, with a diameter of about 300 nm. The addition of CDs to MnO2 causes the surface of the nanocomposite’s appearance to be smoother, which indicates the presence of CDs attached to the surface of MnO2.

Further analysis using EDX, Fig. 3b shows the MCS-Fe sample for representatives, and the similar fashion for other samples should be referred to supplement Fig. 1S. It was observed the K+ ion residue on all synthesized materials, which may fill in between layers due to its ionic size makes K+ not substitute Mn4+ in MnO6 octahedron. Dopants Fe and Cu were detected which indicates that dopants were incorporated in the MnO2 matrix a priori substitute Mn in MO6 octahedron. Furthermore, carbon was also detected, which confirmed the FTIR and FESEM analysis given previously.

Further detailed analysis insight into the morphology, TEM analysis, and SAED were used in MC’s samples. Figure 4 shows the shape of the morphology of MCs that flower type which is similar to that of FESEM. Furthermore, at higher magnifications up to 300.000 × (Fig. 4b), the grains are observed as typically elongated nanorods of the dimension ≈ 2 nm (width) and ≈100 nm (length) and shortened in Fe/Cu-doped sample. It is also the core cell type grains shown by the MCS sample (Fig. 4b inset) that signifies MnO2 grains are covered by CDs, while non-carbonated sample MS are absent from carbon cells. This occurrence reinforces the analysis given by FESEM and EDX previously.

The SAED pictures show a circles fringe indicating polycrystal diffraction and are indexed as (110) and (020) reflection planes of δ-MnO2 (Table 1); however, a wide fringe is presented which is an indication of low crystalline arrangement; otherwise, the coincidence of the reflection plane owing to γ-MnO2 as described in XRD analysis previously and CDs coated grains.

XPS analysis

The elemental composition and surface functional group types of δ-MnO2 (MS), δ-MnO2/CDs composite (MCS), and Fe/Cu-doped MnO2/CDs (MCS-Fe, MCS-Cu), as well as the state of Mn and O in the materials were studied using XPS. Figure 5 shows the MCS-Fe sample of the XPS survey spectrum and the deconvolution of selected peaks high-resolution spectrum of Mn3s, C1s, O1s, Mn2p, and Fe2p. Further data should be referred to in Fig. 2S. It demonstrates that the composite is primarily made up of the elements Mn, C, and O. The high-resolution XPS of Mn2p is shown in Fig. 5e (so did for other samples depicted in Fig. 2S); there are three distinct characteristic peaks at 641.92 eV, 643.75 eV, 653.52 eV, and 654.35 eV which are indexed to Mn2p3/2 and Mn2p1/2, respectively (Table 2). While the energy difference between Mn2p3/2 and Mn2p1/2 characteristic peaks is 11.80 eV, it proves the presence of Mn in the form of + 3 and + 4 valence in the composite material. Based on high-resolution XPS spectra of Mn2p and O1s, it can be decided that the Mn element in the composite is in the form of MnO2.

The Mn 3 s is used to calculate the average oxidation state of Mn, with reducing energy separation among the 7 S and 5 S multiplet associated with an increasing oxidation state [24]. From the deconvolution process using Gaussian function, Mn3s spectrum analysis (Fig. 5b), possessing a spin-energy splitting of 4.77, 4.57, and 5.03 eV and using Beyreuther equation [25], revealed the average oxidation state of Mn are 2.832, 3.594, 2.009, and 2.648 5.384, 4.784, 6,032 and 5.529 for MS, MCS, MCS-Fe, and MCS-Cu, respectively. This demonstrates that the average oxidation states (AOS) of Mn are Mn3+ and Mn4+. All deconvolution of Mn 2p peaks as well as the AOS are presented in Table 2.

The deconvoluted O1s spectrum (Fig. 5d) can be fitted with the presence of an Mn–O–Mn bond (cantered at 529.49 eV), and an Mn–O-H bond (531.1 eV) belonging to defect oxide or hydroxyl-like groups [26]. The lattice oxygen Mn–O–Mn content was gradually decreased with the carbon and dopant (Fe, Cu), with the areal of Mn–O-Mn over MS, MCS, MCS-Fe, and MCS-Cu summarized in Table 2. Another important difference in the O 1 s spectra of MCS nanocomposites compared to that of doping samples is the decrease in the relative intensity of peak, which can suggest a decrease in the number of Mn–O bonds. This may be due to the existence of Mn3+, Fe2+, Fe3+, or Cu2+ species on the surface, indicating the possibility of oxygen vacancies in the sample.

Additionally, to study the structural configuration of carbon dots and their defects (such as vacancies and disorder) in MnO2/CDs’ nanocomposites, the C1s peak of MCS-Fe was deconvoluted into three peaks with binding energies of 284.73 eV is related to C = C/C–C graphitic structure (sp2), 286.26 eV attributed to C–O in hydroxyls, epoxy groups, and phenols, and 288.09 eV associated with C=O/C–OOH in ketones, aldehydes, and quinones [27]. An addition of CDs has a significant effect on the composition of the C–C/C=C functional group. Meanwhile, Fe and Cu doping caused a level shift of binding energy that tend to interact between dopant and carbon and confirms the presence of defects and vacancies in this sample. The FWHM of nanocomposites varies in the range of 1–2.5 eV.

Deconvolution of Fe2p revealed the energy characteristic Fe3+ at 710.82 eV and 712.58 eV 2p3/2, while the 2p1/2 indicated Fe3+ at 724.71 eV. Furthermore, Cu 2p peaks, which include Cu 2p3/2 peak at 935.34 eV to satellite peaks at 947 eV, and the Cu 2p1/2 peak at 956.81 eV. In general, the presence of the Cu2O phase is confirmed. The lack of this phase in the XRD pattern, on the other hand, suggests that its presence is limited to the surface layer and the creation of exposure to air and oxygen. Regardless, the most common oxidation state in this material is Cu2+. Presumably, Fe2+, Fe3+ and Cu2+ substitute Mn4+ in MO6 octahedron creating defect \({\mathrm{Fe}}_{\mathrm{Mn}}^{{\prime\prime}}\) \({\mathrm{Fe}}_{\mathrm{Mn}}^{\prime}\), \({\mathrm{Cu}}_{\mathrm{Mn}}^{{\prime\prime}}\), and \({V}_{\mathrm{O}}^{\cdot\cdot}\).

Electrical properties

The electrical circuit model of the arrangement described in paragraph 2.2. includes a wiring circuit, material response, and electrodes. However, given the attained data, the wiring and electrode response should be insignificant comparing the material response, and hence, the circuit model approach should become the serial of a parallel circuit of resistance and capacitance of grain and grain boundary. The electrical analysis therefore should be conducted using two methods: the Nyquist plot and the Debye plot based on the circuit model given in Fig. 6 (inset) of the material then deduced to the equation as depicted in Eqs. (3–5) [28]. The resistance R1, R2, and capacitance C1, C2 should be deduced through either impedance Z′–Z″ plot or Debye relaxation where ωRC’s = 1 at the maximum of Z′′(ω)

Figure 6 depicts a Nyquist plot of real impedance Z′ versus imaginary impedance Z′′ for all samples, demonstrating the formation of negative Z′ which signifies a capacitive response. Focusing on the material aspect, two semicircles are composed of grain resistance and capacitance, and grain boundary resistance and capacitance responses. The addition of CDs in the sample results in larger radius semicircles. The small semicircle observed in MS suggests that the electrical processes in the material arise because of grain material contribution. The semicircle radius increased dramatically in MCS-Fe and MCS-Cu samples, indicating that doping Fe and Cu results in the formation of defects that inhibit electron mobility, increasing resistance.

Figure 7a depicts the real impedance Z′ component versus frequency. The amplitude of Z′ is greater in the low-frequency region, decreases monotonically with increasing frequency, and then drops significantly above f ≈ 104 Hz. Furthermore, the magnitude of Z′ increases with the addition of CD and dopant, and its value for all samples combine in the higher frequency region. This could be due to the release of space charge polarization caused by the material's decreased barrier properties at high frequencies. Cu and Fe doping increases oxygen vacancies caused by the possibility of substitution of Fe3+, Fe2+, Cu2+, and Cu+ on Mn4+.

Figure 7b shows the frequency dependence of imaginary impedance Z″ at different composite, with a typical Debye relaxation curve at f ≈ 103 Hz and f ≈ 105 Hz, as well as the detailed numerical values of R1 and R2 determined by relaxation frequency. As shown in the graph, the Z″ value rises initially, reaches a peak Z″ max, and then falls with frequency. With the addition of CDs and dopants, the position of the Z″ peak increases and regularly shifts to a lower frequency, indicating a gathering of relaxation times in the system. Table 3 summarizes the numerical values of material resistance (R1 and R2) concluded by the Nyquist plot and Debye relaxation frequency, with a focus on the grain response of the Z′ and Z″.

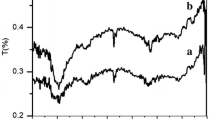

The permittivity of the material is related to the capacitance. The relative permittivity and phase as a function of frequency are depicted in Fig. 8 for various samples. All samples showed that dielectric constants reduced with increasing frequency before achieving constant values in the high-frequency region.

At low frequencies, space charge determines relative permittivity, whereas dipole polarization determines it at high frequencies. The unbounded electrons produced during defect reactions caused by unusually high relative permittivity are referred to as space charges. The presence of multiple defects in the material causes the formation of defect dipoles, which leap to face the high frequency of the external electric field, resulting in low permittivity.

Figure 9 depicts the relationship between area capacitance and frequency. All samples had MnO2 areal capacitances with CDs, and the doping with Fe and Cu varies slightly between samples, with the MS sample having the highest values. The high areal capacitance at low frequencies is predominantly the response of space charges and drops quickly with increasing frequency.

Conclusion

The synthesis of MnO2 carbon dots was successfully carried out at low temperatures; no significantly different results are presented by treatment at room temperature and 80 °C. The powder was a poorly crystallized compound resulting from the small grain size. Carbon dots are well adhered to the MnO2 surface making the core–shell type grains. Mn poses an oxidation state of + 3 and 4 + . The K+ ionic residue has a large size; it is rather filled between two layers of MnO6 octahedron chains. The Fe and Cu dopant present in a mixed oxidation state, incorporated in the MnO2 matrix generating defects \({\mathrm{Fe}}_{\mathrm{Mn}}^{\prime}\), \({\mathrm{Cu}}_{\mathrm{Mn}}^{{\prime\prime}}\), and \({V}_{\mathrm{O}}^{\cdot\cdot}\). The presence of the oxygen vacancy disrupts the charge mobility resulting in a decrease in the conductivity of doped material.

Data availability

Data related to this article is available on demand.

References

Wang, Y., Guo, J., Wang, T., Shao, J., Wang, D., Yang, Y.-W.: Mesoporous transition metal oxides for supercapacitors. Nanomaterials 5, 1667–1689 (2015). https://doi.org/10.3390/nano5041667

Baral, A., Satish, L., Zhang, G., Ju, S., Ghosh, M.K.: A review of recent progress on nano MnO2: synthesis, surface modification and applications. J. Inorg. Organomet. Polym. 31, 899–922 (2021). https://doi.org/10.1007/s10904-020-01823-z

Devaraj, S., Munichandraiah, N.: Effect of crystallographic structure of MnO2 on its electrochemical capacitance properties. J. Phys. Chem. C 112, 4406–4417 (2008). https://doi.org/10.1021/jp7108785

Hatakeyama, T., Okamoto, N.L., Ichitsubo, T.: Thermal stability of MnO2 polymorphs. J. Solid State Chem. 305, 122683 (2022). https://doi.org/10.1016/j.jssc.2021.122683

Balachandran, D.: First principles study of structure, defects and proton insertion in MnO2 n.d.:100.

Hastuti, E., Subhan, A., Amonpattaratkit, P., Zainuri, M., Suasmoro, S.: The effects of Fe-doping on MnO2: phase transitions, defect structures and its influence on electrical properties. RSC Adv. 11, 7808–7823 (2021). https://doi.org/10.1039/D0RA10376D

Hastuti, E., Subhan, A., Amonpattaratkit, P., Zainuri, M., Triwikantoro, T., Suasmoro, S.: Oxidation state, local structure distortion, and defect structure analysis of Cu doped α-MnO2 correlated to conductivity and dielectric properties. Heliyon 8, e11459 (2022). https://doi.org/10.1016/j.heliyon.2022.e11459

Wang, B., Qiu, J., Feng, H., Wang, N., Sakai, E., Komiyama, T.: Preparation of MnO2/carbon nanowires composites for supercapacitors. Electrochim. Acta 212, 710–721 (2016). https://doi.org/10.1016/j.electacta.2016.07.066

Xia, H., Wang, Y., Lin, J., Lu, L.: Hydrothermal synthesis of MnO2/CNT nanocomposite with a CNT core/porous MnO2 sheath hierarchy architecture for supercapacitors. Nanoscale Res. Lett. (2012). https://doi.org/10.1186/1556-276X-7-33

Kim, S., Lee, J., Kang, J.S., Jo, K., Kim, S., Sung, Y.-E., et al.: Lithium recovery from brine using a λ-MnO2/activated carbon hybrid supercapacitor system. Chemosphere 125, 50–56 (2015). https://doi.org/10.1016/j.chemosphere.2015.01.024

Malak-Polaczyk, A., Matei-Ghimbeu, C., Vix-Guterl, C., Frackowiak, E.: Carbon/λ-MnO2 composites for supercapacitor electrodes. J. Solid State Chem. 183, 969–974 (2010). https://doi.org/10.1016/j.jssc.2010.02.015

Cui, L., Ren, X., Sun, M., Liu, H., Xia, L.: Carbon dots: synthesis, properties and applications. Nanomaterials 11, 3419 (2021). https://doi.org/10.3390/nano11123419

Gao, H., Cao, S., Cao, Y.: Hierarchical core-shell nanosheet arrays with MnO2 grown on mesoporous CoFe2O4 support for high-performance asymmetric supercapacitors. Electrochim. Acta 240, 31–42 (2017). https://doi.org/10.1016/j.electacta.2017.04.062

Dixini, P.V.M., Carvalho, B.B., Gonçalves, G.R., Pegoretti, V.C.B., Freitas, M.B.J.G.: Sol–gel synthesis of manganese oxide supercapacitor from manganese recycled from spent Zn–MnO2 batteries using organic acid as a leaching agent. Ionics 25, 4381–4392 (2019). https://doi.org/10.1007/s11581-019-02995-6

Neelapala, S.D., Shetty, A., Gaggar, G., Mall, R., Dasari, H.: Development of iron doped manganese oxide (Mn2−xFexO3) catalysts for soot oxidation applications. Int. J. Appl. Eng. Res. 13, 7 (2018)

Benedetti, T.M., Gonçales, V.R., Petri, D.F.S., de Torresi, S.I.C., Torresi, R.M.: Macroporous MnO2 electrodes obtained by template assisted electrodeposition for electrochemical capacitors. J. Braz. Chem. Soc. 21, 1704–1709 (2010). https://doi.org/10.1590/S0103-50532010000900016

Dong, Y., Li, K., Jiang, P., Wang, G., Miao, H., Zhang, J., et al.: Simple hydrothermal preparation of α-, β-, and γ-MnO2 and phase sensitivity in catalytic ozonation. RSC Adv. 4, 39167 (2014). https://doi.org/10.1039/C4RA02654C

Mondal, J., Srivastava, S.K.: δ-MnO2 nanoflowers and their reduced graphene oxide nanocomposites for electromagnetic interference shielding. ACS Appl. Nano Mater. 3, 11048–11059 (2020). https://doi.org/10.1021/acsanm.0c02247

Cremonezzi, J.M.O., Tiba, D.Y., Domingues, S.H.: Fast synthesis of δ-MnO2 for a high-performance supercapacitor electrode. SN Appl. Sci. 2, 1689 (2020). https://doi.org/10.1007/s42452-020-03488-2

Huang, H., Sun, G., Hu, J., Jiao, T.: Low temperature Synthesis of MnO2/graphene nanocomposites for supercapacitors. J. Chem. 2015, 1–8 (2015). https://doi.org/10.1155/2015/629362

Ji, C., Ren, H., Yang, S.: Control of manganese dioxide crystallographic structure in the redox reaction between graphene and permanganate ions and their electrochemical performance. RSC Adv. 5, 21978–21987 (2015). https://doi.org/10.1039/C5RA01455G

Chen, X., Yan, S., Wang, N., Peng, S., Wang, C., Hong, Q., et al.: Facile synthesis and characterization of ultrathin δ-MnO2 nanoflakes. RSC Adv. 7, 55734–55740 (2017). https://doi.org/10.1039/C7RA08962G

Zhang, H., Wu, A., Fu, H., Zhang, L., Liu, H., Zheng, S., et al.: Efficient removal of Pb(ii) ions using manganese oxides: the role of crystal structure. RSC Adv. 7, 41228–41240 (2017). https://doi.org/10.1039/C7RA05955H

Ilton, E.S., Post, J.E., Heaney, P.J., Ling, F.T., Kerisit, S.N.: XPS determination of Mn oxidation states in Mn (hydr)oxides. Appl. Surf. Sci. 366, 475–485 (2016). https://doi.org/10.1016/j.apsusc.2015.12.159

Beyreuther, E., Grafström, S., Eng, L.M., Thiele, C., Dörr, K.: XPS investigation of Mn valence in lanthanum manganite thin films under variation of oxygen content. Phys. Rev. B (2006). https://doi.org/10.1103/PhysRevB.73.155425

Zhan, S., Qiu, M., Yang, S., Zhu, D., Yu, H., Li, Y.: Facile preparation of MnO2 doped Fe2O3 hollow nanofibers for low temperature SCR of NO with NH3. J. Mater. Chem. A 2, 20486–20493 (2014). https://doi.org/10.1039/C4TA04807E

Araújo, M.P., Nunes, M., Rocha, I.M., Pereira, M.F.R., Freire, C.: Electrocatalytic activity of new Mn3O4@oxidized graphene flakes nanocomposites toward oxygen reduction reaction. J. Mater. Sci. 54, 8919–8940 (2019). https://doi.org/10.1007/s10853-019-03508-6

Heath, J.P.: Simulation of impedance spectroscopy in electroceramics using a finite element method n.d.:207

Acknowledgements

This research is supported by the Indonesian Ministry of Research and Higher Education through the Basic research program managed by DRPM-ITS Contract No. 1376/PKS/ITS/2022.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

I declare that the work submitted for publication indicated above is original, has not been published before, and is not under consideration for publication anywhere. I declare that there is no conflict of interest concerning this publication. This statement and declaration have been approved by all co-authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hastuti, E., Fitriana, F., Zainuri, M. et al. Low-temperature synthesis of doped MnO2–carbon dots nanocomposite: an analysis of nanostructure and electrical properties. Mater Renew Sustain Energy 12, 159–169 (2023). https://doi.org/10.1007/s40243-023-00237-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40243-023-00237-4