Abstract

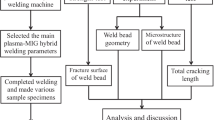

In this paper, the effect of plasma arc welding (PAW) process parameters on the mechanical properties and macro- and microstructure of Ti-6Al-4V alloy is discussed. These parameters including welding current, welding speed, and plasma gas orifice diameter have an effect on the weld bead depth and width. Macrograph results indicate that there is a certain range of welding electric current and welding speed in which full-penetration weld is obtained and weld beads are free from defect. Experimental results show that the specimen mechanical strength is favorable and comparable to those of the base material, but the sample elongation is low entirely. Moreover, the results indicate that using an optimum range of welding speed and current, which lead to decreased heat input, makes greater mechanical strength and better relative ductility. The fusion zone microstructure consists of martensite (α′), massive α (αm), acicular α, and retained β phase.

Similar content being viewed by others

References

Yonesawa K (1987) Welding of titanium and titanium alloys. Weld Int 1:1131–1142

ASM International Handbook Committee (1990) Properties and selection: nonferrous alloys and special-purpose materials. ASM Handbook, Ohio

Khorasani AM, Goldberg M, Doeven EH, Littlefair G (2015) Titanium in biomedical applications-properties and fabrication: a review. J Biomater Tissue Eng 5:593–619

Leonov VP, Mikhaylov VI (2016) Technological and constructional features of welding titanium alloys for marine structures. Weld Int 30:403–407

Liitjering G, Williams JC (2003) Titanium-engineering materials and processes. Springer, Heidelberg

Kar SK, Ghosh A, Fulzele N, Bhattacharjee A (2013) Quantitative microstructural characterization of a near beta Ti alloy, Ti-5553 under different processing conditions. Mater Charact 81:37–48

ASM International Handbook Committee (1991) Heat treating. ASM Handbook, Ohio

Fan X, Li Q, Zhao A, Shi Y, Mei W (2017) The effect of initial structure on phase transformation in continuous heating of a ta15 titanium alloy. Metals 7:1–12

Matthew J, Donachie J (2000) Titanium: a technical guide. ASM Handbook, Ohio

Attallah MM, Zabeen S, Cernik RJ, Preuss M (2009) Comparative determination of the α/β phase fraction in α+β-titanium alloys using X-ray diffraction and electron microscopy. Mater Charact 60:1248–1256

ASM International Handbook Committee (1993) Welding, brazing, and soldering. ASM Handbook, Ohio

Otani T (2007) Titanium welding technology. Nippon Steel Tech Rep 95:88–92

Cui S, Shi Y, Zhu T, Liu W (2019) Microstructure, texture, and mechanical properties of Ti-6Al-4V joints by K-TIG welding. J Manuf Process 37:418–424

Yan G, Tan MJ, Crivoi A, Li F, Kumar S, Chia CHN (2017) Improving the mechanical properties of TIG welding Ti-6Al-4V by post weld heat treatment. Procedia Eng 207:633–638

Henckell P, Ali Y, Metz A, Bergmann JP, Reimann J (2019) In situ production of titanium aluminides during wire arc additive manufacturing with hot-wire assisted GMAW process. Metals 9:1–13

Szusta J, Tüzün N, Karakaş Ö (2019) Monotonic mechanical properties of titanium grade 5 (6Al-4V) welds made by microplasma. Theor Appl Fract Mech 100:27–38

Karimzadeh F, Salehi M, Saatchi A, Meratian M (2005) Effect of microplasma arc welding process parameters on grain growth and porosity distribution of thin sheet Ti6Al4V alloy weldment. Mater Manuf Process 20:205–219

Mathisen MB, Eriksen L, Yu Y, Jensrud O, Hjelen J (2014) Characterization of microstructure and strain response in Ti-6Al-4V plasma welding deposited material by combined EBSD and in-situ tensile test. Trans Nonferrous Metals Soc China 24:3929–3943

Weiss L, Zollinger J, Sallamand P, Cicala E, Mathieu A, Fleury E (2019) Mechanical properties and microstructural study of homogeneous and heterogeneous laser welds in α, β, and α + β titanium alloys. Weld World 63:53–62

Saresh N, Pillai MG, Mathew J (2007) Investigations into the effects of electron beam welding on thick Ti-6Al-4V titanium alloy. J Mater Process Technol 192-193:83–88

Padhy GK, Wu CS, Gao S (2018) Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: a review. J Mater Sci Technol 34:1–38

Zhang Y, Sato YS, Kokawa H, Park SH, Hirano S (2008) Microstructural characteristics and mechanical properties of Ti-6Al-4V friction stir welds. Mater Sci Eng A 485:448–455

Dhinakaran V, Shanmugam NS, Sankaranarayanasamy K (2017) Some studies on temperature field during plasma arc welding of thin titanium alloy sheets using parabolic Gaussian heat source model. J Mech Eng Sci 231:695–711

Lathabai S, Jarvis BL, Barton KJ (2001) Comparison of keyhole and conventional gas tungsten arc welds in commercially pure titanium. Mater Sci Eng A 299:81–93

Baruah SBM (2016) Influence of heat input in microwelding of titanium alloy by microplasma arc. J Mater Process Technol 231:100–112

Short AB, McCartney DG, Webb P, Preston E (2011) Influence of nozzle orifice diameter in keyhole. Sci Technol Weld Join 16:446–453

Wu CS, Wang L, Ren WJ, Zhang XY (2014) Plasma arc welding: process, sensing, control and modeling. J Manuf Process 16:74–85

B. A. F. ASME boiler and pressure vessel committee (2015) welding, qualification standard for welding, brazing, and fusing procedures; welders; brazers; and welding, brazing, and fusing operators. The American Society of Mechanical Engineers, New York

Balasubramanian TS, Balakrishnan M, Balasubramanian V, Manickam MAM (2011) Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints. Trans Nonferrous Metals Soc China 21:1253–1262

Motyka M, Kubiak K, Sieniawski J, Ziaja W (2014) Phase transformations and characterization of alpha+beta titanium alloys. Comprehensive Materials Processing, Elsevier, Rzeszow, pp 7–36

Murav’ev VI, Kleshnina ON, Kuznetsov AA, Bakhmatov PV (2012) Effect of the conditions of the welding thermal cycle on the structure and properties of weld metal in titanium alloys. Weld Int 26:22–29

Wu M, Xin R, Wang Y, Zhou Y, Wang K, Liu Q (2016) Microstructure, texture and mechanical properties of commercial highpurity thick titanium plates jointed by electron beam welding. Mater Sci Eng A 677:50–57

Skal’s’kyi VR, Lyasota IM (2010) Estimation of the heat-affected zone for the electron-beam welding of plates. Mater Sci 46:115–123

Reda R, Nofal A, Hussein A-H (2013) Effect of quenching temperature on the mechanical properties of cast ti-6al-4v alloy. J Metall Eng 2:48–54

Jovanovic MT, Tadic S, Zec S, Miskovic Z, Bobic I (2006) The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti-6Al-4V alloy. Mater Des 27:192–199

Imam M, Gilmore C (1983) Fatigue and microstructural properties of quenched Ti-6AI-4V. Metall Trans A 14A:233–240

Venkatesh BD, Chen DL, Bhole SD (2009) Effect of heat treatment on mechanical properties of Ti-6Al-4V ELI alloys. Mater Sci Eng A 506:117–124

Ahmed T, Rack HJ (1998) Phase transformations during cooling in α+β titanium alloys. Mater Sci Eng A 243:206–211

Acknowledgments

We are deeply grateful to Mr. Fereidoun Tosynejad, expert of the metallography laboratory of the Space Transportation Research Institute, who contributed greatly to this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Vahidshad, Y., Khodabakhshi, A.H. An investigation of different parameters on the penetration depth and welding width of Ti-6Al-4V alloy by plasma arc welding. Weld World 65, 485–497 (2021). https://doi.org/10.1007/s40194-020-01024-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01024-9