Abstract

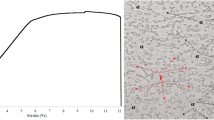

In the present work, the influence of current pulsation on microstructural morphology and mechanical properties of micro-plasma arc welded of 0.7-mm thick Alloy 718 is investigated. The pulsation of current improves the solidification morphology as compared to continuous mode. The effect of peak current, duty cycle, and pulse frequency on cooling rate, weld morphology, and mechanical properties are reported herein. The calculated solidification parameters from the 3D finite element-based heat transfer model are used to predict the solidification behavior of the weld zone. The weld joint mechanical properties are found inferior to the base material due to the presence of intermetallic phases. Current pulsation with optimum heat input in micro-plasma arc welding shows the improvement in the weld mechanical properties. The average heat input reduced by current pulsation, leads to a high cooling rate, and results in fine microstructure and lower segregation of Nb in the interdendritic region. Lower segregation hinders the formation of deleterious Laves phase and improved the mechanical properties of the micro-plasma arc welded Alloy 718.

Similar content being viewed by others

References

Kuo CM, Yang YT, Bor HY et al (2009) Aging effects on the microstructure and creep behavior of Alloy 718 superalloy. Mater Sci Eng A 510:289–294

Lingenfelter A (1989) Welding of Inconel alloy 718: a historical overview. In: Lona EA (ed) Superalloys 718 - metallurgy and applications. TMS, pp 673–683

Singh S, Andersson J (2019) Varestraint weldability testing of cast ATI® 718PlusTM—a comparison to cast Alloy 718. Weld World 63:389–399. https://doi.org/10.1007/s40194-018-0626-2

Draxler J, Edberg J, Andersson J, Lindgren L-E (2019) Modeling and simulation of weld solidification cracking part III. Weld World 63:1883–1901. https://doi.org/10.1007/s40194-019-00784-3

Gobbi S, Zhang L, Norris J et al (1996) High powder CO2 and Nd-YAG laser welding of wrought Alloy 718. J Mater Process Technol 56:333–345

Mei Y, Liu Y, Liu C et al (2016) Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Alloy 718. Mater Des 89:964–977. https://doi.org/10.1016/j.matdes.2015.10.082

Sahu AK, Bag S, Huang K (2020) Mitigation of micro-cracks in dissimilar welding of Alloy 718 and austenitic stainless steel. Philos Mag Lett 0:1–10. https://doi.org/10.1080/09500839.2020.1774674

Ye X, Hua X, Wang M, Lou S (2015) Controlling hot cracking in Ni-based Inconel-718 superalloy cast sheets during tungsten inert gas welding. J Mater Process Technol 222:381–390. https://doi.org/10.1016/j.jmatprotec.2015.03.031

Huang CA, Wang TH, Lee CH, Han WC (2005) A study of the heat-affected zone (HAZ) of an Alloy 718 sheet welded with electron-beam welding (EBW). Mater Sci Eng A 398:275–281. https://doi.org/10.1016/j.msea.2005.03.029

Hong JK, Park JH, Park NK et al (2008) Microstructures and mechanical properties of Alloy 718 welds by CO2 laser welding. J Mater Process Technol 201:515–520. https://doi.org/10.1016/j.jmatprotec.2007.11.224

Radhakrishna C, Rao KP (1994) Studies on creep/stress rupture behaviour of superalloy 718 weldments used in gas turbine applications. Mater High Temp 12:323–327

Thompson RG, Mayo DE, Radhakrishnan B (1991) The relationship between carbon content, microstructure, and intergranular liquation cracking in cast nickel alloy 718. Metall Trans A 22:557–567. https://doi.org/10.1007/BF02656823

Knorovsky GA, Cieslak MJ, Headley TJ et al (1989) ALLOY 718: a solidification diagram. Metall Trans A 20:2149–2158. https://doi.org/10.1007/BF02650300

Chen W, Chaturvedi MC, Richards NL (2001) Effect of boron segregation at grain boundaries on heat-affected zone cracking in wrought ALLOY 718. Metall Mater Trans A 32:931–939

Odabaşı A, Ünlü N, Göller G, Eruslu MNi̇ (2010) A study on laser beam welding (LBW) technique: effect of heat input on the microstructural evolution of superalloy Alloy 718. Metall Mater Trans A 41:2357–2365. https://doi.org/10.1007/s11661-010-0319-y

Radhakrishna CH, Rao KP (1997) The formation and control of Laves phase in superalloy 718 welds. J Mater Sci 32:1977–1984

Sahu AK, Bag S (2020) Probe pulse conditions and solidification parameters for the dissimilar welding of Alloy 718 and AISI 316L stainless steel. Metall Mater Trans A 51:2192–2208. https://doi.org/10.1007/s11661-020-05705-4

Baruah M, Bag S (2016) Influence of heat input in microwelding of titanium alloy by micro plasma arc. J Mater Process Technol 231:100–112. https://doi.org/10.1016/j.jmatprotec.2015.12.014

Norrish J (2006) Advanced welding processes, 2nd edn. Elsevier, Cambridge

Thavamani R, Balusamy V, Nampoothiri J et al (2018) Mitigation of hot cracking in Alloy 718 superalloy by ultrasonic vibration during gas tungsten arc welding. J Alloys Compd 740:870–878. https://doi.org/10.1016/j.jallcom.2017.12.295

Yadaiah N, Bag S (2012) Effect of heat source parameters in thermal and mechanical analysis of linear GTA welding process. ISIJ Int 52:2069–2075

Dye D, Hunziker O, Roberts SM, Reed RC (2001) Modeling of the mechanical effects induced by the tungsten inert-gas welding of the IN718 superalloy. Metall Mater Trans A 32:1713–1725

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15:299–305. https://doi.org/10.1007/BF02667333

Thompson RG (1988) Microfissuring of Alloy 718 in the weld heat-affected zone. JOM 40:44–48. https://doi.org/10.1007/BF03258151

Baruah M, Bag S (2017) Influence of pulsation in thermo-mechanical analysis on laser micro-welding of Ti6Al4V alloy. Opt Laser Technol 90:40–51. https://doi.org/10.1016/j.optlastec.2016.11.006

Chen HC, Pinkerton AJ, Li L (2011) Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Alloy 718 for aerospace applications. Int J Adv Manuf Technol 52:977–987

Oreper GM, Szekely J, Eagar TW (1986) The role of transient convection in the melting and solidification in arc weldpools. Metall Trans B 17:735–744

Manikandan SGK, Sivakumar D, Rao KP, Kamaraj M (2014) Effect of weld cooling rate on Laves phase formation in Alloy 718 fusion zone. J Mater Process Technol 214:358–364. https://doi.org/10.1016/j.jmatprotec.2013.09.006

Janaki Ram GD, Venugopal Reddy A, Prasad Rao K, Madhusudhan Reddy G (2004) Control of Laves phase in Alloy 718 GTA welds with current pulsing. Sci Technol Weld Join 9:390–398

Kou S (2003) Welding metallurgy, 2nd edn. Wiley, New Jersey

Ma D (2004) Response of primary dendrite spacing to varying temperature gradient during directional solidification. Metall Mater Trans B 35:735–742

Cao X, Rivaux B, Jahazi M et al (2009) Effect of pre- and post-weld heat treatment on metallurgical and tensile properties of Alloy 718 alloy butt joints welded using 4 kW Nd:YAG laser. J Mater Sci 44:4557–4571. https://doi.org/10.1007/s10853-009-3691-5

Qian M, Lippold JC (2003) The effect of rejuvenation heat treatments on the repair weldability of wrought Alloy 718. Mater Sci Eng A 340:225–231. https://doi.org/10.1016/S0921-5093(02)00187-9

Acknowledgements

The authors gratefully acknowledge the experimental facility provided by the Department of Mechanical Engineering, Central Workshop, and Central Instrument Facility (CIF) of IIT Guwahati, Assam, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Sahu, A.K., Bag, S. Influence of current pulsation on solidification parameters during micro-plasma arc welding of thin sheet Alloy 718. Weld World 65, 2403–2419 (2021). https://doi.org/10.1007/s40194-021-01191-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01191-3