Abstract

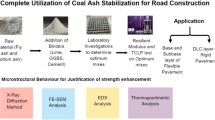

Low calcium fly ash generated by thermal power stations has a high potential for use in engineering applications instead of being discarded in vast quantities in landfills, presenting environmental difficulties. However, due to its insufficient self-cementing properties, low calcium fly ash must be stabilized with cementitious materials to provide the desired strength and stiffness. The current study is aimed at the use of ground granulated blast furnace slag (GGBS) in combination with conventional additives such as lime and cement to stabilize class F fly ash for its use in the flexible pavement as a base material. The effect of hydraulic binder content and curing time on unconfined compressive strength, durability, resilient modulus, and permanent strain was investigated. Fly ash mixtures containing 3% lime or cement and 9% (88F + 3L + 9G) and 15% (82F + 3C + 15G) GGBS, respectively, were found to be the best two mixes based on the criteria, which included experimental parameters and per ton binder cost in TOPSIS analysis. The resilient modulus of the proposed base mixes was approximately 82% higher than the conventional base layer of flexible pavement. The results of finite element analysis showed that pavement with a base layer mix of 88F + 3L + 9G had up to 98% and 138% higher service life, respectively, for fatigue failure and rutting failure criteria than pavement with wet-mix macadam (WMM) material. Furthermore, values of permanent strain for optimum fly ash mixes were 27–32% lower than WMM, with cost savings of up to 32,356 USD per kilometer per lane (3.75 m width) obtained by cost analysis.

Similar content being viewed by others

Data Availability

The data supporting this study's findings are available from the corresponding author upon reasonable request.

References

CEA (2021) Fly ash generation at coal/lignite based thermal power stations and its utilization in the country. Cent Electr Authority, New Delhi

Hussain J, Zhou K (2022) Globalization, industrialization, and urbanization in Belt and Road initiative countries: implications for environmental sustainability and energy demand. Environ Sci Pollut Res 29:80549–80567. https://doi.org/10.1007/s11356-022-21520-3

Kumar GS, Shankar S (2023) Strength and durability characteristics of lime fly ash-stabilized recycled concrete aggregate for use in low-volume rural roads. Indian Geotech J 53:78–92. https://doi.org/10.1007/s40098-022-00659-3

Tiwari N, Satyam N (2021) Coupling effect of pond ash and polypropylene fiber on strength and durability of expansive soil subgrades: an integrated experimental and machine learning approach. J Rock Mech Geotech Eng 13:1101–1112. https://doi.org/10.1016/j.jrmge.2021.03.010

Gopinathan P, Santosh MS, Dileepkumar VG et al (2022) Geochemical, mineralogical and toxicological characteristics of coal fly ash and its environmental impacts. Chemosphere 307:135710. https://doi.org/10.1016/j.chemosphere.2022.135710

MOEF (Ministry of Environment forst and climate C (2016) The Gazette of India: extraordinary, part II-Sec 3(ii): notification No: S.O. 254(E)

Lal A, Patel MA (2020) Studies on the properties of fly ash–rice husk ash-based geopolymer for use in black cotton soils. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-020-00224-z

Yao ZT, Ji XS, Sarker PK et al (2015) A comprehensive review on the applications of coal fly ash. Earth Sci Rev 141:105–121. https://doi.org/10.1016/j.earscirev.2014.11.016

Saride S, Avirneni D, Javvadi SCP et al (2015) Evaluation of fly ash treated reclaimed asphalt pavement for base/subbase applications. Indian Geotech J 45:401–411. https://doi.org/10.1007/s40098-014-0137-z

Bakare MD, Shahu JT, Patel S (2023) Complete substitution of natural aggregates with industrial wastes in road subbase: a field study. Resour Conserv Recycl 190:106856. https://doi.org/10.1016/j.resconrec.2022.106856

Singh SP, Tripathy DP, Ranjith PG (2008) Performance evaluation of cement stabilized fly ash-GBFS mixes as a highway construction material. Waste Manag 28:1331–1337. https://doi.org/10.1016/j.wasman.2007.09.017

Sudla P, Donrak J, Hoy M et al (2019) Laboratory investigation of cement-stabilized marginal lateritic soil by crushed slag-fly ash replacement for pavement applications. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)

Pai RR, Patel S, Shahu JT (2022) Fatigue response of industrial waste mixes for use as cemented base materials in flexible pavement. Int J Geosynth Gr Eng 8:1–17. https://doi.org/10.1007/s40891-022-00407-w

Gollakota ARK, Volli V, Shu CM (2019) Progressive utilisation prospects of coal fly ash: a review. Sci Total Environ 672:951–989. https://doi.org/10.1016/j.scitotenv.2019.03.337

Sharma AK, Sivapullaiah PV (2016) Strength development in fly ash and slag mixtures with lime. Proc Inst Civ Eng Gr Improv 169:194–205

Mohanty S, Roy N, Singh SP, Sihag P (2021) Strength and durability of flyash, GGBS and cement clinker stabilized dispersive soil. Cold Reg Sci Technol. https://doi.org/10.1016/j.coldregions.2021.103358

Lav AH, Lav MA (2000) Microstructural development of stabilized fly ash as pavement base material. J Mater Civ Eng 80:157–163

Pani A, Singh SP (2016) Effect of temperature on the strength of lime-stabilised fly ash. Environ Geotech 7:189–199. https://doi.org/10.1680/jenge.17.00050

Sivapullaiah PV, Ali A, Moghal B (2011) Role of gypsum in the strength development of fly ashes with lime. J Mater Civ Eng. https://doi.org/10.1061/ASCEMT.1943-5533.0000158

Pai RR, Patel S, Bakare MD (2020) Applicability of utilizing stabilized native soil as a subbase course in flexible pavement. Indian Geotech J 50:289–299. https://doi.org/10.1007/s40098-020-00432-4

Barmade S, Patel S, Dhamaniya A (2022) Performance evaluation of stabilized reclaimed asphalt pavement as base layer in flexible pavement. J Hazardous Toxic Radioact Waste. https://doi.org/10.1061/(asce)hz.2153-5515.0000656

Bakare MD, Pai RR, Patel S, Shahu JT (2019) Environmental sustainability by bulk utilization of fly ash and GBFS as road subbase materials. J Hazardous Toxic Radioact Waste 23:04019011. https://doi.org/10.1061/(asce)hz.2153-5515.0000450

Bakare MD, Shahu JT, Patel S (2024) Stress-dependent behavior of lightly stabilized industrial waste subbase using falling weight deflectometer. Geotech Test J. https://doi.org/10.1520/GTJ20220283

Patel S, Shahu JT (2016) Resilient response and permanent strain of steel slag-fly ash-dolime mix. J Mater Civ Eng 28:1–11. https://doi.org/10.1061/(asce)mt.1943-5533.0001619

Patel D, Kumar R, Chauhan K, Patel S (2021) Using copper slag and fly ash stabilised with lime or cement as a road base material. Proc Inst Civ Eng Constr Mater. https://doi.org/10.1680/jcoma.18.00055

Lav MA, Lav AH (2014) Effects of stabilization on resilient characteristics of fly ash as pavement material. Constr Build Mater 54:10–16. https://doi.org/10.1016/j.conbuildmat.2013.12.029

Lekarp F, Dawson A (1998) Modelling permanent deformation behaviour of unbound granular materials. Constr Build Mater 12:9–18. https://doi.org/10.1016/S0950-0618(97)00078-0

ASTM Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM C618-22. https://doi.org/10.1520/C0618-22

BIS (Bureau of Indian Standards) (2015) Determination of water content-dry density relation using heavy compaction. IS 2720 Part VIII, New Delhi

ASTM D5102 Standard test methods for unconfined compressive strength of compacted soil-lime mixtures. https://doi.org/10.1520/D5102-09

ASTM (2015) Standard test methods for wetting and drying compacted soil-cement mixtures. D559M-15. https://doi.org/10.1520/D0559

IRC:37-2018 (2018) Guidelines for the design of flexible pavement-IV revision. Indian Road Congr New Delhi, India

Patel D, Modhera C, Gaurav J, Patel VN (2023) Experimental investigation on mechanical properties of ternary blended concrete using manufactured sand. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-023-01087-9

Materials A AASHTO T 307 (Modified) Determining the resilient modulus of soils and aggregate materials, vol 307, pp 3–6

Mandal S, Singh JP (2007) Stabilization of soil using ground granulated blast furnace slag and fly ash. Int J Innov Res Sci Eng Technol. https://doi.org/10.15680/IJIRSET.2016.0512038

IRC:SP:89 (Part III) (2018) Guidelines for the design of stabilized pavements (Part II). Indian Road Congr New Delhi, India

Hwang C-L, Yoon K (1981) Methods for multiple attribute decision making. Springer, Berlin, pp 58–191. https://doi.org/10.1007/978-3-642-48318-9_3

Salla SR, Uppara RB, Kannazia AK et al (2023) An experimental and environmental impact assessment of slag-based mineral admixture for sustainable development. Innov Infrastruct Solut 8:1–15. https://doi.org/10.1007/s41062-022-00998-3

NCHRP (2003) Harmonized test methods for laboratory determination of resilient modulus for flexible pavement design. Natl Coop Highw Res Progr 1–28A

Gonawala RJ, Khapre S, Kumar R, Chauhan KA (2021) Suitability of EAF slag and GGBFS mix as cementitious base/subbase layer for low volume road construction. Int J Geotech Eng 15:252–258. https://doi.org/10.1080/19386362.2019.1621458

Arulrajah A, Piratheepan J, Disfani MM, Bo MW (2013) Resilient moduli response of recycled construction and demolition materials in pavement subbase applications. J Mater Civ Eng 25:1920–1928. https://doi.org/10.1061/(asce)mt.1943-5533.0000766

Ghosh A, Subbrao C (2016) Microstructural development in fly ash modified with lime and gypsum. J Mater Civ Eng 1561:65–70

Xu A, Sarkar SL (1994) Microstructural development in high-volume fly-ash cement system. J Mater Civ Eng 6:117–136

Stark J, Bollmann K (2000) Late ettringite formation in concrete, part 1. ZKG Int 53:1–25

Stark J, Bollman K (2022) Delayed ettringite formation in concrete. Mater Sci Eng. https://api.semanticscholar.org/CorpusID:108290859

Funding

No funding has been received for this research investigation.

Author information

Authors and Affiliations

Contributions

HNK: Writing-Original draft preparation, Conceptualization, Methodology, Data curation. SP: Writing-Original draft preparation, Supervision, Reviewing and Editing.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kedar, H.N., Patel, S. Complete Replacement of Granular Base Layer with Stabilized Fly Ash for Road Construction. Indian Geotech J (2023). https://doi.org/10.1007/s40098-023-00817-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40098-023-00817-1