Abstract

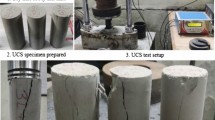

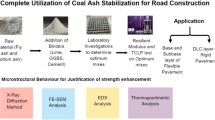

This study explores the utilization of steel slag and fly ash in road construction to address the increasing demand for pavement materials and the scarcity of natural aggregates. For this purpose, steel slag–fly ash composite is stabilized with lime and ground granulated blast furnace slag (GGBS) to assess their utility as a subbase and base material in flexible pavements. Laboratory tests, including compaction and unconfined compressive strength, are conducted on the trial mixes to determine the optimal combinations. Subsequently, durability and resilient modulus tests are performed on the optimum mixes to evaluate their suitability as subbase and base materials. The study identifies the mixes 56% Steel slag + 40% Fly ash + 1% Lime + 3% GGBS and 86% Steel slag + 10% Fly ash + 1% Lime + 3% GGBS as the optimum choices for the subbase layer, while the mixes 76% Steel slag + 20% Fly ash + 1% Lime + 3% GGBS and 70% Steel slag + 20% Fly ash + 1% Lime + 9% GGBS is selected as the optimum mixes for the base layer of flexible pavement and Dry Lean concrete layer for rigid pavement, respectively. After 28 days of curing, the resilient moduli of the optimal subbase and base mixes are 86% and 122% higher than those of conventional granular subbase (GSB) and wet mix macadam (WMM), respectively. Plaxis-3D software demonstrates that the pavement constructed with optimal mixtures in the subbase and base layers has a longer service life than pavement constructed with a conventional granular subbase and wet mix macadam layers. These findings highlight the potential of utilizing bulk quantities of industrial by-products in road construction, offering an environmentally-friendly solution while enhancing pavement performance and longevity.

Similar content being viewed by others

Data availability

All data generated during the study appear in this article.

References

PIB (2022) Road infrastructure in India. https://www.ibef.org/industry/roads-india#

Pai RR, Patel S, Shahu JT (2022) Fatigue response of industrial waste mixes for use as cemented base materials in flexible pavement. Int J Geosynth Ground Eng 8:1–17. https://doi.org/10.1007/s40891-022-00407-w

Bakare MD, Shahu JT, Patel S (2023) Complete substitution of natural aggregates with industrial wastes in road subbase: a field study. Resour Conserv Recycl 190:106856. https://doi.org/10.1016/j.resconrec.2022.106856

Lav AH, Lav MA (2000) Microstructural development of stabilized fly ash as pavement base material. J Mater Civ Eng 80:157–163

Patel S, Shahu JT (2016) Resilient response and permanent strain of steel slag–fly ash-dolime mix. J Mater Civ Eng 28:04016106. https://doi.org/10.1061/(asce)mt.1943-5533.0001619

Bakare MD, Pai RR, Patel S, Shahu JT (2019) Environmental sustainability by bulk utilization of fly ash and GBFS as road subbase materials. J Hazard Toxic Radioact Waste 23:04019011. https://doi.org/10.1061/(asce)hz.2153-5515.0000450

Li H, Tong Y, Zhang H et al (2021) Study on road performance of cement fly ash stabilized steel slag—concrete recycled macadam. Materials (Basel) 14:1–20. https://doi.org/10.3390/ma14247530

Joshi AR, Patel S (2023) Investigation into sustainable application of class c fly ash layer in flexible pavement. J Hazard Toxic Radioact Waste 27:1–11. https://doi.org/10.1061/(asce)hz.2153-5515.0000727

Ahmed M, Bashar I, Alam ST et al (2021) An overview of Asian cement industry: environmental impacts, research methodologies and mitigation measures. Sustain Prod Consum 28:1018–1039. https://doi.org/10.1016/j.spc.2021.07.024

Faheem M, Tahir M, Mustafa M, Bakri A (2022) Potential of industrial by-products based geopolymer for rigid concrete pavement application. Constr Build Mater 344:128190. https://doi.org/10.1016/j.conbuildmat.2022.128190

Yuan J, Zhang T, Yao J (2016) Experimental study and isolation mechanism analysis on emulsion wax curing agent used on cement-stabilized granular base. Innov Infrastruct Solut 1:1–9. https://doi.org/10.1007/s41062-016-0028-5

Kumar B (2013) Properties of pavement quality concrete and dry lean concrete with copper slag as fine aggregate. Int J Pavement Eng 14(8):746–751. https://doi.org/10.1080/10298436.2012.729059

Singh S, Ransinchung GDRN, Monu K, Kumar P (2018) Laboratory investigation of RAP aggregates for dry lean concrete mixes. Constr Build Mater 166:808–816. https://doi.org/10.1016/j.conbuildmat.2018.01.131

Singh S, Monu K, Ransinchung GD (2020) Laboratory investigation of RAP for various layers of flexible and concrete pavement. Int J Pavement Eng 21:1780–1793. https://doi.org/10.1080/10298436.2019.1567920

Sarkar PP, Debnath B (2023) Feasibility study of brick aggregate as a partial replacement of natural stones in dry lean concrete mix. J Mater Civ Eng 35(8):04023263-1–04023263-13. https://doi.org/10.1061/JMCEE7.MTENG-15264

IS-4032 1985 (2019) (2019) Method of chemical analysis of hydraulic cement. Bureau of Indian Standards, New Delhi, pp 1–47

Pai RR, Bakare MD, Patel S, Shahu JT (2021) Structural evaluation of flexible pavement constructed with steel slag–fly ash–lime mix in the base layer. J Mater Civ Eng 33:04021097. https://doi.org/10.1061/(asce)mt.1943-5533.0003711

ASTM (2015) Standard specification for graded aggregate material for bases or subbases for highways or airports. ASTM, West Conshohocken

BIS (Bureau of Indian Standards) (2015) Determination of water content-dry density relation using heavy compaction. IS 2720 Part VIII, New Delhi

IS (2020) Determination of Unconfined Compressive Strength of Stabilized Soils. IS 4332 Part-V, New Delhi, India,

IS (2006) Determination of Water Content- Dry Density Relation Using Heavy Compaction. IS 4332 Part-V, New Delhi, India, 2020 (Indian Stand 2720:

ASTM D5102 Standard test methods for unconfined compressive strength of compacted soil–lime mixtures. https://doi.org/10.1520/D5102-09

Indian Roads Congress (IRC) (2002) Rural roads manual. IRC SP 20

ASTM (2015) Standard test methods for wetting and drying compacted soil-cement mixtures. D559M−15. 10.1520/D0559_

AASHTO T307 (2017) Determining the resilient modulus of soils and aggregate materials. Washingt State Dep Transp 307:3–6

USEPA (1992) Toxicity characteristic leaching procedure. USEPA Method 1311:1–35

Patel S, Ph D, Shahu JT, Ph D (2017) Comparative study of slags stabilized with fly ash and dolime for utilization in base course. J Mater Civ Eng 29:1–8. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002017

Patel S, Shahu JT (2016) Resilient response and permanent strain of steel slag–fly ash-dolime mix. J Mater Civ Eng 28:1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001619

Indian Standards BIS 2720-8 (1983): Methods of test for soils, part 8: determination of water content-dry density relation using heavy compaction.

Shahu JT, Patel S, Senapati A (2013) Engineering properties of copper slag–fly ash–dolime mix and its utilization in the base course of flexible pavements. J Mater Civ Eng 25:1871–1879. https://doi.org/10.1061/(asce)mt.1943-5533.0000756

Patel S, Shahu JT (2018) Comparison of industrial waste mixtures for use in subbase course of flexible pavements. J Mater Civ Eng 30:1–10. https://doi.org/10.1061/(asce)mt.1943-5533.0002320

Patel D, Kumar R, Chauhan K, Patel S (2021) Using copper slag and fly ash stabilised with lime or cement as a road base material. Proc Inst Civ Eng Constr Mater. https://doi.org/10.1680/jcoma.18.00055

Indian Roads Congress (IRC) (2014) Guidelines for the use of dry lean concete assub-base for rigid pavement. IRC SP 49

Arulrajah A, Ali MMY, Piratheepan J et al (2012) Geotechnical properties of waste excavation rock in pavement subbase applications. J Mater Civ Eng 24:924–932. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000419

Arulrajah A, Piratheepan J, Disfani MM, Bo MW (2013) Resilient moduli response of recycled construction and demolition materials in pavement subbase applications. J Mater Civ Eng 25:1920–1928. https://doi.org/10.1061/(asce)mt.1943-5533.0000766

Puppala AJ, Asce M, Hoyos LR, Potturi AK (2011) Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000268

Saghafi B, Al Nageim H, Visulios P, Ghazireh N (2013) Use of waste limestone dust and steel slag in UK highways type 1 unbound mixtures. Proc Inst Civ Eng Constr Mater 166:99–107. https://doi.org/10.1680/coma.11.00029

Indian Roads Congress (IRC) (2010) Guidelines for soil and granular material stabilization using cement, lime & fly ash. IRC SP 89

BIS IS10500 (2012) Indian standard drinking water specification (second revision). Bureau of Indian Standards (BIS), New Delhi, pp 1–11

Dhadse S, Kumari P, Bhagia LJ (2008) Fly ash characterization, utilization and government initiatives in India - a review. J Sci Ind Res (India) 67:11–18

Singh R, Singh RK, Gupta NC, Guha BK (2010) Assessment of heavy metals in fly ash and groundwater-a case study of NTPC Badarpur thermal power plant, Delhi, India. Pollut Res 29:685–689

Izquierdo M, Querol X (2012) Leaching behaviour of elements from coal combustion fly ash: an overview. Int J Coal Geol 94:54–66. https://doi.org/10.1016/j.coal.2011.10.006

Allan ML, Kukacka LE (1995) Blast furnace slag-modified grouts for in situ stabilization of chromium-contaminated soil. Waste Manag 15:193–202. https://doi.org/10.1016/0956-053X(95)00017-T

NCHRP (2003) Harmonized test methods for laboratory determination of resilient modulus for flexible pavement design. National Cooperative Highway Research Program 1–28A

Indian Roads Congress (IRC) (2018) Tentative guidelines for the design of flexible pavements. IRC 37

Jagad G, Modhera C, Patel D, Patel V (2023) Mechanical and microstructural characteristics of manufactured sand-based high-strength geopolymer concrete and its environmental impact. Pract Period Struct Des Constr. https://doi.org/10.1061/ppscfx.sceng-1308

Pani A, Singh SP (2016) Effect of temperature on the strength of lime-stabilised fly ash. Environ Geotech 7:189–199. https://doi.org/10.1680/jenge.17.00050

Mohanty S, Roy N, Singh SP, Sihag P (2021) Strength and durability of flyash, GGBS and cement clinker stabilized dispersive soil. Cold Reg Sci Technol. https://doi.org/10.1016/j.coldregions.2021.103358

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Formal consent is not required for this type of study.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kedar, H.N., Patel, S. & Shirol, S.S. Bulk utilization of steel slag–fly ash composite: a sustainable alternative for use as road construction materials. Innov. Infrastruct. Solut. 9, 21 (2024). https://doi.org/10.1007/s41062-023-01325-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01325-0