Abstract

In this research, new catalyst prepared by supporting CoFe2O4 on copper slag (CS) and characterization of this catalyst was done with using scanning electron microscopy image, energy-dispersive X-ray spectroscopy, BET surface area, and X-ray diffraction patterns. UV + H2O2 processes by CoFe2O4/CS as a photocatalyst was used for degradation of 2-nitrophenol (2NP) as a pollutant in water. Response surface methodology in the Basis of a three-variable Box–Behnken design was applied to determine the effect of pH values (4, 7 and 10), concentration of 2-nitrophenol (10, 20 and 30 ppm), and concentration of H2O2 (30, 60 and 90 ppm) on the levels of response and optimized these operational parameters. The optimal conditions were determined as pH = 10, concentration of 2-nitrophenol = 10 ppm, and concentration of H2O2 = 90 ppm. Degradation efficiency in optimal condition was 96.55%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, a variety of nanoparticles with various shapes such as spheres, nanotubes, nano-horns, and nano-cages, made of different materials have already been fabricated and explored for many scientific fields, including chemistry, material sciences, physics, medicine, and electronics [1]. The advantages of the nanoparticles are mainly due to their nanoscale size and large surface area.

Nanoparticles play an important role in heterogeneous catalysis. One of the major applications of heterogeneous catalysis is photocatalytic oxidation to promote complete mineralization of hazardous pollutants to benign materials. Semiconductor heterogeneous photocatalysis which is classified as advanced oxidation process (AOP) is a useful and effective method for the oxidation of resistant pollutants, such as phenolic compounds [2, 3].

Ferrite nanoparticles have been intensively investigated due to their remarkable electrical and magnetic properties and wide practical applications in catalytic process, ferrofluid technology, information storage system, magnetocaloric refrigeration, and medical diagnosis [1, 4].

Cobalt ferrite (CoFe2O4) is a class of semiconductors with narrow bandgaps, exhibits characteristics of light response, possesses good photochemical stability, as well as favorable magnetism. Many works have investigated the photocatalytic degradation of the nitrophenols in aqueous dispersions containing TiO2 or ZnO. The main problem in this process is to separate the catalyst from solution [2, 3]. The presence of CoFe2O4 magnetic nanoparticles fairly enhances the efficiency of the photocatalytic degradation of organic pollutants and can be easily separated from the solution by applying an external magnetic field [5, 6].

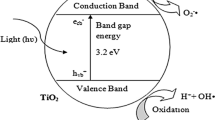

CoFe2O4 such as ZnO, ZnS, and TiO2 is a semiconductor then mechanism of photocatalytic activity of this compound under ultraviolet radiation is electron–hole. Based on this mechanism, the effect of ultraviolet radiation to the surface of semiconductor electrons is transferred from the valence band into the conductive band. The holes in the valence band and the electron in conducting band are created. Holes are strongly oxidizers and after reacting with water or hydroxide anion create hydroxyl radicals. Electrons in the valence band react with dissolved oxygen and after some steps, hydroxyl radicals are produced [5–8].

Copper slag (CS) is very stable and cheap; it was chosen as the base of the CoFe2O4 for increasing catalyst surface. Mechanical and thermal property of CS is suitable for supporting of catalyst.

Recent research efforts were concentrated on photocatalytic degradation of aromatics wastewater treatment. Aromatics (such as nitrophenols) are inclusive of the compounds, due to the relative stability in the environment, water solubility, toxicity, and health problems. Removal of these pollutants from the output of industrial effluents is of great importance of protecting the environment. Aromatic compounds, a large collection of environmental factors in cancer ubiquitous environmental pollutants such as air, water and soil, can be seen. Thus, these compounds are harmful to human health. Aromatic compounds present in industrial effluents, oil spills, waste, and improper disposal of oil residues can influence the surface water [7, 8].

In this study, a new catalyst prepared by supporting CoFe2O4 on copper slag and characterized using scanning electron microscopy (SEM) image and X-Ray diffraction patterns. For degradation of 2-nitrophenol was used UV + H2O2 process in the presence of CoFe2O4/CS as a photocatalyst.

Response surfaces methodology (RSM) is a set of statistical techniques and applied mathematics on modeling on experimental results. This method can be used for studying the effect of several factors (with different levels) and their influence on each other. TheCoFe2O4/CS as a photocatalysis.method is one type of response surface methodology. For photocatalytic degradation of 2-nitrophenol, three-factor and three-level Box–Behnken experimental design was used [9–12]. The second order equation was used in Box–Behnken experimental design [13, 14].

If all variables are assumed to be measurable, the response surfaces can be expressed as follows:

The goal is to optimize the response variable y. The assumption is that the independent variables x, continuously and trial and error control is very little and negligible.

Then, be sure to find a good approximation for the functional relationship between independent variables and the response equation of the second order, which is properly shown in Eq. (2) [15].

According to Eq. (1), χ1, χ2, χ3,…, χk are the input factors which influence the response y, k, and β 0, β ii (1, 2, …, k), β ij (i = 1, 2, …, k; j = 1, 2, …, k) are unknown parameters and ε is a random error. The β coefficients, which should be determined in the second order model, are obtained by the least square method. In general, Eq. (2) can be written in matrix form.

where Y is matrix of measured values, matrix of independent variables. The matrixes b and ε consist of coefficients and errors, respectively. The solution of Eq. (3) can be obtained by the matrix approach.

where X′ is the transpose of the matrix X and (X′ X)−1 is the inverse of the matrix X′ X [16–18].

Materials and methods

Materials

In this study, 2-nitrophenol, Cobalt and Iron nitrate salt and other materials were provided from Merck Company (Germany). Copper slag was purchased from the Iranian company of Messbareh. The pH values were adjusted to desired level using dilute NaOH and H2SO4. The shape, size, and surface morphology of the synthesized CoFe2O4/CS were examined using the obtained images of a Philips XL-30 Scanning Electron Microscope (SEM). The X-Ray Diffraction (XRD) analysis of the samples was done using a DX27-mini diffractometer. BET surface area of materials was determined by N2 adsorption–desorption method at 77 K, measured using a BELSORP-mini II instrument. The samples were degassed under vacuum at 473 K for 12 h before the BET measurement. All Ultraviolet/Visible (UV/Vis) absorption spectra were obtained using an Agilent 8453 spectrophotometer. A Metrohm pH meter model 827 was used for measurement of pH amounts. Likewise, to separate the catalyst from samples, an ALC 4232 centrifuge was employed.

Experimental method

50 ml 0.25 M Cobalt nitrate solutions (prepared from Co(NO3)2·6H2O, Merck) were added to the 50 ml 0.5 M Ferric nitrate solutions (prepared from Fe(NO3)3·9H2O, Merck), 100 ml 2 M molar urea solutions was added to this solution and reflux for 12 h in a hot water bath at 90 °C. After completing the process, catalyst CoFe2O4 was precipitate. The precipitate isolated by filtering was washed with distilled water and drying in 110 °C. To stabilize the catalyst on copper slag, copper slag was mixed with CoFe2O4 powder and was put into the furnace for 6 h at 550 °C.

Schematic view of apparatus was show in Fig. 1. Circulate Packed Bed Reactor (CPBR) with a total volume of 1 L and effective volume of 0.2 L was used in this process. One UV lamp with a power of (15 W, Philips) was placed directly inside the reactor and around the UV lamp was filled with catalyst. The CPBR was filled with 70 g of catalyst CoFe2O4/copper slag.

Based on the Box–Behnken experimental design method, several experiments were conducted and factors influencing the photocatalytic degradation were studied. The factors influencing the photocatalytic degradation [pH, the initial concentration of 2-nitrophenol (C2NP) and concentration of hydrogen peroxide (\({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\))] were studied.

For photocatalytic degradation experiments, the different volume levels of hydrogen peroxide were added to the 2-nitrophenol solution. Using a dilute solution of sodium hydroxide and sulfuric acid, pH of solutions were adjusted. The resulting solution was transferred to the feed tank and send in to the reactor using a water pump. At certain time intervals, samples were taken and COD was measured.

Results and discussion

Catalyst identification

Identification of the catalyst was performed by XRD and SEM devices. The corresponding powder X-ray diffraction (XRD) pattern provides further crystallinity and phase information about the obtained CoFe2O4. The observed peak positions (as shown in Fig. 2) are consistent with the characteristic peaks reported for CoFe2O4 in the literature [19]. The major crystalline phases present in copper slag was Fayalite (2FeO.SiO2)-specified peaks at the 2ϴ = 52, and Magnetite (Fe3O4), Hedenbergite Ca(Fe, Mg)(SiO3)2, Hematite, and Maghemite-specified peaks in the range of 2· = 28–31, which is consistent with previous research [20].

Moreover, the mean size of the as-synthesized nanoparticles is calculated from the peak broadening in the XRD pattern using the Debye–Scherrer formula. The average size of CoFe2O4 is 96 nm.

The surface morphology and the approximate particle size of the CoFe2O4 were characterized by SEM and related EDX analysis. The results (Fig. 3) show that the particles are smooth, having homogeneous surface and very similar nano-spherical particles. Although sizes of particles are different, all have a spherical shape. As show in Fig. 3, all surface of CS has covered with CoFe2O4 nano-spherical shape. EDX analysis of product also proved that substances that have been established on the surface consist only of CoFe2O4 Nano particle.

Low-temperature (77 K) nitrogen adsorption-desorption isotherms are used for pore structure analysis of porous materials. The Brunauer–Emmett–Teller (BET) method is used for the determination of surface area of new materials.

Figure 4 shows the adsorption–desorption isotherms and BET surface area for the copper slag, CoFe2O4, and CoFe2O4/CS. The adsorption isotherms of the copper slag sample are of type IV and present hysteresis loops of type H2 classification with previous research [21], indicating that the structure is mainly mesoporous with pores having narrow mouths (ink-bottle pores). The presented type IV isotherm and present hysteresis loops of type H1, characteristic of mesoporous materials with bottleneck (cylindrical pore geometry) pores and spherical particles, are arranged in a fairly uniform way for CoFe2O4 and CoFe2O4/CS.

The BET surface area of copper slag, CoFe2O4, and CoFe2O4/CS were determined as 152.46, 283.77, and 310.73 (m2/g), respectively. It seems that supporting of nano-spherical CoFe2O4 on the CS has been increasing the BET surface area of the catalyst.

Box–Behnken design

In this research, optimization of 2-nitrophenol degradation processes, with response surface methodology, using Box–Behnken model, was performed. Three independent variables of pH (X 1), the initial concentration of 2-nitrophenol (X2), and the concentration of hydrogen peroxide (X 3), in three levels (−1, 0, +1) were tested and shown in Table 1 [22–24].

With detailed tests was determined the scope of variables. The number of tests required for Box–Behnken model was determined with Eq. (5) [25].

According to the Eq. (5), N is the number of samples (tests), K is the number of factors (variables), and C 0 is the number of central points.

Table 2 shows the Box–Behnken design of experiment and response achieved.

The quadratic model and analysis of variance (ANOVA)

All 15 experimental runs designed by the software were performed according to Table 3. The response was set as percentage of degradation after 180 min. The percentage of initial concentration of pollutant decomposed by the photocatalytic process or the percent of photodegradation efficiency (Degradation%) as a function of time is given by:

The regression equations given in Table 3 were derived from the analysis of variances.

Analysis quadratic polynomials and quadratic model, as it is the best model, for relationships between variables and degradation efficiency 2-nitrophenol was used.

Table 4 shows analysis of variance and was used to validate models.

The significance of each term of the predictive model was evaluated by p values using a 0.05 significance level; and smaller the p value the more significant are the corresponding term. The effect of the independent variables on the degradation of 2-nitrophenol followed the order: concentration of hydrogen peroxide (\({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\)) > pH > initial concentration of 2-nitrophenol (C2NP) [26–28].

Figure 5 shows the difference between actual and predicted values for efficiency degradation of 2-nitrophenol, to check whether uniformity of variance assumption with the residual charting compared to predict values is possible.

Effect of parameters on the system performance

In this study, to investigate more deeply the effect of each variable, the three-dimensional (3D) and contour (2D) plots were formed according to the second order polynomial model to analyze the change in response. Figures 6, 7, and 8 depict the surface and contour plots of each interacting variable with two variables kept constant and the other two varying within experimental range.

For photocatalytic degradation efficiency, \({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\) in solution was found to have the greatest effect on the response, with the highest F value (Table 5) of 16.25; while both the pH and C2NP had less effect regarding the degradation efficiency. According to Table 5, the interaction effects between the variables appeared insignificant due to the larger values of p. The photocatalytic degradation efficiency of 2-nitrophenol was found to increase to decreased C2NP and increased concentration of H2O2 and pH.

As seen from Figs 6, 7 and 8, degradation efficiency of 2-nitrophenol increased with increasing the pH values, because hydroxyl free radicals are formed faster and better in the alkaline pH.

By reducing the initial concentration of 2-nitrophenol, the contaminant degradation processes carried out better. With the increase in concentration of pollutants, part of the light energy is absorbed by the molecules of pollutants and high-energy beams do not reach the catalyst surface.

It is seen also that concentration of hydrogen peroxide is an important factor that influences degradation efficiency. Photocatalytic degradation increases with increasing the amount of hydrogen peroxide. In the process, hydrogen peroxide decomposes and produces hydroxyl radicals. In addition, hydrogen peroxide, such as molecular oxygen, can attract photocatalytic conduction band electrons and thereby produce hydroxyl radicals [29, 30].

Optimum condition and verification

The accurate optimal values of the variables were obtained and shown in Table 5. According to the forecasts done, verification experiments were conducted under optimum operational conditions (pH = 10, C2NP = 10 ppm, \({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\) = 90 ppm). The three replicate experiments yielded an average maximum of degradation efficiency of 96.55%. The similarity between the predicted and experimental results verified the validity of the model and existence of an optimal point. This confirms that the RSM was a powerful tool for determining the exact optimal values of the individual factors [31, 32].

Conclusions

In this study, CoFe2O4 particles were successfully synthesized and based on CS. Synthesize particles were then utilized as a catalyst for the photocatalytic degradation of 2-Nitrophenol in CPBR reactor. The Box–Behnken design was adopted to study the effects of three influencing factors, which were pH, C2NP, and \({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\) on the degradation efficiency of 2-nitrophenol by CoFe2O4/ CS. Through ANOVA analysis, Concentration of H2O2 was found to have the most significant effects on degradation efficiency compared to pH and C2NP. Response Surface Methodology was applied as an experimental design to explore the optimum conditions for the photocatalytic degradation of 2-nitrophenol. At optimal conditions (pH = 10, C2NP = 10 ppm, \({\text{C}}_{{{\text{H}}_{2} {\text{O}}_{2} }}\) = 90 ppm), the degradation efficiency, of the experiment done, was 96.55%.

References

Locharoenrat, K.: Review article: recent advances in nanomaterial fabrication. J. Phys: Conf. Ser. 495, 1–6 (2014)

Ahmed, S., Rasul, M.G., Martens, W.N., Brown, R., Hashib, M.A.: Heterogeneous photocatalytic degradation of phenols in wastewater: a review on current status and developments. Desalination 261, 3–18 (2010)

Chen, X., Mao, S.S.: Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem. Rev. 107(7), 2891–2959 (2007)

Erik Casbeer, E., Virender, K., Sharma, V.K., Li, X.Z.: Synthesis and photocatalytic activity of ferrites under visible light: A review. Sep. Purif. Technol. 87, 1–14 (2012)

El-Shobaky, G.A., Turky, A.M., Mostafa, N.Y., Mohamed, S.K.: Effect of preparation condition on physicochemical, surface and catalytic properties of cobalt ferrite prepared by coprecipitation. J. Alloys Compd. 493, 415–422 (2010)

Golsefidi, M.A., Yazarlou, F., Nezamabad, M.N., Nezamabad, B.N., Karimi, M.: Effects of capping agent and surfactant on the morphology and size of CoFe2O4 nanostructures and photocatalyst properties. J. Nanostruct. 6, 121–126 (2016)

Palmisano, G., Addamo, M., Augugliaro, V., Caronna, T., Garcıa-Lopez, E., Loddo, V., Palmisano, L.: Influence of the substituent on selective photocatalytic oxidation of aromatic compounds in aqueous TiO2 suspensions. Chem. Commun. 9, 1012–1014 (2006)

Shimizu, K., Akahane, H., Kodama, T., Kitayama, Y.: Selective photo-oxidation of benzene over transition metal-exchanged BEA zeolite. Appl. Catal. A 269, 75–80 (2004)

Sharmaa, P., Singh, L., Dilbaghi, N.: Optimization of process variables for decolorization of Disperse Yellow 211 by Bacillus subtilis using Box–Behnken design. J. Hazard. Mater. 164, 1024–1029 (2009)

Ferreira, S., Dos Santos, W., Quintella, C., Neto, B., Bosque-Sendra, J.: Doehlert matrix: a chemometric tool for analytical chemistry-review. Talanta 63, 1061–1067 (2004)

Box, G., Hunter, J.: Multi-factor experimental designs for exploring response surfaces. Ann. J. Math Stat. 28, 195–241 (1957)

Kansal, S.K., Singh, M.D., Sud, D.: Optimization of photocatalytic process parameters for the degradation of 2,4,6-trichlorophenol in aqueous solutions. Chem. Eng. Commun. 194, 787–802 (2007)

Ranjan, D., Mishra, D., Hasan, S.H.: Bioadsorption of arsenic: an artificial neural networks and response surface methodological approach. Ind. Eng. Chem. Res. 50, 9852–9863 (2011)

Nelofer, R., Ramanan, R., Basri, M., Ariff, A.B.: Comparison of the estimation capabilities of response surface methodology and artificial neural network for the optimization of recombinant lipase production by E. coli BL21. J. Ind. Microbiol. Biotechnol. 39, 243–254 (2012)

Annadurai, G., Sivakumar, T., Rajesh Babu, S.: Photocatalytic decolourization of congo red over ZnO powder using Box–Behnken design of experiments. Bioprocess. Eng. 23, 167–173 (2000)

Mourabet, M., Rhilassi, A., Boujaady, H., Bennani-Ziatni, M., Hamri, R., Taitai, A.: Removal of fluoride from aqueous solution by adsorption on Apatitic tricalcium phosphate using Box–Behnken design and desirability function. Appl. Surf. Sci. 258, 4402–4410 (2012)

Salahi, A., Noshadi, I., Badrnezhad, R., Kanjilal, B., Mohammadi, T.: Nano-porous membrane process for oily wastewater treatment: optimization using response surface methodology. J. Environ. Chem. Eng. 1, 218–225 (2013)

Garg, U.K., Kaur, M.P., Garg, V.K., Sud, D.: Removal of nickel (II) from aqueous solution by adsorption on agricultural waste biomass using a response surface methodological approach. Bioresour. Technol. 99, 1325–1331 (2008)

Khataee, A.R., Kasiri, M.B., Alidokht, L.: Application of response surface methodology in the optimization of photocatalytic removal of environmental pollutants using nanocatalysts. Environ. Technol. 32, 1669–1684 (2011)

Marghussian, V.K., Maghsoodipoor, A.: Fabrication of unglazed floor tiles containing Iranian copper slags. Ceram. Int. 25, 617–622 (1999)

Sing, K.S.W., Everett, D.H., Haul, R.A.W., Moscou, L., Pierotti, R.A., Rouquerol, J., Siemeniewska, T.: Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 57, 603–619 (1985)

Lin, Y., Ferronato, C., Deng, N., Wu, F., Chovelon, J.M.: Photocatalytic degradation of methylparaben by TiO2: multivariable experimental design and mechanism. Appl. Catal. B 88, 32–41 (2009)

Gopinath, K.P., Muthukumar, K., Velan, M.: Sonochemical degradation of Congo red: optimization through response surface methodology. J. Chem. Eng. 157, 427–433 (2010)

Sharmaa, P., Singh, L., Dilbaghi, N.: Optimization of process variables for decolorization of Disperse Yellow 211 by Bacillus subtilis using Box–Behnken design. J. Hazard. Mater. 164, 1024–1029 (2009)

Sangal, V.K., Kumar, V., Mishra, I.M.: Optimization of structural and operational variables for the energy efficiency of a divided wall distillation column. Comput. Chem. Eng. 40, 33–40 (2012)

Mrowetz, M., Selli, E.: Photocatalytic degradation of formic and benzoic acids and hydrogen peroxide evolution in TiO2 and ZnO water suspension. J. Photochem. Photobiol. A 180, 15–22 (2006)

Kansal, S.K., Singh, M.D., Sud, D.: Parametric optimization of photocatalytic degradation of catechol in aqueous solution by response surface methodology. Indian J. Chem. Technol. 14, 145–153 (2007)

Nordin, M.Y., Venkatesh, V.C., Sharif, S., Elting, S., Abdullah, A.: Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 104 steel. J. Mater. Process. Technol. 145, 46–58 (2004)

Rauf, M.A., Marzouki, N., Korbahtim, B.K.: Photolytic decolorization of Rose Bengal by UV/H2O2 and data optimization using response surface method. J. Hazard. Mater. 159, 602–609 (2008)

Cho, I.H., Zoh, K.D.: Photocatalytic degradation of azo dye (Reactive Red 120) in TiO2/UV system: optimization and modeling using a response surface methodology (RSM) based on the central composite design. Dyes Pigm. 75, 533–543 (2007)

Korbahti, B.K., Rauf, M.A.: Response surface methodology (RSM) analysis of photoinduced decoloration of toludine blue. Chem. Eng. J. 136, 25–30 (2008)

Sakkas, V.A., Islam, M.A., Stalikas, C., Albanis, T.A.: Photocatalytic degradation using design of experiments: a review and example of the Congo red degradation. J. Hazard. Mater. 175, 33–44 (2010)

Acknowledgements

The authors thank the Arak Islamic Azad University for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zeynolabedin, R., Mahanpoor, K. Preparation and characterization of nano-spherical CoFe2O4 supported on copper slag as a catalyst for photocatalytic degradation of 2-nitrophenol in water. J Nanostruct Chem 7, 67–74 (2017). https://doi.org/10.1007/s40097-017-0216-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-017-0216-7