Abstract

Nanotechnology has found its way to petroleum engineering, it is well-accepted path in the oil and gas industry to recover more oil trapped in the reservoir. But the addition of nanoparticles to a liquid can result in the simplest flow becoming complex. To understand the working mechanism, there is a need to study the flow behaviour of these particles. This review highlights the mechanism affecting the flow of nanoparticles in porous media as it relates to enhanced oil recovery. The discussion focuses on chemical-enhanced oil recovery, a review on laboratory experiment on wettability alteration, effect of interfacial tension and the stability of emulsion and foam is discussed. The flow behaviour of nanoparticles in porous media was discussed laying emphasis on the physical aspect of the flow, the microscopic rheological behaviour and the adsorption of the nanoparticles. It was observed that nanofluids exhibit Newtonian behaviour at low shear rate and non-Newtonian behaviour at high shear rate. Gravitational and capillary forces are responsible for the shift in wettability from oil-wet to water-wet. The dominant mechanisms of foam flow process were lamellae division and bubble to multiple bubble lamellae division. In a water-wet system, the dominant mechanism of flow process and residual oil mobilization are lamellae division and emulsification, respectively. Whereas in an oil-wet system, the generation of pre-spinning continuous gas foam was the dominant mechanism. The literature review on oil displacement test and field trials indicates that nanoparticles can recover additional oil. The challenges encountered have opened new frontier for research and are highlighted herein.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As most of the oil fields in the world are approaching maturation, more emphasis is placed on enhanced oil recovery (EOR) methods, because two thirds of the original oil in place (OOIP) is left unproduced. Since the porosity and permeability of most reservoirs varies, early breakthrough result in by-passed crude. EOR process can improve the recovery efficiency; chemical-enhanced oil recovery (CEOR) can recover about 37% OOIP. Oil can be trapped microscopically in the reservoir by capillary forces and oil can also be by passed macroscopically by water flood. CEOR therefore, is aimed at finding chemical that could be added to water to reduce the capillary forces and increase the sweep efficiency. The major chemical used in the industry to achieve this are polymer, surfactant and alkaline. Surfactant lowers the interfacial tension between the oil and water, alter the wettability of the rock, generate emulsion and stabilize foam. Polymers on the other hand increases the viscosity, which reduces the mobility ratio, and therefore improves the sweep efficiency, whereas alkali increase pH, generate in situ surfactants and reduce adsorption of anionic surfactants [1]. The combination of all the chemicals alkaline, surfactant and polymer (ASP) is also in use but due to high cost of chemicals and fall in crude oil price, petroleum engineers has sought for ways to remedy this situation. With the introduction of nanotechnology in EOR, it is a way to solve the numerous problem plaguing the oil and gas industry.

Nanotechnology is the use of nanoparticles ranging from 1 to 100 nm size in the study of combination science, medical, engineering and technology. At present, nanotechnology has been used in medicine, electronics, electrical, space, science and engineering [2]. It has enjoyed wide range of use because of its large surface area which makes it easier to interact with solvent molecules when added to make suspension, optical transparency (copper nanoparticle), electrical conductivity (silicon nanoparticle), chemical catalyst (platinum nanoparticle), colour change (gold nanoparticle), thermal properties like heat transfer, cooling, insulation, and property of mechanical strength like ultra-high strength of material [3, 4].

Nanotechnology has also found its way to petroleum engineering, it is a well-accepted path in the oil and gas industry to recover more oil trapped in the reservoir, it has recorded success in reservoir characterization, drilling and well-completion jobs [5]. In EOR, nanoparticle is still in the laboratory stage where its efficiency is being studied. And few field trials have been reported [6]. Different laboratory studies [7, 8] and pilot field application have reported [6] that nanofluids can recover oil trapped in the reservoir. Therefore, nanoparticle can change the wettability of the rock surface, reduce interfacial tension between oil and water interface, and lower the chemical adsorption into the reservoir rock surface [9].

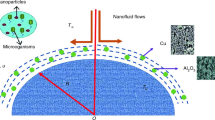

The application of nanoparticles in EOR process can be summarized into three major approaches; nanofluids, nanocatalyst and nanoemulsion [10]. Nanofluids are usually base fluid with nanoparticles size less than 100 nm in colloidal suspension [11]. The base fluid in this case can be water, oil or gas. Nanofluid in EOR are usually used to improve water flooding and the mechanism responsible include; IFT reduction, disjoining pressure, wettability reduction, viscosity increase, pore channel plugging and asphaltene precipitation. Nanoparticles can also be used to stabilize emulsion, it can overcome the challenges encountered by other stabilizers such as surfactants [12]. The high viscosity of nanoemulsion can control mobility ratio during flooding. It is therefore, very useful in heavy oil recovery [13]. And can penetrate through pore throats without much retention. Whereas nanocatalyst are used as catalyst in steam injection of heavy oil reservoir [14]. The advantages of using nanocatalyst to conventional catalyst include; upgrading of heavy oil reservoir by converting bitumen to lighter products. Nanocatalyst such as iron and nickel can also breakdown carbon–sulphur bonds within asphaltenes, increase saturates and aromatics in the heavy oil [10]. The summary of the application of nanoparticles in EOR is shown in Fig. 1.

Two characteristics of nanoparticles that make them very attractive to the oil and gas industry are their large surface area and the ability to manipulate their behaviour and structure. Therefore, nanotechnology involves the tailoring of a material at the atomic level to attain a unique property, which can then be manipulated at will for a certain application. The different types of nanoparticles are; metal nanoparticles (gold, silver, lead and iron), organic polymer nanoparticles and the inorganic polymer nanoparticles (silica, tin, germanium phosphorus and sulfur), the organic polymers can be natural or synthetic. The natural polymer nanoparticles include; sucrose, maltose, carbohydrate, chitosan, Arabic gum and biomolecules while the synthetic is mostly derived from petroleum products [4].

The addition of nanoparticles to a liquid, can result in the simplest flow becoming complex, to understand the working mechanism, there is need to study the flow behaviour of these particles. There are a lot of reviews on nanoparticles in oil and gas industry from Kong and Ohadi [15] to Sun et al. [10]. The work of Hadi et al. [16] was on polymer-coated nanoparticles, and Sharma et al. [17] discussed a little on the effect of surfactant on nanoparticles, but they are more general in the discussion, making the work of on this subject to be scattered in the literature.

This review, therefore, highlights the mechanism affecting the flow of nanoparticles in porous media as it relates to EOR. The discussion focuses on CEOR, a critical review on laboratory experiment on wettability alteration, effect of interfacial tension and the stability of emulsion and foam is discussed. The mechanisms affecting the flow behaviour of nanoparticles in porous media was discussed laying emphasis on the physical aspect of the flow, the microscopic rheological behaviour and the adsorption of the nanoparticle. A compilation of the experimental studies on nanoparticles flooding process as it affects incremental oil recovery is presented and two field trials are included. This review will provide update on existing literature on this subject and the recent development in CEOR. The challenges encountered have opened new frontier for research and are all highlighted herein.

Nanotechnology in CEOR

Wettability alteration

Wettability can be defined as the relationship between the solid surface to the solid–fluid and fluid–fluid interaction [18]. Spreading of liquids and wetting of surface influences oil recovery mechanism. Surface agents can change the wettability of rock surface; wettability affects capillary pressure and relative permeability curve. Nanoparticles have been proven to have great impacts on wettability alteration. The use of nanoparticles can form a two-dimensional layer in the presence of a three-phase contact region formed between the oily soil and the solid substrate [19]. It plays an important role in disjoining the structural pressure (force normal to the interface). The wettability of any solid surface can be determined using spontaneous imbibition, contact angle measurement, zeta potential measurement and surface imaging test.

The changing of the wettability of the reservoir rock from oil-wet to water-wet can ease extraction of oil and improve oil recovery [9]. A surface is said to be water-wet if the water contact angle is < 90° and oil-wet if the water contact angle is > 90° IFT.

Mechanism of wettability alteration by nanoparticles

The surface and interfacial energies are used to determine if a surface is water or oil wet, the contact angle formed is as a result of the force balance between the spreading coefficient (S) of water on a solid in contact with both oil and water. Nanoparticles increase S by removing the oily soils from solid surface using the mechanism called ‘Rollup’. In laboratory experimentation, the contact angle, the Amott test, the centrifuge method, the core displacement test is used to determine wettability. The contact angle is used to determine the wettability of a three-phase system, it is used to determine formation wettability. The imaging method gives a clear picture of the wetting mechanism in oil–water–rock system as shown in Fig. 2. The centrifuge method uses the correlation between the degree of wetting and the area under the capillary pressure curve, it is consistent with the Amott method but better in near neutral area.

Contact angle on a rock, a oil-air–rock before treatment, b oil–air–rock after treatment with silica, c water–air–rock before treatment, d water–air–rock after treatment with silica nanoparticles [28]

Wettability alteration by nanoparticles is due to their adsorption on the rock surface, which forms a water-wet layer on it. Adsorption of a very active and energetic material on a solid surface can significantly alter the surface energy and wettability of the system [20]. Adsorption happens when the balance between the capillary force and viscous forces changes. The viscous force is decreased, whereas the capillary force increases. Therefore, the viscous force needed to overcome capillary forces are reduced [21]. The large surface area of nanoparticles can lead to an increase in the proportion of atoms on the surface of the particles, which results in an increase in surface energy with the ability to alter the wettability of the rock [22]. Mohammed and Babadagli [23] described wettability alteration from oil-wet to mix-wet and then to strongly water-wet condition by analysing the balance between capillary and gravitational forces. The shift in wettability from strong oil-wet to water-wet is because of two mechanisms. Firstly, from strong oil-wet to mix-wet and secondly from mixed-wet to strong water-wet [24]. The main factor in the first mechanism is gravitational forces, which change the balance of the wetting forces. And displaces the weight of the fluid from the bulk to the interface. Defined as capillary forces, by reducing the capillary forces, which leads to wettability alteration from strong oil-wet to mixed-wet [24]. Also, the component for oil/brine/rock such as oil/brine component, mineral surface, and system history condition may also control the wetting tendency [25].

Giraldo [20] observed that in a fluid containing nanoparticles or micelles immersed in oil droplet on a surface, they were two contact lines instead of one that is usually observed in a traditional mechanism. This inner and outer spreading lines, therefore, account for faster spreading of a nanoparticle solution on a surface for higher concentration and viscosity compared to traditional mechanism. Which might have led to increase in relative permeability of oil due to the wettability alteration by nanoparticles. Oil recovery can increase by 20% when high concentration of nanoparticles is injected. They suggested 2–3% concentration as increase in concentration can result to decrease in permeability [26]. This is usually associated with the nanoparticle size, salt concentration and bulk volume [27, 28].

Moustafa et al. [29] used a combination of Magnesium/Aluminium layered double hydroxide, their results show that 4.0 g L−1 concentration decreases the brine phase contact angle in the presence of oil from 66° to 60°. Hendraningrat and Torsaeter [30] using Aluminium, Silicium and Titanium oxide nanoparticles on Berea sandstone core, reported a 5–7% increase in recovery by Titanium oxide, this shows that the wettability was altered as Titanium made the quartz plate more water-wet. They concluded that oil recovery increases as nanoparticles size decreases and the contact angle alteration decreases towards more water-wet quartz. Karimi et al. [31] demonstrated that zircon oxide nanoparticles can alter the wettability of carbonate rock reservoir, the SEM and XRD analysis verified that nanoparticles can significantly change the wettability of reservoir rock. The influence of nanoparticles on wetting behaviour of fractured limestone was also demonstrated by Nwidee et al. [32]. They investigated the influence of zirconium(iv) oxide (ZrO2) and nickel(ii) oxide (NiO). The contact angle measurement demonstrated that application of nanofluid in oil-wet or intermediate-wet formation can increase oil recovery by wettability alteration as the nanoparticles adsorb on the surface of the calcite crystals and promote oil displacement. Time, concentration and salinity where responsible for the decrease in the water contact angle. The work of Mohammadi et al. [21] shows the success of gamma alumina nanoparticles in enhancing oil recovery in carbonate rock when they observed a maximum change in contact angle and 11.25% increase in recovery. Ju and Fan [33] used lipophobic and hydrophobic polysilicon nanoparticles to alter the wettability of sandstone from oil-wet to water-wet. TEM analysis revealed that nanoparticles where attached to the pore walls. Again, the work of Li and Torsaeter [34] was an improved study on wettability alteration and they confirmed earlier reports. Ju et al. [26] using a physical model, mathematical model, and a numerical simulator were able to increase recovery by 15.38% when treated with water-wetting wettability control agent (IWWCA) and increasing the oil-wetting wettability control agent (IOWCA) improves recovery (60–80%) in water injection rate. Onyekonwu and Ogolo [7] studied the wettability alteration of three different polysilicon nanoparticles to enhance oil recovery. The nanoparticles used were lipophobic and hydrophobic (LHPN), hydrophobic and lipophobic (HLPN) and neutrally wet (NWPN). They reported that HLPN and NWPN are good agent for enhanced oil recovery with a total recovery between 42.95 and 53.38% for LHPN, 70.62–86.92% for NWPN and 70.0–93.13% for HLPN.

Wan Sulaiman et al. [35] used silica nanoparticle in carbonate rock to alter the wettability of the rock, and to test the efficiency of silica nanoparticle in enhancing oil recovery in high salinity. They reported a 65.5% recovery of the original oil in place. Nazari et al. [36] in their work on wettability alteration of carbonate rocks, ZrO2, titanium dioxide (TiO2), magnesium oxide (MgO), aluminium dioxide (Al2O3), cerium oxide (CeO2) and carbon nanotube (CNT), where all used for contact angle measurement while calcium carbonate (CaCO3) and silicon dioxide (SiO2) where used for core flooding. The result showed 8–9% additional recovery. Maghzi et al. [37] monitored the wettability alteration using silica nanoparticles during water flooding of heavy oil, they experimented with micromodel and reported a 26% incremental oil recovery using silica nanoparticles. Experimental results by some researcher are summarised in Table 1.

Challenges of nanoparticles in altering wettability

Some factors could mitigate against the success of wettability alteration using nanoparticles, such factors include; concentration of the nanoparticles, nature of the reservoir, hydrophobicity of the nanoparticles, type of nanoparticles and nature of the oil.

Hydrophilic polysilicon makes a water-wet formation more water-wet, and this might lead to poor recovery [7, 38]. Therefore, hydrophilic polysilicon nanoparticles should be restricted to oil-wet formation while, the hydrophobic polysilicon should be restricted to water-wet formation. The nature of the oil also has a significant role to play in wettability alteration, the selection of nanoparticles should depend on the type of oil. Roustaei et al. [39] reported that silicon oxide is more effective in the wettability alteration of light oil. Whereas Huibers et al. [40] recommend the use of silica nanoparticles when the contact angle in light crude was mostly affected by the addition of 0.001 wt% nanoparticle, which altered the wettability of sandstone. While the contact angle of light crude plateaux, the heavy oil continued to increase with increase in nanoparticle concentration, indicating that a maximum contact angle in heavy oil was not achieved. Nanoparticles disrupts the viscoelastic network formed by asphaltenes aggregates in the presence of resins which causes viscosity reduction in heavy oil [41]. Therefore, ZrO2 nanoparticles was reported by Wei and Babadagli [42] to have a potential to be used in the recovery of heavy oil (Tables 2, 3).

The nature of reservoir also plays an important role in determining the type of nanoparticles to be used. As all carbonate reservoirs are suggested to be oil-wet [43]. Therefore, the right nanoparticle and optimum concentration of the nanoparticle is required. Al2O3, SiO2 and Fe2O3 nanoparticles are effective for altering wettability of sandstone rocks [44]. Whereas ZrO2 and NiO nanoparticles are effective for Limestone formations [32]. ZrO2 was considered a better wettability modifier than NiO, and it also exhibited a better performance than SiO2 and Al2O3 nanofluids [32, 45]. Through microscopic imaging and theoretical calculations, the wettability alteration of ZrO2 is due to its deposition on rock surface which is governed by the partition coefficient of the nanomaterial in water and oil phase.

Hydration of nanoparticles is another major challenge encountered, ions within the clay material interact with the water leading to hydration and expansion of the d-space of the clay material [46]. To combat this problem, the use of swelling inhibitors should be employed. In formulating nanoparticles, the size control is very important for the success of EOR operations. The right size is needed to flow through the porous media, as large size will block the pore-throat of the media leading to formation damage. Also, nanoparticle retention and entrapment must be prevented to the barest minimum for a successful wettability alteration to be achieved.

Interfacial tension (IFT) reduction

The main mechanism is the migration and arrangement of the oil–water interface, which is dependent on the hydrophobic and hydrophilic properties of the nanoparticles. The purpose of surfactant flooding is to increase the capillary number by reducing IFT between the oil and water [1, 47]. Nanofluids of 70–150 nm dissolved in aqueous solution of surfactants can result in effective oil displacement of 35% compared to using only surfactants in a homogeneous reservoir, and 17% in a heterogeneous reservoir at a temperature of 25 °C. The increase in recovery because of lowering of IFT occurs when the fluid changes characteristics from Newtonian to non-Newtonian state [48].

Mechanism of IFT reduction

IFT is used to determine nanofluid movement in porous media, it is important to determine the IFT between the oil and fluid in EOR technique. The pendant drop and the spinning drop methods are widely used to measure IFT. The theory behind the mechanism of operation in nanoparticles IFT tension is still under debate, but to get a good insight into the working mechanism between the nanoparticles, rock and fluid. The Poisson–Boltzmann and Derjaguin–Landau–Verwey–Overbeek (DLVO) theory of approximation are used. Be that as it may, to understand the forces in play, the particle size, the force of attraction and DLVO theory must be considered.

Particle size

The morphology of particles as well as the area to volume ratio for the particle molecule to interact with fluid molecules is an important aspect that governs surface tension in a complex fluid. Near-spherical morphologies has a minor increment in the interfacial energy compared to hexagonal pillar and flake-like morphologies. Therefore, surface tension of nanofluid also shows slight increment with size [49]. Nanoparticles have high surface to volume ratio with high contact area. These enable a high diffusion rate, mass transfer which can change the properties of fluid [50]. Nanoparticles can be measured in microscale that is, they have the tendency to spread homogenously in porous media, reaching corners that originally were not touched by conventional methods. The polarity of fluid can also affect surface tension of nanoparticles according to the electric double layer (EDL) formed at the particle–fluid interface. The particles at the interface will experience a weaker repulsive force from the particles in the bulk. There is a tendency of desorption to the bulk from the interface leading to no appreciable change in surface tension. This might be because of high viscosity of the fluids. Particles Brownian motion might have been partially hindered and the particles finds it difficult to adsorb from the bulk to the interface and vice versa.

The governing mechanism is a multiphase zone comprising of the interface of the solid nanoparticles, the suspended base fluid and the coexisting interface. The surface energy associated with each of these interfaces depends on the characteristics of the nanoparticles suspended, the base fluid of the suspension and the surrounding fluid region [49]. The bulk surface tension of the resulting suspension is determined by the collective interaction of the vector additions of the forces at the microscopic and the summation of such interaction. The hydrophilic or hydrophobic nature of the particles is the driving force that determines the affinity of the particles towards one of the phases [51]. The particles affinity towards the surface is a strong function of the equilibrium interface contact angle, which favours the particles partial wetting behaviour. The mechanical agitation of the particles at the fluid–air interface is shown in Fig. 3. The particle must satisfy the minimum energy criteria to be positioned at the interface with height (h) protruding out from the fluid interface as shown in Fig. 3. Creating a localized contact angle (θ), which is the point of stable equilibrium made by the particles at nanoscale three-phase contact point [49]. Whereas the particle radius is (r) and the radius of the interface area of the fluid occupied by the solid particle is (b).

Schematic representation of nanoparticles at fluid air interface [49]

Electrical layer

As the reservoir is said to have a charged surface, so also is the rock surface which is considered to have a constant net charge, positive forces are arranged at the rock surface while negative forces in the fluid interface, ignoring the gravitational forces working on the nanoparticles for pronouncement of the charged forces, this region of opposite charge is referred to as the EDL. The Poisson–Boltzmann equation is used to predict nanoparticle flow behaviour in porous media at charged interface [50], which is expressed as;

whereas ψ is the electric potential, z is the axis perpendicular to the surface, e is the charge of the electron, no is the particle concentration, \( \varepsilon \) is the permittivity, h is the height of nanochannel, s is the cross section, KB is the Boltzmann constant, T is the temperature.

Most colloidal particles are surrounded by EDL. It can be assumed that nanoparticles suspended in the base fluid in the form of colloidal particles are surrounded by EDL. The force of attraction and repulsion are exerted on the nanoparticles [52]. The force of attraction is governed by van der Waals forces, which induces coalescence of the particles if the distance between the particles exceeds the energy barrier. Whereas the force of repulsion is governed by Coulombs force, which prevents coalescence of the particles [52]. The distance of the EDL can determine the amount of Coulomb force acting on the nanoparticles. As sufficient Coulomb force is needed to act on the nanoparticles to attain a stable nanofluid [53].

DLVO theory

DVLO theory states that the stability of two particles in close proximity is dependent on the total energy of their interaction. It considers the forces of attraction and repulsion between the nanoparticles, rock and fluid such as van der Waals attraction, EDL, born repulsion, acid–base interactions and hydrodynamic forces [9]. Based on DLVO modelling, the basic assumption is that the particles are spherical, which does not hold for all manufactured nanoparticles as some are rod-like, triangular, polygonal. The force of attraction between these particles differs and there is need to reduce the electrostatic repulsion between the nanoparticle building block [54]. Therefore, the small size and large surface area of nanoparticles conflicts with the fundamental assumptions of DLVO theory leading to series of challenges. When particles reach a small size, it surfaces curvature becomes too substantial enough to assume it is flat, which becomes a problem when considering its aggregation with respect to DLVO theory. This is because as the size of the particle decreases, high number of the atom exist at the surface which will affect the electronic structure, surface and reactivity charge [55]. The chemical composition of most material can also pose a problem to this theory, as some ferromagnetic materials like iron and magnetite can cause magnetic attraction without a magnetic field which can lead to rapid aggregation. Therefore, the shape and size of nanoparticles can control nanoparticle aggregation and should be taken into consideration when manufacturing nanoparticles.

Roustaei et al. [39] measured the IFT and wettability of polysilicon nanoparticles, using hydrophilic and hydrophobic polysilicon (HLP) and naturally wet polysilicon (NWP). They reported a reduction in the IFT from 26.3 to 1.75 mN m−1 and, oil recovery increased to 32.2 and 28.5% with 4 g L−1 of HLP and NWP, respectively. Hendraningrat et al. [56] also reported that hydrophilic silica nanoparticles can reduce IFT between water and oil phase and make the solid phase more wet, the nano fluid increase the oil recovery about 4.5% compared to brine flooding.

Baez et al. [57] used a novel amphiphobic nanoparticle-based functionalized CNT and they were very effective in reducing IFT.

Ragab and Hannora [58] using alumina in flooding experiment had a recovery in the range of 62–81%, the reason was due to the reduction in IFT of the nanoparticles.

Kim and Krishnamoorti [59] studied the behaviour of water soluble poly oligo (ethylene oxide) monomethyl ether methacrylate. The synthesized nanoparticles reduced the interfacial tension from 50 to 20 mN m−1 at a concentration of 1–100 ppm.

Comparative study on the effect of surfactant and nanoparticles on IFT reduction

The use of surfactant to reduce IFT tension has its own limitations, in this section, an attempt is made to compare these limitations with the solutions nanoparticles can provide vis-a-vis their effects. The mechanism of surfactant and nanoparticles is to reduce IFT, in surfactant flooding, this is closely related to solubilisation of oil and water. On like nanoparticles which uses the Poisson–Boltzmann equation and DLVO theory, surfactant uses the Healy and Reed correlation equation and the Huh equation to understand the relationship between the IFT and solubilisation. Factors such as concentration of surfactant, salinity, temperature, divalent ions, and formation can affect IFT [1, 60].

Effect of formation

The high adsorption rate of anionic surfactant in carbonate reservoir coupled with the high cost of cationic surfactant has made the application of surfactant flooding to be limited to sandstone reservoirs and only few applications in carbonate. But Bayat and Junin [9] reported that nanoparticles of Al2O3, TiO2 and SiO2 were able to recovery 52.6, 50.9 and 48.7% OOIP, respectively in limestone porous media. These high recoveries were attributed to the nanoparticles mobility. Also, the magnitude of the EDL repulsion in comparison with the London-van der Waals attraction between the formation was greatly diminished when nanoparticles propagated through the porous media [61]. Godinez and Darnault [62] believed that deposition process is a key retention mechanism of nanoparticles. This because, as the solution pH of nanoparticles approach point of zero charge, the mobility and transport of the nanoparticles will be limited. This is due to the reduction of electrostatic interaction forces, leading to the increase in the deposition rate. Whereas Ju and Fan [33] reported that adsorption of nanoparticles at pore walls and pore throat blocking is high close to the inlet of the porous media. The control of particle size during injection and reaction times of nanoparticles inside the porous media is very important. This is because the size of the particles could reduce the pressure through permeability reduction. Also, particles size could impact on dispersion ability, adsorption affinity and catalytic activity of nanoparticles inside the medium [14].

Effect of salinity and divalent ions

Surfactant tends to precipitate at high salinity and for most surfactants the optimum salinity is not high and as such, divalent may be associated with it, thus affecting surfactant performance [63]. Wan Sulaiman et al. [35] reported the use of hydrophilic silica nanoparticles in oil-wet limestone at different nanofluid concentration with different formation brine concentration. A high recovery of up to 65.4% OOIP by lowering of the IFT was reported. Figure 4 shows the oil recovery at different concentration of brine with nanofluid.

Oil recovery at different concentration of brine with nanofluid [35]

Bayat and Junin [9] concluded that the mobility of nanoparticles through porous media strongly depend on the stability, porous media surface charge and roughness. This implies that nanoparticles with the same surface charge as the porous media are more stable against deposition and can easily be transport through the porous media. Whereas those with opposite surface charge will lead to noticeable adsorption on the porous media.

Effect of reservoir temperature

Surfactant also precipitate at high temperature, the median temperature for the surveyed surfactant project is 25.3 °C [47]. Ranka et al. [64] stabilized nanoparticles at high-temperature reservoir condition. They reported the use of hydrophilic silica and hydrophobic polystyrene nanoparticles to achieve a long-term colloidal stability up to twice the stability limit previously reported in open literature. Bayat et al. [65] demonstrated that using Al2O3, TiO2 and SiO2 nanofluid can reduce IFT by 33, 37 and 42%, respectively compared to brine. The reduced trend was observed for all temperatures as shown in Fig. 5. This shows that nanoparticles have low affinity to be adsorbed compared to surfactants. The low adsorption rate can lead to increased oil recovery. The mechanism in play is the decrease in capillary forces, by the deformation of the trapped oil droplets.

IFT of oil/aqueous phase at different temperatures and at ambient temperature [65]

Challenges of nanoparticles in reducing IFT

At lower surfactant concentration, addition of nanoparticle reduces IFT but, at higher concentration, IFT increases when nanoparticles are added. This can be attributed to the electrostatic repulsive interaction between the nanoparticles and the surfactant that promoted the diffusion of the surfactant towards the interface [66]. Nanoparticles can act as a carriers of surfactant molecules towards the interface, but at high concentration the nanoparticles attract the surfactant molecules which can lead to aggregation of the surfactant molecules [67]. One of the major challenges of nanomaterial design is the control of colloidal stability of the particles to prevent aggregation and damaging interaction with the surrounding, as tiny particles tends to aggregate and form bigger particle cluster. This is due to the surface energy as a result of high surface energy of the nanoparticles which might lead to adsorption of other particles or molecules on the surface. This might change the physical and chemical properties of the nanoparticles making it less effective in reducing IFT. The hydrating layer surrounding each nanoparticles act as a repulsive barrier which prevents the nanoparticles from attaching to each other due to the attractive van de Waals forces. Therefore, at lower linker concentration both spherical and rod-like nanoparticles tend to form linear chains because of the need to reduce the electrostatic repulsion between the building blocks of the nanoparticles. When the concentration of the linkers is increased the attachment is no longer linear [54]. Interfacial interaction between two faces in a hybrid solution is the most decisive factor affecting the properties of the resulting material. Therefore, the dispersion of the nanoparticles is of great importance to the properties of the nanoparticles as such surface modification with active functional groups can optimize the efficiency of the process [68].

Nanoemulsions in EOR

Nanoemulsion have drop length-scale less than 100 nm, they can retain their morphology with the change in oil volume fraction. The ease of nanoemulsion preparation stability and increased bioavailability are the main features of their formulation which have attracted researchers [69]. They are basically three types of nanoemulsion; oil in water emulsion where, oil droplets are dispersed in the continuous aqueous phase. Water in oil emulsion where, water droplets are dispersed in the continuous aqueous oil phase. And bi-continuous nanoemulsion where, micro domains of oil and water intersperse within the system. The characteristics of nanoemulsion that makes them attractive for EOR application includes; their lack of shear-thickening and sedimentation problem. This is because of their small size. Nanoemulsion have high dispersibility compared to microemulsion. Their small size droplet can prevent flocculation. And they are easily stabilized against Brownian collision with a polymeric surfactant that produces steric repulsion [70].

Application of nanoemulsion in EOR

Nanoemulsion are suited for large-scale field applications, this is because they can penetrate through pore throats without retention [71]. This attribute of nanoemulsion, has had a huge impact on EOR mechanism as residual oil is recovered from the reservoir. Small drop size of nanoemulsion which is usually smaller than the pore throat in gravel-pack and reservoir rock can result in good injectivity and penetration without filtration [72]. This can prevent the issue of gravity-driven separation due to the density difference of the two phases. Binks et al. [73] also reported that nanoemulsion can withstand harsh reservoir condition of high pressure, temperature, shear and salinity. Therefore, nanoemulsion can remain stable in the reservoir at these prevailing conditions.

Effect of nanoparticles on stability of emulsion

Emulsion when generated in situ or injected have the capacity to divert flow to the by-passed oil by blocking swept out pores [74]. It also helps to entrain oil into the mobile aqueous phase which will lead to a better sweep efficiency. Studies have also shown that emulsion can increase viscosity and decrease mobility ratio, which will in turn lead to increased recovery [75]. Surfactants are mostly used to stabilize emulsion but under harsh reservoir condition, surfactant emulsion has its limitations and its high mobility ratio cannot be controlled. Nanoparticles can be used to stabilize emulsion and is more advantageous than surfactants. Droplet images of emulsion made with 0.1 wt% cetyl trimethylammonium bromide (CTAB) and various nanoparticle concentration is shown in Fig. 6.

Droplet images of emulsion made with 0.1 wt% CTAB and various nanoparticle concentration [74]

Nanoparticles have significant effect on the displacement dynamics of wetting and non-wetting phases, in situ emulsion takes place when octane displaces brine containing nanoparticles. Nanoparticle stabilized emulsion can also stabilize oil front, but the physics behind the non-wetting and wetting phase imbibition is different for nanoparticles dispersion displacement process. The coated nanoparticles could accumulate at the displacement front at the oil–water interfacial area because of the lipophilic nature of the nanoparticles. Nanoparticle can seriously affect the phase behaviour of oil–water system, nanoparticle-induced toluene-in-water and crude oil-in-water emulsions are stable at elevated temperature. This was achieved by the short-chain polyethylene oxide polymer with silane end group which coated over the nanoparticles. But other hydrocarbon like hexane, decane and mineral oil are not able to form stable emulsions. The concentration of salt and concentration nanoparticles has opposite effects on the stability of emulsion. Viscous emulsion is more stable and are very important for oil recovery [76].

Villamizer et al. [77] studied the stability of silica nanohybrid single wall carbon tube (SWCNT) in EOR. They reported that the hybrid shows good stability at different pH and salinity. Low concentration of nanoparticles can stabilize emulsion for months which has a potential application in EOR.

Pei et al. [78] showed that nanoparticles-surfactant stabilized emulsion was able to recover heavy oil by making emulsion thick and achieved desired mobility that can improve the sweep efficiency. In their experiment using a micro-model as the porous media, they reported a recovery of 40% of OOIP.

Griffith et al. [79] in their work on Boise sandstone cores with silica nanoparticles-stabilized pentane in water (natural gas liquid-emulsion) as the injecting fluid, while light oil was the residual oil, the result showed up to 82% residual oil recovery.

Kim et al. [80] studied the synergy’s benefit of employing nanoparticles in emulsion for improved mobility control especially under high salinity control using hydrophilic silica nanoparticles and surfactant in oil-in-brine emulsion formation. They successfully generated a strong and stable emulsion with a combination of either cationic or non-ionic surfactant with nanoparticles compared to surfactant and nanoparticles themselves alone.

The combination of two or more nanoparticles can be employed to stabilize emulsion. McClements and Jafari [81] reported that the combination of two different emulsifier may lead to the formation of emulsion with different droplet size and has a better stability compared to when used separately. Using mixture emulsifier during homogenization process can reduce the size of the droplet produced. This is because one of the emulsifier may adsorb quickly and reduce the IFT. But may be less effective in stabilizing the droplet against coalescence. Whereas the other emulsifier may be less effective at reducing IFT but, maybe very effective in impeding droplet coalescence.

Foam stability using nanoparticles

The change in height of form generated with time and the time taken by the foam to reach half of its original life is a measure of its stability. The rate of foam collapsed can decrease with increasing surfactant concentration. However, foam stability only increases with increase in surfactant concentration. The type of nanoparticle and the concentration of the nanoparticles are the two influential parameters on the stability of foam and the nanoparticle suspension. Which can be made to have a better stability thereby, prolonging the generated lifetime of the foam [82]. SiO2 and Al2O3 nanoparticles were reported by Bayat et al. [82] to have high foam stability based on the foam half-life time, and a direct relationship between the nanoparticle stability against deposition in aqueous phase and foam stability. Therefore, the stability of the nanoparticles against deposition in the aqueous phase before it is utilized for fabrication of foam was also an important factor in stabilizing CO2 foam with nanoparticles. This was observed when the nanoparticles affected the morphology and size of the foam bubbles as the shape changed from polyhedral to spherical and the size of the bubbles becomes smaller and uniform [82]. But in the presence of oil, foam stability depends mainly on the viscosity and density of the oil [83]. The addition of nanoparticles will increase the stability due to aggregation of the nanoparticles at the thin Lamella of the foam (Fig. 7), which prevented spreading of the oil at the gas–liquid interface. The modification of silica-sodium dodecyl sulfate (SDS) mixture resulted in optimum foam stability, whereas the slower liquid drainage from the foam did not result in high foam stability. Nanoparticles when used to stabilize foam, can withstand high temperature reservoir condition, at low concentration, nanoparticles can be used to stabilize foam, but at high salinity, the stability of foam decreases [84]. This was observed by Yekeen et al. [85] when they noticed that the foam stability decreased in the presence of salt until the transition salt concentration was reached. Beyond the transition salt concentration, the foam stability will increase with the increasing salt concentrations [85]. The dominant mechanisms of the foam flow process were lamellae division and bubble to multiple bubble lamellae division as shown in Fig. 7. These mechanisms dominated the residual oil mobilization and displacement by the foam and it was found to be a directly proportional to the displacement and emulsification of the oil as shown in Fig. 8. In a water-wet system (Fig. 8), the dominant mechanism of the flow process and residual oil mobilization are lamellae division and emulsification oil, respectively, but in the oil-wet system, the generation of pore spinning continuous gas foam was the dominant mechanism governing the foam flow process and residual oil mobilization [86]. In the generation of SiO2-SDS and Al2O3-SDS foam, the pore level mechanism controlling the behaviour of the nanoparticle-surfactant foam in the porous media are similar which led to improved foam dynamic stability in water-wet and oil-wet porous media [86].

Occurrence of bubble-to-multiple-bubble lamellae division, a SiO2-SDS foam flow in the absence of oil, b SiO2-SDS foam flow process in the presence of oil, c Al2O3-SDS foam flow process in the presence of oil [85]

Mechanism of residual oil mobilization in water-wet system, a emulsification of oil during SiO2-SDS foam flow, b effective emulsification, c oil emulsification, d inter-bubble trapping and oil trapping at the pore walls [86]

Generally, the performance of foam was enhanced with increasing nanoparticle hydrophobicity which increases stability but decreases foamability with increasing concentration of the nanoparticles. Therefore, nanoparticles increase foam apparent viscosity, improves foam stability by adsorption and aggregation at the foam lamellae which increases the film thickness. And dilatational viscoelasticity which prevents liquid drainage and film thinning leading to bulk and bubble scale stability [87].

Experimental results show that foam can be generated at a critical shear rate higher than 4000 s−1 [87]. But using dynamic experiment to produce foam by nanoparticle dispersion with CO2 injection in a glass bead column, stable form was formed at shear rate higher than 1419 s−1 at 1500 psig. Increase in the injection rate increased the shear rate to 3312 s−1, and increased viscosity from 1.5 to 2.5 times higher than the normal dispersion without foam [88].

Yu et al. [89] applied nanoparticle stabilized CO2 foam to improve oil recovery in high and low permeability core after water flooding, they reported a 48.7% recovery in a 33 mD permeability and 35.8% in a 270 mD permeability.

Singh and Mohanty [90] studied foam stabilization with silica nanoparticles and Bioterage AS-40 surfactant for EOR. They reported that the concentration of nanoparticles is important for foam stability, which increases the recovery by 10% of OOIP. Also, Nguyen et al. [91] controlled the mobility in EOR using nanoparticle stabilized CO2 in water foam using microfluidic method. Their report shows that coated silica nanoparticle stabilized CO2 foam is more stable than SDS, which recorded an additional 17% oil after water flooding.

Mo et al. [92] reported increase in recovery from 64.9 to 75.8% when pressure was increased from 1200 to 2500 psi but an increase in temperature reduced the recovery when working with nanosilica-stabilized CO2 foam.

Nanoparticle flow behaviour in porous media

Nanoparticles must be able to flow deep into the reservoir to assist in oil displacement, studies have shown that some challenges are encountered in the flow of nanoparticles in porous media [93, 94]. Therefore, the need to understand the mechanism affecting the flow of nanoparticles in porous media is of importance. The emphasis here will be on the physical aspect of the flow, the microscopic rheological behaviour and the adsorption of the nanoparticles in porous media. The transparent visualization of fluid flow through porous media and the mechanism that takes place during oil recovery by nanoparticle or nanoparticle retention in porous media can be well understood by microfluidic approach using lab-on-a-chip approach, and by macro and micromodel experiments.

Nanoparticle filtration

This occur when the particles are larger than some of the pores in the porous media, especially when nanoparticles are co-polymerized or with surfactants. This may also occur for non-aggregated nanoparticles when injected in low permeability rocks (tight sandstones). Therefore, the size and shape of the nanoparticles are important parameters that can affect filtration. It is important to note that filtration can be initiated by the larger particles, which will cause further filtration, which may lead to decrease in size of the pores after initial filtration [57].

Nanoparticle adsorption in porous media

The flow of nanoparticles through porous media exhibit a Brownian motion, due to the size of the particles, several forces like the Van der walls forces attracts potential forces and control the interaction between the nanoparticles and the porous media walls [95]. Adsorption and desorption takes place depending on the attraction and repulsion force between the porous media wall and nanoparticles. During the flow of nanoparticles through porous media, mainly diffusion, convection and hydrodynamics play major role [34]. However, the adsorption of nanoparticles onto rock surface is influenced by born repulsion and controlled by hydrodynamic forces.

-

1.

Born repulsion: the adsorption of nanoparticles onto the surface is influenced by the born repulsion which occurs because of the coming together of the nanoparticles surface and the walls of the pores of the media.

-

2.

Hydrodynamic force: the hydrodynamic force controls the suspension of a flowing liquid, when the nanoparticles flows through porous media, if the hydrodynamic forces are low, the particles will be suspended onto pore surface and might get adsorbed depending on the surface charge.

Adding nanoparticles into chemical slugs reduce adsorption. These happen during the interaction of chemicals and the rock surface, hydrogen bonding, covalent bonding, hydrophobic bonding and solvation of various species. Therefore, it is a necessity to prevent this interaction, EOR chemical adsorbs at solid–liquid interface by transferring molecules from solution phase to the solid–liquid interface. This only happens when the molecules are favoured in comparison to the bulk phase. Micellization starts to form at higher concentration and form hemimicelles with one or two layers [60]. The solid surface adsorption starts to increase until a bilayer is formed on the solid surface. Addition of nanoparticles helps the molecules at the liquid–liquid interface and affect the interfacial and adsorption behaviour of the process [96, 97]. Even when nanoparticles are of the right size and stable in solution, adsorption can also impede their transportation through porous media. The less the nanoparticles are adsorbed, on the rocks, the economics of oil recovery is improved [98]. Studies have shown that when nanoparticles are coated with polymer, it results to stable particles in solution, but it can also lead to high adsorption and retardation of nanoparticles when injected into the porous media [99, 100]. The electrostatic repulsion and the hydrophobic and hydrophilic interaction between the nanoparticles and the rock can reduce adsorption. Nanoparticles with favourable surface charge that matches that of the rock may exhibit less adsorption [100].

Esmaeilzadel et al. [96] studied the adsorption of anionic, cationic and non-ionic surfactant on carbonate rock in the presence of ZrO2 nanoparticles. They reported that adding ZrO2 to SDS surfactant increases the adsorption onto fluid/fluid interface rather than solid–liquid interface.

Zabala et al. [101] investigated the adsorption capacity of alumina nanoparticles at reservoir condition with Mirador-formation plug cores. They reported a remarkable increase in production 100,000 bbl cumulative production in 4 months, by injecting nanoparticles suspension into a glass model. Hendraningrat et al. [102] investigated nanoparticles retention in porous media. From the result of the visualization experiment, they concluded thus; that nanoparticles were deposited and adsorbed at the surface, which led to reduction in permeability by blocking the pore throat of the model.

Li and Torsaeter [34] investigated the performance of nanoparticles in oil recovery, they reported that adsorption of nanoparticles in glass micro model may cause plugging of the channel and thereby reduce permeability by changing the pressure drop during the experimental process.

Bayat and Junin [9] studied the influence of clay particles on Al2O3 and TiO2 nanoparticles transport and retention through limestone porous media. They concluded that there was a decline in the recovery with Al2O3 and TiO2 nanoparticles because of the presence of clay in the porous media. The position of the clay particles at the pore-throat and the morphology of the clay caused the nanoparticles to be trapped. Therefore, the mobility of Al2O3 and TiO2 nanoparticles through porous media is sensitive to clay type and concentration.

Rheological flow behaviour of nanofluids

The rheological flow behaviour of fluid is defined based on the relationship between the shear stress (τ) and shear rate (γ), where the shear stress is, the tangential force applied per unit area, whereas the shear rate is the change of shear strain per unit time. Viscosity (µ) therefore, can simply be defined as the resistance to flow of liquid suspension, which is expressed as the ratio of the shear stress to shear rate. Fluid behaviour can, therefore be classified as Newtonian and non-Newtonian. For Newtonian fluids, the relationship between the shear stress and rate is linear, that is it remains constant while, that of the non-Newtonian changes with shear stress and rate.

Non-Newtonian fluids can be classified into four major group; the dilatant where the viscosity of the fluid increases when shear is applied example: quicksand, corn flour and water. The pseudoplastic in this case the more shear is applied, the fluid become less viscous example: ketchup, polymer. Rheopectic this is similar to dilatant, but the difference is when shear is applied, the viscosity increases with time, that is, it is time dependent example: we have cream, gypsum paste. Thixotropic where shear is applied, the viscosity decreases with time, which makes it also time-dependent examples are: paint, cosmetic, asphalt, glue. We can therefore, conclude that non-Newtonian fluid are either time-dependent or non-time dependent.

Newtonian and non-Newtonian flow behaviour of nanofluids

The rheology flow behaviour of nanofluids can be measured by the rheometer [103, 104]. The rheological flow behaviour of nanofluid affects the pressure drop of the nanofluid. And therefore, gives an idea of the nanofluid structure which can be used in predicting the thermal conductivity of the fluid [72].

Richmond et al. [105] studied the rheological behaviour of SiO2 and TiO2 in deionized, they observed that SiO2 alone displayed a Newtonian behaviour while, SiO2/TiO2 mixture exhibited a Bingham plastic behaviour. The addition of TiO2, increased the plastic viscosity compared to pure SiO2. TiO2 nanofluid in distilled water showed shear thinning, the intensity increased with concentration of the nanofluid, the viscosity decreases with temperature [103, 106]. But upon exceeding a shear rate of 100 s−1, it showed a Newtonian behaviour [103]. Alphonse et al., [107] and Penkavova et al. [108] on the other hand reported a Newtonian behaviour for TiO2 with water at low shear rate and changed to shear thinning when the shear rate exceeded 100 s−1.

Tseng and Wu [109, 110] studied the behaviour of Al2O3 with pure water and double distilled water in a shear range of 1–1000 s−1. For pure water, there was a transition from shear thinning to shear thickening as the shear rate exceed 100 s−1, while for double distilled water, all the suspension showed shear thinning behaviour at low shear rate and shear thickening as the shear rate exceed the critical value. Whereas the work of Prasher et al. [111] and Anoop et al. [112] on alumina/propylene glycol (PG), Al2O3/water, Al2O3/ethylene glycol (EG) nanoparticles, CuO/EG, they observed all the fluids exhibited Newtonian behaviour.

The work of Tseng and Chen [113, 114] was on nickel/terpineol at shear rate ranges between 1 and 1000 s−1. All the suspension containing nickel nanofluid showed shear thinning behaviour over the entire shear rate. Whereas nickel/-terpineol exhibited shear thinning behaviour for particle concentration. Silver/diethylene glycol (DEG) nanofluid exhibited a non-Newtonian (pseudoplastic) flow behaviour at a shear rate range between 1 and 200 s−1 and the viscosity increased with increase in the concentration of the fluid [115]. While, nanofluid of gold/water, the fluid exhibited Newtonian behaviour, larger-size (50 nm) nanofluid showed higher viscosity compared to smaller size (10–20 nm) nanofluid. Viscosity decreased with a rise in temperature [116].

Duan et al. [117] studied the flow behaviour of graphite nanofluid in deionized water, at a shear rate range between 1 and 100 s−1. The suspension behaviour exhibited shear thinning behaviour, viscosity increased with increase in concentration of the fluid. They also reported that the enhancement of the nanofluid held for 3-days was higher than that of the freshly prepared nanofluid. The work of Moghaddam et al. [118] was on graphene nanofluid in glycerol, at the low shear rate, the nanofluid showed shear thinning behaviour for all temperature but at high shear rate, the nanofluid behaved as Newtonian fluid and the shear thinning behaviour increased with increase in concentration.

Fe3O4 nanofluid in deionized water show Newtonian behaviour at low concentration and exhibited shear thinning behaviour at higher concentration [119, 120]. But for Fe3O4 in polyethylene glycol (PEG), all the suspension showed shear thinning behaviour [121].

Resiga et al. [122] investigated the flow behaviour of magnetite/transformer oil nanofluid with size range of 6–7 nm and shear rate range between 1 and 1000. They concluded that all the suspensions showed Newtonian behaviour.

Effects of surfactants on the rheological flow behaviour of nanofluids

Surfactants are used to prepare stable nanofluids, to achieve a uniform particle structure throughout the suspension. It is observed by most studies that the addition of surfactant to the nanofluid changes the flow behaviour of the nanofluid [123, 124].

Yang et al. [125] work on multi-walled carbon nanotube (MWCNT)/poly-olefin oil, dispersed in polyisobutene succinimide. They concluded that the suspension with the lowest (0.3%) and highest (8%) dispersant concentration exhibited a shear thinning behaviour while, the intermediate (3 wt%), exhibited a Newtonian behaviour. In their separate work on MWCNT/poly-olefin oil but with PIBSI 1000 and PIBSI 500 as the dispersant, they reported that the suspension without dispersant showed slight shear thinning behaviour at low temperature. But the shear thinning increase with increase in temperature and was very strong at 75 °C. The suspension with PIBSI 1000 showed a mild shear thinning behaviour while, that of PIBSI 500 was very strong [126]. Phuoc et al. [124] in their work on MWCNT/deionized water with chitosan as the dispersant, reported that suspension with low CNT and chitosan concentration, behaved as Newtonian Fluid. While at high concentration, it exhibited shear thinning behaviour. Upon adding 0.1–0.2 wt% of chitosan in water increased the viscosity, while adding 0.5 wt% decreased the viscosity and changed the flow behaviour to non-Newtonian.

Tseng and Lin [126] investigated the rheological flow behaviour of BaTio3/ethanol-isopropanol with anionic and cationic polymeric dispersant (KD and PS-2). They observed that the addition of the dispersant changes the flow behaviour from pseudoplastic to dilatant as the shear rate passed 800 s−1. The viscosity changed to the minimum value when the dispersant KD-6 was added. Similarly, Tseng and Li [127] used BaTio3/distilled water with ammonium polyacrylate surfactant (NH4PA), upon adding NH4PA, the suspension was close to Newtonian at the low shear rate, while it deviated from linear to dilatant flow at high shear rate. When indium tin oxide (ITO)/deionized water was used with NH4PA, the viscosity reduced by about 99% as compared to the original suspension. At low shear rate the suspension behaved like a Bingham fluid and changed to shear thinning when the shear rate exceeds a critical level [128].

Phuoc and Massoudi et al. [120] studied the rheological flow behaviour of Fe2O3/deionized nanofluid with polyvinylpyrrolidone (PVP) and poly-ethylene oxide (PEO) surfactant. They reported that, the PEO and PVP exhibited a Newtonian behaviour at low concentration (0.2 wt%) and exhibited shear thinning at higher concentration of the nanoparticle.

Effect of polymer on the rheological flow behaviour of nanofluids

In polymer flooding activity, the essence of adding polymer to brine is to increase the viscosity for better sweep efficiency [4]. Studies have shown that adding nanofluids to polymer solution enhances the viscosity of the solution [37]. Adding nanofluids to polymer increases the network and chain of the polymer, which in turn increases the viscosity of the nanofluid. Therefore, nanofluid induced polymer has higher viscosity than polymer solution alone. Figure 9 is the oil recovery performance of injected polymer and nanoparticle-induced polymer fluid.

Oil recovery performance of injected polymer and nanoparticle-induced polymer fluid [37]

Nanofluids are used to improve the mechanical, electrical and barrier properties of polymers, there are used as thickening agent for low viscosity Newtonian fluid. It is therefore, desirable to know the effect of these nanoparticles to the rheology of the nanofluid and the approach needed to model the rheology of the system. The rheology also provides a means to determine the degree of exfoliation of the nanofluid in a polymer melt, the particles are therefore, sensitive to structure, shape and particle size [129].

The addition of particles to a flowing liquid with complementary disturbance of the flow lines, can result in the simplest flow becoming complex. The flow pattern changes where there is increase and spatial variation of the shear rate in the continuous phase and transient behaviour of the liquid element. The Van der Waals forces between particles encourages agglomeration and influence the flow properties from the increase in flow phase value. Aggregation of nanoparticles increases the distortion of flow lines and have effects on the rheological properties such as viscosity and normal stress [37, 129].

At equal concentration, well-dispersed nanofluid exhibit different rheological behaviour compared to agglomerated counterparts. The complications therefore, invalidate any assumptions governing macroscopic homogeneity for the application of complex equation over the homogenous phase. To account for additional time derivatives, spatial as well as particle–particle and particle–matrix molecular interaction, factors such as particle size, porous media such as pH, polarity and inherent functionality also dictates the flow in porous media by regulating aggregation and flocculation. The degree of slip at the wall of the porous media and the amount of phase separation is influenced by the plate roughness or vane geometry. Viscosity as a function of concentration has been modelled by several authors [130,131,132,133,134,135]:

whereas Ø is the packing volume fraction, k is the constant of integration and η is the intrinsic viscosity.

Maghzi et al. [37] investigated the effect of silica nanofluid on the rheological behaviour of polyacrylamide to enhanced oil production. They concluded that preliminary study showed that Nano solution showed pseudoplastic behaviour and had a good match with the power law model. But the rheological behaviour of the polyacrylamide showed a slight deviation from the power law model at medium shear rate and the deviation increased at higher shear rate. But for both fluids, there was minimum deviation. Addition of nanofluid improved the pseudoplasticity and increased viscosity for all the test.

Cheraghian and Khalilinezhad [136] studied the effect of nanoclay on the rheological behaviour of polymeric solution. They reported that there is a lower and upper limit for effective viscosity of the polymer solution in porous media. The ultimate recovery increased by 5% compared to polymer flooding alone.

Cheraghian [137] applied nano-fumed silica to increase the viscosity of polymer in heavy oil flooding. They concluded that, the viscosity of the nano suspension increased with nanofluid weight fraction. More nanoparticles had direct effect on the fluid shear stress and the ultimate recovery by nanosilica increased by 8.3% compared to polymer flooding alone. Similarly, the effect of TiO2 nanofluid on heavy oil recovery during polymer flooding was investigated. They concluded that for polymer flooding to be effective, the concentration of the nanofluid should be above a threshold value, the threshold value for titanium dioxide was 2.3 wt%. The ultimate oil recovery by nanofluid flooding increased by 3.9% compared to polymer flooding alone [138].

Mathematical modelling of nanoparticle flow behaviour

The flow behaviour of nanoparticles in porous media can be govern by the following assumptions; the porous media is heterogenous, the flow is one-dimensional under isothermal condition, the rock and fluid are incompressible, the oil and water are governed by the Darcy’s law and as such gravitational force is neglected. Oil and water are Newtonian fluids therefore, the viscosity and density are kept constant, the nanoparticles are discretized into n size intervals.

The continuity equation of oil (o) and water (w) are governed by the following equations:

whereas x is the distance from the inlet of the porous media, l is the line, Ø is the porosity, sl is the saturation, µl is viscosity, pl is pressure of the phase l and kl (= krl) is the effective permeability of phase l. Whereas Eq. (7) is the expression for capillary force, where a, b, c are empirical parameters and Sw is water saturation.

Ju and Fan [33] used a mathematical model to describe nanoparticles transport in a two-phase flow. The water phase permeabilities increased from 1.6 to 2.1 of the original values, but there was a decrease in absolute permeabilities because of the adsorption of the nanoparticles at the pore throat of the porous media. The hybrid computational approach that combines the lattice Boltzmann model for binary fluid with Brownian dynamic model for nanoparticles was used to capture the interaction among fluids, nanoparticles and pore wall. Ma et al. [139] demonstrated that nanoparticles can alter the IFT between two fluids and contact angle at the pore walls which affects the dynamics of the capillary fillings. But Cleary et al. [140] confirmed the Darcy’s law for drift velocities in a saturated medium. Whereas a non-linear behaviour was observed for higher values using the smoothed particle hydrodynamics (SPH) when they demonstrated that the flow through a porous structure can be treated at a mesoscopic level similar to that used in lattice gas and lattice Boltzmann simulation. It also showed that complex physics such as multiphase flow, realistic equation of state, heat transfer and curing can be included in a rigorous manner. Furthermore, complex geometry can be handled in a simple manner and the extension from two-dimensional flow is straight forward. In the absence of gravitational force, El-Amin et al. [141] used a highly non-linear parabolic partial differential equation to numerically solve an efficient algorithm. They developed a mathematical model to describe the magnetic nanoparticles-water suspension that imbibes into water–oil two phase flow in a porous media under magnetic field effect. The saturation of nanoparticles water suspension increases, while the nanoparticle concentration decreases slightly under the effect of the magnetic field as the deposited nanoparticles concentration increases. This was demonstrated by a set of numerical exercise of hypothetical cases to show how an external magnetic field can influence the transport of nanoparticles in a two-phase system in a porous media [142]. The water–nanoparticles suspension was treated as a miscible mixture, whereas it is immiscible with the oil phase. They concluded that the magnetic source location has a significant influence on the physical variables of the model. Based on the flow direction and the location of the magnet, the magnetic field can assist or oppose the flow of this two-phase system. The concentration of the nanoparticles is observed to decrease slightly as a result of slight increase in deposition of nanoparticles. The magnet can assist the flow of the ferrofluid suspension when placed next to the inflow/outflow boundary. The concentration of the nanoparticles seems to increase under the effect of magnetic field as the concentration of the nanoparticles deposited decreases [141].

Modification of nanoparticles

The surface chemistry of a material determines its filtration, adsorption and the rheological behaviour of the material in porous media. Therefore, proper surface modification can control particle properties which can lead to proper emulsification, reduced particle retention, wettability alteration and stabilization of foam. A well-designed surface modified nanoparticle can change particle hydrophobicity and thus alleviate particle retention on the rock surface [46]. As careful control of emulsification and demulsification leads to delivery of nanoparticles to targeted areas in the formation.

The interfacial interaction between two phases present in a hybrid solution is one of the decisive factors affecting properties of nanoparticles, a good dispersion can be achieved by surface modification of the nanoparticles with active functional groups to enhance the compatibility between the nanoparticles with surfactant or polymer thereby, optimizing the efficiency of the process.

The surface modification of nanoparticles can be realized by chemical or physical methods.

-

1.

Chemical methods: the use of chemical methods involve modification with either modifier agents or by grafting polymers. The most commonly used chemical modifying agents are the silane coupling agents which possess hydrolysable and organofunctional ends. The general structure of the coupling agents can be represented as RSiX3, where the X represents the hydrolysable groups, which are typically chloro, ethoxy, or methoxy groups. Whereas the R is an organic group of different functionalities chosen to meet the requirements of the polymer. The functional group X reacts with the hydroxyl groups on the surface of the nanoparticles, while the alkyl chain reacts with the polymer matrix. In this way, the hydrophilic surface of nanoparticles is converted into hydrophobic [143]. Grafting of polymer is also an effective method used to increases the hydrophobicity of particles. Surface modification by grafting is achieved through two main approaches;

The advantages of grafting polymerization include;

-

(a)

Grafting of polymers can improve the interfacial interaction between the grafting polymer on the nanoparticles and the matrix polymer. This can be achieved by molecular entanglement of the polymer to the nanoparticles.

-

(b)

Grafted polymerization can also increase the hydrophobicity of nanoparticles. Which can be useful as fillers and for matrix miscibility.

-

(c)

It provides flexible structural properties between the nanocomposites. This can be achieved by changing the species of the grafting monomers and the grafting conditions. This is because, different grafting polymers might have different interfacial characteristics.

Guo et al. [145] functionalized SiO2 nanoparticle with a silane compound, 3-methacryloxypropyltrimethoxysilane (MPS) (Fig. 10) and found that the grafting ratio of MPS on the surface of nanosilica increased with MPS content.

Modification of a nanoparticle with MPS (silane coupling agent) [145]

Sabzi et al. [146] carried out surface modification of TiO2 nanoparticles with amino propyltrimethoxysilane (APS) and investigated its effect on polyurethane composite coating. Iijima et al. [147] tuned the stability of TiO2 nanoparticles in various solvents by mixed silane alkoxides and obtained a well dispersed TiO2 in acidic aqueous solution, while Ukaji et al. [148] used 3-aminopropyltriethoxysilane (APTES) and n-propyltriethoxysilane (PTES) to suppress the photo-catalytic activity of fine TiO2 particles as inorganic ultraviolet filter. All the researchers observed an improvement of the properties of nanoparticles used after the surface modification process.

-

2.

Physical method: the surface modification of nanoparticles based on physical interaction is usually implemented by adsorption of surfactants or macromolecules onto the surface of the nanoparticles. The principle of surfactant treatment is the preferential adsorption of a polar group of a surfactant to the surface of the nanoparticles by electrostatic interaction. The surfactant used for surface modification of nanoparticles are the cationic and anionic surfactants [138]. The hydrophilic head of the surfactant reduces the interaction between the nanoparticles within agglomerates by reducing the physical interaction while, the hydrophobic tail easily incorporates them into the polymer matrix (Fig. 11). Thereby, improving their efficiency [143]. For instance, silica was treated with CTAB to improve the chemical interaction between the SiO2 and the polymer [149]. Nanoslica was also modified with oleic acid, the oleic acid was bonded to the silica surface with a single hydrogen bond [150].

Fig. 11 Commonly used surfactants for functionalisation of nanoparticles [143]

Adsorption of polymer can also provide surface hydrophobicity of silica nanoparticles. This was demonstrated by Reculusa et al. [151] when they modified the surface of silica nanoparticles by adsorption of an oxyethylene based macromonomers. Hydrogen bond with the silanol functions present on the surface of the silica was formed. This was possible due to the hydrophilic nature of the monomers due to the presence of ethylene oxide group. On the other hand, the methacrylate group which contains a polymerizable group for the syrene reaction might also be responsible.

Lai et al. [152] modified SiO2 nanoparticles with stearic acid to improve their dispersion and the adhesion between the filler and polymer matrix. They reported that the modified nano-SiO2 viewed under scanning electron microscope was seen to disperse uniformly in poly (ether ether ketone) than the unmodified counterpart. Tang et al. [153] modified nano-sized SiO2 with oleic acid (OA) and the surface-modified silica nanoparticles (SiO2–OA) were dispersed in poly (amic acid). They observed that the surface modification of the nanoparticles caused an enhanced dynamic mechanical properties and thermal stability of the polymer.

Behzadi and Mohammadi et al. [154] modified silica nanoparticles with polyethylene glycol as a hydrophobic agent and propyl chain as the hydrophilic agent. The oil water IFT was decreased by 50% and it modified the oil wetted surface from strongly oil wet to water-wet. The increase in nanoparticle concentration increased the surface activity as the functional nanoparticles can greatly improve the performance of the biochemical analysis. Which can accelerate the signal transduction, enhance signal intensity and enable the radiance of the signal due to the unique properties of the nanoparticles. The pre-level investigation experiment with the surface modified silica nanoparticles reveals that hydrophilic and environmental friendly silica nanoparticles can also modify micro model wettability.

The surface chemistry does not only affect the quality of the nanoparticles in terms of stability, mono-dispersity and biocompatibility but can also prove that the functional groups of –COO−, –NH3+, –CHO or the charges on the nanoparticles can be exploited for ligand exchange. Yang et al. [155] modified ALOOH nanoparticles with partial hydrophobic, positive and slightly negative charged. Small aggregate adsorbs to the surface and form compatibility network in the foam film resulting in a stable foam. The surface chemistry is therefore, a vital tool for surface medication as it dictates the sensitivity and mediation of the specific nanoparticles assay, which is vital to the orientation of the functional ligand on the nanoparticles [155]. Taber et al. [156] determined the best nanohybrid that can be used as a pickering emulsion for EOR. They prepared different carbon structure (single-walled carbon nanotube, SWCNT and multiwalled carbon nanotube, MWCNT) nanohybrid with SiO2 nanoparticles with different weight-percent using sol–gel method. The results showed that nanofluid could significantly change the wettability of the carbonate rock from oil to water wet and decreases the IFT. Pickering emulsion have a good stability at 0.1, 1% salinity, at moderate and high temperature (25 and 90 °C), neutral and alkaline (7, 10) pH, which is suitable for oil reservoir condition. Therefore, 70% NWCNT/SiO2 nanohybrid pickering emulsion can be used for EOR.

Characterization methods for evaluating the influence of nanoparticles in EOR

Nanoparticles can be characterised based on their surface morphology, particle size and surface charge. The surface morphology, particle size and shape are determined by the electron microscopy technique. Whereas the physical stability and dispersibility of the nanoparticles are affected by the surface charge of the nanoparticles [157].

-

(a)

Surface morphology: the electron microscopy technique is usually used to determine the surface morphology with a direct visualization of the nanoparticles. The scanning electron microscopy (SEM) and the transmission electron microscope (TEM) are used for this purpose. The SEM can provide the morphology and size analysis of the nanoparticles. But its limitation is insufficient information on the size distribution and the true population average [158]. The difficulty in studying the structure of nanoparticles is due to their small size, which can hinder the use of traditional methods in measuring their physical properties. TEM technique can provide imaging, diffraction and spectroscopic information of the nanoparticles. The advantage of TEM is that, it can provide the shape, size, defect, surface structure, crystals, electronic state and composition in nanometre-size region of thin film, nanoparticles and nanomaterial system [157].

-

(b)

Particle size: particle size is a physical property that gives the basic information of the nanoparticles. It determines the distribution and retention of the nanoparticles in the target area [159]. Dynamic light scattering (DLS) is used to determine the size of the nanoparticles. It measures the Brownian motion of the nanoparticles in suspension and relates it to velocity (Known as the translational diffusion coefficient) to the size of the nanoparticle. According to the Stoke’s–Einstein equation [159] DLS is fast and can provides a simple estimate of the particles size. But the limitation of DLS is that, it is poor in analysing multimodal particle size distribution [160]. Nanoparticle tracking analysis (NTA) is another imaging technique. It can track a single particle based on the fluorescence microscopy atomic image analysis. The size is determined from the average displacement of the nanoparticle undergoing Brownian motion at a time [161]. The advantage of this method is that, it can track a single nanoparticle and provides a high resolution for the sample and aggregation.

-

(c)