Abstract

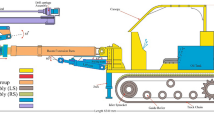

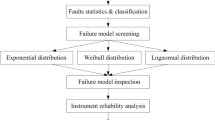

Drilling, as the initial stage of exploitation in open-pit mining, has a significant effect on subsequent mining stages. Any failure in a drilling machine stops the drilling operation and, as a result, all following operational phases come to a halt. The drilling system is the most important part of the drilling operation. This study selected two new rotary-type drilling machines (A and B) in Sarcheshmeh Copper Mine in Iran as a case study to perform a reliability and availability analysis of their drilling systems. The drilling system was divided into three independent subsystems; drill string, rotary head, and mast. The reliability modeling used a reliability block diagram and Monte Carlo simulation. Reliability and availability were evaluated, and the importance of each subsystem estimated. A preventive maintenance schedule was proposed using weighed reliability allocation to achieve the reliability target. The results show the mast is the most reliable subsystem. Importance measure analysis indicates the drill string and rotary head are the most critical subsystems of machines A and B, respectively. Finally, under the proposed maintenance policy, the reliability of the drilling systems of machines A and B is improved.

Similar content being viewed by others

References

J. Barabady, U. Kumar, Reliability analysis of mining equipment: a case study of a crushing plant at Jajarm bauxite mine in Iran. Reliab. Eng. Syst. Saf. 93, 647–653 (2008)

J. Balaraju, M. Govinda Raj, C.H.S.N. Murthy, Estimation of reliability-based maintenance time intervals of Load–Haul–Dumper in an underground coal mine. J. Min. Environ. 9(3), 761–770 (2018)

N. Vayenas, X. Wu, Maintenance and reliability analysis of a fleet of load–haul–dump vehicles in an underground hard rock mine. Int. J. Min. Reclam. Environ. 23(3), 227–238 (2009)

P. Pandey, A.K. Mukhopadhyay, S. Chattopadhyaya, Reliability analysis and failure rate evaluation for critical subsystems of the dragline. J. Braz. Soc. Mech. Sci. Eng. 40(2), 50 (2018)

F. Simon, B. Javad, B. Abbas, Availability analysis of the main conveyor in the Svea Coal Mine in Norway. Int. J. Min. Sci. Technol. 24(5), 587–591 (2014)

S.P. Dubey, M.D. Uttarwar, M.S. Tiwari, Reliability study of 42 cu. m Shovel and 240 Te Dumper Equipment System with Special Reference to Gevra OCP, SECL, Bilaspur. Procedia Earth Planet. Sci. 11, 189–194 (2015)

A.H. Tumanggor, Reliability value analysis of dump truck 108 unit (case study: South Kalimantan coal mining company), in AIP Conference Proceedings, vol 2044, no 1. (AIP Publishing, 2018), p. 020019

Z. Allahkarami, A.R. Sayadi, A. Lanke, Reliability analysis of motor system of dump truck for maintenance management, in Current Trends in Reliability, Availability, Maintainability and Safety, ed. by U. Kumar, A. Ahmadi, A.K. Verma, P. Varde (Springer, Berlin, 2016), pp. 681–688

M.J. Rahimdel, M. Ataei, R. Kakaei, S.H. Hoseinie, Reliability analysis of drilling operation in open pit mines/Analiza niezawodności urządzeń wiertniczych wykorzystywanych w kopalniach odkrywkowych. Arch. Min. Sci. 58(2), 569–578 (2013)

M.J. Rahimdel, S.H. Hosienie, M. Ataei, R. Khalokakaei, The reliability and maintainability analysis of pneumatic system of rotary drilling machines. J. Inst. Eng. India Ser. D 94(2), 105–111 (2013)

M.J. Rahimdel, S.H. Hoseinie, B. Ghodrati, RAM analysis of rotary drilling machines. Min. Sci. 23, 77–89 (2016)

B.V. Gokhale, Rotary Drilling and Blasting in Large Surface Mines, vol. 26 (Taylor and Frances Group, London, 2011), pp. 553–560

C.L. Jimeno, E.L. Jimeno, F.J.A. Carcedo, Drilling and Blasting of Rock (A.A. Balkema, Rotterdam, 1995), pp. 48–63

A. Rustan, C. Cunningham, W. Fourney, K.R.Y. Simha, Mining and Rock Construction Technology Desk Reference (CRC Press, London, 2011)

B.S. Dhillon, Mining Equipment, Reliability, Maintainability and Safety. Springer Series in Reliability Engineering (Springer, Berlin, 2008), pp. 27–38

B.S. Dhillon, Maintainability, Maintenance and Reliability for Engineers (CRC Press, Boca Raton, 2006), pp. 143–160

ReliaSoft Corporation. Blocksim 9 User’s Guide. www.reliasoft.com (2013)

Reliasoft Corporation. System analysis reference (2014)

M. Modarres, Risk Analysis in Engineering: Techniques, Tools, and Trends (CRC Press, Boca Raton, 2006)

A. Barabadi, J. Barabady, T. Markeset, Application of reliability models with covariates in spare part prediction and optimization—a case study. Reliab. Eng. Syst. Saf. 123, 1–7 (2014)

G. Feng, E. Patelli, M. Beer, F.P. Coolen, Imprecise system reliability and component importance based on survival signature. Reliab. Eng. Syst. Saf. 150, 116–125 (2016)

H. Wang, H. Pham, Reliability and Optimal Maintenance (Springer, Berlin, 2006)

K.B. Misra (ed.), Handbook of Performability Engineering (Springer, Berlin, 2008)

D.B. Kececiyoglu, Reliability Engineering Handbook. DEStech Publication, USA 1, 721 (2002)

MathWave. EasyFit Professional 5.5 software, MathWave Technologies (2010)

Acknowledgements

The authors thank R&D office of Iranian National Copper Company for its support during this research. We would also like to express our gratitude to the workers and employees of Sarcheshmeh Copper Mine for their cooperation. The authors would like also to thank for the support of CAMM (Centre of Advanced Mining and Metallurgy) project in this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahimdel, M.J., Ataei, M. & Ghodrati, B. Modeling and Simulation Approaches for Reliability Analysis of Drilling Machines. J. Inst. Eng. India Ser. C 101, 125–133 (2020). https://doi.org/10.1007/s40032-019-00533-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-019-00533-x