Abstract

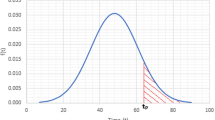

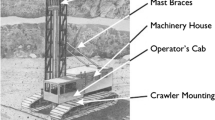

The coal mining business is quickly expanding to meet the increasing demand for coal for power plants. They are introducing a variety of intricate and sophisticated equipment for the system’s mechanization and atomization. The mining industry spends a significant amount of money on this equipment. The equipment’s reliability, maintainability, and availability have all become critical parameters in ensuring ongoing output. The greatest option for mechanization in underground mines for making holes for coal preparation and roof rock support is to use UDM in tandem with LHD. UDM has the ability to drill holes in any direction and at any angle. It is necessary to measure and ensure its reliability to reduce coal production downtime. OEM has designed the UDM to serve at minimum for 8 years of life, 25,000 h of operation, and 473,000 m of total drilling, whichever comes later. The Markov approach was used to assess the UDM system’s reliability by examining the failure and repair rates of seven modules of UDM connected in series, which is novel to this study, as no prior antecedent research has been done in this area. UDM’s reliability declined after 8 years of operation, while its maintainability skyrocketed. The availability of the UDM may be increased from 79 to 88% by lowering the unavailability of hydraulic, electrical, and drill units by 4, 2, and 3%, respectively. This study demonstrates how strengthening the maintainability of the allied system of UDM, as well as resolving operating faults, can improve UDM availability and assure a smooth and continuous production rate in the mines.

Highlights

-

The UDM (Underground Drilling Machine) and LHD (Load-Haul-Dump) were introduced as the superior possibilities for mechanization in underground mines for coal preparation and roof rock support, offering the capacity to drill holes in any direction and angle.

-

UDM’s reliability, maintainability, and availability are rigorously assessed using the Markov approach, with a focus on meeting the OEM design requirements of 8 years of service life, 25,000 operating hours, or 473,000 m of total drilling.

-

To evaluate the UDM system’s dependability and how it changes over time, as shown in tables and graphs, it is necessary to identify specific modules within it and their connections, treating them as a series system.

-

Exhibiting how improving system availability by reducing the unavailability of specific modules can have a significant positive impact on the availability of the entire system.

-

Recommendations for specific training programs for UDM operators to help them handle the equipment while it is in use and prevent mechanical damage, improving the machine’s overall safety and dependability in underground coal mining operations.

Similar content being viewed by others

Data Availability

My manuscript has no associated data.

Abbreviations

- MF:

-

Main Frame

- EG:

-

Electrical Group

- HG:

-

Hydraulic Group

- TR:

-

Track Right Side

- TL:

-

Track Left Side

- BA:

-

Boom Assembly

- DA:

-

Drill Unit

- MTTF:

-

Mean Time to Failure

- MTTR:

-

Mean Time to Repair

- \(\lambda\) :

-

Failure Rate

- \(\mu\) :

-

Repair Rate

- R :

-

Reliability

- M :

-

Maintainability

- A :

-

Availability

- \(P_{{\text{w}}}\) :

-

Working condition

References

Agrawal AK, Murthy VMSR, Chattopadhyaya S (2019) Investigations into reliability, maintainability and availability of tunnel boring machine operating in mixed ground condition using Markov chains. Eng Fail Anal 105:477–489

Ahmadi S et al (2020) An overview of the reliability analysis methods of tunneling equipment. Open Const Build Technol J 14(1):218–229

Ansari MdO, Chattopadhyaya S, Joyjeet Ghose S, Sharma DK, Li C, Wojciechowski S, Dwivedi SP, Kilinc HC, Królczyk JB, Walczak D (2022) Productivity enhancement by prediction of liquid steel breakout during continuous casting process in manufacturing of steel slabs in steel plant using artificial neural network with backpropagation algorithms. Materials 15(2):670. https://doi.org/10.3390/ma15020670

Babu MS, Sankar GR, Velpula VR, Chu YM, Khan MI, Raju CSK, Hejazi HA, Makhdoum BM, Eldin SM (2023) Chemically reactive flow of viscous thermophoretic fluid over wedge with variable thermal conductivity and viscosity. Case Stud Therm Eng 45:102924

Bhimrao SA, Dolas DR (2015) Availability analysis of forging press using Markov model. Int J Res Manuf Technol Manage 3(2):9–16

Bhushan K, Chattopadhyaya S, Sharma S, Sharma K, Li C, Zhang Y, Eldin EMT (2022) Analyzing reliability and maintainability of crawler dozer BD155 transmission failure using Markov method and total productive maintenance: a novel case study for improvement productivity. Sustainability 14:14534. https://doi.org/10.3390/su142114534

Bisht V et al (2021) Prediction of breakdown hours of load haul dumper by long short term memory network. IOP Conf Ser Mater Sci Eng 1104(1):012006

Chattopadhyaya S, Dinkar BK, Mukhopadhyay AK, Sharma S, Machado J (2021) Meta-analysis and forest plots for Sustainability of heavy load carrier equipment used in industrial mining environment. Sustainability (MDPI) 13(15):8672. https://doi.org/10.3390/su13158672

Chu YM, Abbasi A, Al-Khaled K, Farooq W, Khan SU, Khan MI, Eldin SM, Guedri K (2023) Mathematical modeling and computational outcomes for the thermal oblique stagnation point investigation for non-uniform heat source and nonlinear chemical reactive flow of Maxwell nanofluid. Case Stud Therm Eng 41:102626

Dewangan N et al (2019) Degradation analysis of gear oil SAE 90 used in load haul dumper machine. IOP Conf Ser Mater Sci Eng 624(1):012011

Dhillon BS (2006) Maintainability, maintenance, and reliability for engineers. CRC Press, Boca Raton

Dhillon BS (2008) Mining equipment reliability. Springer, London

Dinkar BK, Mukhopadhyay AK, Chattopadhyaya S, Sharma S, Alam F, Machado J (2021) Statistical reliability assessment for small sample of failure data of dumper diesel engines based on power law process and maximum likelihood estimation. Appl Sci 11(12):5387. https://doi.org/10.3390/app11125387

Gaurav K et al (2019) Reliability and maintainability analysis of universal drill machine at Saoner mines, Nagpur, India. IOP Conf Ser Mater Sci Eng 691(1):012014

Gupta G, Mishra RP, Jain P (2015) Reliability analysis and identification of critical components using Markov model. 2015 IEEE international conference on industrial engineering and engineering management (IEEM). IEEE

Gustafson A et al (2014) Development of a Markov model for production performance optimization. Application for semi-automatic and manual LHD machines in underground mines. Int J Min Reclam Environ 28(5):342–355

Khan MI, Alzahrani F (2022) Optimized framework for slip flow of viscous fluid towards a curved surface with viscous dissipation and Joule heating features. Appl Math Comput 417:126777

Khoshalan, HA, Torabi SR, Maleki D (2015) RAM analysis of hydraulic system of earth pressure balance tunnel boring machine. Indian J Sci Technol 8(28):1–9

Kumar U, Klefsjö B (1992) Reliability analysis of hydraulic systems of LHD machines using the power law process model. Reliab Eng Syst Saf 35(3):217–224

Kumar U, Klefsjö B, Granholm S (1989) Reliability investigation for a fleet of load haul dump machines in a Swedish mine. Reliab Eng Syst Saf 26(4):341–361

Larsson R (2021) Development and application of a tool for assessing the impact of failure modes on performance of underground drill rigs. Dissertation, Örebro University. https://urn.kb.se/resolve?urn=urn:nbn:se:oru:diva-93415

Li J, Wang Y, Nguyen X, Zhuang X, Li J, Querol X, Do V (2022) First insights into mineralogy, geochemistry, and isotopic signatures of the Upper Triassic high-sulfur coals from the Thai Nguyen Coal field, NE Vietnam. Int J Coal Geol 261:104097. https://doi.org/10.1016/j.coal.2022.104097

Li J, Lin Y, Nguyen X, Zhuang X, Li B, Querol X, Cordoba P (2023) Enrichment of strategic metals in the Upper Triassic coal from the Nui Hong open-pit mine, Thai Nguyen Coalfield. NE Vietnam Ore Geol Rev 153:105301. https://doi.org/10.1016/j.oregeorev.2023.105301

Liu Z, Li S, Ijaz Khan M, Abdelmohsen SAM, Eldin SM (2023a) Bicriteria multi-machine scheduling with equal processing times subject to release dates. Netw Heterog Media 18(3):1378–1392

Liu W, Zhou H, Zhang S, Zhao C (2023b) Variable parameter creep model based on the separation of viscoelastic and viscoplastic deformations. Rock Mech Rock Eng 56(6):4629–4645. https://doi.org/10.1007/s00603-023-03266-7

Ma S, Qiu H, Yang D, Wang J, Zhu Y, Tang B, Cao M (2023) Surface multi-hazard effect of underground coal mining. Landslides 20(1):39–52. https://doi.org/10.1007/s10346-022-01961-0

PandeyMukhopadhyayChattopadhyaya PAKS (2018) Reliability analysis and failure rate evaluation for critical subsystems of the dragline. J Braz Soc Mech Sci Eng 40(2):1–11

Rahimdel MJ, Ataei M, Khalokakaei R (2016a) Reliability analysis and maintenance scheduling of the electrical system of rotary drilling machines. Current trends in reliability, availability, maintainability and safety. Springer, Cham, pp 623–632

Rahimdel MJ, Hoseinie SH, Ghodrati B (2016b) RAM analysis of rotary drilling machines. Mining Sci 23:77–89

Samanta B, Sarkar B, Mukherjee SK (2001) Reliability analysis of shovel machines used in an open cast coal mine. Miner Resour Eng 10(02):219–231

Samanta B, Sakar B, Mukherjee SK (2004) Reliability modelling and performance analyses of an LHD system in mining. J South Afr Inst Min Metall 104(1):1–8

Sarkhel S, Dey UK (2015) Reliability modelling of side discharge loader for availability estimation and maintenance planning in underground coal mines. Int J Sci Eng Res 6:847–854

She A, Wang L, Peng Y, Li J (2023) Structural reliability analysis based on improved wolf pack algorithm AK-SS. Structures 57:105289. https://doi.org/10.1016/j.istruc.2023.105289

Siddiqui MAH et al (2021) Sludge formation analysis in hydraulic oil of load haul dumper 811MK V machine running at elevated temperatures for bioenergy applications. Int J Chem Eng 2021:1–14

Siddiqui MAH et al (2022a) Real-time comprehensive energy analysis of the LHD 811MK-V machine with mathematical model validation and empirical study of overheating: an experimental approach. Arab J Sci Eng 47:9043–9059

Siddiqui MAH et al (2022b) Investigation of geo-mining green roof seismic energy balancing with resin bolting by Universal Drilling Machine: a novel energy-absorbing-based support system. Arab J Geosci 15(5):1–25

Siddiqui MAH, Akhtar S, Chattopadhyaya S, Sharma S, Li C, Dwivedi SP, Antosz K, Machado J (2022c) Technical risk assessment for the safe design of a man-rider chair lift system. Machines 10(9):769. https://doi.org/10.3390/machines10090769

Siddiqui MAH, Akhtar S, Chattopadhyaya S, Sharma S, El Haj M, Assad JS, Aggarwal V, Dwivedi SP, Saxena A (2022d) Investigation of geo-mining green roof seismic energy balancing with resin bolting by Universal Drilling Machine: a novel energy-absorbing- based support system. 2021. Arab J Geosci 15:431. https://doi.org/10.1007/s12517-022-09594-2

Siddiqui MAH, Agrawal AK, Chattopadhyaya S (2020) In situ non-destructive testing of man riding chair lift system. In: Proceedings of international conference in mechanical and energy technology. Springer, Singapore

Tao Y, Shi J, Guo W, Zheng J (2023) Convolutional neural network based defect recognition model for phased array ultrasonic testing images of electrofusion joints. J Pressure Vessel Technol 145(2):024502. https://doi.org/10.1115/1.4056836

Tie Y, Rui X, Shi-Hui S, Zhao-Kai H, Jin-Yu F (2023) A real-time intelligent lithology identification method based on a dynamic felling strategy weighted random forest algorithm. Pet Sci. https://doi.org/10.1016/j.petsci.2023.09.011

Tripathi V, Chattopadhyaya S, Mukhopadhyay AK, Saraswat S, Sharma S, Li C, Rajkumar S, Georgise FB (2021) A novel smart production management system for the enhancement of industrial sustainability in industry 4.0. Math Probl Eng (Hindawi) 2022:6424869. https://doi.org/10.1155/2022/6424869

Tripathi V, Chattopadhyaya S, Mukhopadhyay AK, Sharma S, Li C, Singh S, Saleem W, Salah B, Mohamed A (2022a) Recent progression developments on process optimization approach for inherent issues in production shop floor management for industry 4.0. Processes 10:1587. https://doi.org/10.3390/pr10081587

Tripathi V, Chattopadhyaya S, Mukhopadhyay AK, Sharma S, Li C, Singh S, Hussan WU, Salah B, Saleem W, Mohamed A (2022b) A sustainable productive method for enhancing operational excellence in shop floor management for industry 4.0 using hybrid integration of lean and smart manufacturing: an ingenious case study. Sustainability 14(12):7452. https://doi.org/10.3390/su14127452

Tuncay D, Demirel N (2017) Reliability analysis of a dragline using fault tree analysis. Madencilik 56(2):55–64

Ugurlu OF, Kumral M (2020) Reliability-based performance analysis of mining drilling operations through Markov chain Monte Carlo and mean reverting process simulations. SIMULATION 96(7):593–604

Varun Kumar RS, Sowmya G, Jayaprakash MC, Prasannakumara BC, Khan MI, Guedri K, Kumam P, Sitthithakerngkiet K, Galal AM (2022) Assessment of thermal distribution through an inclined radiative-convective porous fin of concave profile using generalized residual power series method (GRPSM). Sci Rep 12(1):13275

Varun Tripathi S, Chattopadhyaya AKM, Suvandan Saraswat S, Sharma CL, Rajkumar S (2021) Development of a data-driven decision-making system using lean and smart manufacturing concept in industry 4.0: a case study. Math Probl Eng 2022:3012215. https://doi.org/10.1155/2022/3012215

Varun Tripathi S, Chattopadhyaya AK, Mukhopadhyay SS, Li C, Di Bona G (2022) A sustainable methodology using lean and smart manufacturing for the cleaner production of shop floor management in industry 4.0. Mathematics (MDPI) 10(3):347. https://doi.org/10.3390/math10030347

Vashistha S et al (2019) Reliability and maintainability analysis of LHD loader at Saoner Mines, Nagpur, India. IOP Conf Ser Mater Sci Eng 691(1):012013

Wang J, Liang F, Zhou H, Yang M, Wang Q (2022a) Analysis of position, pose and force decoupling characteristics of a 4-UPS/1-RPS parallel grinding robot. Symmetry 14(4):825. https://doi.org/10.3390/sym14040825

Wang Y, Lou M, Wang Y, Wu W, Yang F (2022b) Stochastic failure analysis of reinforced thermoplastic pipes under axial loading and internal pressure. China Ocean Eng 36(4):614–628. https://doi.org/10.1007/s13344-022-0054-3

Wang Y, Lou M, Wang Y, Fan C, Tian C, Qi X (2023) Experimental investigation of the effect of rotation rate and current speed on the dynamic response of riserless rotating drill string. Ocean Eng 280:114542. https://doi.org/10.1016/j.oceaneng.2023.114542

Waqas M, Nasir M, Khan MI, Boujelbene M, Alshammari S, Chouikhi N, Rajeh T (2023) Marangoni forced convective thermally developed two-phase dusty flow of fluid with heat source/sink phenomenon. Int J Mod Phys B 37(13):2350126

Xin X, Ijaz Khan M, Li S (2023) Scheduling equal-length jobs with arbitrary sizes on uniform parallel batch machines. Open Math 21(1):20220562. https://doi.org/10.1515/math-2022-0562

Xu L, Cai M, Dong S, Yin S, Xiao T, Dai Z, Reza Soltanian M (2022) An upscaling approach to predict mine water inflow from roof sandstone aquifers. J Hydrol 612:128314. https://doi.org/10.1016/j.jhydrol.2022.128314

Yin H, Wu Q, Yin S, Dong S, Dai Z, Soltanian MR (2023a) Predicting mine water inrush accidents based on water level anomalies of borehole groups using long short-term memory and isolation forest. J Hydrol 616:128813. https://doi.org/10.1016/j.jhydrol.2022.128813

Yin H, Zhang G, Wu Q, Yin S, Soltanian MR, Thanh HV, Dai Z (2023b) A deep learning-based data-driven approach for predicting mining water inrush from coal seam floor using microseismic monitoring data. IEEE Trans Geosci Remote Sens. https://doi.org/10.1109/TGRS.2023.3300012

Yu H, Wang H, Lian Z (2022) An assessment of seal ability of tubing threaded connections: a hybrid empirical-numerical method. J Energy Res Technol 145(5):052902. https://doi.org/10.1115/1.4056332

Zhan C, Dai Z, Soltanian MR, de Barros FPJ (2022) Data-worth analysis for heterogeneous subsurface structure identification with a stochastic deep learning framework. Water Resour Res. https://doi.org/10.1029/2022WR033241

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this research through the Research Group Program Under the Grant Number:(R.G.P.2/283/44).

Funding

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this research through the Research Group Program Under the Grant Number:(R.G.P.2/283/44).

Author information

Authors and Affiliations

Contributions

Conceptualization, MAHS, SA, SC, SS; methodology, MAHS, SA, SC, SS; formal analysis, MAHS, SA, SC, SS; investigation, MAHS, SA, SC, SS; writing—original draft preparation, MAHS, SA, SC, SS; writing—review and editing, SS, AK, MA; supervision, SS, AK, MA; project administration, SS, AK, MA; funding acquisition, SS, MA. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interests

The authors declare no competing interests.

Consent to Participate

Not applicable.

Consent to Publish

All authors have read and approved this manuscript.

Ethical Approval.

Not applicable.

Hazards and Human or Animal Subjects

The researcher did not conduct relevant experiments involving living creature subjects within that work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Siddiqui, M.A.H., Akhtar, S., Chattopadhyaya, S. et al. 611 Universal Drilling Machine Reliability Modeling and Performance Evaluation in Subterranean Coal Mines. Rock Mech Rock Eng 57, 3559–3575 (2024). https://doi.org/10.1007/s00603-023-03705-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03705-5