Abstract

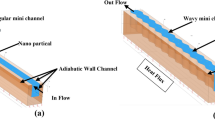

Heat transfer methods in small scales have been studied widely to enhance the thermal efficiency and performance of heat sinks in the field of cooling electronic devices. In this study, a comprehensive numerical investigation was conducted to evaluate thermal performance of block heat sinks for cooling electronic processors by using Nanofluid. Two different blocks including spiral and serpentine blocks were designed and tested under various working conditions using Nanofluid Fe3O4/water with a volume concentration of 0.2% and obtained results were compared to water in the term of heat transfer rate and efficiency. As one of the main aims of this study, thermophysical properties of under evaluation nanofluid were analyzed using experimental data and theoretical equation and subsequently obtained heat transfer results for all cases were discussed. ANSYS-Fluent software was utilized as a CFD method to solve the problem and perform analysis from simulation.

Similar content being viewed by others

Abbreviations

- A:

-

Surface area (m2)

- \(c_{p}\) :

-

Specific heat capacity of liquid (J/kg K)

- D :

-

Diameter (m)

- \(k\) :

-

Thermal conductivity (W/m K)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- L :

-

Length (m)

- \(Nu\) :

-

Nusselt number (\(Nu = \frac{hd}{k})\)

- PEC:

-

Performance evaluation criteria

- f :

-

Friction factor

- \(\dot{Q}_{ }\) :

-

Heat flow rate (W)

- \(\dot{q}\) :

-

Heat flux (W/m2)

- Re :

-

Reynolds number (\(Re = \frac{{\rho vd_{ } }}{\mu }\))

- T :

-

Temperature (K)

- V :

-

Velocity (m/s)

- h :

-

Heat transfer coefficient (W/m2 K)

- P :

-

Pressure (Pa)

- \(\dot{V}_{ }\) :

-

Volume flow (m3/s

- \(\mu\) :

-

Dynamic viscosity (kg/m s)

- \(\rho\) :

-

Density of liquid (kg/m3)

- ø:

-

Volume fraction

- f :

-

Friction factor

- W:

-

Water

- in:

-

Inlet

- out:

-

Outlet

- bf:

-

Base fluid

- nf:

-

Nanofluid

- p:

-

Particle

References

Afshari F, Sözen A, Khanlari A, Tuncer AD, Şirin C (2020) Effect of turbulator modifications on the thermal performance of cost-effective alternative solar air heater. Renew Energy 158:297–310

Ashjaee M, Goharkhah M, Khadem LA, Ahmadi R (2015) Effect of magnetic field on the forced convection heat transfer and pressure drop of a magnetic nanofluid in a miniature heat sink. Heat Mass Transf 51(7):953–964

Dehghanpour H, Yilmaz K, Afshari F, Ipek M (2020) Electrically conductive concrete: a laboratory-based investigation and numerical analysis approach. Constr Build Mater 260:119948

Durmuş A, Benli H, Kurtbaş İ, Gül H (2009) Investigation of heat transfer and pressure drop in plate heat exchangers having different surface profiles. Int J Heat Mass Transf 52(5–6):1451–1457

Escher W, Brunschwiler T, Shalkevich N, Shalkevich A, Burgi T, Michel B, Poulikakos D (2011) On the cooling of electronics with nanofluids. J Heat Transf 133(5):051401–1

Farajollahi B, Etemad SG, Hojjat M (2010) Heat transfer of nanofluids in a shell and tube heat exchanger. Int J Heat Mass Transf 53(1–3):12–17

Güler HÖ, Sözen A, Tuncer AD, Afshari F, Khanlari A, Şirin C, Gungor A (2020) Experimental and CFD survey of indirect solar dryer modified with low-cost iron mesh. Sol Energy 197:371–384

Huminic G, Huminic A (2011) Heat transfer characteristics in double tube helical heat exchangers using nanofluids. Int J Heat Mass Transf 54(19–20):4280–4287

Ijam A, Saidur R (2012) Nanofluid as a coolant for electronic devices (cooling of electronic devices). Appl Therm Eng 32:76–82

Khaleduzzaman SS, Rahman S, Selvaraj J, Mahbubul IM, Sohel MR, Shahrul IM (2014) Nanofluids for thermal performance improvement in cooling of electronic device. Adv Mater Res 832:218–223

Khanlari A, Sözen A, Variyenli Hİ (2019) Simulation and experimental analysis of heat transfer characteristics in the plate type heat exchangers using TiO2/water nanofluid. Int J Numer Methods Heat Fluid Flow 29(4):1343–1362

Kumar N, Sonawane SS (2016) Experimental study of Fe2O3/water and Fe2O3/ethylene glycol nanofluid heat transfer enhancement in a shell and tube heat exchanger. Int Commun Heat Mass Transf 78:277–284

Kumar V, Tiwari AK, Ghosh SK (2016) Effect of chevron angle on heat transfer performance in plate heat exchanger using ZnO/water nanofluid. Energy Convers Manag 118:142–154

Kumar PM, Vijayan V, Kumar BS, Vivek CM, Dinesh S (2018) Computational analysis and optimization of spiral plate heat exchanger. J Appl Fluid Mech 11:121–128

Li Z, Asadi S, Karimipour A, Abdollahi A, Tlili I (2020) Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/liquid paraffin nanofluid. Int Commun Heat Mass Transf 110:104436

Naphon P (2007) Thermal performance and pressure drop of the helical-coil heat exchangers with and without helically crimped fins. Int Commun Heat Mass Transf 34(3):321–330

Nguyen CT, Roy G, Gauthier C, Galanis N (2007) Heat transfer enhancement using Al2O3–water nanofluid for an electronic liquid cooling system. Appl Therm Eng 27(8–9):1501–1506

Pantzali MN, Mouza AA, Paras SV (2009) Investigating the efficacy of nanofluids as coolants in plate heat exchangers (PHE). Chem Eng Sci 64(14):3290–3300

Prabhanjan DG, Raghavan GSV, Rennie TJ (2002) Comparison of heat transfer rates between a straight tube heat exchanger and a helically coiled heat exchanger. Int Commun Heat Mass Transf 29(2):185–191

Putra N, Iskandar FN (2011) Application of nanofluids to a heat pipe liquid-block and the thermoelectric cooling of electronic equipment. Exp Therm Fluid Sci 35(7):1274–1281

Selbaş R, Kızılkan Ö, Reppich M (2006) A new design approach for shell-and-tube heat exchangers using genetic algorithms from economic point of view. Chem Eng Process 45(4):268–275

Selvakumar P, Suresh S (2012) Convective performance of CuO/water nanofluid in an electronic heat sink. Exp Therm Fluid Sci 40:57–63

Seyf HR, Feizbakhshi M (2012) Computational analysis of nanofluid effects on convective heat transfer enhancement of micro-pin-fin heat sinks. Int J Therm Sci 58:168–179

Sözen A, Khanları A, Çiftçi E (2019) Experimental and numerical investigation of nanofluid usage in a plate heat exchanger for performance improvement. Int J Renew Energy Dev 8(1):27–32

Sundar LS, Singh MK, Sousa AC (2013) Investigation of thermal conductivity and viscosity of Fe3O4 nanofluid for heat transfer applications. Int Commun Heat Mass Transf 44:7–14

Tiwari AK, Ghosh P, Sarkar J (2013) Performance comparison of the plate heat exchanger using different nanofluids. Exp Therm Fluid Sci 49:141–151

Tuncer AD, Sözen A, Khanlari A, Amini A, Şirin C (2020) Thermal performance analysis of a quadruple-pass solar air collector assisted pilot-scale greenhouse dryer. Sol Energy 203:304–316

Xuan Y, Roetzel W (2000) Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf 43(19):3701–3707

Yarmand H, Gharehkhani S, Kazi SN, Sadeghinezhad E, Safaei MR (2014) Numerical investigation of heat transfer enhancement in a rectangular heated pipe for turbulent nanofluid. Sci World J 2014(2014):1–9

Zheng D, Wang J, Chen Z, Baleta J, Sundén B (2020) Performance analysis of a plate heat exchanger using various nanofluids. Int J Heat Mass Transf 158:119993

Acknowledgements

This present CFD simulation work was carried out in line with the joint project supported by the Scientific and Technological Research Council of Turkey (TÜBİTAK, Project No. 119N727) and University of Tabriz and Iran Ministry of Science, Research and Technology (MSRT, Project No. 99-24-800). The authors gratefully acknowledge the support of the project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Author states that there is no conflict of interest.

Additional information

Editorial responsibility: Q. Aguilar-Virgen.

Rights and permissions

About this article

Cite this article

Afshari, F., Muratçobanoğlu, B. Thermal analysis of Fe3O4/water nanofluid in spiral and serpentine mini channels by using experimental and theoretical models. Int. J. Environ. Sci. Technol. 20, 2037–2052 (2023). https://doi.org/10.1007/s13762-022-04119-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04119-6