Abstract

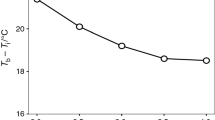

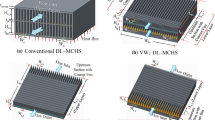

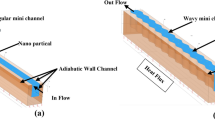

Heat sinks are used in thermal management of the electronic devices such as supercomputers, data centres and batteries and fuel cells. Particularly, cooling requirements of microprocessors increase due to an increase in miniaturization and computational requirements. Efficient working of heat sinks is important to maintain certain temperature by dissipating heat to the environment. Development of efficient heat transfer mechanism is dependent on the highly conductive working fluids and heat transfer surfaces with high heat transfer coefficients. In the present investigation, four different geometries and three working fluids have been investigated to optimize the heat dissipation rate. In the present research, the thermal and hydraulic performance of heat sinks has been investigated. Experiments and numerical simulations have been conducted at different flow rates for different designs of heat sinks using water and CuO-, Al2O3-based nanofluids. Volume concentrations of 0.67% and 0.4% were used for Al2O3–H2O and CuO–H2O nanofluids, respectively, and 2.5 g each of aluminium and copper oxides nanoparticles were used. The simulated base temperature was 110 °C through mice element for the experimentation. Optimized configuration of the heat sink was obtained using water, and experiments were performed to examine the heat transfer enhancement using water and nanofluids. The main purpose of this investigation is to minimize the base temperature of the heat sink and to increase the heat transfer rate. The minimum base temperatures obtained for Al2O3–H2O nanofluids and water were 43.4 °C and 45.2 °C, respectively, on the mini-channel heat sink with 0.5 mm fin spacing.

Similar content being viewed by others

Abbreviations

- Q̇ :

-

Heat transfer rate (W)

- ṁ :

-

Mass flow rate (kg/s)

- C p :

-

Specific heat (kJ/kg, °C)

- T out :

-

Fluid outlet temperature (°C)

- T in :

-

Fluid inlet temperature (°C)

- h :

-

Heat transfer coefficient

- A r :

-

Heat transfer area (mm2)

- LMTD:

-

Log of mean temperature difference (°C)

- T b :

-

Base temperature (°C)

- ∅:

-

Volume fraction

- \( w_{{{\mathrm{np}}}} \) :

-

Weight of nanoparticle (g)

- ρ nf :

-

Density of nanoparticle (kg/m3)

- ρ bf :

-

Density of base fluid (kg/m3)

- \( C_{{{\mathrm{nf}}}} \) :

-

Specific heat capacity of nanofluids (J/K)

- \( \mu_{{{\mathrm{nf}}}} \) :

-

Viscosity of nanofluids [(N s)/m2]

- Rth:

-

Thermal resistance (°C/W)

- \( \nabla \cdot T \) :

-

Temperature in x, y, z directions (°C)

- \( \nabla \cdot \overrightarrow {V} \) :

-

Velocity in x, y, z directions, respectively (m/s)

References

Garimella, S.V.; Yeh, L.-T.; Persoons, T.: Thermal Management challenges in telecommunication systems and data centers. IEEE Trans. Compon. Packag. Manuf. Technol. 2, 1307–1316 (2012)

Garimella, S.V.; Persoons, T.; Weibel, J.; Yeh, L.-T.: Technological drivers in data centers and telecom systems: multiscale thermal, electrical and energy management. Appl. Energy 107, 66–80 (2013)

Whitney, J.; Delforge, P.: Data Center Efficiency Assessment. Natural Resources Defense Council, New York (2014)

Ebrahimi, K.; Jones, G.F.; Fleischer, A.S.: A review of data center cooling technology, operating conditions and the corresponding low grade waste heat recovery opportunities. Renew. Sustain. Energy Rev. 31, 622–638 (2014)

Rao, Z.; Wang, Q.; Huang, C.: Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system. Appl. Energy 164, 659–669 (2016). https://doi.org/10.1016/j.apenergy.2015.12.021

Huo, Y.; Rao, Z.; Liu, X.; Zhao, J.: Investigationofpowerbatterythermalmanagement by using mini-channel cold plate. Energy Convers. Manag. 89, 387–395 (2015). https://doi.org/10.1016/j.enconman.2014.10.015

Ju, H.; Meng, H.; Wang, C.-Y.: A single-phase, non-isothermal model for PEM fuel cells. Int. J. Heat Mass Transf. 48, 1303–1315 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2004.10.004

Kandlikar, S.G.; Garimella, S.; Li, D.; Colin, S.; King, M.R.: Heat Transfer and Fluid Flow in Minichannels and Microchannels, 2nd edn. Butterworth-Heinemann, Oxford (2013)

Yeh, L.T.: Review of heat transfer technologies in electronic equipment. J. Electron. Packag. 117, 333–339 (1995)

Panão, M.R.O.; Guerreiro, J.P.P.V.; Moreieira, A.L.N.: Microprocessor cooling based on an intermittent multijet spray system. Int. J. Heat Mass Transf. 55, 2854–2863 (2012)

Sidik, A.C.; et al.: An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int. Commun. Heat Mass Transf. 88, 74–83 (2017)

Wang, X.D.; An, B.; Xu, J.L.: Optimal geometric structure for nanofluid-cooled microchannel heat sink under various constraint conditions. Energy Convers. Manag. 65, 528–538 (2013)

Kim, S.: Methods for thermal optimization of microchannel heat sinks. Heat Transf. Eng. 7632(251), 37–49 (2010)

Kar, S.P.; Rath, P.: A phase density based enthalpy model for laser assisted phase change process. Int. Commun. Heat Mass Transf. 40(1), 12–18 (2013)

Naphon, P.; Wongwises, S.; Wiriyasart, S.: Application of two-phase vapor chamber technique for hard disk drive cooling of PCs. Int. Commun. Heat Mass Transfer 40(1), 32–35 (2013)

Keshavarz Moraveji, M.; Mohammadi Ardehali, R.; Ijam, A.: CFD investigation of nanofluid effects (cooling performance and pressure drop) in mini-channel heat sink. Int. Commun. Heat Mass Transf. 40(1), 58–66 (2013)

Kefayati, G.H.R.: Effect of a magnetic field on natural convection in an open cavity subjugated to water/alumina nanofluid using Lattice Boltzmann method. Int. Commun. Heat Mass Transfer 40(1), 67–77 (2013)

Mohammed, H.A.; Hasan, H.A.; Wahid, M.A.: Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts. Int. Commun. Heat Mass Transf. 40(1), 36–46 (2013)

Chein, R.; Chen, J.: Numerical study of the inlet/outlet arrangement effect on microchannel heat sink performance. Int. J. Therm. Sci. 48(8), 1627–1638 (2009)

Gao, J.W.; Zheng, R.T.; Ohtani, H.; Zhu, D.S.; Chen, G.: Experimental investigation of heat conduction mechanisms in nanofluids. Clue on clustering. Nano Lett. 9(12), 4128–4132 (2009)

Shoukat, A.A.; Khan, M.Z.; Israr, A.; Anwar, M.: “Comparison of heat sink’s fin-spacing using CuO–H2O based nanofluids for high heat generating microprocessor: an experimental study. J. Taibah Univ. Sci. (2017). https://doi.org/10.1080/16583655.2018.1473945

Dawoud, B.; Amer, E.; Gross, D.M.: Experimental investigation of an adsorptive thermal energy storage. Int. J. Energy Res. 31, 135–147 (2007)

Hung, T.C.; Huang, Y.X.; Yan, W.M.: Thermal performance analysis of porous-microchannel heat sinks with different configuration designs. Int. J. Heat Mass Transf. 66, 235–243 (2013)

Animasaun, I.L.; Sandeep, N.: Buoyancy induced model for the flow of 36 nm alumina–water nanofluid along upper horizontal surface of a paraboloid of revolution with variable thermal conductivity and viscosity. Powder Technol. 301, 858–867 (2016). https://doi.org/10.1016/j.powtec.2016.07.023

Koriko, O.K.; Omowaye, A.J.; Sandeep, N.; Animasaun, I.L.: Analysis of boundary layer formed on an upper horizontal surface of a paraboloid of revolution within nanofluid flow in the presence of thermophoresis and Brownian motion of 29 nm CuO. Int. J. Mech. Sci. 124–125, 22–36 (2017). https://doi.org/10.1016/j.ijmecsci.2017.02.020

Animasaun, I.L.: 47 nm alumina–water nanofluid flow within boundary layer formed on upper horizontal surface of paraboloid of revolution in the presence of quartic autocatalysis chemical reaction. Alex. Eng. J. 55(3), 2375–2389 (2016). https://doi.org/10.1016/j.aej.2016.04.030

Animasaun, I.L.; Mahanthesh, B.; Jagun, A.O.; Bankole, T.D.; Sivaraj, R.; Shah, Nehad Ali; Saleem, S.: Significance of lorentz force and thermoelectric on the flow of 29 nm CuO–water nanofluid on an upper horizontal surface of a paraboloid of revolution. J. Heat Transf. 141(2), 022402 (2018). https://doi.org/10.1115/1.4041971

Animasaun, I.L.; Koriko, O.K.; Adegbie, K.S.; Babatunde, H.A.; Ibraheem, R.O.; Sandeep, N.; Mahanthesh, B.: Comparative analysis between 36 nm and 47 nm alumina–water nanofluid flows in the presence of Hall effect. J. Therm. Anal. Calorim. 135(2), 873–886 (2018). https://doi.org/10.1007/s10973-018-7379-4

Khan, W.A.: Modeling of Fluid Flow and Heat Transfer for Optimization of Pin-Fin Heat Sinks. University of Waterloo, Waterloo (2004)

Wan, Z.; Joshi, Y.K.: Pressure drop and heat transfer characteristics of pin fin enhanced microgaps in single phase microfluidic cooling. Int. Mech. Eng. Congress Expos. 1–8 (2013)

Dixit, T.; Ghosh, I.: Low Reynolds number thermo-hydraulic characterization of offset and diamond minichannel metal heat sinks. Exp. Therm. Fluid Sci. 51, 227–238 (2013)

Kim, S.; Choi, E.; Cho, Y.I.: The effect of header shapes on the flow distribution in a manifold for electronic packaging applications. Int. Commun. Heat Mass Transf 22(3), 329–341 (1995)

Markussen, A.; Brix, W.; Elmegaard, B.; Carlsen, H.; Hansen, M.O.L.; Jakobsen, A.: Modelling Refrigerant Distribution in Minichannel Evaporators. Technical University of Denmark (DTU), Denmark (2016)

Naphon, P.; Nakharintr, L.: Heat transfer of nanofluids in the mini-rectangular fin heat sinks. Int. Commun. Heat Mass Transf. 40(1), 25–31 (2013)

Ravi, R.: Phase rule and the azeotrope—a critique and a new interpretation. Int. Commun. Heat Mass Transf. 40(1), 19–24 (2013)

Kumar, B.R.; Sivaraj, R.: MHD viscoelastic fluid non-Darcy flow over a vertical cone and a flat plate. Int. Commun. Heat Mass Transf. 40(1), 1–6 (2013)

Awasthi, M.K.; Asthana, R.: Viscous potential flow analysis of capillary instability with heat and mass transfer through porous media. Int. Commun. Heat Mass Transf. 40(1), 7–11 (2013)

Mohammed, H.A.; Abed, A.M.; Wahid, M.A.: The effects of geometrical parameters of a corrugated channel with in out-of-phase arrangement. Int. Commun. Heat Mass Transf. 40(1), 47–57 (2013)

Jajja, S.; Ali, W.; Ali, H.: Multiwalled carbon nanotube nanofluid for thermal management of high heat generating computer processor. Heat Transf. Asian Res. 43, 653–666 (2013). https://doi.org/10.1002/htj.21107

Tariq, H.A.; Shoukat, A.A.; Anwar, M.; Israr, A.; Ali, H.M.: Water cooled micro-hole cellular structure as a heat dissipation media: an experimental and numerical study. Therm. Sci. Int. Sci. J. 1, 1–13 (2018)

Tariq, H.A.; Shoukat, A.A.; Hassan, M.; Anwar, M.: Thermal management of microelectronic devices using micro-hole cellular structure and nanofluids. J. Therm. Anal. Calorim. 1, 1–12 (2018). https://doi.org/10.1007/s10973-018-7852-0

Saeed, M.; Kim, M.: Heat transfer enhancement using nanofluids (Al2O3–H2O) in mini-channel heatsinks. Int. J. Heat Mass Transf. 120, 671–682 (2018)

Shoukat, A.A.; Shaban, M.; Israr, A.; Shah, O.R.; Khan, M.Z.; Anwar, M.: Stability of nanofluids and their use for thermal management of a microprocessor: an experimental and numerical study. Heat Mass Transf. 54, 2771–2782 (2018)

Garimella, S.V.: Analysis and Optimization of the Thermal Performance of Microchannel Heat Sinks. CTRC Research Publications (2005)

Saeed, M.; Kim, M.-H.: Header design approaches for mini-channel heatsinks using analytical. Appl. Therm. Eng. 110, 1500–1510 (2017). https://doi.org/10.1016/J.APPLTHERMALENG.2016.09.069

Jajja, S.A.; Ali, W.; Ali, H.M.; Ali, A.M.: Water cooled minichannel heat sinks for microprocessor cooling: effect of fin spacing. Appl. Therm. Eng. 64(1–2), 76–82 (2014)

Pradeep, S.T.: Nano Fluids; Science and Technology, 5th edn. Wiley, Hoboken (2007)

Albadr, J.; Tayal, S.; Alasadi, M.: Heat transfer through heat exchanger using Al2O3 nanofluid at different concentrations. Case Stud. Therm. Eng. 1(1), 38–44 (2013)

Mangrulkar, C.K.; Kriplani, V.M.; Dhoble, A.S.: Experimental investigation of convective heat transfer enhancement using alumina/water and copper oxide/water nanofluids. Therm Sci. 2015(5), 1–12 (2015)

Peyghambarzadeh, S.M.; Hashemabadi, S.H.; Chabi, A.R.; Salimi, M.: Performance of water based CuO and Al2O3 nanofluids in a Cu–Be alloy heat sink with rectangular microchannels. Energy Convers. Manag. 86, 28–38 (2014)

Rafati, M.; Hamidi, A.A.; Shariati Niaser, M.: Application of nanofluids in computer cooling systems (heat transfer performance of nanofluids). Appl. Therm. Eng. 45–46, 9–14 (2012)

Kamatchi, R.; Venkatachalapathy, S.: Parametric study of pool boiling heat transfer with nanofluids for the enhancement of critical heat flux: a review. Int. J. Therm. Sci. 87, 228–240 (2015)

Wen, D.; Ding, Y.: Formulation of nanofluids for natural convective heat transfer applications. Int. J. Heat Fluid Flow 26(6), 855–864 (2005)

Corcione, M.: Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 52(1), 789–793 (2011)

Kakac, S.; Pramuanjaroenkij, A.: Review of convective heat transfer enhancement with nanofluids. Int. J. Heat Mass Transf. 52(13–14), 3187–3196 (2009)

Keblinski, P.; Eastman, J.A.; Cahill, D.G.: Nanofluids for thermal transport. Mater. Today 8(6), 36–44 (2005)

Rubio-jimenez, C.A.; Hernandez-guerrero, A.; Cervantes, J.G.; Lorenzini-gutierrez, D.; Gonzalez-valle, C.U.: CFD study of constructal microchannel networks for liquid-cooling of electronic devices. Appl. Therm. Eng. 95, 374–381 (2016)

Xie, X.L.; Tao, W.Q.; He, Y.L.: Numerical study of turbulent heat transfer and pressure drop characteristics in water-cooled minichannel heat sink. J. Electron. Packag. 129, 247–255 (2007)

Anwar, M.; Tariq, H.A.; Shoukat, A.A.; Ali, H.M.; Ali, H.: Numerical study for heat transfer enhancement using CuO–H2O nano-fluids through mini-channel heat sinks for microprocessor cooling. Therm. Sci. Int. Sci. J. 1, 1–13 (2019). https://doi.org/10.2298/TSCI180722022A

Tariq, H.A.; Israr, A.; Khan, Y.I.; Anwar, M.: Numerical and experimental study of cellular structures as a heat dissipation media. Heat Mass Transf. 55, 501–511 (2019). https://doi.org/10.1007/s00231-018-2439-7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M., Shoukat, A.A., Tariq, H.A. et al. Header Design Optimization of Mini-channel Heat Sinks Using CuO–H2O and Al2O3–H2O Nanofluids for Thermal Management. Arab J Sci Eng 44, 10327–10338 (2019). https://doi.org/10.1007/s13369-019-04022-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04022-2