Abstract

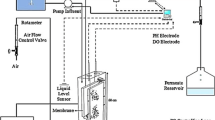

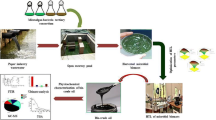

The objective of this paper was to introduce the aerobic microbiological reactor technology for wastewater treatment of biodiesel plants and find out the key factors that are involved in membrane fouling. The research was carried out in two steps. In the first step, sulfuric acid of pH 2, 2.5 and 3 was added to biodiesel wastewater and significant reduction in organic pollutants was observed at pH 2.5 such as chemical oxygen demand, and oil and grease were found to be 74–84 and 84.2–92.6 %, respectively. In the second step, microbiological reactor was operated at different hydraulic retention times of 15, 12, 9 and 6 h along with an increase in organic loading rates (range 1–3 g/L day) on individual hydraulic retention times. However, overall chemical oxygen demand and oil and grease removal efficiency remained in the range of 91.7–97.20 and 95.5–97.9 %, respectively, throughout the experiment, while severe membrane fouling was observed with decreasing hydraulic retention time due to decrease in dissolved oxygen concentration and increase in mixed liquid suspended solids, and soluble microbial product containing protein and polysaccharide. At lower hydraulic retention time of 6 h, an increase in particle size was reported as 27.9–62.7 μm, and soluble microbial product containing protein and polysaccharide reported as 20–60 and 19–59 mg/L, respectively. Higher soluble microbial product level led to increase in particle size with irregular shape, which led to severe membrane fouling.

Similar content being viewed by others

References

APHA (1995) Standard methods for the examination of water and wastewater, 19th edn. American Public Health Association, Baltimore

Berrios M, Skelton L (2008) Comparison of purification methods of biodiesel. Chem Eng J 144:459–465

Bolzonella D, Pavan P, Battistoni P, Cecchi F (2006) Anaerobic co-digestion of sludge with other organic wastes and phosphorus reclamation in wastewater treatment plants for biological nutrients removal. Water Sci Technol 53:177–186

Brookes A, Jefferson B, Guglielmi G, Judd J (2006) Sustainable flux fouling in a membrane bioreactor: impact of flux and MLSS. Sep Sci Technol 41:1279–1291

Calvo L, Leclerc J, Tanguy G, Cames M, Patemotte G, Valentin G, Rostan A, Lapicque F (2003) An electrocoagulation unit for the purification of soluble oil wastes of high COD. Environ Prog 22:57–65

Canakci M, Gerpen V (2001) Biodiesel production from oils and fats with high free fatty acids. Trans ASAE 44:1429–1436

Chang S, Kim N (2005) Wastewater treatment using membrane filtration–effect of biosolids concentration on cake resistance. Process Biochem 40:1307–1314

Chang S, Le Clech P, Jefferson B, Judd S (2002) Membrane fouling in membrane bioreactors for wastewater treatment. J Environ Eng ASCE 128:1018–1029

Chavalparit O, Meanseta P (2006) Treatment of agro-industrial wastewater by means of electro-coagulation: crude palm oil mill in Thailand. In: Proceedings of the 12th Thailand–Korea Conference Environmental Engineering, Korea Advanced Institute of Science and Technology (KAIST), Soul, Korea, 21–25

Chavalparit O, Ongwandee M (2009) Optimizing electrocoagulation process for the treatment of biodiesel wastewater using response surface methodology (RSM). J Environ Sci 21:1491–1496

Dufresne R, Lavallee C, Lebrun E, Lo N (1998) Comparison of performance between membrane bioreactor and activated sludge system for the treatment of pulping process wastewaters. Tappi J 81:131–135

Emamjomeh M, Sivakumar M (2009) Review of pollutants removed by electrocoagulation and electrocoagulation/flotation processes. J Environ Manage 90:1663–1667

Feng C, Sugiura N, Maekawa T (2004) Performance of two new electrochemical treatment system for wastewaters. J Environ Sci Health 39:2533–2543

Frost and Sullivan (2003) European bioreactor market. Report B208

Frost and Sullivan (2010) Growing opportunities for membrane systems in Indian water and wastewater treatment market, Report

Hong P, Bae H, Tak M, Hong A (2002) Randall, Fouling control in activated sludge submerged hollow fiber membrane bioreactors. Desalination 143:219–228

Huang Z, Ong L, Ng Y (2010) Submerged anaerobic membrane bioreactor for low-strength wastewater treatment: effect of HRT and SRT on treatment performance and membrane fouling. J Water Res 45:1543–1554

IPPC-Reference Document on Best Available Techniques in Common Waste Water and Waste Gas Treatment/Management Systems in the Chemical Sector, Feb (2003). http://eippcb.jrc.es

Jaruwat P, Kongiao S, Hunsom M (2010) Management of biodiesel wastewater by the combined processes of chemical recovery and electrochemical treatment. Energy Conver Manage 51:531–537

Jefferson B, Brookes A, Le-Clech P, Judd J (2004) Methods for understanding organic fouling in MBRs. Water Sci Technol 49:237–244

Kato S, Yoshimura H, Hirose K, Amornkitbamurung M, Sakka M, Sugahara I (2005) Application of microbial consortium system to wastewater from biodiesel fuel generator. IEA-Waterqual, Singapore, CD-ROM

Kimura J (1991) Japan’s aqua renaissance’90 project. Water Sci Technol 23:1573–1582

Lesjean B, Rosenberge S, Laabs C, Jekel M, Gnirss R, Amy G (2005) Correlation between membrane fouling and soluble/colloidal organic substances in membrane bioreactors for municipal wastewater treatment. Water Sci Technol 51:1–8

Marchetti M, Miguel U, Errazu F (2007) Possible methods for biodiesel production. Renew Sustain Energy Rev 11:1300–1311

Meng F, Shi B, Yang F, Zhang H (2007) Effect of hydraulic retention time on membrane fouling and biomass characteristics in submerged membrane bioreactors. Bioprocess Biosyst Eng 30:359–367

Nagaoka H, Yamanishi S, Miya A (1998) Modeling of biofouling by extracellular polymers in a membrane separation activated sludge. Water Sci Technol 38:497–504

Ngamlerdpokin K, Kumjadpai S, Chatanon P, Tungmanee U, Chuenchuanchom S, Jaruwat P, Lertsathitphongs P, Hunsom M (2011) Remediation of biodiesel wastewater by chemical and electro-coagulation. J Environ Manage 92:2454–2460

Nishiro N, Nakashimada Y (2007) Recent development of anaerobic digestion processes for energy recovery from wastes. J Biosci Bioeng 103:105–112

Raunkjaer K, Hvitved T, Nielsen H (1994) Measurement of pools of protein, carbohydrate and lipid in domestic wastewater. J Water Res 28:251–262

Rosenberger S, Evenblij H, Te S, Wintgens T, Laabs C (2005) The importance of liquid phase analyses to understand fouling in membrane assisted activated sludge processes-six case studies of different European research groups. J Membr Sci 263:113–126

Siles J, Gutiérrez M, Martin M, Martin A (2011) Physical–chemical and biomethanization treatments of wastewater from biodiesel manufacturing. Bioresour Technol 102:6348–6351

Suehara K, Kawamoto Y, Fujii E, Kohda J, Nakano Y, Yano T (2005) Biological treatment of wastewater discharged from biodiesel fuel production plant with alkali-catalyzed trans-esterification. J Biosci Bioeng 100:437–442

Tri P (2002) Oily wastewater treatment by membrane bioreactor process coupled with biological activated carbon process, Thesis: AIT. Bangkok, Thailand

Wilen M, Balmer P (1999) The effect of dissolved oxygen concentration on the structure, size and size distribution of activated sludge flocs. Water Res 33:391–400

Acknowledgments

The authors gratefully acknowledge the great support from the Graduate School of Prince of Songkhla University and DOE (Discipline of Excellent Chemical Engineering).

Author information

Authors and Affiliations

Corresponding author

Appendix 1: COD input calculations for MBR

Appendix 1: COD input calculations for MBR

1. Calculation of COD input

Or

where HRT is hydraulic retention time (h), V is volume of reactor (L), A is filtration area (m2), and J is permeate flux (L/m2 h)

Or

where VOLR is volumetric organic loading rate (g/L day), V is volume of reactor (L), Q is permeate flow rate (L/day), and S 0 is COD input (mg/L) (Tables 6, 7)

Abbreviations

- COD

-

Chemical oxygen demand (mg/L)

- BOD

-

Biological oxygen demand (mg/L)

- O&G

-

Oil and grease (mg/L)

- HRT

-

Hydraulic retention time (h)

- MLSS

-

Mixed liquid suspended solids (mg/L)

- MLVSS

-

Mixed liquid volatile suspended solids (mg/L)

- SMP

-

Soluble microbial products (mg/L)

- SMPp

-

Soluble microbial product containing protein (mg/L)

- SMPc

-

Soluble microbial product containing polysaccharide (mg/L)

- DO

-

Dissolved oxygen (mg/L)

- PSD

-

Particle size distribution (µm)

- TMP

-

Transmembrane pressure (KPa)

- FFA

-

Free fatty acids (mL/L)

- FAME

-

Fatty acid methyl esters (mL/L)

- OLR

-

Organic loading rate (g/L day)

- SRT

-

Solid retention time (days)

Rights and permissions

About this article

Cite this article

Khan, Y., Yamsaengsung, R., Chetpattananondh, P. et al. Treatment of wastewater from biodiesel plants using microbiological reactor technology. Int. J. Environ. Sci. Technol. 12, 297–306 (2015). https://doi.org/10.1007/s13762-014-0501-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-014-0501-7