Abstract

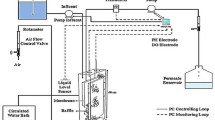

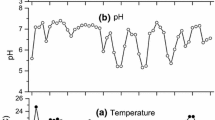

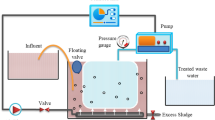

The present study aims to shed more light on the use of membrane bioreactors (MBRs) for the treatment of vegetable oil refinery wastewaters (VORWs). A MBR was operated for 157 days in which it was fed with real VORW of varying composition at a range of organic loading rates (0.20 ± 0.05–3.79 ± 0.29 kg COD m−3 day−1). The hitherto unconsidered fate of VORW constituents through the biological process was followed using gas chromatography/mass spectrometry analysis. This analysis revealed that only 19% of the identified feed constituents remained in the MBR effluent whereas ten new compounds were formed. Linear correlation analysis attributed the effluent residual COD to soluble microbial products (SMP) and non-readily biodegradable recalcitrant oily compounds. Trend of change of MLSS, mixed liquor viscosity and SMP with increasing OLR suggested that when MBR is operated under industrial conditions for the VORW treatment, the mixed liquor fouling propensity potentially increases with increasing OLR in the range studied.

Similar content being viewed by others

References

Seres Z, Maravic N, Takaci A, Nikolic I, Soronja-Simovic D, Jokic A, Hodur C (2016) Treatment of vegetable oil refinery wastewater using alumina ceramic membrane: optimization using response surface methodology. J Clean Prod 112:3132–3137. https://doi.org/10.1016/j.jclepro.2015.10.070

Dohare D, Meshram R (2014) Biological treatment of edible oil refinery wastewater using activated sludge process and sequencing batch reactors—a review. Int J Eng Res Sci Technol 3:251–260

Aslan S, Alyüz B, Bozkurt Z, Bakaoglu M (2009) Characterization and biological treatability of edible oil wastewaters. Pol J Environ Stud 18:533–538

Ma Zh, Lei T, Ji X, Gao X, Gao C (2015) Submerged membrane bioreactor for vegetable oil wastewater treatment. Chem Eng Technol 38:101–109. https://doi.org/10.1002/ceat.201400184

Chipasa KB (2001) Limits of physicochemical treatment of wastewater in the vegetable oil refining industry. Pol J Environ Stud 10:141–147

Saatci Y, Hasar H, Cici M (2002) Effects of organic loading and oil-grease for the treatment of edible oil effluent in a pilot-scale upflow anaerobic sludge blanket process. Int J Environ Pollut 18:301–308. https://doi.org/10.1504/IJEP.2002.000713

Azbar N, Yonar T (2004) Comparative evaluation of a laboratory and full-scale treatment alternatives for the vegetable oil refining industry wastewater (VORW). Process Biochem 39:869–875. https://doi.org/10.1016/S0032-9592(03)00193-6

Degenaar AP, Ismail A, Bux F (2008) Comparative evaluation of the microbial community in biological processes treating industrial and domestic wastewaters. J Appl Microbiol 104:353–363. https://doi.org/10.1111/j.1365-2672.2007.03563

Reddy K, Drysdale GD, Bux F (2003) Evaluation of activated sludge treatment and settleability in remediation of edible oil effluent. Water SA 29:245–250. https://doi.org/10.4314/wsa.v29i3.4924

Rajkumar K, Muthukumar M, Sivakumar R (2010) Novel approach for the treatment and recycle of wastewater from soya edible oil refinery industry—an economic perspective. Resour Conserv Recycl 54:752–758. https://doi.org/10.1016/j.resconrec.2009.12.005

Sharma S, Sharma AK, Verma S, Dodiya HS (2014) Edible oil refinery waste water treatment by using effluent treatment plant. Int J Chem Stud 2:36–42

Mkhize SP, Atkinson BW, Bux F (2000) Evaluation of a laboratory-scale biological process for the treatment of edible oil effluent. Water SA 2:555–558

Abdollahzadeh Sharghi E, Bonakdarpour B (2013) The study of organic removal efficiency and halophilic bacterial mixed liquor characteristics in a membrane bioreactor treating hypersaline produced water at varying organic loading rates. Bioresour Technol 149:486–495. https://doi.org/10.1016/j.biortech.2013.09.110

Qin L, Fan Zh, Xu L, Zhang G, Wang G, Wu D, Long X, Meng Q (2015) A submerged membrane bioreactor with pendulum type oscillation (PTO) for oily wastewater treatment: membrane permeability and fouling control. Bioresour Technol 183:33–41. https://doi.org/10.1016/j.biortech.2015.02.018

Alkmim AR, da Costa PR, Moser PB, Neta LSF, Santiago VMJ, Cerqueira AC, Reis BG, Amaral MCS (2017) Potential use of membrane bioreactor to treat petroleum refinery effluent: comprehension of dynamic of organic matter removal, fouling characteristics and membrane lifetime. Bioprocess Biosyst Eng 40(12):1839–1850. https://doi.org/10.1007/s00449-017-1837-4

Bagheri M, Mirbagheri SA (2018) Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour Technol 258:318–334. https://doi.org/10.1016/j.biortech.2018.03.026

Isma MIA, Idris A, Omar R, Razreena ARP (2014) Effects of SRT and HRT on treatment performance of MBR and membrane fouling. Int J Chem Mol Nucl Mater Metall Eng 8:488–492

Deng L, Guo W, Ngo HH, Zhang H, Wang J, Li J, Xia S, Wu Y (2016) Biofouling and control approaches in membrane bioreactors. Bioresour Technol 221:656–665. https://doi.org/10.1016/j.biortech.2016.09.105

Yu L, Yang Y, Yang B, Li Z, Zhang X, Hou Y, Lei L, Zhang D (2018) Effects of solids retention time on the performance and microbial community structures in membrane bioreactors treating synthetic oil refinery wastewater. Chem Eng J 344:462–468. https://doi.org/10.1016/j.cej.2018.03.073

Hong S, Aryal R, Vigneswaran S, Johir MAH, Kandasamy J (2012) Influence of hydraulic retention time on the nature of foulant organics in a high rate membrane bioreactor. Desalination 287:116–122. https://doi.org/10.1016/j.desal.2011.07.030

Degermenci N, Cengiz I, Yildiz E, Nuhoglu A (2016) Performance investigation of a jet loop membrane bioreactor for the treatment of an actual olive mill wastewater. J Environ Manag 184:441–447. https://doi.org/10.1016/j.jenvman.2016.10.014

Dominguez L, Cases V, Birek Ch, Rodríguez M, Prats D (2012) Influence of organic loading rate on the performance of ultrafiltration and microfiltration membrane bioreactors at high sludge retention time. Chem Eng J 181–182:132–143. https://doi.org/10.1016/j.cej.2011.11.040

Johir MAH, Vigneswaran S, Sathasivan A, Kandasamy J, Chang CY (2012) Effect of organic loading rate on organic matter and foulant characteristics in membrane bioreactor. Bioresour Technol 113:154–160. https://doi.org/10.1016/j.biortech.2011.12.002

Abdollahzadeh Sharghi E, Shorgashti A, Bonakdarpour B (2016) The study of organic removal efficiency and membrane fouling in a submerged membrane bioreactor treating vegetable oil wastewater. Int J Eng 29:1341–1348

Ghasemian P, Abdollahzadeh Sharghi E, Davarpanah L (2017) The influence of short values of hydraulic and sludge retention time on performance of a membrane bioreactor treating sunflower oil refinery wastewater. Int J Eng 30:1417–1424

World Bank Group (2015) Environmental, health, and safety guidelines for vegetable oil production and processing. Int Finance Corporation 12:1–24

Abdollahzadeh Sharghi E, Bonakdarpour B, Roustazade P, Amoozegar MA, Rabbani AR (2013) The biological treatment of high salinity synthetic oilfield produced water in a submerged membrane bioreactor using a halophilic bacterial consortium. J Chem Technol Biotechnol 88:2016–2026. https://doi.org/10.1002/jctb.4061

APHA (2012) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington, DC

US EPA Office of Water, Engineering and Analysis Division (1999) Method 1664, Revision A: N-hexane extractable material (HEM; oil and grease) and silica gel treatable n-hexane extractable material (SGT-HEM; non-polar material) by extraction and gravimetry. Washington, DC

Abdollahzadeh Sharghi E, Bonakdarpour B, Pakzadeh M (2014) Treatment of hypersaline produced water employing a moderately halophilic bacterial consortium in a membrane bioreactor: Effect of salt concentration on organic removal performance, mixed liquor characteristics and membrane fouling. Bioresour Technol 164:203–213. https://doi.org/10.1016/j.biortech.2014.04.099

Chang IS, Lee CH, Ahn KH (1999) Membrane filtration characteristics in membrane coupled activated sludge system: the effect of floc structure on membrane fouling. Sep Sci Technol 34:1743–1758. https://doi.org/10.1016/j.procbio.2004.06.019

Zhang D, Trzcinski AP, Kunacheva C, Stuckey DC, Liu Y, Tan SK, Ng WJ (2016) Characterization of soluble microbial products (SMPs) in a membrane bioreactor (MBR) treating synthetic wastewater containing pharmaceutical compounds. Water Res 102:594–606. https://doi.org/10.1016/j.watres.2016.06.059

Tellez GT, Nirmalakhandan N, Gardea-Torresdey JL (2002) Performance evaluation of an activated sludge system for removing petroleum hydrocarbons from oilfield produced water. Adv Environ Res 6:455–470. https://doi.org/10.1016/S1093-0191(01)00073-9

Babatsouli P, Palogos I, Michalodimitraki E, Costa C, Kalogerakis N (2015) Evaluation of a MBR pilot treating industrial wastewater with a high COD/N ratio. J Chem Technol Biotechnol 90:26–33. https://doi.org/10.1002/jctb.4364

Matošić M, Crnek V, Jakopović HK, Mijatović I (2009) Municipal wastewater treatment in a membrane bioreactor. Fresenius Environ Bull 18:2275–2281

Rodriguez FA, Reboleiro-Rivas P, Osorio F, Martinez-Toledo MV, Hontoria E, Poyatos JM (2012) Influence of mixed liquid suspended solids and hydraulic retention time on oxygen transfer efficiency and viscosity in a submerged membrane bioreactor using pure oxygen to supply aerobic conditions. Biochem Eng J 60:135–141. https://doi.org/10.1016/j.bej.2011.10.016

Meng F, Shi B, Yang F, Zhang H (2007) Effect of hydraulic retention time on membrane fouling and biomass characteristics in submerged membrane bioreactors. Bioprocess Biosyst Eng 30:359–367

Chen L, Gu Y, Cao C, Zhang J, Ng JW, Tang C (2014) Performance of a submerged anaerobic membrane bioreactor with forward osmosis membrane for low-strength wastewater treatment. Water Res 50:114–123. https://doi.org/10.1016/j.watres.2013.12.009

Yang F, Bick A, Shandalov S, Brenner A, Oron G (2009) Yield stress and rheological characteristics of activated sludge in an airlift membrane bioreactor. J Membr Sci 334:83–90. https://doi.org/10.1016/j.memsci.2009.02.022

Duan L, Song Y, Yu H, Xia S, Hermanowicz SW (2014) The effect of solids retention times on the characterization of extracellular polymeric substances and soluble microbial products in a submerged membrane bioreactor. Bioresour Technol 163:395–398. https://doi.org/10.1016/j.biortech.2014.04.112

Pajoum Shariati SR, Bonakdarpour B, Zare N, Zokaee Ashtiani F (2011) The effect of hydraulic retention time on the performance and fouling characteristics of membrane sequencing batch reactors used for the treatment of synthetic petroleum refinery wastewater. Bioresour Technol 102:7692–7699. https://doi.org/10.1016/j.biortech.2011.05.065

Wu J, Huang X (2009) Effect of mixed liquor properties on fouling propensity in membrane bioreactors. J Membr Sci 342:88–96. https://doi.org/10.1016/j.memsci.2009.06.024

Kunacheva C, Stuckey DC (2014) Analytical methods for soluble microbial products (SMP) and extracellular polymers (ECP) in wastewater treatment systems: a review. Water Res 61:1–18. https://doi.org/10.1016/j.watres.2014.04.044

Juang LC, Tseng DH, Chen YM, Semblante GU, You SJ (2013) The effect soluble microbial products (SMP) on the quality and fouling potential of MBR effluent. Desalination 326:96–102. https://doi.org/10.1016/j.desal.2013.07.005

Masse A, Sperandio M, Cabassud C (2006) Comparison of sludge characteristics and performance of a submerged membrane bioreactor and an activated sludge process at high solids retention time. Water Res 40:2405–2415. https://doi.org/10.1016/j.watres.2006.04.015

Tuan HQ, Schreiner M (2011) Characterization of natural edible oils regarding their quality and safety related constituents, Master Thesis, Division of Food Chemistry, Department of Food Sciences and Technology, University of Natural Resources and Life Sciences, Vienna

Joshi PA, Mishra RL (2015) Studies on GC-MS analysis of fungal biodegraded vegetable oils. Indian J Appl Res 5:44–48. https://doi.org/10.15373/2249555X

Dass PM, Danbature WL, Karu E, Ibrahim A, Ledo AB (2013) Extraction and biodegradation of Baobab (Adansonia digitata) seeds oil by fungi (Aspergillus niger). J Nat Sci Res 3:128–136

Lousada-Ferreira M, Geilvoet S, Moreau A, Atasoy E, Krzeminski P, van Nieuwenhuijzen A, van der Graaf J (2010) MLSS concentration: still a poorly understood parameter in MBR filterability. Desalination 250:618–622. https://doi.org/10.1016/j.desal.2009.09.036

Lee S, Kim MH (2013) Fouling characteristics in pure oxygen MBR process according to MLSS concentrations and COD loadings. J Membr Sci 428:323–330

Acknowledgements

This work was supported by the Iran National Science Foundation (INSF) [Grant number 93034669].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abdollahzadeh Sharghi, E., Shourgashti, A. & Bonakdarpour, B. Considering a membrane bioreactor for the treatment of vegetable oil refinery wastewaters at industrially relevant organic loading rates. Bioprocess Biosyst Eng 43, 981–995 (2020). https://doi.org/10.1007/s00449-020-02294-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02294-9