Abstract

The search for environmentally friendly materials that can replace synthetic plastics is still relevant. In this work, we have for the first time conducted a detailed study of films based on industrial-scale biodegradable polymers/starch acetate (AcSt) and polyvinyl alcohol (PVA). The PVA content in the film compositions ranged from 0 to 30% (by weight based on the total polymer weight). The film structures were evaluated by XRD, FTIR spectroscopy, and SEM methods. We also investigated the properties important for practical use of polymer films: the swelling degree, water vapor permeability, oil permeability, tensile strength, elongation-at-break, biodegradability, and phytotoxicity. The results showed that AcSt and PVA display sufficiently good compatibility in the blends and form continuous and smooth films. The increased PVA content in the compositions improved the mechanical characteristics of the films. The PVA additions (15–30% by weight based on the total polymer weight) reduced oil permeability of the samples. All the obtained films met the biodegradability criteria according to the International Standard ISO 846:1997-Plastics-Evaluation of the action of microorganisms.The seed germination test showed that the films exhibited zero phytotoxicity. The films with a PVA content of 25–30% (by weight based on the total polymer weight) can be an ecofriendly and low-cost alternative to some synthetic coating and packaging films.

Graphical abstract

Similar content being viewed by others

References

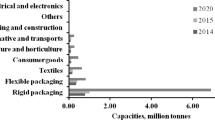

European bioplastics, Bioplastics market data, https://www.european-bioplastics.org/market

Rouch D (2021) Plastic future: How to reduce the increasing environmental footprint of plastic packaging. Clarendon Policy Strategy Group 11:1–43

BeMiller J, Whistler R (2009) Starch: chemistry and technology, 3rd edn. Elsevier, Amsterdam

Ochubiojo E, Rodrigues A (2012) In: Valdez B (ed) Starch: from food to medicine: Scientific, health and social aspects of the food industry. InTech(http://www.intechopen.com/books)

Han F, Liu M, Gong H, Lu S, Ni B, Zhang B (2012) Synthesis, characterization and functional properties of low substituted acetylated corn starch. Int J Biol Macromol 50:1026–1034. https://doi.org/10.1016/j.ijbiomac.2012.02.030

Fringant C, Desbrières J, Rinaudo M (1996) Physical properties of acetylated starch-based materials: relation with their molecular characteristics. Polymer 37:2663–2673. https://doi.org/10.1016/0032-3861(96)87626-9

Ačkar Đ, Babić J, Jozinović A, Miličević B, Jokić S, Miličević R, Rajič M, Šubarić D (2015) Starch modification by organic acids and their derivatives: a review. Molecules 20:19554–19570. https://doi.org/10.3390/molecules201019554

Haq F, Yu H, Wang L, Teng L, Haroon M, Khan RU, Mehmooda S, Amina BU, Ullaha RS, Khana A, Nazira A (2019) Advances in chemical modifications of starches and their applications. Carbohydr Res 476:12–35. https://doi.org/10.1016/j.carres.2019.02.007

Escamilla-García M, Reyes-Basurto A, García-Almendárez BE, Hernández-Hernández E, Calderón-Domínguez G, Rossi-Márquez G, Regalado-González C (2017) Modified starch-chitosan edible films: physicochemical and mechanical characterization. Coatings 7:224. https://doi.org/10.3390/coatings7120224

Coma V, Copinet A, Couturier Y, Prudhomme JC (1995) Biofragmentation of acetylated starch by the α-amylase of Aspergillus oryzae. Starch-Starke 47:100–107. https://doi.org/10.1002/star.19950470306

Copinet A, Bliard C, Onteniente JP, Couturier Y (2001) Enzymatic degradation and deacetylation of native and acetylated starch based extruded blends. Polym Degrad Stab 71:203–212. https://doi.org/10.1016/S0141-3910(00)00110-5

Tuovinen LM, Peltonen SH, Suortti TM, Crowther NJ, Elomaa MA, Järvinen KP (2002) Enzymatic degradation of and bovine serum albumin release from starch-acetate films. Biomacromol 3:284–290. https://doi.org/10.1021/bm015581e

Tuovinent L, Peltonen S, Järvinen K (2003) Drug release from starch-acetate films. J Control Release 91:345–354. https://doi.org/10.1016/10.1016/S0168-3659(03)00259-1

Tuovinen L, Peltonen S, Liikola M, Hotakainen M, Lahtela-Kakkonen M, Poso A, Järvinen K (2004) Drug release from starch-acetate microparticles and films with and without incorporated alpha-amylase. Biomaterials 25:4355–4362. https://doi.org/10.1016/j.biomaterials.2003.11.026

Nutan M, Soliman M, Taha E, Khan M (2005) Optimization and characterization of controlled release multi-particulate beads coated with starch acetate. Int J Pharm 294:89–101. https://doi.org/10.1016/j.ijpharm.2005.01.013

Sofyane A, Ablouh E, Lahcini M, Elmeziane A, Khouloud M, Kaddami H, Raihane M (2021) Slow-release fertilizers based on starch acetate/glycerol/polyvinyl alcohol biocomposites for sustained nutrient release. Mater Today Proc 36:74–81. https://doi.org/10.1016/j.matpr.2020.05.319

Panrong T, Karbowiak T, Harnkarnsujarit N (2020) Effects of acetylated and octenyl-succinated starch on properties and release of green tea compounded starch/LLDPE blend films. J Food Eng 284:110057. https://doi.org/10.1016/j.jfoodeng.2020.110057

Chiellini E, Corti A, D’Antone S, Solaro R (2003) Biodegradation of poly (vinyl alcohol) based materials. Prog Polym Sci 28:963–1014. https://doi.org/10.1016/S0079-6700(02)00149-1

Katerinopoulou K, Giannakas A, Grigoriadi K, Barkoula NM, Ladavos A (2014) Preparation and characterization of acetylated cornstarch-(PVOH)/clay nanocomposite films. Carbohydr Polym 102:216–222. https://doi.org/10.1016/j.carbpol.2013.11.030

Zhu JF, Zhang GH, Lai ZC (2007) Synthesis and characterization of maize starch acetates and its biodegradable film. Polym-Plast Technol Eng 46:1135–1141. https://doi.org/10.1080/03602550701558116

Lin D, Zhou W, Zhao J, Lan W, Chen R, Li Y, Xing B, Li Z, Xiao M, Wu Z, Li X, Chen R, Zhang X, Chen H, Zhang Q, Qin W, Li S (2017) Study on the synthesis and physicochemical properties of starch acetate with low substitution under microwave assistance. Int J Biol Macromol 103:316–326. https://doi.org/10.1016/j.ijbiomac.2017.05.056

Alexander LE (1970) X-Ray diffraction methods in polymer science. Wiley-Interscience, New York

Kochkina NE, Butikova OA (2019) Effect of fibrous TiO2 filler on the structural, mechanical, barrier and optical characteristics of biodegradable maize starch/PVA composite films. Int J Biol Macromol 139:431–439. https://doi.org/10.1016/j.ijbiomac.2019.07.213

Yan QQ, Hou HX, Guo P, Dong HZ (2012) Effects of extrusion and glycerol content on properties of oxidized and acetylated corn starch-based films. Carbohydr Polym 87:707–712. https://doi.org/10.1016/j.carbpol.2011.08.048

Zucconi FM, Monaco A, Forte M, De Bertoldi M (1985) Phytotoxins during the stabilization of organic matter. In: Gasser JKR (ed) Composting of agricultural and other wastes. Elsevier Applied Publishers, London, UK, pp 73–86

Colussi R, Pinto VZ, Halal SLM, Vanier NL, Villanova FA, Silva RM, Zavareze EDR, Dias ARG (2014) Structural, morphological, and physicochemical properties of acetylated high-, medium-, and low-amylose rice starches. Carbohydr Polym 103:405–413. https://doi.org/10.1016/j.carbpol.2013.12.070

Domene-López D, García-Quesada JC, Martin-Gullon I, Montalbán MG (2019) Influence of starch composition and molecular weight on physicochemical properties of biodegradable films. Polymers 11:1084. https://doi.org/10.3390/polym11071084

Popescu M, Dogaru B, Goanta M, Timpua D (2018) Structural and morphological evaluation of CNC reinforced PVA/starch biodegradable films. Int J Biol Macromol 116:385–393. https://doi.org/10.1016/j.ijbiomac.2018.05.036

Blackwell J, Marchessault R (1971) Part IV. In: Bikales N, Segal L (eds) Cellulose and Cellulose Derivatives. Wiley, New York

Xu Y, Miladinov V, Hanna M (2004) Synthesis and characterization of starch acetates with high substitution. Cereal Chem 81:735–740. https://doi.org/10.1094/cchem.2004.81.6.735

Sin L, Rahman W, Rahmat A, Samad A (2010) Computational modeling and experimental infrared spectroscopy of hydrogen bonding interactions in polyvinyl alcohol-starch blends. Polymer 51:1206–1211. https://doi.org/10.1016/j.polymer.2010.01.021

van Soest J, Tournois H, de Wit D, Vliegenthart J (1995) Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr Res 279:201–214. https://doi.org/10.1016/0008-6215(95)00270-7

Kochkina N, Lukin N (2020) Structure and properties of biodegradable maize starch/chitosan composite films as affected by PVA additions. Int J Biol Macromol 157:377–384. https://doi.org/10.1016/j.ijbiomac.2020.04.154

de Lima BC, Crepaldi M, Junior O, de Oliveira A, Martins A, Garcia P, Bonafé E (2020) Biodegradable films based on commercial κ-carrageenan and cassava starch to achieve low production costs. Int J Biol Macromol 165:582–590. https://doi.org/10.1016/j.ijbiomac.2020.09.150

Humbert S, Lame O, Séguéla R, Vigier G (2011) A re-examination of the elastic modulus dependence on crystallinity in semi-crystalline polymers. Polymer 52:4899–4909. https://doi.org/10.1016/j.polymer.2011.07.060

Utracki L, Wilkie C (2014) Polymer blends handbook. Springer reference, Milwaukee

Surov O, Voronova M, Rubleva N, Afineevskii A, Zakharov A (2019) Cellulose nanocrystals as a compatibilizer for improved miscibility of water-soluble polymer binary blends. J Appl Polym Sci. https://doi.org/10.1002/APP.48662

Tian H, Yuan L, Zhou D, Niu J, Cong H, Xiang A (2018) Improved mechanical properties of poly (vinyl alcohol) films with glycerol plasticizer by uniaxial drawing. Polym Adv Technol 29:2612–2618. https://doi.org/10.1002/pat.4374

Tang X, Alavi S (2011) Recent advances in starch, polyvinyl alcohol based polymer blends, nanocomposites and their biodegradability. Carbohydr Polym 85:7–16. https://doi.org/10.1016/j.carbpol.2011.01.030

Yam K (2009) The Wiley Encyclopedia of Packaging Technology, 3rd edn. Wiley, USA

Acknowledgements

The authors thank the Upper Volga Region Centre of Physicochemical Research (Ivanovo, Russia) for the opportunity to use the equipment of the Centre for making some tests of the samples.

Author information

Authors and Affiliations

Contributions

NEK: conceptualization, methodology, validation, software, data curation, formal analysis, visualization, and writing—original draft preparation. OAB: investigation and software. NDL: conceptualization, writing—reviewing and editing, and funding acquisition.

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kochkina, N.E., Butikova, O.A. & Lukin, N.D. Ecofriendly films based on low-substituted starch acetate enhanced by polyvinyl alcohol additions. Iran Polym J 31, 1361–1371 (2022). https://doi.org/10.1007/s13726-022-01083-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01083-3