Abstract

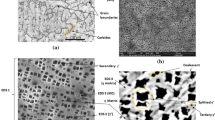

XH 67 is a nickel-based superalloy, which is used in critical parts of modern aerospace engines. In the present study, XH 67 specimens in five different heat treatment conditions selected based on the processing and application have been investigated for their microstructures, morphology, and composition of the matrix and second-phase particles. Optical microscopic (OM) analysis revealed the presence of bi-model neck-lace type grains and equiaxed grains as a result of different heat treatment conditions. Scanning electron microscopy (SEM) and elemental composition analysis revealed precipitates and second-phase particles. Carbides such as Ti (N, C) and (W, Mo, Ti) C were observed having different sizes and shapes. Cr-rich carbide phases were found to be preferentially segregated along the grain boundaries. X-ray diffraction analysis was carried out for assessing the phases present in the alloy. X-ray diffraction analysis revealed the gamma matrix and the precipitate phase are crystallographically identical (coherent). Transmission electron microscopic (TEM) analysis of the specimens confirmed the presence of uniformly distributed spherical Ni3 (Al, Ti) precipitates which impart thermal stability to the superalloy. Presence of different types of carbides is also revealed by TEM analysis.

Similar content being viewed by others

References

T.M. Pollock, S. Tin, Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J. Propuls. Power. 22, 361–374 (2006). https://doi.org/10.2514/1.18239

N. El-Bagoury, NI based superalloy: casting technology, metallurgy, development, properties and applications. Int. J. Eng. Sci. Res. Technol. 5, 108–152 (2016)

V.I. Lukin, V.N. Semenov, L.L. Starova, G.I. Morozova, I.P. Zhegina, N.V. Moiseev, E.V. Golev, V.V. Dmitriev, B.A. Kozykov, Structure of the weld and near-weld zone in nickel alloys ÉP202 and ÉK61. Met. Sci. Heat Treat. 43, 484–488 (2001). https://doi.org/10.1023/a:1014801022530

V.N. Semenov, N.V. Akimov, V.P. Glushko, Formation of cracks in EP202 and EK61 alloys in welding of structures of liquid rocket engines. Weld. Int. 27, 159–162 (2013). https://doi.org/10.1080/09507116.2012.695550

R.C. Reed, C.M.F. Rae, Physical Metallurgy of the Nickel-Based Superalloys, 5th edn (Elsevier, New York, 2014) https://doi.org/10.1016/B978-0-444-53770-6.00022-8

L.N. Zimina, G.F. Kosheleva, T.V. Egorshina, Dendritic and zonal heterogeneities in the KhN67MTYu and KhN60MVTYu alloys. Met. Sci. Heat Treat. 8, 209–212 (1966). https://doi.org/10.1007/BF00660390

M.-S. Chen, G.-Q. Wang, H.-B. Li, Y.-C. Lin, Z.-H. Zou, Y.-Y. Ma, Annealing treatment methods and mechanisms for refining mixed and coarse grains in a solution treatment nickel-based superalloy. Adv. Eng. Mater. 21, 1900558 (2019). https://doi.org/10.1002/adem.201900558

M.S. Chen, Z.H. Zou, Y.C. Lin, H. Bin Li, W.Q. Yuan, Effects of annealing parameters on microstructural evolution of a typical nickel-based superalloy during annealing treatment. Mater. Charact. 141, 212–222 (2018). https://doi.org/10.1016/j.matchar.2018.04.056

M.S. Chen, Z.H. Zou, Y.C. Lin, H. Bin Li, G.Q. Wang, Y.Y. Ma, Microstructural evolution and grain refinement mechanisms of a Ni-based superalloy during a two-stage annealing treatment. Mater. Charact. 151(2019), 445–456 (2019). https://doi.org/10.1016/j.matchar.2019.03.037

Y.C. Lin, H. Yang, L. Li, Effects of solutionizing cooling processing on γ″ (Ni 3 Nb) phase and work hardening characteristics of a Ni–Fe–Cr-base superalloy. Vacuum. 144, 86–93 (2017). https://doi.org/10.1016/j.vacuum.2017.07.025.This

Z.L. Travina NT, Nikitin AA, , Dislocation arrays formed during creep of heat-resistant nickel alloys. Met. Sci. Heat Treat. 21, 855–860 (1979)

F. Sun, Y.F. Gu, J.B. Yan, Z.H. Zhong, M. Yuyama, Dislocation motion in a NI–Fe-based superalloy during creep-rupture beyond 700 °C. Mater. Lett. 159, 241–244 (2015). https://doi.org/10.1016/j.matlet.2015.06.076

H. Murakami, T. Saito, Y.T. Chen, Y. Takata, K. Kawagishi, W.C. Hsu, A.C. Yeh, Effect of heat treatments on the microstructural evolution of a single crystal high-entropy superalloy. Metals (Basel). 10, 1600 (2020)

Acknowledgement

Authors wish to acknowledge Dr. D. Sivakumar, Group Head, MCTG, and Dr. Bhanu Pant, Group Director, MMG, for their guidance in carrying out the work. Authors wish to place on record their deep sense of gratitude to Shri M Mohan, Deputy Director, VSSC (MME), for his support. They also wish to acknowledge LPSC, Valiamala for providing the specimens for the analysis. Finally, they are indebted to Director, VSSC, for his permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jalaja, K., Chakravadhanula, V.S.K., Manwatkar, S.K. et al. Microstructural Characterization of XH 67 Nickel-Based Superalloy Under Different Heat Treatment Conditions. Metallogr. Microstruct. Anal. 10, 257–265 (2021). https://doi.org/10.1007/s13632-021-00734-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00734-w