Abstract

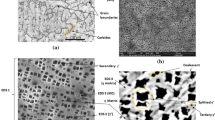

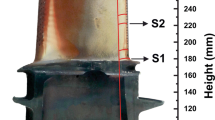

Nickel-based superalloys are normally present in mechanical components requiring resistance to high temperatures and extreme mechanical stresses, e.g., gas turbine blades. The large amount of γ′-precipitates coherent with the γ-matrix in these superalloys ensures excellent properties at high operating temperatures. Nevertheless, after long service periods, the γ′-precipitates grow and lose coherence with the matrix. Intermediate thermal treatments are a potential solution to recover the microstructure, extending the component lifetime. Thermal cycles for γ′-dissolution and reprecipitation define the efficiency of such thermal treatments. The objectives of this work are to analyze the aging kinetics of the nickel-based superalloy GTD-111 (used in gas turbine blades for thermoelectric energy generation) and to study the effects of solution and preprecipitation treatment temperatures on the microstructure and hardness obtained by rejuvenation thermal treatment. For the experiments, samples were previously aged under laboratory conditions during 2,000 h at 1,000 °C. The subsequent rejuvenation thermal treatments consisted of four steps: solution (at 1,150, 1,175, and 1,190 °C), preprecipitation (at 1,055 and 1,120 °C), and reprecipitation (at 845 °C). The resulting microstructures were analyzed using scanning electron microscopy and Vickers hardness measurements. During the aging treatment, the average size of γ′-particles changed from 0.20 µm2, as found in virgin material, to 0.99 µm2 after 2,000 h of aging; the hardness changed from 417 to 320 HV, respectively. For solution treatment at 1,150 °C, total dissolution of γ′-particles did not occur and they presented a bimodal size distribution of coarse and fine particles. For solution treatment at 1,175 and 1,190 °C, the γ′-particles were fine and homogeneous, and the maximum hardness obtained after reprecipitation was 460 HV for 1,190 °C solution treatment and 1,120 °C preprecipitation.

Similar content being viewed by others

References

B.G. Choi, I.S. Kim, D.H. Kim, C.Y. Jo, Temperature dependence of MC decomposition behavior in Ni-base superalloy GTD-111. Mater. Sci. Eng. A 478, 329–335 (2008)

N. El-Bagoury, A. Nofal, Microstructure of an experimental Ni base superalloy under various casting conditions. Mater. Sci. Eng. A 527, 7793–7800 (2010)

E. Lvova, D. Norsworthy, Influence of previous operational cycle on the microstructure of rejuvenated Ni-base superalloy gas turbine blades after their return to service, in Proceedings of the 29th Turbomachinery Symposium (2000), pp. 113–124

N. El-Bagoury, Microstructure and mechanical properties of aged nickel base superalloy. Arch. Appl. Sci. Res. 3(2), 266–276 (2011)

R.A. Stevens, P.E.J. Flewitt, The effects of γ′ precipitate coarsening during isothermal aging and creep of the nickel-base superalloy IN-738. Mater. Sci. Eng. 37, 237–247 (1979)

P. Wangyao, V. Krongtong, P. Tuengsook, W. Hormkrajai, N. Panich, The relationship between reheat-treatment and hardness behaviour of cast nickel superalloy, GTD-111. J. Mater. Miner. 16(1), 55–62 (2006)

E. Lvova, A comparison of aging kinetics of new and rejuvenated conventionally cast GTD-111 gas turbine blades. J. Mater. Eng. Perform. 16(2), 254–264 (2007)

S.A. Sajjadi, S.M. Zebarjad, R.I.L. Guthrie, M. Isac, Microstructure evolution of high-performance Ni-base superalloy GTD-111 with heat treatment parameters, in 12 th International Scientific Conference—Achievements in Mechanical & Materials Engineering (2003), pp. 773–776

R.A. Stevens, P.E.J. Flewitt, Intermediate regenerative heat treatments for extending the creep life of the superalloy IN-738. Mater. Sci. Eng. 50, 271–284 (1981)

A. Kountras, Metallographic study of gamma—gamma prime structure in the Ni-based superalloy GTD-111. Thesis for the Degree of Master of Science in Materials Science and Engineering—MIT, 2004

P. Wangyao, N. Chuankrerkkul, S. Polsilapa, P. Sopon, W. Homkrajai, Gamma prime phase stability after long-term thermal exposure in cast based superalloy, IN-738. Chiang Mai J. Sci. 36(3), 312–319 (2009)

D.A. Porter, K.E. Easterling, Phase Transformations in Metals and Alloys, 2nd edn. (Chapman and Hall, London, 1992)

P.M.A. Cortez, Estudo microestrutural da superliga de níquel GTD-111 durante o seu envelhecimento e após tratamentos térmicos de rejuvenescimento. Master thesis in Mechanical Engineering. Universidade do Porto, Portugal, 2014

Acknowledgments

We thank Tractebel Energia S.A. for supply of experimental material and research contributions, CAPES for a scholarship granted to the doctorate student Almir Turazi, and the Central Laboratory of Electron Microscopy of Universidade Federal de Santa Catarina (LCME-UFSC) for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Turazi, A., de Oliveira, C.A.S., Bohórquez, C.E.N. et al. Study of GTD-111 Superalloy Microstructural Evolution During High-Temperature Aging and After Rejuvenation Treatments. Metallogr. Microstruct. Anal. 4, 3–12 (2015). https://doi.org/10.1007/s13632-014-0177-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0177-x