Abstract

This paper provides a useful guide how to characterize material anisotropy by nanoindentation. Hardness and indentation modulus of austenitic stainless steel (grade A304) were characterized by instrumented indentation at the grain scale (at low indentation load and depth of penetration). We applied the grid indentation method on an area containing several grains with different crystallographic orientation which was simultaneously characterized by electron back-scatter diffraction. Hardness and indentation modulus dependencies on crystallographic orientation were then evaluated and compared with single crystal Young’s modulus and finite element simulations.

Similar content being viewed by others

References

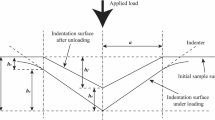

W.C. Oliver, G.M. Pharr, Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1580 (1992)

W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J. Mater. Res. 19, 3–20 (2004)

ISO 14577-2, Instrumented Indentation Test for Hardness and Materials Parameters (ISO, Geneva, 2002)

A.C. Fischer-Cripps, Nanoindentation, 3rd edn. (Springer, New York, 2011)

I.N. Sneddon, The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47–57 (1965)

J.R. Willis, Hertzian contact of anisotropic bodies. J. Mech. Phys. Solids 14, 163–176 (1966)

J.J. Vlassak, W.D. Nix, Indentation modulus of elastically anisotropic half spaces. Philos. Mag. A 67, 1045–1056 (1993)

J.J. Vlassak, W.D. Nix, Measuring the elastic properties of anisotropic materials by means of indentation experiments. J. Mech. Phys. Solids 42, 1223–1245 (1994)

G. Constantinides, K.S. Ravi Chandran, F.-J. Ulm, K.J. Van Vliet, Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater. Sci. Eng. A 430, 189–202 (2006)

N.X. Randall, M. Vandamme, F.-J. Ulm, Nanoindentation analysis as a two-dimensional tool for mapping the mechanical properties of complex surfaces. J. Mater. Res. 24, 679–690 (2009)

J. Nohava, P. Haušild, Š. Houdková, R. Enžl, Comparison of isolated indentation and grid indentation methods for HVOF sprayed cermets. J. Therm. Spray Technol. 21, 651–658 (2012)

P. Haušild, J. Nohava, P. Pilvin, Characterisation of strain-induced martensite in a metastable austenitic stainless steel by nanoindentation. Strain 47, 129–133 (2011)

P. Haušild, A. Materna, J. Nohava, On the identification of stress–strain relation by instrumented indentation with spherical indenter. Mater. Des. 37, 373–378 (2012)

D.T. Sandwell, Biharmonic spline interpolation of GEOS-3 and SEASAT altimeter data. Geophys. Res. Lett. 2, 139–142 (1987)

Marc 2012, Volume A, Theory and User Information, MSC.Software Corporation, 813 p (2012)

H.M. Ledbetter, Predicted monocrystal elastic constants of 304-type stainless steel. Phys. B+C 128, 1–4 (1985)

J.C. Hay, A. Bolshakov, G.M. Pharr, A critical examination of the fundamental relations used in the analysis of nanoindentation data. J. Mater. Res. 14, 2296–2305 (1999)

H.J. Bunge, Quantitative Texture Analysis (Deutsche Gesellschaft für Metallkunde, Berlin, 1982)

J.C. Stinville, C. Tromas, P. Villechaise, C. Templier, Anisotropy changes in hardness and indentation modulus induced by plasma nitriding of 316L polycrystalline stainless steel. Scripta Mater. 64, 37–40 (2011)

C. Tromas, J.C. Stinville, C. Templier, P. Villechaise, Hardness and elastic modulus gradients in plasma-nitrided 316L polycrystalline stainless steel investigated by nanoindentation tomography. Acta Mater. 60, 1965–1973 (2012)

L. Ma, D.J. Morris, S.L. Jennerjohn, D.F. Bahr, L.E. Levine, The role of probe shape on the initiation of metal plasticity in nanoindentation. Acta Mater. 60, 4729–4739 (2012)

Y. Huang, A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program. Mechanics Report 178, Division of Engineering and Applied Sciences, Harvard University, Cambridge, Massachusetts, (1991)

Acknowledgments

This work was carried out in the frame of the research projects GACR P108/12/1872 (Czech Science Foundation) and SGS13/223/OHK4/3T/14 (Grant Agency of the Czech Technical University in Prague).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haušild, P., Materna, A. & Nohava, J. Characterization of Anisotropy in Hardness and Indentation Modulus by Nanoindentation. Metallogr. Microstruct. Anal. 3, 5–10 (2014). https://doi.org/10.1007/s13632-013-0110-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-013-0110-8