Abstract

Chitosan is one of the most abundant biopolymers in nature with high economic value due to its biocompatibility, biodegradability, lack of toxicity, and antifungal activity. In this study, chitosan was extracted from three different sources: Blaps lethifera (CSB), Pimelia fernandezlopezi (CSP), and Musca domestica (CSM). The ash content (AC), moisture content (MC), fat binding capacity (FBC), water binding capacity (WBC), and deacetylation degree (DD) were determined for the prepared chitosans. The effect of the DD of chitosan on the antibacterial activity of gram (positive/negative) bacteria and the azo dyes (methylene blue, MB) removal from wastewater was also investigated. Chitosan extracts showed good antibacterial activity against Listeria innocua, Bacillus subtiliis, Staphylococcus aureus, Salmonella typhimurium, and Pseudomonas aeruginosa. The MB dye removal of CSB-chitosan, CSP-chitosan, and CSM-chitosan reached 37%, 87%, and 26%, respectively, at a contact time of 2 h, a low initial dye concentration MB of 13 ppm, a solution temperature of 25 °C, and a pH = 7.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

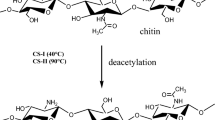

Chitosan is a linear polysaccharide composed of randomly distributed N-acetyl-D-glucosamine and β-linked D-glucosamine. Chitosan is a deacetylated form of chitin (which may be variously deacetylated) and is soluble (sometimes with difficulty) in acidic solutions [1,2,3]. Chitin, which can be extracted from fungi [4], crustaceans [5], and insects [6], can be deacetylated to produce chitosan. This process makes chitin more acid soluble and improves its biological properties, especially its antibacterial activity [7, 8]. The ratio of the two monomer units determines the molecular weight and degree of deacetylation of chitosan, which significantly affects the antibacterial activity of chitosan [7, 9]. However, chitosan’s solubility severely limits its ability to function. Chitosan has three different forms of reactive functional groups: -NH2 at C-2, -OH at C-6, and -OH at C-3. It is frequently used to boost chitosan’s bioactivity and water solubility as well as to combine it with other compounds to broaden its range of applications [10]. The -NH2 group at C-2 distinguishes chitosan from chitin (by less than 50%) in terms of its physical, chemical, and biological activities. The amino group at C-2 and the -OH group at C-6 are the two main chemical alterations that are made to chitosan [2, 11]. The metric determining the molar percentage of monomeric glucosamine units in chitosan is its degree of deacetylation.

Chitosan is a fibrous biopolymer that can reduce the body’s absorption of fat and cholesterol from food [12]. It also helps blood clot when applied to wounds [13]. As a delivery carrier, it has great potential and cannot be compared with other polymers [14]. The Food and Drug Administration (FDA) has approved chitosan as GRAS (generally recognized as safe). Several antimicrobial drugs containing chitosan have been approved by the FDA [10]. Chitosan is partly soluble in water at DD of 70–85% and readily soluble in water at DD of 95–100% but such DD levels are difficult to achieve. Chitosan exhibits an intrinsic antibacterial activity, inhibiting bacteria growth. The rupture of the cell and changes in membrane permeability are brought on by the chitosan chain’s attachment to the negatively charged bacterial cell wall. The next step is binding to DNA, which inhibits DNA replication and results in cell death. Thus, chemical modifications of chitosan such as quaternary ammonium salinization, phosphorylation, sulfonation, and carboxylation can significantly alter its antibacterial capabilities [10].

Adsorption was found to be a very effective and cheap method among all available wastewater treatment methods. Due to the high concentration of –OH and NH2- groups in the polymer skeleton of chitosan and its derivatives, they are environmentally friendly polymers for the adsorption of drugs, dyes, and heavy metals [15]. In this study, chitosan was extracted from three different local sources: Blaps lethifera (CSB), Pimelia fernandezlopezi (CSP), Musca domestica (CSM), and the ash content (AC), moisture content (MC), fat binding capacity (FBC), and water binding capacity (WBC) of the produced chitosan were determined. The effect of DD of chitosan on antibacterial activity and elimination of azo dyes from wastewater was investigated. The factors of operation and medium, including chitosan source, contact time, dye concentration, and pH, were also investigated. The most critical change is that wastewater containing AZO dyes is extremely difficult to treat because the AZO dyes are refractory molecules that are stable to oxidants and resistant to aerobic digestion. Treating wastewater containing low concentrations of AZO dye molecules is another challenge.

2 Materials and methods

2.1 Materials

Acetic acid (CH3COOH; 98%), sodium hydroxide (NaOH,97%), hydrochloric acid (HCl, 99%), hydrogen peroxide (H2O2, 98%), dimethyl sulfoxide (DMSO, 99%), and methylene blue (C16H18ClN3S, 82%) were purchased from Biochem Chemophara. A Bioscan Industrie Algeria provided the Mueller–Hinton agar. Insects (Blaps lethifera, Pimelia fernandezlopezi, Musca domestica) were employed as a variety of local resources to extract chitosan. The insects used in this study are widely distributed worldwide and in Algeria and were not endangered or protected species in the field study. The specimens (insects) were acquired in a dead and dry state, and no special permit was required for access to the site.

2.2 Extraction of chitosan

Chitosan was obtained from different insects (Blaps lethifera, Pimelia fernandezlopezi, Musca domestica) and prepared according to the method of Kaya [16], as shown in Fig. 1, with a slight modification. Briefly, 1 M HCl was applied with 30 g of each insect powder for 1 h at 40 °C. After demineralization, deproteinization steps were performed for 2 h of 1 M NaOH at 80 °C and then washed with water until neutral, and decolorization was performed by treating the obtained polymer with 10 v/v % H2O2 for 30 at 50 °C. The obtained chitin was then subjected to deacetylation with 50 w/v% NaOH, which was repeated to achieve a higher DD in the chitosan. The resulting chitosan was then dried for 24 h in a vacuum oven at 50 °C.

2.3 Physicochemical characterization

After drying, the chitosan was weighed and its water yield was calculated according to the following procedure: Yield (%) = (weight of chitosan dried, g)/(weight of insect, g) × 100. By using FTIR spectroscopy, the DD of chitosan was calculated using the following formula:\(\mathrm{DD}\left(\mathrm{\%}\right)=100-\left[100\times \left({\mathrm{A}}_{1655}/{\mathrm{A}}_{3450}\right)/1.33\right]\), where: A1655 and A3450 cm−1 are, respectively, the absolute heights of the amide and hydroxyl groups’ absorption bands. where the ratio A1655/A3450 for fully N-acetylated chitosan is indicated by the factor of 1.33 [17]. The following equation was used to calculate the chitosan ash (AC) according to a technique described by R.H. Rdde et al. [18]: Ash (%) = (W1/ W2) × 100, where W1 and W2 are the weight of the sample and residue, respectively. Determined was the moisture content (MC) by vacuum-drying the prepared chitosan for 24 h at 110 °C. Moisture content (MC,%) = (W1-W2/ W1) × 100, W1 and W2 are where the weights of the chitosan samples before and after drying, respectively [19]. The extracted chitosan samples’ fat binding capacity (FBC) and water binding capacity (WBC) were measured using a modified method of Wang and Kinsella [19] approach. WBC% = (water bound, g)/(weight of sample, g) × 100 and FBC (%) = (fat bound, g)/(weight of the sample, g) × 100 were used to compute the WBC and FBC [19]. The absorption spectra were recorded using ultraviolet–visible spectroscopy (UV–Vis, UV-2450 Shimadzu) after 0.1 mg of chitosan was dissolved in 2 mL of acetic acid. The crystal structure of chitosan was examined using an X-ray diffractometer (XRD, Rigaku D/Max-2000, Tokyo, Japan) and a Fourier transform infrared spectrophotometer (FTIR, Perkin-Elmer 1725 ×). The morphology of the various chitosan samples was examined using a scanning electron microscope (SEM, Leo Supra 55-Zeiss Inc., Germany).

2.4 Antibacterial bioassay

The agar well diffusion technique was used to investigate the antibacterial activity of chitosan against a variety of bacterial species, i.e., Listeria innocua (CLIP74915), Bacillus subtiliis (ATCC6633), Staphylococcus Aureus (ATCC6538), Salmonella typhimuruim (ATCC14028), and Pseudomonas aeruginosa (ATCC9027). Wells with a diameter of 6 mm were made in each of the agar plates used with a sterile stainless steel cork borer. The culture plates were prepared and sprayed with 100 L of a 24 h matured broth culture of bacterial strains. Chitosan was used to test antibacterial activity at different concentrations (1 w/v%, 4 w/v%, and 8 w/v% in acetic acid). The samples’ antibacterial efficacy was assessed using ciprofloxacin (CIP-5) as a reference. The plates were titrated with 5 µL chitosan solution. The plates were titrated with 5 µL chitosan solution. Figure 6 shows the inhibitory zones after the plates were incubated at 37 °C for 24 h.

2.5 Dye removal experiment

To evaluate the absorption capacity of chitosan, the dye MB (methylene blue) was used as a model pollutant [18]. In an experiment, the MB dye (13 ppm) was stirred with the appropriate amount of chitosan (400 mg) for 2 h to achieve maximum absorption of MB. Then a UV–Vis spectrometer is used to monitor the evolution of the reaction at different time points. Under UV illumination, the experiment of a complete reduction reaction was carried out. It is easy to see that the intense blue hue of the reaction mixture gradually fades and eventually becomes colorless. The centrifugal solution and removal of chitosan were used to cut off absorption. Using a UV–Vis spectrometer, the absorbance was evaluated for MB dye at 663 nm, which is an indication of the removal efficiency of MB. The difference between the MB dye concentration in the aqueous solution before and after absorption was used to quantify the adsorbed (qe):

where qe is the equilibrium concentration of the dye on the adsorbent (mg.g−1); C0 and Ce are the initial and equilibrium concentrations of the dye solutions, respectively (mg.L−1); V is the volume of the dye solution (L), and m is the weight of the chitosan (g). Dye removal efficiency (%) was obtained using Eq:

where Ce is the immediate concentration and C0 is the initial concentration of MB.

3 Results and discussion

3.1 Characteristics of chitosan

Table 1 displays the findings of the present study, which demonstrated that the dry weights of chitosan isolated from insects (CSB, CSP, and CSM) were 50.0%, 41.6%, and 57.9%, respectively. The difference in chitosan yield was due to the chitosan source and the process of removing proteins and impurities during the deacetylation and precipitation process. The WBC value was 515.1% for CSB followed by CSP-chitosan (287.0%) and CSM-chitosan (301.1%). The range of WBC found in CSP-chitosan and CSM-chitosan was slightly lower than that reported by Chu et al. [19] (458–805%), but the value of CSB-chitosan was in agreement with that found. The FBC of the CSB-chitosan was 296.7%, followed by CSP-chitosan with 433.5% and CSM-chitosan with 455.1%. The range of FBC-chitosan in this study (363.3 to 516.9%) was slightly similar to the value reported by Cho et al. and the value observed by Li et al. from 217 to 403% [20]. Ash is the inorganic residue left when chitosan is completely decomposed by heating in the presence of air. The ash content of chitosan is a key indicator of the effectiveness of calcium carbonate removal and the demineralization stage. High-quality chitosan should have an ash content of less than 1% [21]. As indicated in Table 1. The chitosan obtained from CSM had the greatest ash concentration (8.2%), followed by CSP-chitosan (2%) and CSB-chitosan (1.5%), indicating that the chitosan obtained from CSB has the highest quality. Chitosan isolated from CSP (MC) had a moisture content of 17.2%, followed by CSB (14.3%) and CSM (7.8%).

3.2 UV–Vis spectroscopy analysis

The UV–Vis spectra of chitosan extracted from different insects are shown in Fig. 2. The UV–Vis spectra of CSB-chitosan, CSP-chitosan, and CSM-chitosan each show distinctive absorption bands at 338 nm, 261 nm, and 346 nm, respectively. The absorption spectrum of UV–Vis is similar to the absorption maximum at 300–370 nm reported in previous publications for chitosan [22,23,24]. The band at 300–360 nm gives the absorption related to the direct electronic π-d orbitals and is called the Soret band [23, 25]. The sharp UV bands shown for chitosan in the UV range prove strong’s absorption and their potential applications in Wastewater treatment and nanoparticle production [26, 27].

3.3 FTIR spectroscopy analysis

Figure 3 compares the functional groups and displays the FTIR spectra profiles of isolated chitosan from various sources. Analysis of these spectra shows a broader band at 3100–3500 cm−1 related to the stretching vibrations of free -NH2 groups and water molecules with the—OH and -NH atoms, respectively. The C-H stretching was responsible for the absorption peak at about 2850–2950 cm−1. Due to the elimination of the acetyl group, the band at 1623 cm−1 was an amide I formed by interactions between hydrogen and hydroxyl groups (deacetylated chitin). FTIR analysis was used to determine the chitosan’s DD, The value of the DD depends on several factors such as the source of the sample, the method of preparing the sample, the type of devices used in the analysis, and the method and technique of analysis. The relative DD % for CSB, CSP, and CSM are 87.1%, 88.1%, and 84.2%, respectively (Table 1).

3.4 Crystallinity and crystalline structure

The crystalline structure of chitosan depends strongly on its deacetylation process as well as on its amorphous chitin form. The XRD pattern of CSB-chitosan shows two diffraction peaks occurring at (10.7 and 19.9°), and at 11.5° and 20.4° in CSP. For CSM-chitosan, two peaks at 10.5 and 20.2° are shown in Fig. 4. The following equation is used to calculate the chitosan crystallinity index (CrI) [28]:

Iam is the greatest intensity in the corresponding amorphous area at 2 θ ≈ 11°, while I110 is the maximum intensity at 2 θ≈20°. The crystallinity index values of chitosan obtained from the CSB, CSP, and CSM were 84%, 73%, and 81% respectively, Whereas in other studies, the CrI value of chitosan isolated from other insects, including beetles, cuttlefish, shrimp, and silkworms (B. mori), ranged from 36 to 95% [28,29,30].

3.5 Electron microscopy for scanning (SEM)

The chitosan produced from Blaps lethifera, Pimelia fernandezlopezi, and Musca domestica was selected for examination by SEM (Fig. 5), SEM images of CSB-chitosan showed that the surface has become a smooth polymer, (Fig. 5a) [31, 32], and it is observed by a fibrous structure with a rough surface of the structure of CSP-chitosan (Fig. 5b), and a similar observation was reported by Zainab. et al. [33]. The extracted CSM-chitosan was observed to have lumps on the surface polymer, as in the study of Mohammed et al. [34].

3.6 Antibacterial activities

Bacterial cell membranes are negatively charged due to the presence of highly electronegative groups on their constituent lipopolysaccharides and phospholipids. Chitosan can adhere to the surfaces of negatively charged cells and decreases the permeability of the cell membrane; as a result, leading to cell death. Type of bacteria, growth stage, chitosan Mwt, chitosan concentration, medium temperature, and pH are the main factors that influence the antibacteiral activity of chitosan [35]. Figure 6 shows that the extracted chitosans exhibit strong antibacterial activity against gram-negative bacteria (Salmonella typhimurium and Pseudomonas aeruginosa) and gram-positive bacteria (Bacillus subtiliis, Staphylococcus aureus, and Listeria innocua). The results also show that the higher the DD, the greater the positive charge after amino-protonation of chitosan, and the stronger its antibacterial activity [36]. This explains why CSP-chitosan (88.2% DD) shows the strongest antibacterial activity, followed by CSB-chitosan (87.1% DD), then CSM-chitosan (84.1% DD). Moreover, the antibacterial activity of chitosan increases with increasing chitosan concentration from 0 to 8% [37].

One proposed mechanism for the bactericidal effect of chitosan is its direct blocking ability, which prevents nutrients and oxygen from entering the intracellular space. This mechanism is suitable for higher molecular weight chitosan, which forms a polymer membrane on the surface of the bacterial cell [30]. However, due to the different composition of gram-positive and gram-negative cell walls, the interaction of chitosan with these two types of bacteria is different. Some studies reported that the bactericidal effect of chitosan is stronger in gram-negative bacteria than in gram-positive bacteria, due to the higher affinity of amino groups for anionic radicals in the cell wall [38, 39]. In other studies, gram-positive bacteria were thought to be more sensitive to the antimicrobial activity of chitosan, which is due to the gram-negative outer membrane barrier.

Previous studies reported that chitosan showed higher antibacterial activities than chitosan oligomers and significantly inhibited the growth of most bacteria tested, although the inhibitory effects differed with the MW of the chitosan and the bacterium [40]. The influence of Mwt and concentration of chitosan against E. coli was studied by Nan et al. [37], who studied different types of chitosans (Mwt from 5,5104 to 15,5104 KDa) and concentrations (20 to 1000 ppm). The authors reported that at high concentrations (> 200 ppm), chitosan has a direct blocking ability to prevent nutrients and oxygen from reaching the intracellular space. All chitosan samples with Mwt between 5.5 104 and 15.5 104 Da showed this property. This indicates that this mechanism works best with chitosan of higher molecular weight [41]. Low Mwt chitosan has more ability to penetrate the cell membranes and interacts with DNA in a subsequent bactericidal step and prevents the synthesis of mRNA and proteins after it enters the nucleus of bacteria [42].

3.7 Adsorption of methylene blue

The adsorption method is considered the best solution for the removal of industrial dyes from wastewater. The high content of amino functions in chitosan provides new adsorption properties for many metal ions and organic dyes. As shown in Fig. 7, the deacetylated amino groups in chitosan can be protonated, and the polycationic properties of chitosan are expected to contribute to charged interactions with MB, a basic dye. MB molecules can interact with the chitosan functional groups through covalence, electrostatic, and hydrogen bonding. Modification of the chitosan molecule by increasing the degree of acetylation, grafting (insertion of functional groups), or crosslinking reactions with other polymers may result in better adsorption capacity for hazardous pollutants in wastewater and good resistance to extreme media conditions. DD of chitosan is important, as the adsorption capacity of chitosan is high when the value of DD is increased. This can be seen in Fig. 8, where the chitosan- CSP with the highest DD (88.2%) has the highest adsorption capacity (1.7 mg.g−1), compared to 1 mg.g−1 for the CSB chitosan and 0.8 mg.g−1 for the CSM chitosan. Under optimal conditions, the MB removal efficiencies of CSB-chitosan, CSP-chitosan, and CSM-chitosan reached 37%, 87%, and 26%, respectively, within 120 min. Similar results were reported by Dhanasekaran and colleagues [42]. Table 2 shows the AZO dye removal efficiency of chitosan obtained from different sources compared to this work.

4 Conclusion

Insects can be considered important resources for chitin and chitosan. Studies show that the chitin content of various insect species is up to 40% of the exoskeleton on a dry basis. In this study, chitosan was extracted from three different sources: Blaps lethifera (CSB), Pimelia fernandezlopezi (CSP), and Musca domestica (CSM). Chitosan yield was greatest in Musca domestica, 57.9% on a dry basis, followed by Blaps Lethifera and Pimelia Fernandezlopezi with yields of 50.0% and 41.6%, respectively. The degree of deacetylation (DD) for chitosan from CSB, CSP, and CSM were 87.1%, 88.2%, and 84.1%, respectively. The chitosan isolated from Blaps Lethifera possessed the highest crystallinity, according to X-ray powder diffraction (XRD). Chitosan extracts showed good antibacterial activity against gram-positive and gram-negative bacteria including Listeria innocua, Bacillus subtiliis, Staphylococcus aureus, Salmonella typhimuruim, and Pseudomonas aeruginosa. Due to the high concentration of –OH and NH2- groups in the polymer skeleton of chitosan, it has shown high adsorption capacity for azo dye (methylene blue, MB). The adsorption capacity values for chitosan were approximately 1 mg·g−1 for Blaps lethifera (CSB-chitosan), 1.7 mg·g−1 for Pimelia fernandezlopezi (CSP-chitosan), and 0.8 mg·g−1 for Musca domestica (CSM-chitosan) at neutral pH = 7, contact time of 120 min, and initial MB dye concentration of 13 ppm. These results indicate that the selected insects can be used for chitosan extraction, saving many tons of insect waste as sustainable resources for environmental and pharmaceutical applications.

Data availability

The authors confirm that the data supporting the findings of this study are available in the article.

References

Li J, Wu Y, Zhao L (2016) Antibacterial activity and mechanism of chitosan with ultra high molecular weight. Carbohyd Polym 148:200–205

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174

Di Nardo T, Hadad C, Van Nhien AN, Moores A (2019) Synthesis of high molecular weight chitosan from chitin by mechanochemistry and aging. Green Chem 21:3276–3285

Dhillon GS, Kaur S, Brar SK, Verma M (2013) Green synthesis approach: extraction of chitosan from fungus mycelia. Crit Rev Biotechnol 33:379–403

Ibitoye E, Lokman I, Hezmee M, Goh Y, Zuki A, Jimoh A (2018) Extraction and physicochemical characterization of chitin and chitosan isolated from house cricket. Biomed Mater 13:025009

Soon CY, Tee YB, Tan CH, Rosnita AT, Khalina A (2018) Extraction and physicochemical characterization of chitin and chitosan from Zophobas morio larvae in varying sodium hydroxide concentration. Int J Biol Macromol 108:135–142

Hamdine M, Heuzey M-C, Bégin A (2005) Effect of organic and inorganic acids on concentrated chitosan solutions and gels. Int J Biol Macromol 37:134–142

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63

Yang R, Li H, Huang M, Yang H, Li A (2016) A review on chitosan-based flocculants and their applications in water treatment. Water Res 95:59–89

Wu M, Long Z, Xiao H, Dong C (2016) Recent research progress on preparation and application of N, N, N-trimethyl chitosan. Carbohyd Res 434:27–32

Yahyaei M, Mehrnejad F, Naderi-Manesh H, Rezayan AH (2018) Protein adsorption onto polysaccharides: comparison of chitosan and chitin polymers. Carbohyd Polym 191:191–197

Borderías AJ, Sánchez-Alonso I, Pérez-Mateos M (2005) New applications of fibres in foods: addition to fishery products. Trends Food Sci Technol 16:458–465

Archana D, Dutta J, Dutta P (2013) Evaluation of chitosan nano dressing for wound healing: characterization, in vitro and in vivo studies. Int J Biol Macromol 57:193–203

Zhao D, Yu S, Sun B, Gao S, Guo S, Zhao K (2018) Biomedical applications of chitosan and its derivative nanoparticles. Polymers 10:462

Elamri A, Zdiri K, Hamdaoui M, Harzallah O (2022) "Chitosan: a biopolymer for textile processes and products," Textile Research Journal, p. 00405175221127315

Kaya M, Seyyar O, Baran T, Turkes T (2014) Bat guano as new and attractive chitin and chitosan source. Front Zool 11:1–10

Malini M, Thirumavalavan M, Yang W-Y, Lee J-F, Annadurai G (2015) A versatile chitosan/ZnO nanocomposite with enhanced antimicrobial properties. Int J Biol Macromol 80:121–129

Rødde RH, Einbu A, Vårum KM (2008) A seasonal study of the chemical composition and chitin quality of shrimp shells obtained from northern shrimp (Pandalus borealis). Carbohyd Polym 71:388–393

Marei NH, Abd El-Samie E, Salah T, Saad GR, Elwahy AH (2016) Isolation and characterization of chitosan from different local insects in Egypt. Int J Biol Macromole 82:871–877

No HK, Lee KS, Meyers SP (2000) Correlation between physicochemical characteristics and binding capacities of chitosan products. J Food Sci 65:1134–1137

Nessa F, Masum SM, Asaduzzaman M, Roy S, Hossain M, Jahan M (2010) A process for the preparation of chitin and chitosan from prawn shell waste. Bangladesh J Sci Industrial Res 45:323–330

Vijayalekshmi V (2015) UV-Visible, mechanical and anti-microbial studies of chitosan-montmorillonite clay/TiO2 nanocomposites. Res J Recent Sci 4:131–135

Oh J-W, Chun SC, Chandrasekaran M (2019) Preparation and in vitro characterization of chitosan nanoparticles and their broad-spectrum antifungal action compared to antibacterial activities against phytopathogens of tomato. Agronomy 9:21

Amor IB, Hemmami H, Laouini SE, Temam HB, Zaoui H, Barhoum A (2023) Biosynthesis MgO and ZnO nanoparticles using chitosan extracted from Pimelia Payraudi Latreille for antibacterial applications. World J Microbiol Biotechnol 39:1–12

Lou C-W, Chen A-P, Lic T-T, Lin J-H (2014) Antimicrobial activity of UV-induced chitosan capped silver nanoparticles. Mater Lett 128:248–252

Phan TTV, Phan DT, Cao XT, Huynh T-C, Oh J (2021) Roles of chitosan in green synthesis of metal nanoparticles for biomedical applications. Nanomaterials 11:273

Shashikala M, Nagapadma M, Pinto L, Nambiar S (2013) Studies on the removal of methylene blue dye from water using chitosan. Int J Develop Res 3:40–44

Zhang M, Haga A, Sekiguchi H, Hirano S (2000) Structure of insect chitin isolated from beetle larva cuticle and silkworm (Bombyx mori) pupa exuvia. Int J Biol Macromol 27:99–105

Paulino AT, Simionato JI, Garcia JC, Nozaki J (2006) Characterization of chitosan and chitin produced from silkworm crysalides. Carbohyd Polym 64:98–103

Mohan K, Ganesan AR, Muralisankar T, Jayakumar R, Sathishkumar P, Uthayakumar V et al (2020) Recent insights into the extraction, characterization, and bioactivities of chitin and chitosan from insects. Trends Food Sci Technol 105:17–42

Doshi B, Repo E, Heiskanen JP, Sirviö JA, Sillanpää M (2017) Effectiveness of N, O-carboxymethyl chitosan on destabilization of Marine Diesel, Diesel and Marine-2T oil for oil spill treatment. Carbohyd Polym 167:326–336

Triunfo M, Tafi E, Guarnieri A, Salvia R, Scieuzo C, Hahn T et al (2022) Characterization of chitin and chitosan derived from Hermetia illucens, a further step in a circular economy process. Sci Rep 12:1–17

Sweah ZJ, Malk FH, Hussain WA (2020) "Determination of the optical parameter from chitosan doping with nicotine," in AIP Conference Proceedings, p. 020065

Eddya M, Tbib B, Khalil E-H (2020) A comparison of chitosan properties after extraction from shrimp shells by diluted and concentrated acids. Heliyon 6:e03486

Ardean C, Davidescu CM, Nemeş NS, Negrea A, Ciopec M, Duteanu N et al (2021) Factors influencing the antibacterial activity of chitosan and chitosan modified by functionalization. Int J Mol Sci 22:7449

Jung EJ, Youn DK, Lee SH, No HK, Ha JG, Prinyawiwatkul W (2010) Antibacterial activity of chitosans with different degrees of deacetylation and viscosities. Int J Food Sci Technol 45:676–682

Liu N, Chen X-G, Park H-J, Liu C-G, Liu C-S, Meng X-H et al (2006) Effect of MW and concentration of chitosan on antibacterial activity of Escherichia coli. Carbohyd Polym 64:60–65

Lim S-H, Hudson SM (2004) Synthesis and antimicrobial activity of a water-soluble chitosan derivative with a fiber-reactive group. Carbohyd Res 339:313–319

Hosseinnejad M, Jafari SM (2016) Evaluation of different factors affecting antimicrobial properties of chitosan. Int J Biol Macromol 85:467–475

NO PNHK, Lee S, Meyers S (2002) "Antibacterial activity of chitosans and chitosan oligomers with different molecular weights," Int J Food Microbiol vol. 74, pp. 65–72

de Aragão Tavares E, De Medeiros WMTQ, de Assis Pontes TP, Barbosa MM, De Araujo AA, de Araújo RF Jr et al (2019) Chitosan membrane modified with a new zinc (II)-vanillin complex improves skin wound healing in diabetic rats. Front Pharmacol 9:1511

Amidi M, Mastrobattista E, Jiskoot W, Hennink WE (2010) Chitosan-based delivery systems for protein therapeutics and antigens. Adv Drug Deliv Rev 62:59–82

Arunachalam K (2021) Bio-adsorption of methylene blue dye using chitosan-extracted from Fenneropenaeus indicus shrimp shell waste. J Aquac Mar Biol 10:146–150

Dehghani MH, Dehghan A, Alidadi H, Dolatabadi M, Mehrabpour M, Converti A (2017) Removal of methylene blue dye from aqueous solutions by a new chitosan/zeolite composite from shrimp waste: kinetic and equilibrium study. Korean J Chem Eng 34:1699–1707

Haldorai Y, Shim J-J (2014) An efficient removal of methyl orange dye from aqueous solution by adsorption onto chitosan/MgO composite: a novel reusable adsorbent. Appl Surf Sci 292:447–453

Funding

Open Access funding provided by the IReL Consortium Author Ahmed Barhoum was financially supported by the Joint Egyptian Japanese Scientific Cooperation (JEJSC, ID 42811). Open-access funding is provided by the IReL Consortium, thanks to Dublin City University (DCU) along with the Irish Research eLibrary (IReL) for providing an open-access publishing agreement with Springer Nature.

Author information

Authors and Affiliations

Contributions

Conceptualization, IBA, HH, SEL, AB; methodology, IBA, HH, SEL, AB; software, IBA, HH, SEL, AGA, AB; investigation, IBA, HH, SEL, AB; resources, IBA, HH, SEL, AB; data curation, IBA, HH, SEL, AB; writing—original draft preparation, IBA, HH, SEL, AB, writing—review and editing, AB; supervision, IBA, HH, SEL, AB; project administration, SEL, AB; funding acquisition, SEL, AB. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable, the insects used in this study are widely distributed worldwide and in Algeria and were not endangered or protected species in the field study. The specimens (insects) were acquired in a dead and dry state, and no special permit was required for access to the site.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Chitosan was extracted from different insects by acid–base extraction and decolorization.

• Deacetylation degree, ash contents, water binding, and fat binding were determined.

• Antibacterial effects of different types of chitosan were tested against gram-(+ / −) bacteria.

• The efficacy of different types of chitosan to absorb the methylene blue dye was tested.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amor, I.B., Hemmami, H., Laouini, S.E. et al. Influence of chitosan source and degree of deacetylation on antibacterial activity and adsorption of AZO dye from water. Biomass Conv. Bioref. 14, 16245–16255 (2024). https://doi.org/10.1007/s13399-023-03741-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-023-03741-9