Abstract

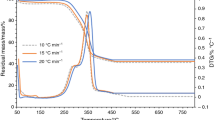

The pyrolysis of the cattle dung was quantified using the Coats-Redfern method. The thermogravimetric and derivate curves (TG/DTG) divided the decomposition into three stages. Apart from stage I (dehydration), stage II exhibited higher thermal decomposition rate in the temperature range of 220–380 °C whereas, in stage III (390–690 °C), a lower decomposition rate was noticed. Comparative kinetic parameters for solid-state reactions showed that first-order reaction (F1) had the highest value of regression coefficient (R2) in both stages. In stage II, the Power-law (P3/2), reaction order-2 and 3 (F2 and F3), and diffusion models (D1 and D2) produced higher activation energy (Ea) values, while 3-diffusion (D3) produced the lowest Ea value. However, in subsequent stage III, only two reaction mechanisms (F1 and F2) were estimated with significant R2 value and F2 showed higher Ea value. The simulated TG/DTG validated that decomposition of cattle dung was best described by F1 in both stages. In addition to kinetic analysis through Coats-Redfern method, mass change at 20 °C/min was also processed by employing artificial neural network (ANN) and the model was validated with a strong R2 value and lower mean squared error (MSE). In thermodynamic analysis, the increase in the heating rate decreased ∆G and increased ∆S for the whole process with stable ∆H. This study provides the theoretical and practical guideline for the utilization of cattle dung as a potential energy source.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article (and/or) its supplementary materials.

References

Wan G, Wang C (2014) Unprecedented urbanisation in Asia and its impacts on the environment. Australian Economic Review 47:378–385. https://doi.org/10.1111/1467-8462.12076

Chang CC, Li R (2019) Agricultural waste. Water Environ Res 91:1150–1167. https://doi.org/10.1002/wer.1211

Edrisi SA, Abhilash PC (2016) Exploring marginal and degraded lands for biomass and bioenergy production: an Indian scenario. Renew Sustain Energy Rev 54:1537–1551. https://doi.org/10.1016/j.rser.2015.10.050

Rahman MM (2020) Exploring the effects of economic growth, population density and international trade on energy consumption and environmental quality in India. Int J Energy Sect Manage 14:1177–1203. https://doi.org/10.1108/IJESM-11-2019-0014

United Nations (2019) The sustainable development goals report 2019. United Nations publication issued by the Department of Economic and Social Affairs 64. https://undocs.org/E/2019/68

Xin Y, Wang D, Li XQ et al (2018) Influence of moisture content on cattle manure char properties and its potential for hydrogen rich gas production. J Anal Appl Pyrol 130:249–255. https://doi.org/10.1016/j.jaap.2018.01.005

Ashraf M, Ramzan N, Khan RU, Durrani AK (2021) Analysis of mixed cattle manure: kinetics and thermodynamic comparison of pyrolysis and combustion processes. Case Studies in Thermal Engineering 26:101078. https://doi.org/10.1016/j.csite.2021.101078

Xin Y, Cao H, Yuan Q, Wang D (2017) Two-step gasification of cattle manure for hydrogen-rich gas production: effect of biochar preparation temperature and gasification temperature. Waste Manage 68:618–625. https://doi.org/10.1016/j.wasman.2017.06.007

Aziz ATHYJAA (2020) Review on cow manure as renewable energy. Modeling and optimization in science and technologies. Springer, pp 203–232

Yue Y, Lin Q, Xu Y et al (2017) Slow pyrolysis as a measure for rapidly treating cow manure and the biochar characteristics. J Anal Appl Pyrol 124:355–361. https://doi.org/10.1016/j.jaap.2017.01.008

Oxenham M (2017) Climate change and cattle farming. Veterinary Record 180:362–363. https://doi.org/10.1136/vr.j1407

Wang Q, Awasthi MK, Zhang Z, Wong JWC (2019) Sustainable composting and its environmental implications. Sustainable resource recovery and zero waste approaches. Elsevier B.V, pp 115–132

Font-Palma C (2019) Methods for the treatment of cattle manure—a review. J Carbon Res 27:1–20. https://doi.org/10.3390/c5020027

Whalen JK, Chang C, Olson BM (2001) Nitrogen and phosphorus mineralization potentials of soils receiving repeated annual cattle manure applications. Biol Fertil Soils 34:334–341. https://doi.org/10.1007/s003740100416

Miao S, Qiao Y, Yin Y et al (2019) Ten-year application of cattle manure contributes to the build-up of soil organic matter in eroded Mollisols. J Soils Sediments 19:3035–3043. https://doi.org/10.1007/s11368-019-02289-4

Rathore NS, Pawar A, Panwar NL (2021) Kinetic analysis and thermal degradation study on wheat straw and its biochar from vacuum pyrolysis under non-isothermal condition. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-01360-w

Mumbach GD, Alves JLF, da Silva JCG et al (2020) Pyrolysis of cocoa shell and its bioenergy potential: evaluating the kinetic triplet, thermodynamic parameters, and evolved gas analysis using TGA-FTIR. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01058-5

Bi H, Wang C, Jiang X et al (2021) Thermodynamics, kinetics, gas emissions and artificial neural network modeling of co-pyrolysis of sewage sludge and peanut shell. Fuel 284:118988. https://doi.org/10.1016/j.fuel.2020.118988

Naqvi SR, Tariq R, Hameed Z et al (2018) Pyrolysis of high-ash sewage sludge: thermo-kinetic study using TGA and artificial neural networks. Fuel 233:529–538. https://doi.org/10.1016/j.fuel.2018.06.089

Rasool T, Srivastava VC, Khan MNS (2018) Utilisation of a waste biomass, walnut shells, to produce bio-products via pyrolysis: investigation using ISO-conversional and neural network methods. Biomass Conversion and Biorefinery 8:647–657. https://doi.org/10.1007/s13399-018-0311-0

Yuan X, He T, Cao H, Yuan Q (2017) Cattle manure pyrolysis process: kinetic and thermodynamic analysis with isoconversional methods. Renewable Energy 107:489–496. https://doi.org/10.1016/j.renene.2017.02.026

Chen G, He S, Cheng Z et al (2017) Comparison of kinetic analysis methods in thermal decomposition of cattle manure by themogravimetric analysis. Biores Technol 243:69–77. https://doi.org/10.1016/j.biortech.2017.06.007

Fernandez-Lopez M, Pedrosa-Castro GJ, Valverde JL, Sanchez-Silva L (2016) Kinetic analysis of manure pyrolysis and combustion processes. Waste Manage 58:230–240. https://doi.org/10.1016/j.wasman.2016.08.027

Naqvi SR, Tariq R, Hameed Z et al (2019) Pyrolysis of high ash sewage sludge: kinetics and thermodynamic analysis using Coats-Redfern method. Renewable Energy 131:854–860. https://doi.org/10.1016/j.renene.2018.07.094

Ali G, Nisar J, Iqbal M et al (2020) Thermo-catalytic decomposition of polystyrene waste: comparative analysis using different kinetic models. Waste Manage Res 38:202–212. https://doi.org/10.1177/0734242X19865339

Balsora HK, Kartik S, Rainey TJ et al (2021) Kinetic modelling for thermal decomposition of agricultural residues at different heating rates. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-01382-4

Shehzad M, Asghar A, Ramzan N et al (2020) Impacts of non-oxidative torrefaction conditions on the fuel properties of indigenous biomass (bagasse). Waste Manage Res 38:1284–1294. https://doi.org/10.1177/0734242X20916843

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Weber B (2019) Real Python. https://realpython.com/matlab-vs-python/#matlab-vs-python-comparing-features-and-philosophy/. Accessed 08/11/2021

Vyazovkin S, Burnham AK, Criado JM et al (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Coats AWRJ (1964) Kinetic parameters from thermogravimetric data. Nature Nature 201:68–69

Varma AK, Singh S, Rathore AK et al (2020) Investigation of kinetic and thermodynamic parameters for pyrolysis of peanut shell using thermogravimetric analysis. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00972-y

Bhattacharjee N, Biswas AB (2020) Physicochemical analysis and kinetic study of orange bagasse at higher heating rates. Fuel 271:117642. https://doi.org/10.1016/j.fuel.2020.117642

Özsin G, Pütün AE (2019) TGA/MS/FT-IR study for kinetic evaluation and evolved gas analysis of a biomass/PVC co-pyrolysis process. Energy Convers Manage 182:143–153. https://doi.org/10.1016/j.enconman.2018.12.060

Yao X, Hu Y, Ge J, et al (2020) A comprehensive study on influence of operating parameters on agglomeration of ashes during biomass gasification in a laboratory-scale gasification system. Fuel 276:. https://doi.org/10.1016/j.fuel.2020.118083

Akyürek Z (2019) Sustainable valorization of animal manure and recycled polyester: co-pyrolysis synergy. Sustainability (Switzerland) 11:1–14. https://doi.org/10.3390/su11082280

Wen S, Yan Y, Liu J et al (2019) Pyrolysis performance, kinetic, thermodynamic, product and joint optimization analyses of incense sticks in N2 and CO2 atmospheres. Renewable Energy 141:814–827. https://doi.org/10.1016/j.renene.2019.04.040

Pravin Kumar SA, Nagarajan R, Midhun Prasad K et al (2019) Thermogravimetric study and kinetics of banana peel pyrolysis: a comparison of ‘model-free’ methods. Biofuels 1:10. https://doi.org/10.1080/17597269.2019.1647375

Tsai WT, Liu SC (2016) Thermochemical characterization of cattle manure relevant to its energy conversion and environmental implications. Biomass Conversion and Biorefinery 6:71–77. https://doi.org/10.1007/s13399-015-0165-7

Tu D, Dong H, Wid BS (2008) Pyrolysis behavior of selected manures using TG-FTTR techniques. Livestock Environment VIII - Proceedings of the 8th International Symposium 215–222. https://doi.org/10.13031/2013.25501

Abdullah A, Ahmed A, Akhter P et al (2020) Bioenergy potential and thermochemical characterization of lignocellulosic biomass residues available in Pakistan. Korean J Chem Eng 37:1899–1906. https://doi.org/10.1007/s11814-020-0624-0

Carballo T, Gil MV, Gómez X et al (2008) Characterization of different compost extracts using Fourier-transform infrared spectroscopy (FTIR) and thermal analysis. Biodegradation 19:815–830. https://doi.org/10.1007/s10532-008-9184-4

Aslam U, Ramzan N, Aslam Z et al (2019) Enhancement of fuel characteristics of rice husk via torrefaction process. Waste Manage Res 37:737–745. https://doi.org/10.1177/0734242X19838620

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Biores Technol 250:422–428. https://doi.org/10.1016/j.biortech.2017.11.077

Ma Z, Wang J, Yang Y et al (2018) Comparison of the thermal degradation behaviors and kinetics of palm oil waste under nitrogen and air atmosphere in TGA-FTIR with a complementary use of model-free and model-fitting approaches. J Anal Appl Pyrol 134:12–24. https://doi.org/10.1016/j.jaap.2018.04.002

Lei Z, Wang S, Fu H et al (2019) Thermal pyrolysis characteristics and kinetics of hemicellulose isolated from Camellia Oleifera Shell. Biores Technol 282:228–235. https://doi.org/10.1016/j.biortech.2019.02.131

Sobek S, Werle S (2020) Isoconversional determination of the apparent reaction models governing pyrolysis of wood, straw and sewage sludge, with an approach to rate modelling. Renewable Energy 161:972–987. https://doi.org/10.1016/j.renene.2020.07.112

Rony AH, Kong L, Lu W et al (2019) Kinetics, thermodynamics, and physical characterization of corn stover (Zea mays) for solar biomass pyrolysis potential analysis. Biores Technol 284:466–473. https://doi.org/10.1016/j.biortech.2019.03.049

Kim YS, Kim YS, Kim SH (2010) Investigation of thermodynamic parameters in the thermal decomposition of plastic waste-waste lube oil compounds. Environ Sci Technol 44:5313–5317. https://doi.org/10.1021/es101163e

Vuppaladadiyam AK, Zhao M, Memon MZ, Soomro AF (2019) Microalgae as a renewable fuel resource: a comparative study on the thermogravimetric and kinetic behavior of four microalgae. Sustainable Energy Fuels 3:1283–1296. https://doi.org/10.1039/c9se00114j

Vasudev V, Ku X, Lin J (2020) Pyrolysis of algal biomass: determination of the kinetic triplet and thermodynamic analysis. Biores Technol 317:124007. https://doi.org/10.1016/j.biortech.2020.124007

Singh YD, Mahanta P, Bora U (2017) Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renewable Energy 103:490–500. https://doi.org/10.1016/j.renene.2016.11.039

Acknowledgements

Authors acknowledge the practical, investigative, and academic support from the Institute of Chemical Engineering and Technology, University of the Punjab, Lahore, and Department of Chemical Engineering, University of Engineering and Technology (Lahore and Kala Shah Kaku Campuses), Pakistan.

Author information

Authors and Affiliations

Contributions

i. Muhammad Ashraf (Ph.D. scholar) did all the experimental work, collected the data, and drafted the initial paper.

ii. Dr. Zaheer Aslam did data analysis and its interpretation, followed by several critical revisions of the main draft.

iii. Dr. Umair Aslam did the characterization work and assisted in ANN theoretical work.

iv. Dr. Naveed Ramzan is the co-supervisor and made revisions in the introduction and experimental sections.

v. Dr. Rafi Ullah Khan supervised this research and made revisions in the kinetic analysis section.

vi. Dr. Abdullah Durrani also co-supervised the work and did revisions on the thermodynamic section.

vii. Miss Samreen Ayaz processed ANN on TGA data.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ashraf, M., Aslam, Z., Ramzan, N. et al. Pyrolysis of cattle dung: model fitting and artificial neural network validation approach. Biomass Conv. Bioref. 13, 10451–10462 (2023). https://doi.org/10.1007/s13399-021-02051-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02051-2