Abstract

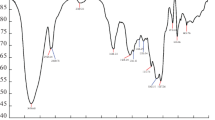

Galactomannans are plant polysaccharides with the beneficial properties, which have a wide range of industrial application. The most important galactomannan derivatives are sulfates, which exhibit the anticoagulant and other biological activities. Here, we report on the results of investigations of the effect of urea-based solvents and activators on the sulfation of galactomannan guar gum with sulfamic acid. It has been shown that 1,4-dioxane is the most effective solvent, while urea is the most effective activator of the sulfation process. The numerical optimization (the Box‒Behnken design) of sulfation of galactomannan guar gum with sulfamic acid in the presence of the most effective activator has been carried out. It has been established that the optimal conditions for obtaining the galactomannan sulfates are a sulfamic acid amount of 34 mmol per 1 g of galactomannan, a temperature of 85 °C, and a time of 2.6 h. The introduction of a sulfate group into a galactomannan molecule has been proven by Fourier transform infra-red spectroscopy. It has been found that the Fourier transform infra-red spectrum of sulfated galactomannan contains absorption bands at 1249 and 817 cm‒1, which correspond to vibrations of the sulfate group. It has been demonstrated using gel permeation chromatography that, during sulfation of guar gum galactomannan by a complex of sulfamic acid and 1,4-dioxane, the molecular weight decreases from 8.5 × 105 to 3.0 × 105 g/mol and the polydispersity value increases from 1.816 to 2.049.

Similar content being viewed by others

References

Thombare N, Jha U, Mishra S, Siddiqui MZ (2016) Guar gum as a promising starting material for diverse applications: a review. Int J Biol Macromol 88:361–372. https://doi.org/10.1016/j.ijbiomac.2016.04.001

Reddy K, Mohan GK, Satla S, Gaikwad S (2011) Natural polysaccharides: versatile excipients for controlled drug delivery systems. Asian J Pharm Sci 6(6):275–286

Liu J, Willför S, Xu C (2015) A review of bioactive plant polysaccharides: biological activities, functionalization, and biomedical applications. Bioact Carbohydr Diet Fibre 5(1):31–61. https://doi.org/10.1016/j.bcdf.2014.12.001

Ahmad S, Ahmad M, Manzoor K, Purwar R, Ikram S (2019) A review on latest innovations in natural gums-based hydrogels: preparations & applications. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.06.113

Nussinovitch A (2010) Plant gum exudates of the world: sources, distribution, properties, and applications CRC Press/Taylor & Francis, Boca Raton

Williams PA (2011) Renewable resources for functional polymers and biomaterials. Polysaccharides, proteins and polyesters. RSC Polymer Chemistry Series. Royal Society of Chemistry, Cambridge.

Mudgil D, Barak S, Khatkar BS (2011) Guar gum: processing, properties and food applications—a review. J Food Sci Technol 51(3):409–418. https://doi.org/10.1007/s13197-011-0522-x

Yamamoto Y (2001) Hypolipidemic effects of a guar gum-xanthan gum mixture in rats fed high sucrose diet. J Jpn Soc Nutr Food Sci 54:139–145

Zhang L-M, Zhou J-F, Hui PS (2005) A comparative study on viscosity behavior of water-soluble chemically modified guar gum derivatives with different functional lateral groups. J Sci Food Agric 85(15):2638–2644. https://doi.org/10.1002/jsfa.2308

Hasan AMA, Abdel-Raouf ME (2018) Applications of guar gum and its derivatives in petroleum industry: a review. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2018.03.005

Jano A, Lame GA, Kokalari TE (2012) Use of extracted green inhibitors as a friendly choice in corrosion protection of low alloy carbon steel Kemija u industriji. J Chem Chem Eng 61(11–12):497–503. https://doi.org/10.15255/KUI.2012.013

About S, Zouarhi M, Chebabe D, Damej M, Berisha A, Hajjaji N (2020) Galactomannan as a new bio-sourced corrosion inhibitor for iron in acidic media. Heliyon 6(3):e03574. https://doi.org/10.1016/j.heliyon.2020.e03574

Adewole JK, Muritala KB (2019) Some applications of natural polymeric materials in oilfield operations: a review. J Petroleum Exploration Prod Technol 9(3):2297–2307. https://doi.org/10.1007/s13202-019-0626-9

Mothé CG, Correia DZ, de França FP, Riga AT (2006) Thermal and rheological study of polysaccharides for enhanced oil recovery. J Therm Anal Calorim 85:31–36. https://doi.org/10.1007/s10973-005-7339-7

Dodi G, Hritcu D, Popa M (2011) Carboxymethylation of guar gum: synthesis and characterization. Cellul Chem Technol 45:171

Gong H, Liu M, Chen J, Han F, Gao C, Zhang B (2012) Synthesis and characterization of carboxymethyl guar gum and rheological properties of its solutions. Carbohyd Polym 88(3):1015–1022. https://doi.org/10.1016/j.carbpol.2012.01.057

Shaikh T, Kumar SS (2011) Pharmaceutical and pharmacological profile of guar gum an overview. Int J Pharm Pharm Sci 3:38–40

Lapasin R, De Lorenzi L, Pricl S, Torriano G (1995) Flow properties of hydroxypropyl guar gum and its long-chain hydrophobic derivatives. Carbohyd Polym 28(3):195–202. https://doi.org/10.1016/0144-8617(95)00134-4

Shi H-Y, Zhang L-M (2007) New grafted polysaccharides based on O-carboxymethyl-O-hydroxypropyl guar gum and N-isopropylacrylamide: synthesis and phase transition behavior in aqueous media. Carbohyd Polym 67(3):337–342. https://doi.org/10.1016/j.carbpol.2006.06.005

Shenoy MA, D’Melo DJ (2010) Synthesis and characterization of acryloyloxy guar gum. J Appl Polym Sci 117:148–154. https://doi.org/10.1002/app.31872

Mestechkina NM, Egorov AV, Shcherbukhin VD (2006) Synthesis of galactomannan sulfates. Appl Biochem Microbiol 42:326. https://doi.org/10.1134/S0003683806030185

Zhang Z, Wang H, Chen T, Zhang H, Liang J, Kong W, Yao J, Zhang J, Wang J (2019) Synthesis and structure characterization of sulfated galactomannan from fenugreek gum. Int J Biol Macromol 125:1184–1191. https://doi.org/10.1016/j.ijbiomac.2018.09.113

Wang X, Wang J, Zhang J, Zhao B, Yao J, Wang Y (2009) Structure-antioxidant relationships of sulfated galactomannan from guar gum. Int J Biol Macromol 46(1):59–66. https://doi.org/10.1016/j.ijbiomac.2009.10.004

Kazachenko AS, Akman F, Sagaama A, Issaoui N, Malyar YN, Vasilieva NY, Borovkova VS (2021) Theoretical and experimental study of guar gum sulfation. J Mol Model 27(1):5. https://doi.org/10.1007/s00894-020-04645-5

Kazachenko AS, Malyar YUN, Vasilyeva NYU, Bondarenko GN, Korolkova IV, Antonov AV, Karacharov AA, Fetisova OYU, Skvortsova GP (2020) Green synthesis and characterization of galactomannan sulfates obtained using sulfamic acid. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-00855-2

Vasilyeva NYu, Levdansky AV, Kuznetsov BN, Skvortsova GP, Kazachenko AS, Djakovitch L, Pinel C (2015) Sulfation of arabinogalactan by sulfamic acid in dioxane. Russ J Bioorg Chem 41:725–731. https://doi.org/10.1134/S1068162015070158

Kazachenko AS, Vasilyeva NYU, Sudakova IG, Levdansky VA, Lutoshkin MA, Kuznetsov BN (2020) Numerical optimization of the abies ethanol lignin sulfation process with sulfamic acid in 1 4 dioxane medium in the presence of urea. J Sib Fed Univ Chem 13(2):232–246. https://doi.org/10.17516/1998-2836-0178

Pen RZ (2014) Planning an experiment at Statgraphics Centurion. Krasnoyarsk: SibSTU, 2014. 293.

Wang X, Wang J, Zhang J, Zhao B, Yao J, Wang Y (2010) Structure–antioxidant relationships of sulfated galactomannan from guar gum. Int J Biol Macromol 46(1):59–66. https://doi.org/10.1016/j.ijbiomac.2009.10.004

Al-Horani RA, Desai UR (2010) Chemical sulfation of small molecules – advances and challenges. Tetrahedron 66(16):2907–2918. https://doi.org/10.1016/j.tet.2010.02.015

Akman F, Kazachenko AS, Vasilyeva NYu, Malyar YuN (2020) Synthesis and characterization of starch sulfates obtained by the sulfamic acid-urea complex. J Mol Struc 1208:127899. https://doi.org/10.1016/j.molstruc.2020.127899

Spillane W, Malaubier JB (2014) Sulfamic acid and its N- and O-substituted derivatives chemical reviews. 114(4):2507–2586. https://doi.org/10.1021/cr400230c

Kuznetsov BN, Vasilyeva NYU, Kazachenko AS, Skvortsova GP, Levdansky VA, Lutoshkin MA (2018) Development of the method of Abies Wood ethanol lignin sulfation using sulfamic acid. J Sib Fed Univ Chem 1(11):122–130. https://doi.org/10.17516/1998-2836-0063

Kuznetsov BN, Levdansky VA, Kuznetsova SA, Garyntseva NV, Sudakova IG, Levdansky AV (2018) Integration of peroxide delignification and sulfamic acid sulfation methods for obtaining cellulose sulfates from aspen wood. Eur J Wood Prod 76(3):999–1007. https://doi.org/10.1007/s00107-017-1262-z

Kazachenko AS, Malyar YuN, Vasilyeva NYu, Fetisova OYu, Chudina AI, Sudakova IG, Antonov AV, Borovkova VS, Kuznetsova SA (2021) Isolation and sulfation of galactoglucomannan from larch wood (Larix Sibirica). Wood Sci Technol. https://doi.org/10.1007/s00226-021-01299-1

Johny LC, Kudre TG, Suresh PV (2021) Production of egg white hydrolysate by digestion with pineapple bromelain: optimization, evaluation and antioxidant activity study. J Food Sci Technol. https://doi.org/10.1007/s13197-021-05188-0

Kazachenko AS, Tomilin FN, Pozdnyakova AA, Vasilyeva NYu, Malyar YuN, Kuznetsova SA, Avramov PV (2020) Theoretical DFT interpretation of infrared spectra of biologically active arabinogalactan sulfated derivatives. Chem Pap. https://doi.org/10.1007/s11696-020-01220-3

Sirviö JA, Ukkola J, Liimatainen H (2019) Direct sulfation of cellulose fibers using a reactive deep eutectic solvent to produce highly charged cellulose nanofibers. Cellulose 26:2303–2316. https://doi.org/10.1007/s10570-019-02257-8

Acknowledgements

This study was carried out using the equipment of the Krasnoyarsk Regional Center for Collective Use, Krasnoyarsk Science Center, Siberian Branch of the Russian Academy of Sciences.

Funding

This study was supported by the Russian Foundation for Basic Research, Government of the Krasnoyarsk Territory, and Krasnoyarsk Territorial Foundation for Support of Scientific and R&D Activities, project no. 20–43-243001. This study was carried out within the budget project #0287–2021-0017 for the Institute of Chemistry and Chemical Technology, Siberian Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

N/A. This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kazachenko, A.S., Malyar, Y.N., Vasilyeva, N.Y. et al. Optimization of guar gum galactomannan sulfation process with sulfamic acid. Biomass Conv. Bioref. 13, 10041–10050 (2023). https://doi.org/10.1007/s13399-021-01895-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01895-y