Abstract

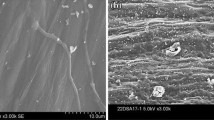

Open rice straw burning has created hazardous effects on the environment and human health. Biological pretreatment of rice straw has been proven as an environmental-benign and economical feasible process for the production of biofuels and value-added products under milder and greener conditions by avoiding harmful chemicals and toxic reagents. A consolidated bioprocess for the production of cellulolytic enzymes and biological pretreatment was developed to achieve a cost-effective saccharification of rice straw. Biodegradation of biomass was slightly enhanced with increase in cultivation time of microbial pretreatment. Furthermore, the modification in biomass due to biological pretreatment weakened the interaction between hemicellulose and lignin that resulted in significant reduction in lignin using Bacillus subtilis subsp. subtilis JJBS300, Myceliophthora thermophila BJTLRMDU3, and Aspergillus oryzae SBS50 for biological pretreatment of rice straw. Bacterial culture produced maximum FPase, CMCase, and β-glucosidase of 28, 17, and 20.36 U/g DMR after 2 days during pretreatment process, whereas M. thermophila produced maximum FPase (85.10 U/g DMR), CMCase (96.89 U/g DMR), and β-glucosidase (91.92 U/g DMR) after 9 days. The mold A.oryzae SBS50 also produced maximum FPase (57.41 U/g DMR), CMCase (55.36 U/g DMR), and β-glucosidase (48.04 U/g DMR) after 9 days of pretreatment. Maximum amount of reducing sugars of 52.41, 86.74, and 49.59 mg/g substrate were liberated from 6-, 5-, and 3-day-old biological pretreated rice straw by B. subtilis, M. thermophila, and A. oryzae, respectively, after enzymatic hydrolysis for 6 h at 60 oC and pH 5.0. Laccase-pretreated rice straw followed by enzymastic saccharification resulted in liberation of 162.82 mg/g reducing sugars at pH 5.0 and 60 °C after 6h using 20 U/g cellulase. Simultaneous laccase pretreatment and saccharification (SLPS) process further enhanced the liberated reducing sugars, i.e., 179.47 mg/g substrate. FTIR, XRD, and SEM analyses showed marked morphological changes as a result of delignification after biological pretreatment of rice straw. Biological pretreatment being an environmental-benign process causing no harm to the environment in comparison to physical and chemical pretreatments of lignocellulosic biomass could be a better pretreatment strategy for bioremediation of lignocellulosic substrates.

Similar content being viewed by others

References

Sawatdeenarunat C, Surendra KC, Takara D, Oechsner H, Khanal SK (2015) Anaerobic digestion of lignocellulosic biomass: challenges and opportunities. Bioresour Technol 178:178–186

Anu, Kumar A, Rapoport A, Kunze G, Kumar S, Singh D, Singh B (2020a) Multifarious pretreatment strategies for the lignocellulosic substrates for the generation of renewable and sustainable biofuels: a review. Renew Energy 160:1228–1252

Anu, Kumar A, Singh D, Kumar V, Singh B (2020b) Production of cellulolytic enzymes by Myceliophthora thermophila and their applicability in saccharification of rice straw. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00783-1

Akhtar N, Gupta K, Goyal D, Goyal A (2016) Recent advances in pretreatment technologies for efficient hydrolysis of lignocellulosic biomass. Environ Prog Sustain Energy 35:489–511

Seidl PR, Goulart AK (2016) Pretreatment processes for lignocellulosic biomass conversion to biofuels and bioproducts. Curr Opin Green Sustain Chem 2:48–53

Rajendran K, Drielak E, Varma VS, Muthusamy S, Kumar G (2017) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production–a review. Biomass Convers Biorefin 8:471–483

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass–an overview. Bioresour Technol 199:76–82

Su Y, Yu X, Sun Y, Wang G, Chen H, Chen G (2018) Evaluation of screened lignin-degrading fungi for the biological pretreatment of corn stover. Sci Rep 8:1–11

Shah TA, Lee CC, Orts WJ, Tabassum R (2018) Biological pretreatment of rice straw by ligninolytic Bacillus sp. strains for enhancing biogas production. Environ Prog Sustain Energy 38:e13036

Wagner AO, Lackner N, Mutschlechner M, Prem EM, Markt R, Illmer P (2018) Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 11:1797

Emerson R (1941) An experimental study on the life cycles and taxonomy of Allomyces. Lloydia 4:77–144

Sapna SB (2013) Improved production of protease-resistant phytase by Aspergillus oryzae and its applicability in the hydrolysis of insoluble phytates. J Ind Microbiol Biotechnol 40:891–899

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Kim S, Holtzapple MT (2006) Effect of structural features on enzyme digestibility of corn stover. Bioresour Technol 97:583–591

Li G, Zhang H, Lu Y, Xue H (2019) Solid state fermentation process coupled biological pretreatment with cellulase production by Piptoporus betulinus for enhanced cellulose hydrolysis. Cellulose 26:3815–3824

Tsegaye B, Balomajumder C, Roy P (2018) Biodegradation of wheat straw by Ochrobactrum oryzae BMP03 and Bacillus sp. BMP01 bacteria to enhance biofuel production by increasing total reducing sugars yield. Environ Sci Pollut Res 25:30585–30596

Tohamy EY, El-Gamal AD, Abouelwafa AM (2019) Bioconversion of rice straw into bioethanol by enzymatic hydrolysis of Bacillus subtilis. IOSR J Pharm Biol Sci 14:09–29

Baramee S, Siriatcharanon AK, Ketbot P, Teeravivattanakit T, Waeonukul R, Pason P, Tachaapaikoon C, Ratanakhanokchai K, Phitsuwan P (2020) Biological pretreatment of rice straw with cellulase-free xylanolytic enzyme-producing Bacillus firmus K-1: structural modification and biomass digestibility. Renew Energy 160:555–563

Kaur P, Kocher GS, Taggar MS (2017) Optimization of saccharification of biological pre-treated rice straw by response surface methodology. Int J Curr Microbiol App Sci 6:1112–1123

Zhang D, Luo Y, Chu S, Zhi Y, Wang B, Zhou P (2016) Biological pretreatment of rice straw with Streptomyces griseorubens JSD-1 and its optimized production of cellulase and xylanase for improved enzymatic saccharification efficiency. Prep Biochem Biotechnol 46:575–585

Ramarajan R, Manohar CS (2017) Biological pretreatment and bioconversion of agricultural wastes, using ligninolytic and cellulolytic fungal consortia. Bioremediat J 21:89–99

Potumarthi R, Baadhe RR, Nayak P, Jetty A (2013) Simultaneous pretreatment and sacchariffication of rice husk by Phanerochete chrysosporium for improved production of reducing sugars. Bioresour Technol 128:113–117

Mohan PR, Ramesh B, Reddy OVS (2012) Biological pretreatment of rice straw by Phenarocheate chrysosporium for the production of cellulases and xylanases using Aspergillus niger isolate. Res J Microbiol 7:1

Noori MS, Karimi K (2016) Chemical and structural analysis of alkali pretreated pinewood for efficient ethanol production. RSC Adv 6:65683–65690

Mohanram S, Rajan K, Carrier DJ, Nain L, Arora A (2015) Insights into biological delignification of rice straw by Trametes hirsuta and Myrothecium roridum and comparison of saccharification yields with dilute acid pretreatment. Biomass Bioenergy 76:54–60

Khedr FG, Tohamy EY, El-Gamal AD, Abouel wafa AM (2019) Bioconversion of rice straw into bioethanol by enzymatic hydrolysis of Bacillus subtilis. IOSR J Pharm BiolSci (IOSR-JPBS) Ser. IV, 14:09–29

Balasubramaniam MK, Rajarathinam R (2013) Implementation of white rot fungal pretreated rice straw for sustainable bioethanol production by Saccharomyces cerevisiae. Int J Eng Res 2:4047–4053

Sreemahadevan S, Roychoudhury PK, Thankamani V, Ahammad SZ (2018) Biological pretreatment of rice straw using an alkalophilic fungus MVI. 2011 for enhanced enzymatic hydrolysis yield. Sustain Energy Technol Assess 30:304–313

Chen KJ, Tang JC, Xu BH, Lan SL, Cao Y (2019) Degradation enhancement of rice straw by co-culture of Phanerochaete chrysosporium and Trichoderma viride. Sci Rep 9:1–7

Rastogi S, Soni R, Kaur J, Soni SK (2016) Unravelling the capability of Pyrenophora phaeocomes S-1 for the production of ligno-hemicellulolytic enzyme cocktail and simultaneous bio-delignification of rice straw for enhanced enzymatic saccharification. Bioresour Technol 222:458–469

Dai Y, Si M, Chen Y, Zhang N, Zhou M, Liao Q, Shi D, Liu Y (2015) Combination of biological pretreatment with NaOH/Urea pretreatment at cold temperature to enhance enzymatic hydrolysis of rice straw. Bioresour Technol 198:725–731

Madian HR, El-Gendy NS, Farahat LA, Ragab AME (2012) Fungal hydrolysis and saccharification of rice straw and ethanol production. Biosci Biotechnol Res Asia 9:467–476

Lloret L, Eibes G, Feijoo G, Moreira MT, Lema JM (2012) Degradation of estrogens by laccase from Myceliophthora thermophila in fed-batch and enzymatic membrane reactors. J Hazard Mater 213:175–183

Sarnthima R, Khammuang S (2018) Laccase from Lentinus polychrous increases the efficiency of cellulose hydrolysis of rice straw to glucose. Orient J Chem 34:1961–1967

Bala A, Singh B (2019) Development of an environmental-benign process for efficient pretreatment and saccharification of Saccharum biomasses for bioethanol production. Renew Energy 130:12–24

Dhiman SS, Haw JR, Kalyani D, Kalia VC, Kang YC, Lee JK (2015) Simultaneous pretreatment and saccharification: green technology for enhanced sugar yields from biomass using a fungal consortium. Bioresour Technol 179:50–57

Bhardwaj N, Kumar B, Agrawal K, Verma P (2020) Bioconversion of rice straw by synergistic effect of in-house produced ligno-hemicellulolytic enzymes for enhanced bioethanol production. Bioresour Technol Rep 10:100352

Li J, Yei X, Ruan S, Cai L, Chang Z (2010) Enzymatic hydrolysis of rice straw pretreated with ammonia. Conference on Environmental Pollution and Public Health:482–485

Phitsuwan P, Permsriburasuk C, Baramee S, Teeravivattanakit T, Ratanakhanokchai K (2017) Structural analysis of alkaline pretreated rice straw for ethanol production. Int J Polym Sci 2017:1–9

Wang L, Han G, Zhang Y (2007) Comparative study of composition, structure and properties of Apocynum venetum fibers under different pretreatments. Carbohydr Polym 69:391–397

Barman DN, Haque MA, Kang TH, Kim GH, Kim TY, Kim MK, Yun HD (2014) Effect of mild alkali pretreatment on structural changes of reed (Phragmites communis Trinius) straw. Environ Technol 35:232–241

Lionetto F, Del Sole R, Cannoletta D, Vasapollo G, Maffezzoli A (2012) Monitoring wood degradation during weathering by cellulose crystallinity. Materials 5:1910–1922

Binod P, Satyanagalakshmi K, Sindhu R, Janu KU, Sukumaran RK, Pandey A (2012) Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew Energy 37:109–116

Waghmare N, Khandare PR, Jeon RVBH, Govindwar SP (2018) Enzymatic hydrolysis of biologically pretreated sorghum husk for bioethanol production. Biofuel Res J 5:846–853

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10

Millati R, Syamsiah S, Niklasson C, Cahyanto MN, Ludquist K, Taherzadeh MJ (2011) Biological pretreatment of lignocelluloses with white-rot fungi and its applications: a review. BioResources 6:5224–5259

Zeng J, Singh D, Chen S (2011) Biological pretreatment of wheat straw by Phanerochaete chrysosporium supplemented with inorganic salts. Bioresour Technol 102:3206–3214

Mustafa AM, Poulsen TG, Sheng K (2016) Fungal pretreatment of rice straw with Pleurotus ostreatus and Trichoderma reesei to enhance methane production under solid-state anaerobic digestion. Appl Energy 180:661–671

Tye YY, Lee KT, Abdullah WNW, Leh CP (2016) The world availability of non-wood lignocellulosic biomass for the production of cellulosic ethanol and potential pretreatments for the enhancement of enzymatic saccharification. Renew Sust Energ Rev 60:155–172

Aslanzadeh S, Ishola MM, Richards T, Taherzadeh MJ (2014) An overview of existing individual unit operations. In Biorefineries 3–36 Elsevier

Liu QP, Hou XD, Li N, Zong MH (2012) Ionic liquids from renewable biomaterials: synthesis, characterization and application in the pretreatment of biomass. Green Chem 14:304–307

Zabed HM, Akter S, Yun J, Zhang G, AwadFN QX, Sahu JN (2019) Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew Sust Energ Rev 105:105–128

Baral NR, Shah A (2017) Comparative techno-economic analysis of steam explosion, dilute sulfuric acid, ammonia fiber explosion and biological pretreatments of corn stover. Bioresour Technol 232:331–343

Chen Y, Huang J, Li Y (2015) Study of the rice straw biodegradation in mixed culture of Trichoderma viride and Aspergillus niger by GCMS and FTIR. Environ Sci Pollut Res 22:9807–9815

Canam T, Dumonceaux TJ, Record E, Li Y (2013) White-rot fungi: the key to sustainable biofuel production? Biofuels 4:247–250

Acknowledgements

The authors acknowledge the Haryana State Council for Science and Technology for the financial assistance in the form of research project (HSCST/R&D/2017/62) and fellowship (1743, dated 12/04/2017) during the tenure of this research work. The authors acknowledge the Department of Science and Technology for providing FIST grant (No. 1196 SR/FST/LS-I/2017/4) for basic infrastructure facility. We are also thankful to Dr. Rajvinder Singh, Department of Genetics (Forensic Science) M.D.U., Rohtak, for FTIR facility and Dr. Anil Ohlan, Department of Physics, M.D.U., Rohtak, for XRD facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anu, Kumar, V., Singh, D. et al. A greener, mild, and efficient bioprocess for the pretreatment and saccharification of rice straw. Biomass Conv. Bioref. 13, 4121–4133 (2023). https://doi.org/10.1007/s13399-021-01450-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01450-9