Abstract

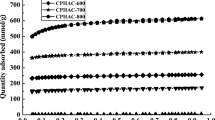

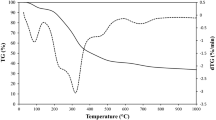

Activated carbon was synthesized from the New Rice for Africa (NERICA) rice husk variety, followed by its evaluation for removal of humic acid from water. Product values of carbon yield, C and total specific surface area, as,BET were employed as the performance criterion. The best physically activated carbon resulted from char activation at 800 °C for 10 min, leading to as,BET and C×as,BET values of 756.8 and 402.7 m2 g−1, respectively. The best chemically activated carbon resulted from 30 wt% H3PO4 activation of rice husk at 400 °C for 30 min, leading to as,BET and C×as,BET values of 2258.4 and 1058.7 m2 g−1, respectively. Despite the higher as,BET value, the maximum adsorption capacity of the best chemically activated carbon (5.3 mg g−1) was found lower than 8.9 and 27.2 mg g−1 exhibited by the chemically activated carbons prepared at 500 and 600 °C, respectively. The best adsorption conditions included carbon dose of 0.5 g, solution pH of 2, and contact time of 60 min. The adsorption capacity of the prepared activated carbons (27.2 mg g−1) was comparable to that of the commercial activated carbon (30.40 mg g−1). The analyses of the adsorption isotherms and kinetics revealed that the experimental data fits well the Langmuir isotherm model, as well as the pseudo-second-order kinetic model. The latter suggests that the adsorption of humic acid onto the activated carbon was controlled by the chemisorption process. Overall, the study revealed that the NERICA rice husk variety has good prospects for preparation of activated carbons for humic acid adsorption.

Similar content being viewed by others

References

Bouras HD, Benturki O, Bouras N, Attou M, Donnot A, Merlin A, Addoun F, Holtz MD (2015) The use of an agricultural waste material from Ziziphus jujuba as a novel adsorbent for humic acid removal from aqueous solutions. J Mol Liq 211:1039–1046. https://doi.org/10.1016/j.molliq.2015.08.028

Kastl G, Sathasivan A, Fisher I (2016) A selection framework for NOM removal process for drinking water treatment. Desalin Water Treat 57(17):7679–7689. https://doi.org/10.1080/19443994.2015.1044476

Korotta-Gamage SM, Sathasivan A (2017) A review: potential and challenges of biologically activated carbon to remove natural organic matter in drinking water purification process. Chemosphere 167:120–138. https://doi.org/10.1016/j.chemosphere.2016.09.097

Jacangelo JG, DeMarco J, Owen DM, Randtke SJ (1995) Selected processes for removing NOM: an overview. J Am Water Works Assoc 87(1):64–77. https://doi.org/10.2307/41295153

Wang W, Wang W, Fan Q, Wang Y, Qiao Z, Wang X (2014) Effects of UV radiation on humic acid coagulation characteristics in drinking water treatment processes. Chem Eng J 256:137–143. https://doi.org/10.1016/j.cej.2014.06.113

Metsämuuronen S, Sillanpää M, Bhatnagar A, Mänttäri M (2014) Natural organic matter removal from drinking water by membrane technology. Sep Purif Rev 43(1):1–61. https://doi.org/10.1080/15422119.2012.712080

Heijman SGJ, Van Paassen AM, Van Der Meer WGJ, Hopman R (1999) Adsorptive removal of natural organic matter during drinking water treatment. Water Sci Technol 40(9):183–190. https://doi.org/10.1016/S0273-1223(99)00655-1

Matilainen A, Sillanpää M (2010) Removal of natural organic matter from drinking water by advanced oxidation processes. Chemosphere 80(4):351–365. https://doi.org/10.1016/j.chemosphere.2010.04.067

Yan WL, Bai R (2005) Adsorption of lead and humic acid on chitosan hydrogel beads. Water Res 39(4):688–698. https://doi.org/10.1016/j.watres.2004.11.007

Joseph L, Flora JRV, Park Y-G, Badawy M, Saleh H, Yoon Y (2012) Removal of natural organic matter from potential drinking water sources by combined coagulation and adsorption using carbon nanomaterials. Sep Purif Technol 95:64–72. https://doi.org/10.1016/j.seppur.2012.04.033

Johnson BR, Eldred TB, Nguyen AT, Payne WM, Schmidt EE, Alansari AY, Amburgey JE, Poler JC (2016) High-capacity and rapid removal of refractory NOM using nanoscale anion exchange resin. ACS Appl Mater Interfaces 8(28):18450–18549. https://doi.org/10.1021/acsami.6b04368

Bhatnagar A, Sillanpää M (2017) Removal of natural organic matter (NOM) and its constituents from water by adsorption—a review. Chemosphere 166:497–510. https://doi.org/10.1016/j.chemosphere.2016.09.098

Lee D-J, Cheng Y-L, Wong R-J, Wang X-D (2018) Adsorption removal of natural organic matters in waters using biochar. Bioresour Technol 260:413–416. https://doi.org/10.1016/j.biortech.2018.04.016

Bjorklund K, Li LY (2017) Adsorption of organic stormwater pollutants onto activated carbon from sewage sludge. J Environ Manag 197:490–497. https://doi.org/10.1016/j.jenvman.2017.04.011

Betancur M, Martínez JD, Murillo R (2009) Production of activated carbon by waste tire thermochemical degradation with CO2. J Hazard Mater 168(2–3):882–887. https://doi.org/10.1016/j.jhazmat.2009.02.167

Iriarte-Velasco U, Álvarez-Uriarte JI, Chimeno-Alanís N, González-Velasco JR (2008) Natural organic matter adsorption onto granular activated carbons: implications in the molecular weight and disinfection byproducts formation. Ind Eng Chem Res 47:7868–7876. https://doi.org/10.1021/ie800912y

Omri A, Lambert SD, Geens J, Bennour F, Benzina M (2014) Synthesis, surface characterization and photocatalytic activity of TiO2 supported on almond Shell activated carbon. J Mater Sci Technol 30(9):894–902. https://doi.org/10.1016/j.jmst.2014.04.007

Hashemian S, Salari K, Yazdi ZA (2014) Preparation of activated carbon from agricultural wastes (almond shell and orange peel) for adsorption of 2-pic from aqueous solution. J Ind Eng Chem 20(4):1892–1900. https://doi.org/10.1016/j.jiec.2013.09.009

Ossman ME, Mansour MS, Fattah MA, Taha N, Kiros Y (2014) Peanut shells and talc powder for removal of hexavalent chromium from aqueous solutions. Bulg Chem Commun 46(3):629–639

Ismanto AE, Wang S, Soetaredjo FE, Ismadji S (2010) Preparation of capacitor’s electrode from cassava peel waste. Bioresour Technol 101(10):3534–3540. https://doi.org/10.1016/j.biortech.2009.12.123

Foo KY, Hameed BH (2012) Porous structure and adsorptive properties of pineapple peel based activated carbons prepared via microwave assisted KOH and K2CO 3 activation. Microporous Mesoporous Mater 148(1):191–195. https://doi.org/10.1016/j.micromeso.2011.08.005

Tehrani NF, Aznar JS, Kiros Y (2015) Coffee extract residue for production of ethanol and activated carbons. J Clean Prod 91:64–70. https://doi.org/10.1016/j.jclepro.2014.12.031

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y (2018) Characterization and alkaline pretreatment of rice husk varieties in Uganda for potential utilization as precursors in the production of activated carbon and other value-added products. Waste Manag 81:104–116. https://doi.org/10.1016/j.wasman.2018.09.050

FAO (2017) Rice Market Monit XX2:1–32

Isoda N, Rodrigues R, Silva A, Gonçalves M, Mandelli D, Figueiredo FCA, Carvalho WA (2014) Optimization of preparation conditions of activated carbon from agriculture waste utilizing factorial design. Powder Technol 256:175–181. https://doi.org/10.1016/j.powtec.2014.02.029

Somasundaram S, Sekar K, Gupta VK, Ganesan S (2013) Synthesis and characterization of mesoporous activated carbon from rice husk for adsorption of glycine from alcohol-aqueous mixture. J Mol Liq 177:416–425. https://doi.org/10.1016/j.molliq.2012.09.022

Guo Y, Zhao J, Zhang H, Yang S, Qi J, Wang Z, Xu H (2005) Use of rice husk-based porous carbon for adsorption of Rhodamine B from aqueous solutions. Dyes Pigments 66(2):123–128. https://doi.org/10.1016/j.dyepig.2004.09.014

Muniandy L, Adam F, Mohamed AR, Ng EP (2014) The synthesis and characterization of high purity mixed microporous/mesoporous activated carbon from rice husk using chemical activation with NaOH and KOH. Microporous Mesoporous Mater 197:316–323. https://doi.org/10.1016/j.micromeso.2014.06.020

Kalderis D, Bethanis S, Paraskeva P, Diamadopoulos E (2008) Production of activated carbon from bagasse and rice husk by a single-stage chemical activation method at low retention times. Bioresour Technol 99(15):6809–6816. https://doi.org/10.1016/j.biortech.2008.01.041

Liou TH, Wu SJ (2009) Characteristics of microporous/mesoporous carbons prepared from rice husk under base- and acid-treated conditions. J Hazard Mater 171(1–3):693–703. https://doi.org/10.1016/j.jhazmat.2009.06.056

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y, John MJ (2019) Optimization of pyrolysis conditions for char production from rice husks and its characterization as a precursor for production of activated carbon. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-019-00399-0

Kumagai S, Shimizu Y, Toida Y, Enda Y (2009) Removal of dibenzothiophenes in kerosene by adsorption on rice husk activated carbon. Fuel 88(10):1975–1982. https://doi.org/10.1016/j.fuel.2009.03.016

Anisuzzaman SM, Joseph CG, Taufiq-Yap YH, Krishnaiah D, Tay VV (2015) Modification of commercial activated carbon for the removal of 2,4-dichlorophenol from simulated wastewater. J King Saud Univ - Sci 27(4):318–330. https://doi.org/10.1016/j.jksus.2015.01.002

Luo Y, Li D, Chen Y, Sun X, Cao Q, Liu X (2019) The performance of phosphoric acid in the preparation of activated carbon-containing phosphorus species from rice husk residue. J Mater Sci 54(6):5008–5021. https://doi.org/10.1007/s10853-018-03220-x

Anzai T, Matsuura Y, Sugawara T, Miura O (2016) Removal of humic acid in water by rice hull magnetic activated carbon and magnetic separation. IEEE Trans Appl Supercond 26(4):8–11. https://doi.org/10.1109/TASC.2015.2512218

Daifullah AAM, Girgis BS, Gad HMH (2004) A study of the factors affecting the removal of humic acid by activated carbon prepared from biomass material. Colloids Surfaces A Physicochem Eng Asp 235(1–3):1–10. https://doi.org/10.1016/j.colsurfa.2003.12.020

Kalderis D, Koutoulakis D, Paraskeva P, Diamadopoulos E, Otal E, Valle JO, Fernández-Pereira C (2008) Adsorption of polluting substances on activated carbons prepared from rice husk and sugarcane bagasse. Chem Eng J 144(1):42–50. https://doi.org/10.1016/j.cej.2008.01.007

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y (2018) Production and performance of activated carbon from rice husks for removal of natural organic matter from water: a review. Chem Eng Res Des 129:271–296. https://doi.org/10.1016/j.cherd.2017.11.008

Yusuff AS (2019) Adsorption of hexavalent chromium from aqueous solution by Leucaena leucocephala seed pod activated carbon : equilibrium , kinetic and thermodynamic studies. Arab J Basic Appl Sci 26(1):89–102. https://doi.org/10.1080/25765299.2019.1567656

Boehm HP (1994) Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon N Y 32(5):759–769

Levchuk I, Rueda Márquez JJ, Sillanpää M (2018) Removal of natural organic matter (NOM) from water by ion exchange—a review. Chemosphere 192:90–104. https://doi.org/10.1016/j.chemosphere.2017.10.101

Ahmad AL, Hameed BH, Maarof HI (2004) Adsorption isotherms for phenol onto activated carbon. Asean J Chem Eng 4(1):70–76

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. Kungliga Svenska Vetenskapsakademiens Handlingar 24:1–39

Ho Y, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124

Kumar A, Jena HM (2016) Preparation and characterization of high surface area activated carbon from fox nut (Euryale ferox) shell by chemical activation with H3PO4. Results Phys 6:651–658. https://doi.org/10.1016/j.rinp.2016.09.012

Giraldo L, Ladino Y, Pirajánc JCM, Rodríguez MP (2007) Synthesis and characterization of activated carbon fibers from Kevlar. Eclética Química 32(4):55–62. https://doi.org/10.1590/S0100-46702007000400008

Mi T, Chen L, Xin S, Yu X (2015) Activated carbon from the Chinese herbal medicine waste by H3PO4 activation. J Nanomater 2015:1–9. https://doi.org/10.1155/2015/910467

Yakout SM, Sharaf El-Deen G (2016) Characterization of activated carbon prepared by phosphoric acid activation of olive stones. Arab J Chem 9:S1155–S1162. https://doi.org/10.1016/j.arabjc.2011.12.002

Prahas D, Kartika Y, Indraswati N, Ismadji S (2008) Activated carbon from jackfruit peel waste by H3PO4 chemical activation: pore structure and surface chemistry characterization. Chem Eng J 140(1–3):32–42. https://doi.org/10.1016/j.cej.2007.08.032

Yacob AR, Al Swaidan HM (2011) Phosphoric acid effect on prepared activated carbon from Saudi Arabia’s date frond waste. Appl Mech Mater 110–116:2124–2130. https://doi.org/10.4028/www.scientific.net/amm.110-116.2124

Johns MM, Toles AC, EW Marshall (2003) Activated carbons from low-density agricultural waste., US 6,537,947 B1

Chun YN, Lim MS, Yoshikawa K (2012) Characteristics of the product from steam activation of sewage sludge. J Ind Eng Chem 18:839–847. https://doi.org/10.1016/j.jiec.2011.11.144

Aznar JS (2011) Characterization of activated carbon produced from coffee residues by chemical and physical activation. KTH Royal Institute of Technology

Lee CL et al (2017) Effect of reaction time and temperature on the properties of carbon black made from palm kernel and coconut shell. Asian J Sci Res 10:24–33. https://doi.org/10.3923/ajsr.2017.24.33

Kazmierezak J, Nowicki P, Pietrzak R (2013) Sorption properties of activated carbons obtained from corn cobs by chemical and physical activation. Adsorption 19:273–281. https://doi.org/10.1007/s10450-012-9450-y

Nowicki P, Kazmierczak J, Pietrzak R (2015) Comparison of physicochemical and sorption properties of activated carbons prepared by physical and chemical activation of cherry stones. Powder Technol 269:312–319. https://doi.org/10.1016/j.powtec.2014.09.023

Anisuzzaman SM, Joseph CG, Daud WMABW, Krishnaiah D, Yee HS (2015) Preparation and characterization of activated carbon from Typha orientalis leaves. Int J Ind Chem 6:9–21. https://doi.org/10.1007/s40090-014-0027-3

Serp P, Machado BF (2015) Nanostructured carbon materials for catalysis. In: Nanostructured Carbon Materials for Catalysis. Royal Society of Chemistry, Cambridge, UK, pp 1–45. https://doi.org/10.1039/9781782622567

Álvarez J, Lopez G, Amutio M, Bilbao J, Olazar M (2015) Physical activation of rice husk pyrolysis char for the production of high surface area activated carbons. Ind Eng Chem Res 54:7241–7250. https://doi.org/10.1021/acs.iecr.5b01589

Rahman MM, Awang M, Mohosina BS, Kamaruzzaman BY, Nik WBW, Adnan CMC (2012) Waste palm shell converted to high efficient activated carbon by chemical activation method and its adsorption capacity tested by water filtration. APCBEE Procedia 1(0):293–298. https://doi.org/10.1016/j.apcbee.2012.03.048

Braghiroli FL, Fierro V, Parmentier J, Vidal L, Gadonneix P, Celzard A (2015) Hydrothermal carbons produced from tannin by modification of the reaction medium : addition of H + and Ag +. Ind Crop Prod 77:364–374. https://doi.org/10.1016/j.indcrop.2015.09.010

Fierro V, Muniz G, Basta AH, El-saied H, Celzard A (2010) Rice straw as precursor of activated carbons : activation with ortho-phosphoric acid. J Hazard Mater 181:27–34. https://doi.org/10.1016/j.jhazmat.2010.04.062

Yorgun S, Yildiz D (2015) Preparation and characterization of activated carbons from Paulownia wood by chemical activation with H3PO4. J Taiwan Inst Chem Eng 53:122–131. https://doi.org/10.1016/j.jtice.2015.02.032

Yeganeh MM, Kaghazchi T, Soleimani M (2006) Effect of raw materials on properties of activated carbons. Chem Eng Technol 29(10):1247–1251. https://doi.org/10.1002/ceat.200500298

Alvarez J, Lopez G, Amutio M, Bilbao J, Olazar M (2014) Upgrading the rice husk char obtained by flash pyrolysis for the production of amorphous silica and high quality activated carbon. Bioresour Technol 170:132–137. https://doi.org/10.1016/j.biortech.2014.07.073

Masoud MS, El-Saraf WM, Abdel-Halim AM, Ali AE, Mohamed EA, Hasan HMI (2012) Rice husk and activated carbon for waste water treatment of El-Mex Bay, Alexandria Coast, Egypt. Arab J Chem 9(Suppl 2):S1590–S1596. https://doi.org/10.1016/j.arabjc.2012.04.028

Hu Z, Srinivasan MP, Ni Y (2001) Novel activation process for preparing highly microporous and mesoporous activated carbons novel activation process for preparing highly microporous and mesoporous activated carbons, no. April 2016:877–886. https://doi.org/10.1016/S0008-6223(00)00198-6

Puziy AM, Poddubnaya OI, Martínez-Alonso A, Suárez-García F, Tascón JMD (2002) Synthetic carbons activated with phosphoric - acid I. surface chemistry and ion binding properties. Carbon N Y 40:1493–1505. https://doi.org/10.1016/S0008-6223(01)00317-7

Pawlicka A, Doczekalska B (2013) Determination of surface oxygen functional groups of active carbons according to the Boehm’s titration method. Ann WULS - SGGW, For Wood Technol 84:11–14

Vukčević M, Kalijadis A, Dimitrijević-Branković S, Laušević Z, Laušević M (2008) Surface characteristics and antibacterial activity of a silver-doped carbon monolith. Sci Technol Adv Mater 9(1). https://doi.org/10.1088/1468-6996/9/1/015006

Sajjadi B, Chen W, Egiebor NO (2018) A comprehensive review on physical activation of biochar for energy and environmental applications. Rev Chem Eng 35(6):735–776. https://doi.org/10.1515/revce-2017-0113

Akpomie KG, Dawodu FA, Adebowale KO (2015) Mechanism on the sorption of heavy metals from binary-solution by a low cost montmorillonite and its desorption potential. Alexandria Eng J 54:757–767. https://doi.org/10.1016/j.aej.2015.03.025

Özacar M, Şengil IA (2005) Adsorption of metal complex dyes from aqueous solutions by pine sawdust. Bioresour Technol 96:791–795. https://doi.org/10.1016/j.biortech.2004.07.011

Omri A, Benzina M, Trabelsi W, Ammar N (2014) Adsorptive removal of humic acid on activated carbon prepared from almond shell: approach for the treatment of industrial phosphoric acid solution. Desalin Water Treat 52(10–12):2241–2252. https://doi.org/10.1080/19443994.2013.800003

Bello OS, Owojuyigbe ES, Babatunde MA, Folaranmi FE (2017) Sustainable conversion of agro-wastes into useful adsorbents. Appl Water Sci 7:3561–3571. https://doi.org/10.1007/s13201-016-0494-0

Maghsoodloo S, Noroozi B, Haghi AK, Sorial GA (2011) Consequence of chitosan treating on the adsorption of humic acid by granular activated carbon. J Hazard Mater 191(1–3):380–387. https://doi.org/10.1016/j.jhazmat.2011.04.096

Tavengwa T, Nikita LC, Tichagwa L (2015) Equilibrium and kinetic studies on the adsorption of humic acid by activated sludge and Bacillus subtilis. Desalin Water Treat 34(6):669–677. https://doi.org/10.1080/19443994.2015.1082510

Noorimotlagh Z, Ravanbakhsh M, Valizadeh MR, Bayati B, Kyzas GZ, Ahmadi M, Rahbar N, Jaafarzadeh N (2020) Optimization and genetic programming modeling of humic acid adsorption onto prepared activated carbon and modified by multi-wall carbon nanotubes. Polyhedron 1179:114354. https://doi.org/10.1016/j.poly.2020.114354

Saleh TA, Siddiqui MN, Al-arfaj AA (2016) Kinetic and intraparticle diffusion studies of carbon nanotubes-titania for desulfurization of fuels. Pet Sci Technol 34(16):1468–1474. https://doi.org/10.1080/10916466.2016.1202972

Acknowledgments

Technical assistance from Ms. Evgenia Tryastsina and Mr. Wabwire Andrew at the Thuenen Institute of Agricultural Technology, Braunschweig, and at Makerere University, Kampala, respectively, is gratefully acknowledged.

Funding

This work is financially supported by the Volkswagen Foundation under its Postdoctoral Fellowships Programme for African Researchers in the Engineering Sciences (Grant No. 90014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• NERICA 1 rice husk (RH) variety was physically and chemically activated.

• Steam activation of RH resulted in surface area as high as 1016.5 m2 g-1.

• H3PO4 activation of the RH resulted in surface area as high as 2258.4 m2 g-1.

• Carbon dose 0.5 g, pH 2, contact time 60 min found optimal to adsorb humic acid.

• Maximum adsorption capacity by the prepared activated carbons was 27.2 mg g-1.

Rights and permissions

About this article

Cite this article

Menya, E., Olupot, P.W., Storz, H. et al. Synthesis and evaluation of activated carbon from rice husks for removal of humic acid from water. Biomass Conv. Bioref. 12, 3229–3248 (2022). https://doi.org/10.1007/s13399-020-01158-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01158-2