Abstract

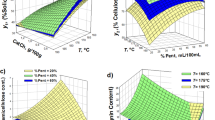

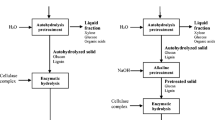

Ensuring environmental and social-economic sustainability in the use of materials from lignocellulosic biomass requires their fractionation and valorization of their main components. In this work, we used Eucalyptus urograndis wood to obtain chemicals and energy. The raw material was characterized in chemical terms and then subjected to autohydrolysis under variable operating conditions to optimize the extraction of hemicellulose derivatives relative to cellulose. The kinetics of the pyrolysis process was modeled in terms of activation energy and hydrogen production. Using temperatures in the range of 180–190 °C and treatment times in the range of 15–30 min allowed more than 74.5% of all hemicellulosic components in the raw material to be selectively extracted into the liquid post-hydrolysis phase, more than 90% of all glucan to remain in the solid phase and up to 27.8% of lignin to be removed. The thermal behavior of solid fraction was examined by thermogravimetric analysis, using variable heating rates under a nitrogen atmosphere, and the activation energy can be estimated by using the Flynn-Wall-Ozawa method. Based on the results, the pyrolysis of E. urograndis can be modeled as a first-order reaction. The activation energy (Ea) at a fractional conversion α between 0.3 and 0.7 was 183 to 199 KJ mol−1 for the raw material, whereas that for the solid residue from autohydrolysis ranged from 179 to 186 kJ mol−1 at same fractional conversion when operational temperature in autohydrolysis was upper 185 °C. Based on the results, using temperatures above 180 °C and times of 15 min or longer [i.e., operating at the (0,0) experimental point for the autohydrolysis process] in combination with degrees of conversion from 0.3 to 0.8 reduced the activation energy of the pyrolysis process in relation to the raw material by up to 12% and removed hemicellulose by more 74.5% from it. In parallel, the comparative analysis of the Ea values and the composition of the pyrolysis gas obtained showed a negative relationship between Ea and the amount of hydrogen produced.

Similar content being viewed by others

References

Connolly D, Lund H, Mathiesen BV (2016) Smart Energy Europe: the technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew Sust Energ Rev 60:1634–1653. https://doi.org/10.1016/j.rser.2016.02.025

GIT Forestry Consulting (2009) GIT Forestry Consulting’s blog, Global Eycalyptus Map. http://git-forestry-blog.blogspot.com/2009/10/globaleucalyptus-map-2009-in-buenos.html. Accessed 22 Jun 2017

REN21 (2015) REN21, renewables 2015 global status report, renewable energy policy network for the 21st century. France

Bogdanski A, Dubois O, Jamieson C, Krell R (2010) Making integrated food-energy systems work for people and climate. Rome

IEA (2016) IEA, world energy outlook 2016. Paris

Dahanayake KC, Chow CL, Long Hou G (2017) Selection of suitable plant species for energy efficient vertical greenery systems (VGS). Energy Procedia 142:2473–2478. https://doi.org/10.1016/j.egypro.2017.12.185

FAO (2001) Future production from forest plantations, forest plantations thematic papers, working paper FP/13. Rome

García-Morote FA, López-Serrano FR, Martínez-García E, Andrés-Abellán M, Dadi T, Candel D, Rubio E, Lucas-Borja M (2014) Stem biomass production of Paulownia elongata × P. fortunei under low irrigation in a semi-arid environment. Forests 5:2505–2520. https://doi.org/10.3390/f5102505

Guerrero M, Ruiz MP, Alzueta MU et al (2005) Pyrolysis of eucalyptus at different heating rates: studies of char characterization and oxidative reactivity. In: Journal of Analytical and Applied Pyrolysis. Elsevier, pp 307–314

Amutio M, Lopez G, Alvarez J, Olazar M, Bilbao J (2015) Fast pyrolysis of eucalyptus waste in a conical spouted bed reactor. Bioresour Technol 194:225–232. https://doi.org/10.1016/j.biortech.2015.07.030

Fernández M, Alaejos J, Andivia E, Vázquez-Piqué J, Ruiz F, López F, Tapias R (2018) Eucalyptus x urograndis biomass production for energy purposes exposed to a Mediterranean climate under different irrigation and fertilisation regimes. Biomass Bioenergy 111:22–30. https://doi.org/10.1016/j.biombioe.2018.01.020

da Silva Morais AP, Sansígolo CA, de Oliveira NM (2016) Effects of autohydrolysis of Eucalyptus urograndis and Eucalyptus grandis on influence of chemical components and crystallinity index. Bioresour Technol 214:623–628. https://doi.org/10.1016/j.biortech.2016.04.124

Loaiza JM, López F, García MT, Fernández O, Díaz MJ, García JC (2016) Selecting the pre-hydrolysis conditions for eucalyptus wood in a fractional exploitation biorefining scheme. J Wood Chem Technol 36:221–223. https://doi.org/10.1080/02773813.2015.1112402

Feria MJ, Alfaro A, López F, Pérez A, García JC, Rivera A (2012) Integral valorization of Leucaena diversifolia by hydrothermal and pulp processing. Bioresour Technol 103:381–388. https://doi.org/10.1016/j.biortech.2011.09.100

Alfaro A, López F, Pérez A, García JC, Rodríguez A (2010) Integral valorization of tagasaste (Chamaecytisus proliferus) under hydrothermal and pulp processing. Bioresour Technol 101:7635–7640. https://doi.org/10.1016/j.biortech.2010.04.059

Axelsson L, Franzén M, Ostwald M, Berndes G, Lakshmi G, Ravindranath NH (2012) Perspective: Jatropha cultivation in southern India: assessing farmers’ experiences. Biofuels Bioprod Biorefin 6:246–256. https://doi.org/10.1002/bbb

Basu P (2013) Biomass gasification, pyrolysis and torrefaction, 2nd edition

Wu C, Wang Z, Huang J, Williams PT (2013) Pyrolysis/gasification of cellulose , hemicellulose and lignin for hydrogen production in the presence of various nickel-based catalysts. Fuel 106:697–706. https://doi.org/10.1016/j.fuel.2012.10.064

Widyawati M, Church TL, Florin NH, Harris AT (2011) Hydrogen synthesis from biomass pyrolysis with in situ carbon dioxide capture using calcium oxide. Int J Hydrog Energy 36:4800–4813. https://doi.org/10.1016/j.ijhydene.2010.11.103

Loaiza JM, López F, García MT, García JC, Díaz MJ (2017) Biomass valorization by using a sequence of acid hydrolysis and pyrolysis processes. Application to Leucaena leucocephala. Fuel 203:393–402. https://doi.org/10.1016/j.fuel.2017.04.135

Kamm B, Kamm M (2007) Biorefineries – multi product processes. Adv Biochem Eng Biotechnol

Chen S, Meng A, Long Y, Zhou H, Li Q, Zhang Y (2015) TGA pyrolysis and gasification of combustible municipal solid waste. J Energy Inst 88:332–343. https://doi.org/10.1016/j.joei.2014.07.007

Pecha B, Garcia-Perez M (2015) Pyrolysis of lignocellulosic biomass. In: Bioenergy. Elsevier, pp 413–442

Loaiza JM, López F, García MT, García JC, Díaz MJ (2018) Integral valorization of tagasaste (Chamaecytisus proliferus) under thermochemical processes. Biomass Convers Biorefinery 8:265–274. https://doi.org/10.1007/s13399-017-0258-6

Domínguez MT, Madejón P, Madejón E, Diaz MJ (2017) Novel energy crops for Mediterranean contaminated lands: valorization of Dittrichia viscosa and Silybum marianum biomass by pyrolysis. Chemosphere 186:968–976. https://doi.org/10.1016/j.chemosphere.2017.08.063

Zhang W, Huang S, Wu S, Wu Y, Gao J (2019) Study on the structure characteristics and gasification activity of residual carbon in biomass ashes obtained from different gasification technologies. Fuel 254:254. https://doi.org/10.1016/j.fuel.2019.115699

Sixta H (2006) Handbook of pulp. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

TAPPI T264-cm-07 (2007) Preparation of wood for chemical analysis. In: TAPPI Test Methods. TAPPI Press, Norcross

TAPPI T222 om-11 (2011) Acid-insoluble lignin in wood and pulp

Wallis AFA, Wearne RH, Wright PJ (1996) Chemical analysis of polysaccharides in plantation eucalypt woods and pulps. Appita J 49:258–262. https://doi.org/10.5902/1980509812359

Montgomery DC (2003) Diseño y análisis de experimentos. Limusa Wiley

Akhnazarova S, Kafarov V (1984) Experiment optimization in chemistry and chemical engineering. Mir Publishers, Moscow

Radojevic M, Balac M, Jovanovic V, Stojiljkovic D, Manic N (2018) Thermogravimetric kinetic study of solid recovered fuels pyrolysis. Hem Ind 72:99–106. https://doi.org/10.2298/HEMIND171009002R

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. J Res Natl Bur Stand Sect A Phys Chem 70A:487–523. https://doi.org/10.6028/jres.070a.043

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881–1886. https://doi.org/10.1246/bcsj.38.1881

Sedjo RA (2001) The role of forest plantations in the world’s future timber supply. For Chron 77:221–225

Brown C (2000) The global outlook for future wood supply from forest plantations

FAO 2010 (2010) Global forest resources assessment 2010. Main Report

Wise LE,Murphy M, Addieco AA (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper trade journal

López F, Alfaro, Caparrós A et al (2008) Aprovechamiento energético e integrado por fraccionamiento de biomasa lignocelulósica forestal y agroindustrial. Caracterización de hemicelulosas, celulosas y otros productos del fraccionamiento. Boletín del CIDEU 5:7–19

Garrote G, Parajó JC (2002) Non-isothermal autohydrolysis of Eucalyptus wood. Wood Sci Technol 36:111–123. https://doi.org/10.1007/s00226-001-0132-2

Garrote G, Domínguez H, Parajó JC (1999) Hydrothermal processing of lignocellulosic materials. Holz Roh Werkst 57:191–202. https://doi.org/10.1007/s001070050039

Gallina G, Cabeza Á, Biasi P, García-Serna J (2016) Optimal conditions for hemicelluloses extraction from Eucalyptus globulus wood: hydrothermal treatment in a semi-continuous reactor. Fuel Process Technol 148:350–360. https://doi.org/10.1016/j.fuproc.2016.03.018

Romaní A, Garrote G, López F, Parajó JC (2011) Eucalyptus globulus wood fractionation by autohydrolysis and organosolv delignification. Bioresour Technol 102:5896–5904. https://doi.org/10.1016/j.biortech.2011.02.070

Pontes R, Romaní A, Michelin M, Domingues L, Teixeira J, Nunes J (2018) Comparative autohydrolysis study of two mixtures of forest and marginal land resources for co-production of biofuels and value-added compounds. Renew Energy 128:20–29. https://doi.org/10.1016/j.renene.2018.05.055

Poletto M, Zattera AJ, Santana RMC (2012) Thermal decomposition of wood: kinetics and degradation mechanisms. In: Bioresource technology. Elsevier Ltd, pp 7–12

Sanchez-Silva L, López-González D, Villaseñor J, Sánchez P, Valverde JL (2012) Thermogravimetric-mass spectrometric analysis of lignocellulosic and marine biomass pyrolysis. Bioresour Technol 109:163–172. https://doi.org/10.1016/j.biortech.2012.01.001

Maliutina K, Tahmasebi A, Yu J (2018) Pressurized entrained-flow pyrolysis of microalgae: enhanced production of hydrogen and nitrogen-containing compounds. Bioresour Technol 256:160–169. https://doi.org/10.1016/j.biortech.2018.02.016

Zhang Q, Shen C, Zhang S, Wu Y (2016) Steam methane reforming reaction enhanced by a novel K2CO3-doped Li4SiO4sorbent: investigations on the sorbent and catalyst coupling behaviors and sorbent regeneration strategy. Int J Hydrog Energy 41:4831–4842. https://doi.org/10.1016/j.ijhydene.2015.12.116

Yang H (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Zhang W, Henschel T, Söderlind U et al (2017) Thermogravimetric and online gas analysis on various biomass fuels. In: Energy Procedia. Elsevier Ltd, pp 162–167

Huang YF, Kuan WH, Chiueh PT, Lo SL (2011) Pyrolysis of biomass by thermal analysis-mass spectrometry (TA-MS). Bioresour Technol 102:3527–3534. https://doi.org/10.1016/j.biortech.2010.11.049

Ranzi E, Cuoci A, Faravelli T, Frassoldati A, Migliavacca G, Pierucci S, Sommariva S (2008) Chemical kinetics of biomass pyrolysis. Energy Fuel 22:4292–4300. https://doi.org/10.1021/ef800551t

Rueda Ordóñez YJ, Tannous KK (2017) Análisis cinético de la descomposición térmica de biomasas aplicando un esquema de reacciones paralelas independientes. Rev UIS Ing 16:119–128. https://doi.org/10.18273/revuin.v16n2-2017011

Suuberg EM, Peters WA, Howard JB (1978) Product composition and kinetics of lignite pyrolysis

Suuberg EM, Peters WA, Howard JB, et al (1985) Proceedings, seventeenth symposium (international) on combustion; the Combustion Institute; Pittsburgh. Academic Press

Funding

This work was funded by the Andalusian Regional Government (Project FEDER Andalucía, UHU-1255540 and postdoctoral fellowship) and the Spanish Government (National Program for Research Aimed at Social Challenges, Grant No. CTQ2017-85251-C2-1-R).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Loaiza, J.M., Palma, A., Díaz, M.J. et al. Effect of autohydrolysis on hemicellulose extraction and pyrolytic hydrogen production from Eucalyptus urograndis. Biomass Conv. Bioref. 12, 4021–4030 (2022). https://doi.org/10.1007/s13399-020-00900-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00900-0