Abstract

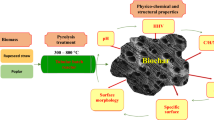

Biochar, a carbon-rich pyrolytic product, has demonstrated positive results as a soil improver and carbon sequestration agent. Its production could be an appropriate and innovative practice for agricultural waste management in the context of environmentally smart agriculture. However, considering the relevant effect of the production conditions on the final biochar properties, its characterization is a necessary step, moreover, if an unknown feedstock is being used. Coffee hulls (CH), pineapple stubble (PS), and palm oil fiber (PF) are typical tropical agro-industrial wastes, and biochar from the first two are not reported before. In this work, biochars from them were obtained after 1 h of pyrolysis at 600 °C. Surface area and pH of biochars were close to 60 m2g−1 and 9, respectively (except for PF which was 29 m2g−1), while torrefied biomass (charred material prepared at 300 °C) presented a surface area close to 1 m2g−1 and neutral pH. Fixed C was approximately 80% (PF and CH) and 59% (PS) for biochars and close to 40% in torrefied biomass. It was concluded that key properties of biochars were mostly determined by the feedstock’s origin. Due to its high ash content and surface area, PS biochar was identified as a suitable soil amendment, while PF and CH biochars showed a higher potential for carbon sequestration in soil due to their high fixed carbon content, demonstrating that the production of biochars from widespread tropical wastes tailored for specific environmental uses is possible.

Similar content being viewed by others

References

Carlson KM, Garrett RD (2018) Environmental impacts of tropical soybean and palm oil crops. In: Oxford Res. Encycl. Environ. Sci. http://oxfordre.com/environmentalscience/view/10.1093/acrefore/9780199389414.001.0001/acrefore-9780199389414-e-234. Accessed 6 Aug 2019

Saini JK, Saini R, Tewari L (2015) Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. 3 Biotech 5:337–353. https://doi.org/10.1007/s13205-014-0246-5

Elkhalifa S, Al-Ansari T, Mackey HR, McKay G (2019) Food waste to biochars through pyrolysis: a review. Resour Conserv Recycl 144:310–320

Lehmann J, Joseph S (2015) In: Lehmann J, Joseph S (eds) Biochar for environmental management: an introduction, Biochar for environmental management science, technology and implementation, 2nd edn. Routledge, pp 1–13

Mosley LM, Willson P, Hamilton B, Butler G, Seaman R (2015) The capacity of biochar made from common reeds to neutralise pH and remove dissolved metals in acid drainage. Environ Sci Pollut Res 22:15113–15122. https://doi.org/10.1007/s11356-015-4735-9

Kookana RS, Sarmah AK, Van Zwieten L et al (2011) Biochar application to soil. Agronomic and environmental benefits and unintended consequences. Adv Agron 112:103–143. https://doi.org/10.1016/B978-0-12-385538-1.00003-2

Liang B, Lehmann J, Solomon D et al (2006) Black carbon increases cation exchange capacity in soils. Soil Sci Soc Am J 70:1719–1730. https://doi.org/10.2136/sssaj2005.0383

Steiner C, Glaser B, Teixeira WG et al (2008) Nitrogen retention and plant uptake on a highly weathered central Amazonian Ferralsol amended with compost and charcoal. J Plant Nutr Soil Sci 171:893–899. https://doi.org/10.1002/jpln.200625199

International Biochar Initiative (2015) Standardized product definition and product testing guidelines for biochar that is used in soil. http://www.biochar-international.org/sites/default/files/Guidelines_for_Biochar_That_Is_Used_in_Soil_Final.pdf. Accessed 6 Aug 2019

Mukome FND, Zhang X, Silva LCR, Six J, Parikh SJ (2013) Use of chemical and physical characteristics to investigate trends in biochar feedstocks. J Agric Food Chem 61:2196–2204. https://doi.org/10.1021/jf3049142

Sumaraj PLP (2017) Influence of surface chemistry of carbon materials on their interactions with inorganic nitrogen contaminants in soil and water. Chemosphere 184:532–547. https://doi.org/10.1016/j.chemosphere.2017.06.021

Zhao SX, Ta N, Wang XD (2017) Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 10:1293. https://doi.org/10.3390/en10091293

Boateng AA, Garcia-Perez M, Mašek O et al (2015) Biochar production technology. In: Lehmann J, Joseph S (eds) Biochar for environmental management, 2nd edn. Routledge, London, pp 127–146

Imam T, Capareda S (2012) Characterization of bio-oil, syn-gas and bio-char from switchgrass pyrolysis at various temperatures. J Anal Appl Pyrolysis 93:170–177. https://doi.org/10.1016/j.jaap.2011.11.010

Zhao C, Jiang E, Chen A (2017) Volatile production from pyrolysis of cellulose, hemicellulose and lignin. J Energy Inst 90:902–913. https://doi.org/10.1016/j.joei.2016.08.004

Coto O (2013) Informe de Consultoría Producto 1: Evaluación de la Generación de Residuos Agrícolas Orgánicos (RAO) en Costa Rica e Identificación de Sector Prioritario. San José, Costa Rica

Solórzano JA, Gilles J, Bravo O et al (2015) Biology and trapping of stable flies (Diptera: Muscidae) developing in pineapple residues (Ananas comosus) in Costa Rica. J Insect Sci 15:145. https://doi.org/10.1093/jisesa/iev127

Domingues RR, Trugilho PF, Silva CA et al (2017) Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS One 12. https://doi.org/10.1371/journal.pone.0176884

Asfaw E, Nebiyu A, Bekele E et al (2019) Coffee-husk biochar application increased AMF root colonization, P accumulation, N2 fixation, and yield of soybean grown in a tropical Nitisol, Southwest Ethiopia. J Plant Nutr Soil Sci 182:419–428. https://doi.org/10.1002/jpln.201800151

Veiga TRLA, Lima JT, de Abreu Dessimoni AL et al (2017) Different plant biomass characterizations for biochar production. CERNE 23:529–536. https://doi.org/10.1590/01047760201723042373

Kiggundu N, Sittamukyoto J (2019) Pryloysis of coffee husks for biochar production. J Environ Prot (Irvine, Calif) 10:1553–1564. https://doi.org/10.4236/jep.2019.1012092

Limwikran T, Kheoruenromne I, Suddhiprakarn A et al (2018) Dissolution of K, Ca, and P from biochar grains in tropical soils. Geoderma 312:139–150. https://doi.org/10.1016/j.geoderma.2017.10.022

Tsai W-T, Liu S-C, Hsieh C-H (2012) Preparation and fuel properties of biochars from the pyrolysis of exhausted coffee residue. J Anal Appl Pyrolysis 93:63–67. https://doi.org/10.1016/j.jaap.2011.09.010

Batista EMCC, Shultz J, Matos TTS, Fornari MR, Ferreira TM, Szpoganicz B, de Freitas RA, Mangrich AS (2018) Effect of surface and porosity of biochar on water holding capacity aiming indirectly at preservation of the Amazon biome. Sci Rep 8:10677. https://doi.org/10.1038/s41598-018-28794-z

Fu B, Ge C, Yue L et al (2016) Characterization of biochar derived from pineapple peel waste and its application for sorption of oxytetracycline from aqueous solution. BioResources 11. https://doi.org/10.15376/biores.11.4.9017-9035

Samsuri AW, Sadegh-Zadeh F, Seh-Bardan BJ (2014) Characterization of biochars produced from oil palm and rice husks and their adsorption capacities for heavy metals. Int J Environ Sci Technol 11:967–976. https://doi.org/10.1007/s13762-013-0291-3

Sukiran MA, Kheang LS, Bakar NA, May CY (2011) Production and characterization of bio-char from the pyrolysis of empty fruit bunches. Am J Appl Sci 8:984–988. https://doi.org/10.3844/ajassp.2011.984.988

Shariff A, Aziz NSM, Abdullah N (2014) Slow pyrolysis of oil palm empty fruit bunches for biochar production and characterisation. J Phys Sci 25:97–112

Abnisa F, Arami-Niya A, Wan Daud WMA et al (2013) Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers Manag 76:1073–1082. https://doi.org/10.1016/j.enconman.2013.08.038

Soil Survey Staff (2014) Kellog soil survey laboratory methods manual. Soil Survey Investigations Report No 42, Version 5.0

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

ASTM International (2013) ASTM D3172-13 standard practice for proximate analysis of coal and coke. Annu B ASTM Stand:3174–3175

Raya-Moreno I, Cañizares R, Domene X, Carabassa V, Alcañiz JM (2017) Comparing current chemical methods to assess biochar organic carbon in a Mediterranean agricultural soil amended with two different biochars. Sci Total Environ 598:604–618. https://doi.org/10.1016/j.scitotenv.2017.03.168

Erich MS, Ohno T (1992) Titrimetric determination of calcium carbonate equivalence of wood ash. Analyst 117:993. https://doi.org/10.1039/an9921700993

Singh B, Dolk MM, Shen Q, Camps-Arbestain M (2017) Biochar pH electrical conductivity and liming potential. In: Singh B, Camps-Arbestain M, Lehmann J (eds) biochar: a guide to analytical methods. Csiro Publishing, p 320

Dhyani V, Bhaskar T (2018) A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew Energy 129:695–716. https://doi.org/10.1016/j.renene.2017.04.035

Zornoza R, Moreno-Barriga F, Acosta JA, Muñoz MA, Faz A (2016) Stability, nutrient availability and hydrophobicity of biochars derived from manure, crop residues, and municipal solid waste for their use as soil amendments. Chemosphere 144:122–130. https://doi.org/10.1016/j.chemosphere.2015.08.046

Bekalo SA, Reinhardt H-W (2010) Fibers of coffee husk and hulls for the production of particleboard. Mater Struct 43:1049–1060. https://doi.org/10.1617/s11527-009-9565-0

Rajasekhar Reddy B, Vinu R (2018) Feedstock characterization for pyrolysis and gasification. In: Agarwal A, Moholkar V, Thallada B (eds) Coal and biomass gasification. Springer, Singapore, pp 3–36

Weber K, Quicker P (2018) Properties of biochar. Fuel 217:240–261. https://doi.org/10.1016/j.fuel.2017.12.054

Cantrell KB, Hunt PG, Uchimiya M, Novak JM, Ro KS (2012) Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour Technol 107:419–428. https://doi.org/10.1016/j.biortech.2011.11.084

Wang K, Johnston PA, Brown RC (2014) Comparison of in-situ and ex-situ catalytic pyrolysis in a micro-reactor system. Bioresour Technol 173:124–131. https://doi.org/10.1016/j.biortech.2014.09.097

Sizmur T, Fresno T, Akgül G, Frost H, Moreno-Jiménez E (2017) Biochar modification to enhance sorption of inorganics from water. Bioresour Technol 246:34–47. https://doi.org/10.1016/j.biortech.2017.07.082

Zhao B, O’Connor D, Zhang J et al (2018) Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J Clean Prod 174:977–987. https://doi.org/10.1016/j.jclepro.2017.11.013

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour Technol 114:644–653. https://doi.org/10.1016/j.biortech.2012.03.022

Windeatt JH, Ross AB, Williams PT et al (2014) Characteristics of biochars from crop residues: potential for carbon sequestration and soil amendment. J Environ Manag 146:189–197. https://doi.org/10.1016/j.jenvman.2014.08.003

Brewer CE, Unger R, Schmidt-Rohr K, Brown RC (2011) Criteria to select biochars for field studies based on biochar chemical properties. BioEnergy Res 4:312–323. https://doi.org/10.1007/s12155-011-9133-7

Leng L, Huang H, Li H, Li J, Zhou W (2019) Biochar stability assessment methods: a review. Sci Total Environ 647:210–222. https://doi.org/10.1016/j.scitotenv.2018.07.402

EBC (2012) “European biochar certificate - guidelines for a sustainable production of biochar” European Biochar Foundation (EBC), Arbaz, Switzerland. http://www.europeanbiochar.org/en/download. Version 8.2E of 1st September 2019, DOI: https://doi.org/10.13140/RG.2.1.4658.7043

Chen H (2014) Chemical composition and structure of natural lignocellulose. In: Biotechnology of lignocellulose. Springer, Dordrecht, pp 25–71

Chintala R, Mollinedo J, Schumacher TE et al (2014) Effect of biochar on chemical properties of acidic soil. Arch Agron Soil Sci 60:393–404. https://doi.org/10.1080/03650340.2013.789870

Anawar HM, Akter F, Solaiman ZM, Strezov V (2015) Biochar: an emerging panacea for remediation of soil contaminants from mining, industry and sewage wastes. Pedosphere 25:654–665. https://doi.org/10.1016/S1002-0160(15)30046-1

Li M, Liu Q, Lou Z et al (2014) Method to characterize acid–base behavior of biochar: site modeling and theoretical simulation. ACS Sustain Chem Eng 2:2501–2509. https://doi.org/10.1021/sc500432d

Li X, Shen Q, Zhang D, Mei X, Ran W, Xu Y, Yu G (2013) Functional groups determine biochar properties (pH and EC) as studied by two-dimensional 13C NMR correlation spectroscopy. PLoS One 8:e65949. https://doi.org/10.1371/journal.pone.0065949

Chen Z, Xiao X, Chen B, Zhu L (2015) Quantification of chemical states, dissociation constants and contents of oxygen-containing groups on the surface of biochars produced at different temperatures. Environ Sci Technol 49:309–317. https://doi.org/10.1021/es5043468

Yuan J-H, Xu R-K, Zhang H (2011) The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour Technol 102:3488–3497. https://doi.org/10.1016/j.biortech.2010.11.018

Das O, Sarmah AK (2015) The love–hate relationship of pyrolysis biochar and water: a perspective. Sci Total Environ 512–513:682–685. https://doi.org/10.1016/j.scitotenv.2015.01.061

Gray M, Johnson MG, Dragila MI, Kleber M (2014) Water uptake in biochars: the roles of porosity and hydrophobicity. Biomass Bioenergy 61:196–205. https://doi.org/10.1016/j.biombioe.2013.12.010

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agric Food Chem 59:2501–2510. https://doi.org/10.1021/jf104206c

Pagnanelli F, Mainelli S, Toro L (2008) New biosorbent materials for heavy metal removal: product development guided by active site characterization. Water Res 42:2953–2962. https://doi.org/10.1016/j.watres.2008.03.012

Funding

This work was supported by the Centro de Investigación en Contaminación Ambiental, the Vicerrectoría de Investigación, UCR (project, ref. 802-B6-529), the Centre for Research on Ecology and Forestry Applications (CREAF), the Spanish Ministry of Economy and Competitiveness (FERTICHAR project, ref. AGL2015-70393-R), the Joint FAO/IAEA project TC COS5/033 “Assessing and implementing biochar use in climate smart and environmentally friendly pineapple production using isotopic techniques,” and by the PhD scholarship awarded to the first author funded by the UCR-World Bank (project Improving Higher Education in Costa Rica). The authors thank the staff of the Alfredo Volio Mata Experimental Station of the University of Costa Rica for their collaboration with the analysis of lignin and cellulose content.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Novel tropical feedstocks (coffee hull and pineapple stubble) and oil palm fiber for biochar production were studied.

• Only slow pyrolysis at 600 °C, and not 300 °C, produced biochar from the tropical agrowastes.

• Higher C in oil palm and coffee biochars was found compared to pineapple biochar.

• Pineapple biochar had a higher surface area and ash content and a high pH.

• Coffee and oil palm biochars are more suitable for soil carbon sequestration.

• Pineapple biochar is more appropriate as a soil amendment.

Rights and permissions

About this article

Cite this article

Chin-Pampillo, J.S., Alfaro-Vargas, A., Rojas, R. et al. Widespread tropical agrowastes as novel feedstocks for biochar production: characterization and priority environmental uses. Biomass Conv. Bioref. 11, 1775–1785 (2021). https://doi.org/10.1007/s13399-020-00714-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00714-0