Abstract

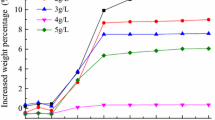

Electroless silver coating on copper powder and its effects on oxidation resistance were investigated by varying the fabrication parameters. Using acetylacetone (C5H8O2) as chelating reagent, silver-coated copper powder was fabricated by displacement reaction method. In the process, acetylacetone forms chelating compound with Cu 2+, which prevent the formation of [Cu (NH3)4]2+. Therefore, Ag + can be reduced continully and deposited on the surface of copper particles. As-coated copper particles were characterized using x-ray diffraction (XRD), scanning electron microscopy (SEM) and x-ray energy dispersive spectroscopy (EDS). The oxidation resistance of silver coated copper powder was investigated by gravimetric method. It was found that a fairly continuous silver layer was formed on the surface of copper powder by the electroless type of substitution plating. When the silver content reached 10 wt. %, silver was homogeneously distributed around the copper particles and few free silver particles were detected. The results showed that the silver coated copper powder with the best oxidation resistance was prepared at 40°C and the C5H8O2/AgNO3 molar ratio was 1:1.

Similar content being viewed by others

References

Y. K. Hong, C. Y. Lee, C. K. Jeong, J. H. Sim, K. Kim, J. Joo, M. S. Kim, J. Y. Lee, S. H. Jeong, and S. W. Byun, Curr. Appl. Phys. 1, 439 (2001).

M. T. Kortschot and R. T. Woodhams, Polym. Compos. 6, 296 (1985).

Y. P. Mamunya, V. V. Davydenko, P. Pissis, and E. Lebedev, Eur. Polym. J. 38, 1887 (2002).

G. Jiang, M. Gilbert, D. J. Hitt, G. D. Wilcox, and K. Balasubramanian, Compos. Part a-Appl. Sci. Manuf. 33, 745 (2002).

I. Novak, I. Krupa, and I. Chodak, Synthetic Met. 144, 13 (2004).

K. S. Park, J. T. Son, H. T. Chung, S. J. Kim, C. H. Lee, K. T. Kang, and H. G. Kim, Solid State Commun. 129, 311 (2004).

Y. Q. Xue, B. J. Gao, and J. F. Gao, J. Colloid Interf. Sci. 191, 81 (1997).

Q. H. Lu and H. Keizou, Funct. Mate. 29, 439 (1998).

J. Li, X. J. Pan, S. D. You, and S. X. Huang, US Patent No. 5, 372, 749 (1994).

X. R. Xu, X. J. Luo, H. R. Zhuang, W. L. Li, and B. L. Zhang, Mater. Lett. 57, 3987 (2003).

B. J. Gao, J. F. Gao, H. M. Jiang, and Z. X. Zhang, Acta Phys.-Chim. Sin. 16, 366 (2000).

K. Noriaki, Y. Joei, and M. Takeo, US Patent No. 4, 652, 465 (1987).

T. Hayashi, US Patent No. 5, 178, 909 (1993).

B. J. Gao, H. M. Jiang, and Z. X. Zhang, Chin. J. Inorg. Chem. 16, 669 (2000).

Z. Q. Zhang, Anal. Chem., p. 519, Science Press, Beijing (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, X.G., Zhang, H.Y. Fabrication and performance of silver coated copper powder. Electron. Mater. Lett. 8, 467–470 (2012). https://doi.org/10.1007/s13391-012-1110-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-012-1110-6