Abstract

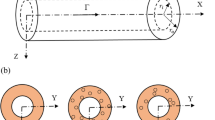

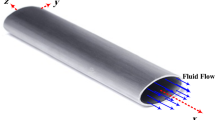

The aim of the current study is to put forward a new model for stability analysis of axially functionally graded micro-pipes conveying fluid. Modified couple stress theory is employed to capture the scale effects. The displacement field is presented in a unified form such that the formulations based on conventional Euler–Bernoulli and Timoshenko theories as well as newly developed higher order shear deformable tube model which properly satisfies transverse shear requirements on free surfaces, are retrievable. The material properties are assumed to be varying through-the-length according to a power-law function. Hamilton’s principle is utilized to derive formulation governing the current fluid–solid interaction problem. In order to generate numerical results, the system of equations is discretized and converted to the standard generalized eigenvalue problem by utilizing differential quadrature technique. The influences of size which is captured by length scale parameter of modified couple stress theory, material distribution pattern, geometrical aspects, and fluid velocity upon the stability of axially functionally graded micro-pipes conveying fluid have been elucidated through detailed numerical investigations. Developed procedures also enable determination of the value of critical flow velocity, which is a significant parameter in designing small-scale pipes containing internal flow.

Similar content being viewed by others

References

Schwengber, A.; Prado, H.J.; Zilli, D.A.; Bonelli, P.R.; Cukierman, A.L.: Carbon nanotubes buckypapers for potential transdermal drug delivery. Mater. Sci. Eng C. 57, 7–13 (2015). https://doi.org/10.1016/j.msec.2015.07.030

Sadeghi-Goughari, M.; Jeon, S.; Kwon, H.-J.: Fluid structure interaction of cantilever micro and nanotubes conveying magnetic fluid with small size effects under a transverse magnetic field. J. Fluids. Struct. 94, 102951 (2020). https://doi.org/10.1016/j.jfluidstructs.2020.102951

Amiri, A.; Pournaki, I.J.; Jafarzadeh, E.; Shabani, R.; Rezazadeh, G.: Vibration and instability of fluid-conveyed smart micro-tubes based on magneto-electro-elasticity beam model. Microfluid. Nanofluid. 20(2), 38 (2016). https://doi.org/10.1007/s10404-016-1706-5

Wu, Z.-J.; Luo, Z.; Rastogia, A.; Stavchansky, S.; Bowman, P.D.; Ho, P.S.: Micro-fabricated perforated polymer devices for long-term drug delivery. Biomed. Microdevices. 13(3), 485–491 (2011). https://doi.org/10.1007/s10544-011-9516-8

Groenesteijn J, van de Ridder L, Lötters JC, Wiegerink RJ. (2014) Modelling of a micro Coriolis mass flow sensor for sensitivity improvement. Sensors, pp. 954–957, IEEE, https://doi.org/10.1109/ICSENS.2014.6985160

Ghazavi, M.R.; Molki, H.; Ali beigloo, A.: Nonlinear vibration and stability analysis of the curved microtube conveying fluid as a model of the micro coriolis flowmeters based on strain gradient theory. Appl. Math. Model. 45, 1020–1030 (2017). https://doi.org/10.1016/j.apm.2017.01.048

Huber, C.: MEMS-based micro-Coriolis technology for high precision density measurement. Tm-Tech. Mess. 83(3), 157–162 (2016). https://doi.org/10.1515/teme-2015-0092

Bhardwaj, P.; Bagdi, P.; Sen, A.K.: Microfluidic device based on a micro-hydrocyclone for particle–liquid separation. Lab. Chip. 11(23), 4012–4021 (2011). https://doi.org/10.1039/C1LC20606K

Sajeesh, P.; Sen, A.K.: Particle separation and sorting in microfluidic devices: a review. Microfluid. Nanofluid. 17(1), 1–52 (2014). https://doi.org/10.1007/s10404-013-1291-9

Paidoussis, M.P.: Fluid-structure interactions: Slender structures and axial flow. Academic Press, London (1998)

Yang, F.; Chong, A.C.M.; Lam, D.C.C.; Tong, P.: Couple stress based strain gradient theory for elasticity. Int. J. Solids. Struct. 39(10), 2731–2743 (2002). https://doi.org/10.1016/S0020-7683(02)00152-X

Lam, D.C.C.; Yang, F.; Chong, A.C.M.; Wang, J.; Tong, P.: Experiments and theory in strain gradient elasticity. J. Mech. Phys. Solids. 51(8), 1477–1508 (2003). https://doi.org/10.1016/S0022-5096(03)00053-X

Eringen, A.C.: On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves. J. Appl. Phys. 54(9), 4703–4710 (1983). https://doi.org/10.1063/1.332803

Lee, U.; Park, J.: Spectral element modelling and analysis of a pipeline conveying internal unsteady fluid. J. Fluids. Struct. 22(2), 273–292 (2006). https://doi.org/10.1016/j.jfluidstructs.2005.09.003

Xu, M.R.; Xu, S.P.; Guo, H.Y.: Determination of natural frequencies of fluid-conveying pipes using homotopy perturbation method. Comput. Math. Appl. 60(3), 520–527 (2010). https://doi.org/10.1016/j.camwa.2010.04.049

Zhang, T.; Ouyang, H.; Zhang, Y.O.; Lv, B.L.: Nonlinear dynamics of straight fluid-conveying pipes with general boundary conditions and additional springs and masses. Appl. Math. Model. 40(17), 7880–7900 (2016). https://doi.org/10.1016/j.apm.2016.03.050

Tang, Y.; Zhen, Y.; Fang, B.: Nonlinear vibration analysis of a fractional dynamic model for the viscoelastic pipe conveying fluid. Appl. Math. Model. 56, 123–136 (2018). https://doi.org/10.1016/j.apm.2017.11.022

Bahaadini, R.; Hosseini, M.; Jamali, B.: Flutter and divergence instability of supported piezoelectric nanotubes conveying fluid. Physica. B Condens. Matter. 529, 57–65 (2018). https://doi.org/10.1016/j.physb.2017.09.130

Ghayesh, M.H.; Farokhi, H.; Farajpour, A.: Global dynamics of fluid conveying nanotubes. Int. J. Eng. Sci. 135, 37–57 (2019). https://doi.org/10.1016/j.ijengsci.2018.11.003

Bahaadini, R.; Saidi, A.R.; Hosseini, M.: On dynamics of nanotubes conveying nanoflow. Int. J. Eng. Sci. 123, 181–196 (2018). https://doi.org/10.1016/j.ijengsci.2017.11.010

Yin, L.; Qian, Q.; Wang, L.: Strain gradient beam model for dynamics of microscale pipes conveying fluid. Appl. Math. Model. 35(6), 2864–2873 (2011). https://doi.org/10.1016/j.apm.2010.11.069

Wang, L.: Size-dependent vibration characteristics of fluid-conveying microtubes. J. Fluids. Struct. 26(4), 675–684 (2010). https://doi.org/10.1016/j.jfluidstructs.2010.02.005

Mirtalebi, S.H.; Ahmadian, M.T.; Ebrahimi-Mamaghani, A.: On the dynamics of micro-tubes conveying fluid on various foundations. SN. Appl. Sci. 1(6), 547 (2019). https://doi.org/10.1007/s42452-019-0562-9

Dai, H.; Wang, L.; Ni, Q.: Dynamics and pull-in instability of electrostatically actuated microbeams conveying fluid. Microfluid. Nanofluid. 18(1), 49–55 (2015). https://doi.org/10.1007/s10404-014-1407-x

Xia, W.; Wang, L.: Microfluid-induced vibration and stability of structures modeled as microscale pipes conveying fluid based on non-classical Timoshenko beam theory. Microfluid. Nanofluid. 9(4–5), 955–962 (2010). https://doi.org/10.1007/s10404-010-0618-z

Mahamood, R.M.; Akinlabi, E.T.: Types of functionally graded materials and their areas of application. In: Mahamood, R.M.; Akinlabi, E.T. (Eds.) Functionally Graded Materials, pp. 9–21. Springer International Publishing, Cham (2017)

Petit, C.; Montanaro, L.; Palmero, P.: Functionally graded ceramics for biomedical application: Concept, manufacturing, and properties. Int. J. Appl. Ceram. Technol. 15(4), 820–840 (2018). https://doi.org/10.1111/ijac.12878

Tang, Y.; Yang, T.: Post-buckling behavior and nonlinear vibration analysis of a fluid-conveying pipe composed of functionally graded material. Compos. Struct. 185, 393–400 (2018). https://doi.org/10.1016/j.compstruct.2017.11.032

Liu, H.; Lv, Z.; Tang, H.: Nonlinear vibration and instability of functionally graded nanopipes with initial imperfection conveying fluid. Appl. Math. Model. 76, 133–150 (2019). https://doi.org/10.1016/j.apm.2019.06.011

Zhu, B.; Chen, X.-C.; Guo, Y.; Li, Y.-H.: Static and dynamic characteristics of the post-buckling of fluid-conveying porous functionally graded pipes with geometric imperfections. Int. J. Mech. Sci. 189, 105947 (2021). https://doi.org/10.1016/j.ijmecsci.2020.105947

Dehrouyeh-Semnani, A.M.; Dehdashti, E.; Yazdi, M.R.H.; Nikkhah-Bahrami, M.: Nonlinear thermo-resonant behavior of fluid-conveying FG pipes. Int. J. Eng. Sci. 144, 103141 (2019). https://doi.org/10.1016/j.ijengsci.2019.103141

Khodabakhsh, R.; Saidi, A.R.; Bahaadini, R.: An analytical solution for nonlinear vibration and post-buckling of functionally graded pipes conveying fluid considering the rotary inertia and shear deformation effects. Appl. Ocean. Res. 101, 102277 (2020). https://doi.org/10.1016/j.apor.2020.102277

Deng, J.; Liu, Y.; Zhang, Z.; Liu, W.: Stability analysis of multi-span viscoelastic functionally graded material pipes conveying fluid using a hybrid method. Eur. J. Mech. A/Solids. 65, 257–270 (2017). https://doi.org/10.1016/j.euromechsol.2017.04.003

Reddy, R.S.; Panda, S.; Natarajan, G.: Nonlinear dynamics of functionally graded pipes conveying hot fluid. Nonlinear. Dyn. 99(3), 1989–2010 (2020). https://doi.org/10.1007/s11071-019-05426-3

Zhu, B.; Xu, Q.; Li, M.; Li, Y.: Nonlinear free and forced vibrations of porous functionally graded pipes conveying fluid and resting on nonlinear elastic foundation. Compos. Struct. 252, 112672 (2020). https://doi.org/10.1016/j.compstruct.2020.112672

Hosseini, M.; Maryam, A.Z.B.; Bahaadini, R.: Forced vibrations of fluid-conveyed double piezoelectric functionally graded micropipes subjected to moving load. Microfluid. Nanofluid. 21(8), 134 (2017). https://doi.org/10.1007/s10404-017-1963-y

Ansari, R.; Gholami, R.; Norouzzadeh, A.; Sahmani, S.: Size-dependent vibration and instability of fluid-conveying functionally graded microshells based on the modified couple stress theory. Microfluid. Nanofluid. 19(3), 509–522 (2015). https://doi.org/10.1007/s10404-015-1577-1

Deng, J.; Liu, Y.; Liu, W.: Size-dependent vibration analysis of multi-span functionally graded material micropipes conveying fluid using a hybrid method. Microfluid. Nanofluid. 21(8), 133 (2017). https://doi.org/10.1007/s10404-017-1967-7

An, C.; Su, J.: Dynamic behavior of axially functionally graded pipes conveying fluid. Math. Probl. Eng. 2017, 6789634 (2017). https://doi.org/10.1155/2017/6789634

Zhou, X.-W.; Dai, H.-L.; Wang, L.: Dynamics of axially functionally graded cantilevered pipes conveying fluid. Compos. Struct. 190, 112–118 (2018). https://doi.org/10.1016/j.compstruct.2018.01.097

Lu, Z.-Q.; Zhang, K.-K.; Ding, H.; Chen, L.-Q.: Nonlinear vibration effects on the fatigue life of fluid-conveying pipes composed of axially functionally graded materials. Nonlinear. Dyn. 100(2), 1091–1104 (2020). https://doi.org/10.1007/s11071-020-05577-8

Ebrahimi-Mamaghani, A.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N.: Thermo-mechanical stability of axially graded Rayleigh pipes. Mech. Based. Des. Struct. Mach. 5, 1–30 (2020). https://doi.org/10.1080/15397734.2020.1717967

Dai, J.; Liu, Y.; Liu, H.; Miao, C.; Tong, G.: A parametric study on thermo-mechanical vibration of axially functionally graded material pipe conveying fluid. Int. J. Mech. Mater. Des. 15(4), 715–726 (2019). https://doi.org/10.1007/s10999-018-09439-5

Mirtalebi, S.H.; Ebrahimi-Mamaghani, A.; Ahmadian, M.T.: Vibration control and manufacturing of intelligibly designed axially functionally graded cantilevered macro/micro-tubes. IFAC-PapersOnLine. 52(10), 382–387 (2019). https://doi.org/10.1016/j.ifacol.2019.10.061

Tang, Y.; Yang, T.: Bi-directional functionally graded nanotubes: fluid conveying dynamics. Int. J. Appl. Mech. 10(04), 1850041 (2018). https://doi.org/10.1142/S1758825118500412

Şimşek, M.; Reddy, J.N.: Bending and vibration of functionally graded microbeams using a new higher order beam theory and the modified couple stress theory. Int. J. Eng. Sci. 64, 37–53 (2013). https://doi.org/10.1016/j.ijengsci.2012.12.002

Aghazadeh, R.; Cigeroglu, E.; Dag, S.: Static and free vibration analyses of small-scale functionally graded beams possessing a variable length scale parameter using different beam theories. Eur. J. Mech. A/Solids. 46, 1–11 (2014). https://doi.org/10.1016/j.euromechsol.2014.01.002

Zhang, P.; Fu, Y.: A higher-order beam model for tubes. Eur. J. Mech. A/Solids. 38, 12–19 (2013). https://doi.org/10.1016/j.euromechsol.2012.09.009

Zhong, J.; Fu, Y.; Wan, D.; Li, Y.: Nonlinear bending and vibration of functionally graded tubes resting on elastic foundations in thermal environment based on a refined beam model. Appl. Math. Model. 40(17), 7601–7614 (2016). https://doi.org/10.1016/j.apm.2016.03.031

Babaei, H.; Reza Eslami, M.: Size-dependent vibrations of thermally pre/post-buckled FG porous micro-tubes based on modified couple stress theory. Int. J. Mech. Sci. 180, 105694 (2020). https://doi.org/10.1016/j.ijmecsci.2020.105694

She, G.-L.; Yuan, F.-G.; Ren, Y.-R.; Liu, H.-B.; Xiao, W.-S.: Nonlinear bending and vibration analysis of functionally graded porous tubes via a nonlocal strain gradient theory. Compos. Struct. 203, 614–623 (2018). https://doi.org/10.1016/j.compstruct.2018.07.063

She, G.-L.; Yuan, F.-G.; Ren, Y.-R.; Xiao, W.-S.: On buckling and postbuckling behavior of nanotubes. Int. J. Eng. Sci. 121, 130–142 (2017). https://doi.org/10.1016/j.ijengsci.2017.09.005

Hutchinson, J.R.: Shear coefficients for timoshenko beam theory. J. Appl. Mech. 68(1), 87–92 (2000). https://doi.org/10.1115/1.1349417

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aghazadeh, R. Stability Analysis of Fluid Conveying Axially Functionally Graded Micro-Pipes Using a Refined Tube Model. Arab J Sci Eng 47, 8739–8750 (2022). https://doi.org/10.1007/s13369-021-06410-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06410-z