Abstract

This study aimed to investigate the influence of two alternative cellulosic materials: bamboo organosolv pulp and recycled waste carton pulp, on the flexural strength, fracture toughness, drying shrinkage, and durability of extruded earth-based building materials by varying the reinforcement content at 5, 7.5, and 10 wt%. The results show the flexural strength and fracture toughness achieved by the inclusion of carton pulp were between the range of 2.87–3.20 MPa and 4.22–4.52 MPa.m0.5, respectively, while the introduction of bamboo pulp gave 2.04–2.20 MPa and 3.76–4.05 MPa.m0.5, respectively. Compared with the unreinforced material, composite reinforced with 5 wt% of recycled waste carton pulp significantly enhanced flexural strength (61%), specific energy (416%), and fracture toughness (57%), while increasing the drying shrinkage (81%) and water absorption (38%) and decreasing the bulk density (15%) of earth-based matrix. Although the addition of cellulose pulp in soil matrix increased the drying shrinkage due to the high absorption capacity of pulp fibre, it decreased the wearing percentage and the shrinkage cracking of the composite which contributed to an improvement in the durability of the earth-based material. The repeated drying shrinkage test led to an improvement in the dimension stability at 87%, 83%, 85%, and 82% for 0, 5, 7.5, and 10 wt% of recycled pulp composite, respectively. Cellulose fibre reacts as crack arrester during loading and shrinkage, improves the durability, and provides a lightweight earth wall material for insulation strategies.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Marques, R.C.; Da Cruz, N.F.; Simões, P.; Faria Ferreira, S.; Pereira, M.C.; De Jaeger, S.: Economic viability of packaging waste recycling systems: a comparison between Belgium and Portugal. Resour. Conserv. Recycl. 85, 22–33 (2014). https://doi.org/10.1016/j.resconrec.2013.12.015

Ibáñez-Forés, V.; Coutinho-Nóbrega, C.; Bovea, M.D.; de Mello-Silva, C.; Lessa-Feitosa-Virgolino, J.: Influence of implementing selective collection on municipal waste management systems in developing countries: a Brazilian case study. Resour. Conserv. Recycl. 134(March), 100–111 (2018). https://doi.org/10.1016/j.resconrec.2017.12.027

Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S.: Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Constr. Build. Mater. 34, 451–456 (2012). https://doi.org/10.1016/j.conbuildmat.2012.02.097

Soroushian, P.; Shah, Z.: Reinforcement of Thin Cement Products with Recycled Wastepaper Fibers. Michigan State University (1993)

Marikunte, S.; Soroushian, P.: Statistical evaluation of long-term durability characteristics of cellulose fiber reinforced cement composites. Mater. J. 91(6), 607–616 (1995)

Soroushian, P.; Shah, Z.; Won, J.P.: Aging effects on the structure and properties of recycled wastepaper fiber cement composites. Mater. Struct. Constr. 29(189), 312–317 (1996). https://doi.org/10.1007/bf02486366

Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F.: What a waste 2.0: a global snapshot of solid waste management to 2050. The World Bank (2018)

Karade, S.R.: Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 24(8), 1323–1330 (2010). https://doi.org/10.1016/j.conbuildmat.2010.02.003

Savastano, H., Jr.; Warden, P.G.; Coutts, R.S.P.: Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 25(3), 311–319 (2003)

Savastano, H.; Warden, P.G.; Coutts, R.S.P.: Evaluation of pulps from natural fibrous material for use as reinforcement in cement product. Mater. Manuf. Process. 19(5), 963–978 (2004). https://doi.org/10.1081/AMP-200030684

Ferrara, L.; Ferreira, S.R.; della Torre, M.; Krelani, V.; de Silva, F.A.; Toledo Filho, R.D.: Effect of Cellulose Nanopulp on Autogenous and Drying Shrinkage of Cement Based Composites. In: Nanotechnology in construction, pp. 325–330. Springer (2015)

Correia, V.D.; Curvelo, A.A.; Marabezi, K.; Almeida, A.E.; Savastano, Junior H.: Bamboo cellulosic pulp produced by the ethanol/water process for reinforcement applications. Ciênc. Florest. 25(1), 127–35 (2015)

Correia, V.D.C.; Santos, S.F.; Mármol, G.; Curvelo, A.A.D.S.; Savastano, H.: Potential of bamboo organosolv pulp as a reinforcing element in fiber-cement materials. Constr. Build. Mater. 72, 65–71 (2014). https://doi.org/10.1016/j.conbuildmat.2014.09.005

Santos, S.F.; Schmidt, R.; Almeida, A.E.F.S.; Tonoli, G.H.D.; Savastano, H.: Supercritical carbonation treatment on extruded fibre-cement reinforced with vegetable fibres. Cem. Concr. Compos. 56, 84–94 (2015). https://doi.org/10.1016/j.cemconcomp.2014.11.007

Ballesteros, J.E.M.; Santos, S.F.; Mármol, G.; Savastano, H.; Fiorelli, J.: Evaluation of cellulosic pulps treated by hornification as reinforcement of cementitious composites. Constr. Build. Mater. 100, 83–90 (2015). https://doi.org/10.1016/j.conbuildmat.2015.09.044

Tonoli, G.H.D.; Joaquim, A.P.; Arsne, M.A.; Bilba, K.; Savastano, H.: Performance and durability of cement based composites reinforced with refined sisal pulp. Mater. Manuf. Process. 22(2), 149–156 (2007). https://doi.org/10.1080/10426910601062065

Ojo, E.B., et al.: Effects of fibre reinforcements on properties of extruded alkali activated earthen building materials. Constr. Build. Mater. 227, 116778 (2019). https://doi.org/10.1016/j.conbuildmat.2019.116778

Muñoz, P.; Letelier, V.; Muñoz, L.; Bustamante, M.A.: Adobe bricks reinforced with paper & pulp wastes improving thermal and mechanical properties. Constr. Build. Mater. (2020). https://doi.org/10.1016/j.conbuildmat.2020.119314

Ojo, E.; Fioroni, C.; Jr, H.S.: Durability of alkali activated clay based composites. In: 4th International Conference on Service Life Design for Infrastructures, No. August (2018)

Manu, D.: Strength and durability properties of cow dung stabilised earth. Civ. Environ. Res. 3(13), 117–126 (2013)

Avirneni, D.; Peddinti, P.R.T.; Saride, S.: Durability and long term performance of geopolymer stabilized reclaimed asphalt pavement base courses. Constr. Build. Mater. 121, 198–209 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.162

Sivakumar, A.; Santhanam, M.: A quantitative study on the plastic shrinkage cracking in high strength hybrid fibre reinforced concrete. Cem. Concr. Compos. 29(7), 575–581 (2007). https://doi.org/10.1016/j.cemconcomp.2007.03.005

Jiang, C.; Yang, Y.; Wang, Y.; Zhou, Y.; Ma, C.: Autogenous shrinkage of high performance concrete containing mineral admixtures under different curing temperatures. Constr. Build. Mater. 61, 260–269 (2014). https://doi.org/10.1016/j.conbuildmat.2014.03.023

Walker, P.J.: Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem. Concr. Compos. 9465(95), 301–310 (1995)

Kampala, A.; Horpibulsuk, S.; Prongmanee, N.; Chinkulkijniwat, A.: Influence of wet-dry cycles on compressive strength of calcium carbide residue-fly ash stabilized clay. J. Mater. Civ. Eng. 26(4), 633–643 (2014). https://doi.org/10.1061/(ASCE)MT.1943-5533.0000853

Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B.: Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 101, 797–809 (2015). https://doi.org/10.1016/j.conbuildmat.2015.10.069

Ghavami, K.; Toledo Filho, R.D.; Barbosa, N.P.: Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 21(1), 39–48 (1999). https://doi.org/10.1016/S0958-9465(98)00033-X

Bouhicha, M.; Aouissi, F.; Kenai, S.: Performance of composite soil reinforced with barley straw. Cem. Concr. Compos. 27(5), 617–621 (2005). https://doi.org/10.1016/j.cemconcomp.2004.09.013

Sangma, S.; Tripura, D.D.: Experimental study on shrinkage behaviour of earth walling materials with fibers and stabilizer for cob building. Constr. Build. Mater. 256, 119449 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119449

Horpibulsuk, S.: Strength and microstructure of cement stabilized clay. In: Scanning Electron Microscopy, IntechOpen (2012)

Maskell, D.; Heath, A.; Walker, P.: Inorganic stabilisation methods for extruded earth masonry units. Constr. Build. Mater. 71, 602–609 (2014). https://doi.org/10.1016/j.conbuildmat.2014.08.094

Khelifi, H.; Lecompte, T.; Perrot, A.; Ausias, G.: Mechanical enhancement of cement-stabilized soil by flax fibre reinforcement and extrusion processing. Mater. Struct. Constr. 49(4), 1143–1156 (2016). https://doi.org/10.1617/s11527-015-0564-z

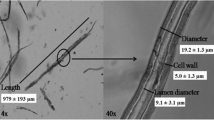

Stanislas, T.T., et al.: Production and characterization of pulp and nanofibrillated cellulose from selected tropical plants. J. Nat. Fibers 00(00), 1–17 (2020). https://doi.org/10.1080/15440478.2020.1787915

Ballesteros, J.E.M.; dos Santos, V.; Mármol, G.; Frías, M.; Fiorelli, J.: Potential of the hornification treatment on eucalyptus and pine fibers for fiber-cement applications. Cellulose 24(5), 2275–2286 (2017)

Ojo, E.B.; Mustapha, K.; Teixeira, R.S.; Savastano, H.; Savastano, H., Jr.: Development of unfired earthen building materials using muscovite rich soils and alkali activators. Case Stud. Constr. Mater. 11, e00262 (2019). https://doi.org/10.1016/j.cscm.2019.e00262

Komadja, G.C., et al.: Assessment of stability of a Himalayan road cut slope with varying degrees of weathering: a finite-element-model-based approach. Heliyon (2020). https://doi.org/10.1016/j.heliyon.2020.e05297

Ojo, E.B., et al.: Mechanical performance of fiber-reinforced alkali activated un-calcined earth-based composites. Constr. Build. Mater. 247, 118588 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118588

Stanislas, T.T., et al.: Effect of cellulose pulp fibres on the physical, mechanical, and thermal performance of extruded earth-based materials. J Build Eng 39(July), 102259 (2021). https://doi.org/10.1016/j.jobe.2021.102259

A. S. for Testing and Materials, “ASTM C 948-81: Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete (2009)

Standard, A.: AS 1012.13: Determination of the Drying Shrinkage of Concrete for Samples Prepared in the Field or in the Laboratory. Standards Australia, Sydney (1992)

Giordano, B.L.; de Souza, R.B.; John, V.M.: Influência do ligante na retração por secagem em fibrocimento. Ambient. Construído 9(4), 7–16 (2009)

Zweben, C.; Smith, W.S.; Wardle, M.W.: Test methods for fiber tensile strength, composite flexural modulus, and properties of fabric-reinforced laminates. In: Composite Materials: Testing and Design (Fifth Conference) (1979)

ASTM E399 Standard: Standard test method for linear-elastic plane-strain fracture toughness KIC of metallic materials. ASTM International, West Conshohocken, PA (2012)

Mustapha, K.; Annan, E.; Azeko, S.T.; Zebaze Kana, M.G.; Soboyejo, W.O.: Strength and fracture toughness of earth-based natural fiber-reinforced composites. J. Compos. Mater. 50(9), 1145–1160 (2016). https://doi.org/10.1177/0021998315589769

Ciaramello, D.: Bamboo as a raw material for the paper industry: studies of three cooking processes with Bambusa tuldoides Munro. Bragantia 29(unico), 11–22 (1970)

ABNT NBR.5640: Telha estrutural de fibrocimento Rio de Janeiro (1995)

Weng, C.H.; Lin, D.F.; Chiang, P.C.: Utilization of sludge as brick materials. Adv. Environ. Res. 7(3), 679–685 (2003). https://doi.org/10.1016/S1093-0191(02)00037-0

Correia, C.; Francisco, S.; Soares, R.; Savastano, H.: Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 160, 376–384 (2018). https://doi.org/10.1016/j.conbuildmat.2017.11.066

Nadhari, W.N.A.W.; Danish, M.; Nasir, M.S.R.M.; Geng, B.J.: Mechanical properties and dimensional stability of particleboard fabricated from steam pre-treated banana trunk waste particles. J. Build. Eng. 26(February), 22–25 (2019). https://doi.org/10.1016/j.jobe.2019.100848

Ismail, S.; Yaacob, Z.: Properties of laterite brick reinforced with oil palm empty fruit bunch fibres. Pertanika J. Sci. Technol. 19(1), 33–43 (2011)

Ballesteros, J.E.M.; Mármol, G.; Filomeno, R.; Rodier, L.; Savastano, H.; Fiorelli, J.: Synergic effect of fiber and matrix treatments for vegetable fiber reinforced cement of improved performance. Constr. Build. Mater. 205, 52–60 (2019). https://doi.org/10.1016/j.conbuildmat.2019.02.007

Kolawole, F.O.O.; Olugbemi, O.M.M.; Kolawole, S.K.K.; Owa, A.F.F.; Ajayi, E.S.S.: Fracture Toughness and Strength of Bamboo-Fiber Reinforced Laterite as Building Block Material. Univers. J. Mater. Sci. 5(3), 64–72 (2017). https://doi.org/10.13189/ujms.2017.050302

IRC: SP :89: Guidelines for soil and granular material stabilization using cement, lime and fly ash. Indian Roads Congr., 53(9):1689–1699 (2010).

Funding

The authors gratefully acknowledge the financial support given by the Pan African Materials Institute (PAMI) under the World Bank African Centres of Excellence Program (Grant No. AUST/PAMI/2015 5415-NG). The author (HS) is also grateful to the Brazilian National Council for Scientific and Technological Development (Conselho Nacional de Desenvolvimento Científico e Tecnológico: {PQ CNPq 307723/2017–8/}.

Author information

Authors and Affiliations

Contributions

Tido Tiwa Stanislas declares that all the authors had a significant participation in the development of this work. Tido Tiwa Stanislas was involved in conceptualization, investigation, and writing—original draft; Gbetoglo Charles Komadja and Odette Fayen Ngasoh were involved in investigation and writing—review and editing; Ifeyinwa Ijeoma Obianyo was involved in investigation, visualization, and writing—review and editing; Peter Azikiwe Onwualu was involved in investigation, visualization, writing—review and editing, and funding acquisition; and Josepha Foba Tendo and Holmer Savastano Junior were involved in conceptualization, supervision, writing—review and editing, and funding acquisition;

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Stanislas, T.T., Komadja, G.C., Ngasoh, O.F. et al. Performance and Durability of Cellulose Pulp-Reinforced Extruded Earth-based Composites. Arab J Sci Eng 46, 11153–11164 (2021). https://doi.org/10.1007/s13369-021-05698-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05698-1