Abstract

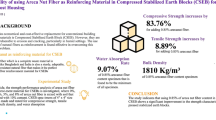

Recently, studies are oriented to introduce sustainable materials in construction. This study aims to investigate the effects of sisal fibers on the thermophysical and mechanical properties of compressed earth blocks (CEB) made of local materials by mixing red clayey soil taken from the M’sila region in Algeria and brick waste (BW). First, the maximum percentage of BW is fixed at 20% while respecting the plasticity criteria. Then, the effects of fibers and cement addition on the engineering properties of CEB are analyzed and compared according to fiber and cement contents. Sisal fibers are added with different percentages varying from 0 to 0.5%, while cement content is used with four percentages: 0, 5, 7, and 9% (by wt% of the newly modified soil). Many tests are performed including, capillary absorption rate, thermal conductivity, compressive/tensile strengths, and abrasion resistance. The results showed that the inclusion of sisal fibers improves the thermal insulation of cement-stabilized blocks by up to 21% and strength by 150%. However, it is observed that the hydrophilic character of sisal fibers increases the capillary absorption by 81%, and the abrasion coefficient increases with the increase in fiber content. Furthermore, the investigation revealed that the use of fibers alone is insufficient to ensure the stability of the blocks in moist conditions since the material fully loses its resistance, which requires the total protection of material against any type of infiltration and/or the use of cement as stabilizing agents. As a result, the research showed that sisal fibers may be used in CEB reinforcement, further an environmentally alternative solution was proposed for managing BW by their use in CEB manufacturing as this contributed to sustainability and circular economy strategies.

Similar content being viewed by others

Availability of data and material

The data of this study are available on request from the corresponding author.

Code availability

Not applicable.

References

Labiad Y, Meddah A, Beddar M (2022) Physical and mechanical behavior of cement-stabilized compressed earth blocks reinforced by sisal fibers. Mater Today Proc. https://doi.org/10.1016/j.matpr.2021.12.446

Meddah A, Laoubi H, Bederina M (2020) Effectiveness of using rubber waste as aggregates for improving thermal performance of plaster-based composites. Innov Infrastruct Solut, pp 1–9. https://doi.org/10.1007/s41062-020-00311-0

Alsaadawi MM, Amin M, Tahwia AM (2022) Thermal , mechanical and microstructural properties of sustainable concrete incorporating Phase change materials. Constr Build Mater 356. https://doi.org/10.1016/j.conbuildmat.2022.129300

Meddah A, Beddar M, Bali A (2014) Experimental study of compaction quality for roller compacted concrete pavement containing rubber tire wastes. Sustainability, eco-efficiency, and conservation in transportation infrastructure asset management. CRC Press, Boca Raton, pp 273–278

Meddah A, Bensaci H, Beddar M, Bali A (2017) Study of the effects of mechanical and chemical treatment of rubber on the performance of rubberized roller-compacted concrete pavement. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-017-0068-5

Tahwia AM, Abd Ellatief M, Heneigel AM, Abd Elrahman M (2022) Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram Int 48:19662–19674. https://doi.org/10.1016/j.ceramint.2022.03.103

Meddah A, Aziz M, Mohamed C (2022) The efficiency of recycling expired cement waste in cement manufacturing : a sustainable construction material. Circ Econ Sustain. https://doi.org/10.1007/s43615-022-00161-1

Danso H, Martinson B, Ali M, Mant C (2014) Performance characteristics of enhanced soil blanks: a quantitative review—Supplementary tables. Build Environ, pp 1–11

Taallah B, Guettala A (2016) The mechanical and physical properties of compressed earth block stabilized with lime and filled with untreated and alkali-treated date palm fibers. Constr Build Mater 104:52–62. https://doi.org/10.1016/j.conbuildmat.2015.12.007

Walker PJ (1995) Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem Concr Compos 17:301–310

Mesbah A, Morel JC, Walker P, Ghavami K (2004) Development of a direct tensile test for compacted earth blocks reinforced with natural fibers. J Mater Civ Eng 16:95–98. https://doi.org/10.1061/(ASCE)0899-1561(2004)16:1(95)

Riza FV, Rahman IA, Zaidi AMA (2011) Preliminary study of compressed stabilized earth brick (CSEB). Aust J Basic Appl Sci 5:6–12

Rigassi V (1995) Blocs de terre comprimée. Volume I. Manuel de production, CRATerre-EAG, Friedrich Vieweg & Sohn, Braunschweig, Allemagne, p 104

Beddar M, Meddah A, Belagraa L (2017) Feasibility of using fibrous waste in cement-based material. In: IOP Conference Series: Materials Science and Engineering

Meddah A, Belagraa L, Beddar M (2015) Effect of the fibre geometry on the flexural properties of reinforced steel fibre refractory concrete. Proc Eng 108:185–192. https://doi.org/10.1016/j.proeng.2015.06.135

Benouadah A, Beddar M, Meddah A (2017) Physical and mechanical behaviour of a roller compacted concrete reinforced with polypropylene fiber. J Fundam Appl Sci 9:623–635. https://doi.org/10.4314/jfas.v9i2.1

Meddah A, Merzoug K (2017) Feasibility of using rubber waste fibers as reinforcements for sandy soils. Innov Infrastruct Solut 2:5. https://doi.org/10.1007/s41062-017-0053-z

Meddah A, Goufi AE, Pantelidis L (2022) Improving very high plastic clays with the combined effect of sand, lime, and polypropylene fibers. Appl Sci 12:9924. https://doi.org/10.3390/app12199924

Ziegler S, Leshchinsky D, Ling HI, Perry EB (1998) Effect of short polymeric fibers on crack development in clays. Soils Found 38:247–253

Khedari J, Charoenvai S, Hirunlabh J (2003) New insulating particleboards from durian peel and coconut coir. Build Environ 38:435–441

Khedari J, Watsanasathaporn P, Hirunlabh J (2005) Development of fibre-based soil-cement block with low thermal conductivity. Cem Concr Compos 27:111–116. https://doi.org/10.1016/j.cemconcomp.2004.02.042

Donkor P, Obonyo E (2016) Compressed soil blocks: influence of fibers on flexural properties and failure mechanism. Constr Build Mater 121:25–33

Keeler E, Sarhat S (2019) Mechanical properties of on-site manufactured compressed earth mechanical properties of on-site manufactured compressed earth blocks. In: Laval (Greater Montreal) C (ed) 7th CSCE International Engineering Mechanics and Materials Specialty Conference. pp 133 (1–10)

Guettala S, Kriker A, Taallah B, Guettala A (2014) Mechanical properties and hygroscopicity behavior of compressed earth block filled by date palm fibers. Constr Build Mater 59:161–168. https://doi.org/10.1016/j.conbuildmat.2014.02.058

Laibi AB, Poullain P, Leklou N et al (2018) Influence of the kenaf fiber length on the mechanical and thermal properties of Compressed Earth Blocks (CEB). KSCE J Civ Eng 22:785–793. https://doi.org/10.1007/s12205-017-1968-9

Mostafa M, Uddin N (2016) Case Studies in construction materials experimental analysis of compressed earth block ( CEB ) with banana fi bers resisting fl exural and compression forces. Case Stud Constr Mater 5:53–63. https://doi.org/10.1016/j.cscm.2016.07.001

Namango S (2006) Development of cost-effective earthen building material for housing wall construction. Doctoral dissertation, BTU Cottbus-Senftenberg

Bouchefra I, Zahra F, Bichri EL, et al (2022) Mechanical and thermophysical properties of compressed earth brick rienforced by raw and treated doum fibers. Constr Build Mater 318:126031. https://doi.org/10.1016/j.conbuildmat.2021.126031

Ajouguim S, Talibi S, Djelal-Dantec C et al (2019) Effect of Alfa fibers on the mechanical and thermal properties of compacted earth bricks. Mater Today Proc 37:4049–4057. https://doi.org/10.1016/j.matpr.2020.07.539

Abdellatief M, Elemam WE, Alanazi H, Tahwia AM (2023) Production and optimization of sustainable cement brick incorporating clay brick wastes using response surface method. Ceram Int 49:9395–9411

NF P 94-056 (1995) Sols, reconnaissance et essais (nalyse granulométrique: méthode par tamisage à sec après lavage (French standard)

EN 197/1 (2011) Standard: cement: composition, specifications and conformity criteria for common cements. Part 1

Ghavami K, Toledo Filho RD, Barbosa NP (1999) Behaviour of composite soil reinforced with natural fibres. Cem Concr Compos 21:39–48. https://doi.org/10.1016/S0958-9465(98)00033-X

Laborel-Préneron A, Aubert JE, Magniont C et al (2016) Plant aggregates and fibers in earth construction materials: a review. Constr Build Mater 111:719–734. https://doi.org/10.1016/j.conbuildmat.2016.02.119

Millogo Y, Morel JC, Aubert JE, Ghavami K (2014) Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr Build Mater 52:71–78. https://doi.org/10.1016/j.conbuildmat.2013.10.094

Shukla SK (2017) Developments in geotechnical engineering. Springer, Cham

Prabakar J, Sridhar RS (2002) Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr Build Mater 16:123–131. https://doi.org/10.1016/S0950-0618(02)00008-9

Sanjay MR, Suchart S, Jyotishkumar P et al (2018) A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2018.11.083

Houben H, Guillaud H (1989) Traité de construction en terre CRATerre. L’Encyclopédie la Constr en terre 1:300

Reddy BVV, Jagadish KS (1993) The static compaction of soils. Géotechnique 43:337–341

Pkla A (2002) Caractérisation en compression simple des blocs de terre comprimée (BTC): applicationaux maçonneries “‘BTC- Mortier de terre.’” ENTPE

AFNor XP (2001) P13-901: Blocs de terre comprimée pour murs et cloisons, Définitions-Spécifications-Méthodes d’essais-Conditions de réception. Saint-Denis La Plaine Cedex: AFNor

Thiombiano A, Fasso B (1197) Mode opératoire pour la réalisation d’essais de résistance sur blocs de terre comprimée. Materials and Structures, RILEM TC 164-EBM: Mechanics of Earth as a Building Material, vol 30, pp 515–517

Cid J, Mazarrón FR, Cañas I (2011) Las normativas de construcción con tierra en el mundo. Inf la Construcción 63:159–169

Mesbah A, Morel JC, Olivier M (1999) Clayey soil behaviour under static compaction test. Mater Struct 32:687–694

Al Rim K, Ledhem A, Douzane O et al (1999) Influence of the proportion of wood on the thermal and mechanical performances of clay-cement-wood composites. Cem Concr Compos 21:269–276

Taoukil D, El Bouardi A, Sick F et al (2013) Moisture content influence on the thermal conductivity and diffusivity of wood-concrete composite. Constr Build Mater 48:104–115. https://doi.org/10.1016/j.conbuildmat.2013.06.067

Simons A, Laborel-Préneron A, Bertron A, et al (2015) Development of bio-based earth products for healthy and sustainable buildings: characterization of microbiological, mechanical and hygrothermal properties. Mater Tech 103. https://doi.org/10.1051/mattech/2015011

Zakham N, El Rhaffari Y, Ammari A et al (2018) Influence of cement content on the thermal properties of compressed earth blocks (CEB) in the dry state. MATEC Web Conf 149:1–5. https://doi.org/10.1051/matecconf/201714901059

Doubi HG, Kouamé AN, Konan LK et al (2017) Thermal conductivity of compressed earth bricks strengthening by shea butter wastes with cement. Mater Sci Appl 08:848–858. https://doi.org/10.4236/msa.2017.812062

Kerali AG, Masce M, Icm APGC (2001) Durability of compressed and cement-stabilised building blocks. PhD thesis, The University of Warwick

Ismail S, Yaacob Z (2011) Properties of laterite brick reinforced with oil palm empty fruit bunch fibres. Pertanika J Sci Technol 19(1):33–43

Jeefferie AR, Nurul Fariha O, Mohd Warikh AR et al (2011) Preliminary study on the physical and mechanical properties of tapioca starch/sugarcane fiber cellulose composite. J Eng Appl Sci 6:1819–6608

Broderick GP, Daniel DE (1990) Stabilizing compacted clay against chemical attack. J Geotech Eng 116:1549–1567

Bogas JA, Silva M, Gomes G et al (2018) Unstabilized and stabilized compressed earth blocks with partial incorporation of recycled aggregates of recycled aggregates. Int J Archit Herit 00:1–16. https://doi.org/10.1080/15583058.2018.1442891

Kitazume M, Terashi M (2013) The deep mixing method. CRC Press, BocaRaton

Ho LS, Nakarai K, Ogawa Y et al (2017) Strength development of cement-treated soils: effects of water content, carbonation, and pozzolanic reaction under drying curing condition. Constr Build Mater 134:703–712. https://doi.org/10.1016/j.conbuildmat.2016.12.065

Eko RM, Offa ED, Ngatcha TY, Minsili LS (2012) Potential of salvaged steel fibers for reinforcement of unfired earth blocks. Constr Build Mater 35:340–346

Izemmouren O, Guettala A, Guettala S (2015) Mechanical properties and durability of lime and natural pozzolana stabilized steam-cured compressed earth block bricks. Geotech Geol Eng 33:1321–1333. https://doi.org/10.1007/s10706-015-9904-6

Venkatarama Reddy BV, Gupta A (2005) Characteristics of soil-cement blocks using highly sandy soils. Mater Struct Constr 38:651–658. https://doi.org/10.1617/14265

Meddah A (2015) Characterization of roller compacted concrete contaning rubber-tire wastes. National Polytechnic school of Algiers

Mohamed AEMK (2013) Improvement of swelling clay properties using hay fibers. Constr Build Mater 38:242–247. https://doi.org/10.1016/j.conbuildmat.2012.08.031

Danso H, Martinson DB, Ali M, Williams JB (2015) Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr Build Mater 101:797–809. https://doi.org/10.1016/j.conbuildmat.2015.10.069

Bouhicha M, Aouissi F, Kenai S (2005) Performance of composite soil reinforced with barley straw. Cem Concr Compos 27:617–621. https://doi.org/10.1016/j.cemconcomp.2004.09.013

Gaw B (2011) Soil reinforcement with natural fibers for low-income housing communities, Major Qualif. Proj Submitt Fac Worcest Polytech Inst Proj Number LDA-1006 Worcest Polytech Inst MA USA

Yetgin Ş, Çavdar Ö, Cavdar A (2008) The effects of the fiber contents on the mechanic properties of the adobes. Constr Build Mater 22:222–227

Meukam P, Noumowe A, Jannot Y, Duval R (2003) Caractérisation thermophysique et mécanique de briques de terre stabilisées en vue de l’isolation thermique de bâtimentThermophysical and mechanical characterization of stabilized clay bricks for building thermal insulation. Mater Struct 36:453–460. https://doi.org/10.1007/bf02481525

Ledhem A, Dheilly RM, Benmalek ML, Quéneudec M (2000) Properties of wood-based composites formulated with aggregate industry waste. Constr Build Mater 14:341–350

Giroudon M, Laborel-Préneron A, Aubert JE, Magniont C (2019) Comparison of barley and lavender straws as bioaggregates in earth bricks. Constr Build Mater 202:254–265. https://doi.org/10.1016/j.conbuildmat.2018.12.126

Babé C, Kidmo DK, Tom A, et al (2020) Thermomechanical characterization and durability of adobes reinforced with millet waste fibers (sorghum bicolor). Case Stud Constr Mater 13. https://doi.org/10.1016/j.cscm.2020.e00422

Okoye BOUEAENM, Chukwuma GO (2013) Natural fibre induced properties on stabilized earth bricks. Indian J Res, pp 1–4

Funding

No applicable.

Author information

Authors and Affiliations

Contributions

YL contributed to resources, visualization and draft paper writing, AM contributed to conceptualization, methodology, writing—review and editing; MB contributed to resources and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Informed consent

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Labiad, Y., Meddah, A. & Beddar, M. Performance of sisal fiber-reinforced cement-stabilized compressed-earth blocks incorporating recycled brick waste. Innov. Infrastruct. Solut. 8, 107 (2023). https://doi.org/10.1007/s41062-023-01078-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01078-w