Abstract

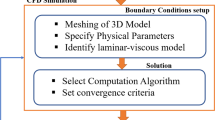

Hydroxyapatite (HA)-based composite bone scaffolds are developed using solvent casting particulate leaching technique by varying the weight percentages of HA from 50 to 70% (w/w) in polymethyl methacrylate matrix. The chemical properties of the developed scaffolds are investigated by XRD analysis which shows the presence of crystalline HA and traces of β-TCP in the scaffolds. The microstructure of the scaffolds is studied by the SEM micrographs, which show porous morphology with an average pore size of 119 ± 18–148 ± 23 µm and a maximum pore size of 148 ± 23 µm for HA 50 scaffold. The highest porosity of 75 ± 2.0% is recorded for HA 50 scaffold by conducting liquid displacement test and a maximum compressive strength of 6.26 ± 0.53 MPa is recorded for HA 60 scaffold by performing uniaxial compression test of the scaffolds. The permeability and wall shear stress (WSS) of the scaffolds are investigated by computational fluid dynamics (CFD). The CFD analysis is performed in a fluid domain developed by Boolean operations on the CAD model of the scaffold developed using micro-computed tomography-based 3D image acquisition technique by Mimics V1. Results show that the permeability increases and WSS decreases with an increase in the porosity of the scaffolds. However, both permeability and WSS obtained for the developed scaffolds are within the limit prescribed for the growth of bone tissues. It is concluded that scaffolds with 60 wt% of HA exhibit the best combination of porosity, permeability and compressive strength making it suitable for bone tissue engineering applications.

Similar content being viewed by others

References

Pilia, M.; Guda, T.; Appleford, M.: Development of composite scaffolds for load-bearing segmental bone defects. Biomed. Res. Int. 2013, 1–15 (2013)

Wu, S.; Liu, X.; Yeung, K.W.K.; Liu, C.; Yang, X.: Biomimetic porous scaffolds for bone tissue engineering. Mater. Sci. Eng. R Rep. 80, 1–36 (2014)

Barua, E.; Deoghare, A.B.; Chatterjee, S.; Mate, V.R.: Characterization of mechanical and micro-architectural properties of porous hydroxyapatite bone scaffold using green microalgae as binder. Arab. J. Sci. Eng. 44, 7707–7722 (2019)

Tang, D.; Tare, R.S.; Yang, L.Y.; Williams, D.F.; Ou, K.L.; Oreffo, R.O.C.: Biofabrication of bone tissue: approaches, challenges and translation for bone regeneration. Biomaterials 83, 363–382 (2016)

Wu, T.; Yu, S.; Chen, D.; Wang, Y.: Bionic design, materials and performance of bone tissue scaffolds. Materials (Basel) 10, 1187 (2017)

Taraballi, F.; Bauza, G.; McCulloch, P.; Harris, J.; Tasciotti, E.: Concise review: biomimetic functionalization of biomaterials to stimulate the endogenous healing process of cartilage and bone tissue. Stem Cells Transl. Med. 6, 2186–2196 (2017)

Truscello, S.; Kerckhofs, G.; Bael, S.; Van, S.; Pyka, G.; Schrooten, J.; Van Oosterwyck, H.: Acta biomaterialia prediction of permeability of regular scaffolds for skeletal tissue engineering: a combined computational and experimental study. Acta Biomater. 8, 1648–1658 (2012)

Li, S.; de Wijn, J.R.; Li, J.; Layrolle, P.; de Groot, K.: Macroporous biphasic calcium phosphate scaffold with high permeability/porosity ratio. Tissue Eng. 9, 535–548 (2003)

Klawitter, J.J.; Hulbert, S.F.: Application of porous ceramics for the attachment of load bearing applications. J. Biomed. Mater. Res. Symp. 2, 161 (1971)

Newman, P.; Zreiqat, H.: Design and fabrication of 3D printed scaffolds with a mechanical strength comparable to cortical bone to repair large bone defects. Sci. Rep. 6, 19468 (2016)

Ayers, R.A.; Wolford, L.M.; Bateman, T.A.; Ferguson, V.L.; Simske, S.J.: Quantification of bone ingrowth into porous block hydroxyapatite in humans. J. Biomed. Mater. Res. 47, 54–59 (1999)

Deb, P.; Barua, E.; Deoghare, A.B.; Lala, S.D.: Development of bone scaffold using Puntius conchonius fish scale derived hydroxyapatite: physico-mechanical and bioactivity evaluations. Ceram. Int. 45, 10004–10012 (2019)

Nauman, E.A.; Fong, K.E.; Keaveny, T.M.: Dependence of intertrabecular permeability on flow direction and anatomic site. Ann. Biomed. Eng. 27, 517–524 (1999)

Blokhuis, T.J.; Termaat, M.F.; den Boer, F.C.; Patka, P.; Bakker, F.C.; Haarman, H.J.T.M.: Properties of calcium phosphate ceramics in relation to their in vivo behavior. J. Trauma Inj. Infect. Crit. Care 48, 179 (2003)

Albrektsson, T.; Johansson, C.: Osteoinduction, osteoconduction and osseointegration. Eur. Spine J. 10, S96–S101 (2001)

Botchwey, E.A.; Dupree, M.A.; Pollack, S.R.; Levine, E.M.; Laurencin, C.T.: Tissue engineered bone: measurement of nutrient transport in three-dimensional matrices. J. Biomed. Mater. Res., Part A 67, 357–367 (2003)

Andrades, A.; Narváez-Ledesma, L.; Cerón-Torres, L.; Cruz-Amaya, P.; LópezGuillén, D.; Laura Mesa-Almagro, M.; Moreno-Moreno, A.: Bone engineering: a matter of cells, growth factors and biomaterials. In: Regenerative Medicine and Tissue Engineering, vol. 25, pp. 616–618. InTech (2013)

Blackwood, K.A.; Bock, N.; Dargaville, T.R.; Ann Woodruff, M.: Scaffolds for growth factor delivery as applied to bone tissue engineering. Int. J. Polym. Sci. 2012, 1–25 (2012)

Bancroft, G.N.; Sikavitsas, V.I.; van den Dolder, J.; Sheffield, T.L.; Ambrose, C.G.; Jansen, J.A.; Mikos, A.G.: Fluid flow increases mineralized matrix deposition in 3D perfusion culture of marrow stromal osteoblasts in a dose-dependent manner. Proc. Natl. Acad. Sci. 99, 12600–12605 (2002)

Carver, S.E.; Heath, C.A.: Influence of intermittent pressure, fluid flow, and mixing on the regenerative properties of articular chondrocytes. Biotechnol. Bioeng. 65, 274–281 (1999)

Fritton, S.P.: Fluid and solute trnasport in bone: flow-induced mechanotransduction. Annu. Rev. Fluid Mech. 41, 347–374 (2010)

Jaasma, M.J.; O’Brien, F.J.: Mechanical Stimulation of Osteoblasts Using Steady and Dynamic Fluid Flow. Tissue Eng. Part A 14, 1213–1223 (2008)

Bhaskar, B.; Owen, R.; Bahmaee, H.; Rao, P.S.; Reilly, G.C.: Design and assessment of a dynamic perfusion bioreactor for large bone tissue engineering scaffolds. Appl. Biochem. Biotechnol. 185, 555–563 (2018)

Maes, F.; Van Ransbeeck, P.; Van Oosterwyck, H.; Verdonck, P.: Modeling fluid flow through irregular scaffolds for perfusion bioreactors. Biotechnol. Bioeng. 103, 621–630 (2009)

Voronov, R.; Vangordon, S.; Sikavitsas, V.I.; Papavassiliou, D.V.: Computational modeling of flow-induced shear stresses within 3D salt-leached porous scaffolds imaged via micro-CT. J. Biomech. 43, 1279–1286 (2010)

Sabzi, M.; Far, S.M.; Dezfuli, S.M.: Characterization of bioactivity behavior and corrosion responses of hydroxyapatite-ZnO nanostructured coating deposited on NiTi shape memory alloy. Ceram. Int. 44, 21395–21405 (2018)

Mersagh Dezfuli, S.; Sabzi, M.: Deposition of ceramic nanocomposite coatings by electroplating process: a review of layer-deposition mechanisms and effective parameters on the formation of the coating. Ceram. Int. 45, 21835–21842 (2019)

Mousavi Anijdan, S.H.; Sabzi, M.; Asadian, M.; Jafarian, H.R.: Effect of sub-layer temperature during HFCVD process on morphology and corrosion behavior of tungsten carbide coating. Int. J. Appl. Ceram. Technol. 16, 243–253 (2019)

Sabzi, M.; Mousavi Anijdan, S.H.; Asadian, M.: The effect of substrate temperature on microstructural evolution and hardenability of tungsten carbide coating in hot filament chemical vapor deposition. Int. J. Appl. Ceram. Technol. 15, 1350–1357 (2018)

Sabzi, M.; Mousavi Anijdan, S.H.; Ghobeiti-Hasab, M.; Fatemi-Mehr, M.: Sintering variables optimization, microstructural evolution and physical properties enhancement of nano-WC ceramics. J. Alloys Compd. 766, 672–677 (2018)

Sabzi, M.; Mersagh Dezfuli, S.: A study on the effect of compositing silver oxide nanoparticles by carbon on the electrochemical behavior and electronic properties of zinc-silver oxide batteries. Int. J. Appl. Ceram. Technol. 15, 1446–1458 (2018)

Ragunathan, S.; Govindasamy, G.; Raghul, D.R.; Karuppaswamy, M.; VijayachandraTogo, R.K.: Hydroxyapatite Reinforced Natural Polymer Scaffold for Bone Tissue Regeneration. In: Materials Today Proceedings (2019)

Elrayah, A.; Xiao, D.; Suliman, E.; Weng, J.: A simple method to prepare hybrid hydroxyapatite scaffold mimicking nature bone. Ceram. Int. 45, 18931–18936 (2019)

Li, Z.; Chu, D.; Gao, Y.; Jin, L.; Zhang, X.; Cui, W.; Li, J.: Biomimicry, biomineralization, and bioregeneration of bone using advanced three-dimensional fibrous hydroxyapatite scaffold. Mater. Today Adv. 3, 100014 (2019)

Hannink, G.; Arts, J.J.C.: Bioresorbability, porosity and mechanical strength of bone substitutes: what is optimal for bone regeneration? Injury 42, S22–S25 (2011)

He, L.; Standard, O.C.; Huang, T.T.Y.; Latella, B.A.; Swain, M.V.: Mechanical behaviour of porous hydroxyapatite. Acta Biomater. 4, 577–586 (2008)

Xu, S.; Guo, W.; Lu, J.; Li, W.: Fabrication and mechanical properties of PLLA and CPC composite scaffolds †. J. Mech. Sci. Technol. 26, 2857–2862 (2012)

Barua, E.; Deoghare, A.B.; Chatterjee, S.; Sapkal, P.: Effect of ZnO reinforcement on the compressive properties, in vitro bioactivity, biodegradability and cytocompatibility of bone scaffold developed from bovine bone-derived HAp and PMMA. Ceram. Int. 45(16), 20331–20345 (2019)

Pang, Y.X.; Bao, X.: Influence of temperature, ripening time and calcination on the morphology and crystallinity of hydroxyapatite nanoparticles. J. Eur. Ceram. Soc. 23, 1697–1704 (2003)

Vossenberg, P.; Higuera, G.A.; van Straten, G.; van Blitterswijk, C.A.; van Boxtel, A.J.B.: Darcian permeability constant as indicator for shear stresses in regular scaffold systems for tissue engineering. Biomech. Model. Mechanobiol. 8, 499–507 (2009)

Dias, M.R.; Fernandes, P.R.; Guedes, J.M.; Hollister, S.J.: Permeability analysis of scaffolds for bone tissue engineering. J. Biomech. 45, 938–944 (2012)

Ali, D.; Sen, S.: Permeability and fluid flow-induced wall shear stress of bone tissue scaffolds: computational fluid dynamic analysis using Newtonian and non-Newtonian blood flow models. Comput. Biol. Med. 99, 201–208 (2018)

Barua, E.; Das, A.; Pamu, D.; Deoghare, A.B.; Deb, P.; Das, S.: Effect of thermal treatment on the physico-chemical properties of bioactive hydroxyapatite derived from caprine bone bio-waste. Ceram. Int. 45, 23265–23277 (2019)

Shi, Y.; Liu, J.; Yu, L.; Zhen, L.; Bo, H.: β-TCP sca ff old coated with PCL as biodegradable materials for dental applications. Ceram. Int. 44, 15086–15091 (2018)

Murphy, C.M.; Haugh, M.G.; Brien, F.J.O.: Biomaterials the effect of mean pore size on cell attachment, proliferation and migration in collagen—glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 31, 461–466 (2010)

Roohani-esfahani, S.; Nouri-khorasani, S.; Lu, Z.; Appleyard, R.; Zreiqat, H.: Biomaterials The influence hydroxyapatite nanoparticle shape and size on the properties of biphasic calcium phosphate scaffolds coated with hydroxyapatite e PCL composites. Biomaterials 31, 5498–5509 (2010)

Cioffi, M.; Boschetti, F.; Raimondi, M.T.; Dubini, G.: Modeling evaluation of the fluid-dynamic microenvironment in tissue-engineered constructs: a micro-CT based model. Biotechnol. Bioeng. 93, 500–510 (2006)

Olmos, L.; Bouvard, D.; Cabezas-Villa, J.L.; Lemus-Ruiz, J.; Jiménez, O.; Arteaga, D.: Analysis of compression and permeability behavior of porous Ti6Al4V by computed microtomography. Met. Mater. Int. 25, 669–682 (2018)

Innocentini, M.D.M.; Faleiros, R.K.; Pisani, R.; Thijs, I.; Luyten, J.; Mullens, S.: Permeability of porous gelcast scaffolds for bone tissue engineering. J. Porous Mater. 17, 615–627 (2010)

Hendrikson, W.J.; Deegan, A.J.; Yang, Y.; van Blitterswijk, C.A.; Verdonschot, N.; Moroni, L.; Rouwkema, J.: Influence of additive manufactured scaffold architecture on the distribution of surface strains and fluid flow shear stresses and expected osteochondral cell differentiation. Front. Bioeng. Biotechnol. 5, 1–11 (2017)

Acknowledgements

The authors would like to thank TEQIP-III and Innovation Lab of NIT Silchar for providing fund for this work. The authors would also like to acknowledge MHRD, Govt. of India, for providing financial assistantship to carry out the research work. The authors acknowledge the Material Science Lab of Mechanical Engineering Department, NIT Silchar for performing Uniaxial Compression Test, CIF, NIT Silchar for XRD analysis of the samples. The authors thank the SAIF, IIT Madras for performing SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mahammod, B.P., Barua, E., Deb, P. et al. Investigation of Physico-mechanical Behavior, Permeability and Wall Shear Stress of Porous HA/PMMA Composite Bone Scaffold. Arab J Sci Eng 45, 5505–5515 (2020). https://doi.org/10.1007/s13369-020-04467-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04467-w