Abstract

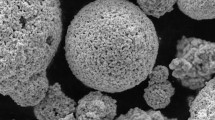

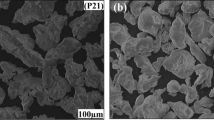

Slurry spray technique (SST) is a simplistic deposition technique which could easily be contrived to the choice of material for appropriate functionality. With the continual technological progress and manufacturing efficiency, the appropriacy of SST needs to be expanded to meet the growing demand for surface engineering. Functionally graded mullite–nickel \((\hbox {3Al}_{2}\hbox {O}_{3}\cdot \hbox {2SiO}_{2}\hbox {-Ni})\)-based environmental barrier coatings were slurry sprayed on ASTM 1018 steel. This study reports the findings pertaining to the fundamental mechanical, thermal, corrosion and microstructural investigations performed to evaluate and ascertain the utility of the coatings produced by SST. Sound and resilient coatings with density in the range 1238–\(5320\hbox { kg/m}^{3}\) and coating thickness in the range of 99–\(380\,\upmu \hbox {m}\) were attained at distinct processing parameters. Within the experimental design space, a maximum adhesion strength value of 18.15 MPa was measured during tensile adhesion test. The developed coatings with microhardness up to \(204.2\hbox { HV}_{0.1}\), exhibit the surface roughness value ranged from 3.27 to \(7.98\,\upmu \hbox {m}\) (Ra) and the porosity with an overall mean value of 9.9% by volume. During the thermal cycling testing, the majority of the specimens did survive up to 30 thermal cycles, which encapsulate acceptable thermal shock resistance of the coatings. The corrosion studies of the mullite–nickel coatings performed by immersion test in \(0.5\hbox {M Na}_{2}\hbox {SO}_{4}\) proclaimed a decent corrosion rate of 5.217 mpy. The microstructural studies supported by SEM/EDS and XRD demonstrate as-sprayed splat morphology and the continuous interface and suggest a good adherence of the coatings fabricated wielding SST.

Similar content being viewed by others

References

Turcer, L.R.; Padture, N.P.: Towards multifunctional thermal environmental barrier coatings (TEBCs) based on rare-earth pyrosilicate solid-solution ceramics. Scr. Mater. (2018). https://doi.org/10.1016/j.scriptamat.2018.05.032

Walston, W.S.: Coating and Surface Technologies for Turbine Airfoils. Superalloys 2004, (2004). https://doi.org/10.7449/2004/Superalloys_2004_579_588

Klocke, F.; Klink, A.; Veselovac, D.; Aspinwall, D.K.; Soo, S.L.; Schmidt, M.; Schilp, J.; Levy, G.; Kruth, J.P.: Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Ann. Manuf. Technol. (2014). https://doi.org/10.1016/j.cirp.2014.05.004

Goward, G.W.: Progress in coatings for gas turbine airfoils. Surf. Coatings Technol. (1998). https://doi.org/10.1016/S0257-8972(98)00667-7

Fundamentals of gas turbine engines, https://www.skybrary.aero/bookshelf/books/1621.pdf. Accessed July 2016

Encapsulation of fly ash by polymers. https://patents.google.com/patent/US20170081496A1/en (2016)

Chávez-Valdez, A.; Arizmendi-Morquecho, A.; Vargas, G.; Almanza, J.M.; Alvarez-Quintana, J.: Ultra-low thermal conductivity thermal barrier coatings from recycled fly-ash cenospheres. Acta Mater. (2011). https://doi.org/10.1016/j.actamat.2011.01.011

Sambyal, P.; Ruhi, G.; Bhandari, H.; Dhawan, S.K.: Advanced anti corrosive properties of poly(aniline-co-o-toluidine)/flyash composite coatings. Surf. Coatings Technol. (2015). https://doi.org/10.1016/j.surfcoat.2015.04.013

Nguyen, M.D.; Bang, J.W.; Bin, A.S.; Kim, S.R.; Kim, Y.; Hwang, K.H.; Pham, V.H.; Kwon, W.T.: Novel polymer-derived ceramic environmental barrier coating system for carbon steel in oxidizing environments. J. Eur. Ceram. Soc. (2017). https://doi.org/10.1016/j.jeurceramsoc.2016.12.049

Verma, R.; Kant, S.; Suri, N.M.: Adhesion strength optimization of slurry sprayed mullite-based coating using Taguchi method. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. (2014). https://doi.org/10.1177/0954408915595948

Verma, R.; Suri, N.M.; Kant, S.: Parametric Appraisal of Slurry-Sprayed Mullite Coatings for Coating Thickness. J. Therm. Spray Technol. (2016). https://doi.org/10.1007/s11666-016-0437-1

Verma, R.; Suri, N.M.; Kant, S.: Effect of parameters on adhesion strength for slurry spray coating technique. Mater. Manuf. Process. (2017). https://doi.org/10.1080/10426914.2016.1221090

Dong, X.; Chen, Z.; Guo, A.; Liu, J.; Wang, X.; Chen, C.: Mechanical and interfacial behavior of single mullite fiber and mullite fiber-based porous ceramics. Ceram. Int. (2018). https://doi.org/10.1016/j.ceramint.2018.05.058

Nguyen, P.: Slurry sprayed thermal barrier coatings for aerospace applications. PhD Thesis, The University of Adelaide, Adelaide, South Australia (2010)

Zeng, A.; Xiong, W.; Wang, C.; Zhou, Q.: Structure and properties of BaFe12O19 coated fly ash cenospheres by sol–gel process. J. Wuhan Univ. Technol. Mater. Sci. Ed. (2006). https://doi.org/10.1007/BF02840901

Wang, J.; Wang, H.; Geng, G.: Flame-retardant superhydrophobic coating derived from fly ash on polymeric foam for efficient oil/corrosive water and emulsion separation. J. Colloid Interface Sci. 525, 11–20 (2018). https://doi.org/10.1016/J.JCIS.2018.04.069

Coatings, I.: Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings 1. https://compass.astm.org/EDIT/html_annot.cgi?C633+13(2017) (2015). Accessed June 2016.

Greenwood, R.; Kendall, K.: Selection of suitable dispersants for aqueous suspensions of zirconia and titania powders using acoustophoresis. J. Eur. Ceram. Soc. (1999). https://doi.org/10.1016/S0955-2219(98)00208-8

Dahl, P.; Kaus, I.; Zhao, Z.; Johnsson, M.; Nygren, M.; Wiik, K.; Grande, T.; Einarsrud, M.A.: Densification and properties of zirconia prepared by three different sintering techniques. Ceram. Int. (2007). https://doi.org/10.1016/j.ceramint.2006.07.005

Shi, J.; Cheng, Z.; Gelin, J.C.; Barriere, T.; Liu, B.: Sintering of 17–4PH stainless steel powder assisted by microwave and the gradient of mechanical properties in the sintered body. Int. J. Adv. Manuf. Technol. (2017). https://doi.org/10.1007/s00170-016-9960-y

Kamal, S.; Jayaganthan, R.; Prakash, S.; Kumar, S.: Hot corrosion behavior of detonation gun sprayed Cr3C2-NiCr coatings on Ni and Fe-based superalloys in Na2SO4-60% V2O5 environment at \(900^{\circ }\text{C}\). J. Alloys Compd. (2008). https://doi.org/10.1016/j.jallcom.2007.09.019

Khor, K.; Gu, Y.: Effects of residual stress on the performance of plasma sprayed functionally graded ZrO2/NiCoCrAlY coatings. Mater. Sci. Eng. A. 277, 64–76 (2000). https://doi.org/10.1016/S0921-5093(99)00565-1

Viswanath, B.; Vijayarangan, S.: Characterization studies of mullite coatings on cast aluminum. J. Therm. spray Technol. 21, 325–334 (2012)

ASTM E2109-01: Standard test methods for determining area percentage porosity in thermal sprayed coatings. https://www.astm.org/Standards/E2109.htm (2014). Accessed July 2016

Guide, S.: Standard Guide for Metallographic Preparation of Thermal Sprayed Coatings 1. https://www.astm.org/Standards/E1920.htm (2003). Accessed June 2016

Markocsan, N.; Nylén, P.; Wigren, J.; Li, X.-H.; Tricoire, A.: Effect of thermal aging on microstructure and functional properties of zirconia-base thermal barrier coatings. J. Therm. Spray Technol. 18, 201–208 (2009)

Feng, F.-J.; Jang, B.-K.; Park, J.Y.; Lee, K.S.: Effect of Yb2SiO5 addition on the physical and mechanical properties of sintered mullite ceramic as an environmental barrier coating material. Ceram. Int. 42, 15203–15208 (2016). https://doi.org/10.1016/J.CERAMINT.2016.06.149

Günthner, M.; Schütz, A.; Glatzel, U.; Wang, K.; Bordia, R.K.; Greißl, O.; Krenkel, W.; Motz, G.: High performance environmental barrier coatings, Part I: Passive filler loaded SiCN system for steel. J. Eur. Ceram. Soc. (2011). https://doi.org/10.1016/j.jeurceramsoc.2011.05.027

Kumar, K.; Gesualdi, J.; Smith, N.D.; Kim, H.: Influence of gaseous atmosphere on electrochemical behavior of nickel alloys in LiCl-KCl-Na2SO4 at \(700^\circ \text{ C }\). Corros. Sci. (2018). https://doi.org/10.1016/J.CORSCI.2018.05.039

Chatha, S.S.; Sidhu, H.S.; Sidhu, B.S.: High temperature hot corrosion behaviour of NiCr and Cr 3C 2-NiCr coatings on T91 boiler steel in an aggressive environment at \(750^{\circ }\text{ C }\). Surf. Coatings Technol. (2012). https://doi.org/10.1016/j.surfcoat.2012.01.060

Zhou, H.; Li, F.; He, B.; Wang, J.; Sun, B.: Effect of plasma spraying process on microstructure and microhardness of titanium alloy substrate. J. Therm. Spray Technol. 17, 284–288 (2008)

Berghaus, J.O.; Marple, B.R.: High-Velocity Oxy-Fuel (HVOF) suspension spraying of mullite coatings. J. Therm. Spray Technol. 17, 671–678 (2008)

Srivastava, M.; Suprita, G.K.: William Grips. Multifunctional electrodeposited Ni-mullite composite coating, V.K. (2013)

Liu, K.; Shi, Y.; He, W.; Li, C.; Wei, Q.; Liu, J.: Densification of alumina components via indirect selective laser sintering combined with isostatic pressing. Int. J. Adv. Manuf. Technol. 67, 2511–2519 (2013)

Withey, E.; Petorak, C.; Trice, R.; Dickinson, G.; Taylor, T.: Design of 7 wt.% Y2O3–ZrO2/mullite plasma-sprayed composite coatings for increased creep resistance. J. Eur. Ceram. Soc. 27, 4675–4683 (2007)

Davis, J.R.: Handbook of Thermal Spray Technology. ASM international (2004)

Nguyen, P.; Harding, S.; Ho, S.-Y.: Experimental studies on slurry based thermal barrier coatings. In: 5th Australasian Congress on Applied Mechanics (ACAM 2007). pp. 545–550. Engineers Australia (2007)

Dong, Y.; Hampshire, S.; Zhou, J. er, Lin, B.; Ji, Z.; Zhang, X.; Meng, G.: Recycling of fly ash for preparing porous mullite membrane supports with titania addition. J. Hazard. Mater. (2010). https://doi.org/10.1016/j.jhazmat.2010.04.010

Goyal, R.; Sidhu, B.S.; Chawla, V.: Characterization of plasma-sprayed carbon nanotube (CNT)-reinforced alumina coatings on ASME-SA213-T11 boiler tube steel. Int. J. Adv. Manuf. Technol. 92, 3225–3235 (2017)

Bernard-Granger, G.; Monchalin, N.; Guizard, C.: Comparisons of grain size-density trajectory during spark plasma sintering and hot-pressing of zirconia. Mater. Lett. (2008). https://doi.org/10.1016/j.matlet.2008.08.042

Malatji, N.; Popoola, A.P.I.; Fayomi, O.S.I.; Loto, C.A.: Multifaceted incorporation of Zn-Al2O3/Cr2O3/SiO2 nanocomposite coatings: anti-corrosion, tribological, and thermal stability. Int. J. Adv. Manuf. Technol. (2016). https://doi.org/10.1007/s00170-015-7463-x

Bernard-Granger, G.; Monchalin, N.; Guizard, C.: Sintering of ceramic powders: determination of the densification and grain growth mechanisms from the “grain size/relative density” trajectory. Scr. Mater. 57, 137–140 (2007)

Atuanya, C.U.; Ekweghiariri, D.I.: Experimental correlation between varying processing properties and wear behaviour of ternary Ni-Co-SiO2 composites coating of mild steel. Int. J. Adv. Manuf. Technol. (2017). https://doi.org/10.1007/s00170-016-8944-2

Bada, S.O.; Potgieter-Vermaak, S.: Evaluation and treatment of coal fly ash for adsorption application. Leonardo Electron. J. Pract, Technol (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, R., Randhawa, J.S., Kant, S. et al. Characterization Studies of Slurry-Sprayed Mullite–Nickel Coatings on ASTM 1018 Steel. Arab J Sci Eng 44, 5897–5919 (2019). https://doi.org/10.1007/s13369-019-03753-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03753-6