Abstract

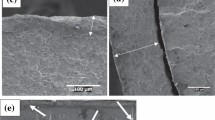

Herein, two Ni-based coatings, namely NiAlFeMo (P21) and NiAlFeCrMo (P31), were deposited on E335 steel using the flame spraying technique. The coatings were subjected to post-treatments at three different temperatures (450, 550, and 650 °C) for one hour. Microstructural analysis revealed that the heat treatments reduced porosities, resulting in more homogeneous and denser microstructures. Additionally, the formation of carbides and alumina was observed. The 550 and 650 °C treatments significantly enhanced the mechanical properties (hardness and indentation modulus) and tribological behavior (wear resistance and friction coefficient) of the studied coatings. Moreover, open-circuit potential (OCP), potentiodynamic polarization, and electrochemical impedance spectroscopy (EIS) were performed to assess the electrochemical characteristics of coatings. They revealed that the coatings treated at 550 and 650 °C exhibited excellent corrosion resistance that can be attributed to the reduction of open pores and the presence of alumina, which enhances the passivity of the surface. Such results underscore the significance of heat treatment in optimizing the microstructural, mechanical, and electrochemical properties of nickel-based coatings, by offering promising prospects for their application in various fields.

Similar content being viewed by others

References

A. Matthews, A. Leyland, K. Holmberg and H. Ronkainen, Design Aspects for Advanced Tribological Surface Coatings, Surf. Coatings Technol., 1998, 100, p 1–6.

F. Amiri, K.S. Niaki and S.E. Vahdat, Repairing the Surface Grooves of St37 Structural Steel Using Flame Spray Welding, Int. J. Precision Eng. Manuf., 2017, 18, p 1873–1879.

A. Kumar, J. Boy, R. Zatorski and L.D. Stephenson, Thermal Spray and Weld Repair Alloys for the Repair of Cavitation Damage in Turbines and Pumps: a Technical Note, J. Thermal Spray Technol., 2005, 14, p 177–182.

S.P. Sharma, D.K. Dwivedi and P.K. Jain, Abrasive Wear Behaviour of Continuously Compacted Thermal-Sprayed Ni Base Alloy Powder Coatings in Different Conditions, Int. J. Surf. Sci. Eng., 2008, 2(3–4), p 240–251.

G. Xanthopoulou, A. Marinou, G. Vekinis, A. Lekatou and M. Vardavoulias, Ni-Al and NiO-Al Composite Coatings by Combustion-Assisted Flame Spraying, Coatings, 2014, 4(2), p 231–252.

H.C. Fals, D. Aguiar, L. Fanton, M.J. Belém and C.R. Lima, A New Approach of Abrasive Wear Performance of Flame Sprayed NiCrSiBFeC/SiC Composite Coating, Wear, 2021, 477, 203887.

R. Karmakar, P. Maji and S.K. Ghosh, A Review on the Nickel Based Metal Matrix Composite Coating, Metals Mater. Int., 2021, 27, p 2134–2145.

G. Gudivada and A.K. Pandey, Recent Developments in Nickel-Based Superalloys for Gas Turbine Applications, J. Alloys Comp., 2023, 963, 171128.

W.S. da Silva, R.M.D. Souza, J.D.B. Mello and H. Goldenstein, Room Temperature Mechanical Properties and Tribology of NICRALC and Stellite Casting Alloys, Wear, 2011, 271(9–10), p 1819–1827.

P. Shi, W. Wang, S. Wan, Q. Gao, H. Sun, X. Feng, G. Yi, E. Xie and Q. Wang, Tribological Performance and High Temperature Oxidation Behaviour of Thermal Sprayed Ni-and NiCrAlY-Based Composite Coatings, Surf. Coat. Technol., 2021, 405, 126615.

J.C. Schab, J.R.A. Zimmermann, P.D. Grasso, A. Stankowski, S. Heinze, A. Marquardt and C. Leyens, Thermodynamic Calculation and Experimental Analysis of Critical Phase Transformations in HVOF-Sprayed NiCrAlY-Coating Alloys, Surf. Coat. Technol., 2019, 357, p 924–938.

G. Prashar and H. Vasudev, A Review on the Influence of Process Parameters and Heat Treatment on the Corrosion Performance of Ni-Based Thermal Spray Coatings, Surf. Rev. Lett., 2022, 29, p 2230001.

P. Daram and C. Banjongprasert, The Influence of Post Treatments on the Microstructure and Corrosion Behavior of Thermally Sprayed NiCrMoAl Alloy Coating, Surf. Coat. Technol., 2020, 384, 125166.

A. Srichen, S. Linjee and C. Banjongprasert, Corrosion Behavior of Heat-Treated NiCrMoAl Alloy Coatings Produced via Arc Spraying, Surf. Interf., 2023, 39, 102880.

M. Benegra, A.L.B. Santana, O. Maranho and G. Pintaude, Effect of Heat Treatment on Wear Resistance of Nickel Aluminide Coatings Deposited by HVOF and PTA, J. Thermal Spray Technol., 2015, 24, p 1111–1116.

B. Li, Y. Gao, J. Jia, M. Han, H. Guo and W. Wang, Influence of Heat Treatments on the Microstructure as Well as Mechanical and Tribological Properties of NiCrAlY-Mo-Ag Coatings, J. Alloys Comp., 2016, 686, p 503–510.

A. Srichen, S. Moonngam, S. Linjee and C. Banjongprasert, Tribological Behaviors of Arc Sprayed NiCrMoAl Alloy Coating After Heat Treatments, Surf. Coat. Technol., 2022, 437, 128325.

ASTM-E2546-15. Standard Practice for Instrumented Indentation Testing, ASTM International, West Conshohocken, PA (2015).

B. Matthes, E. Broszeit, J. Aromaa, H. Ronkainen, S.P. Hannula, A. Leyland and A. Matthews, Corrosion Performance of Some Titanium-Based Hard Coatings, Surf. Coat. Technol., 1991, 49(1–3), p 489–495.

J.N. Ndumia, J. Zhu, B.V. Gbenontin, M. Kang, X. Liu and S.M. Nyambura, Effect of Heat Treatment on the Microstructure and Corrosion Behavior of Arc-Sprayed FeCrAl/Al Coating, J. Mater. Eng. Perform., 2023, 32(4), p 1489–1497.

Q. Xie, Z. Fu, X. Wei, X. Li, W. Yue, J. Kang and J. Meng, Effect of Substrate Bias Current on Structure and Properties of CrNx Films Deposited by Plasma Enhanced Magnetron Sputtering, Surf. Coat. Technol., 2019, 365, p 134–142.

C. Brunetti, A.S.C.M. D’Oliveira, G. Pintaude and D. Yano, Modification of NiAl Intermetallic Coatings Processed by PTA with Chromium Carbides, J. ASTM Int., 2011, 8, p 150–161.

G. Pintaude, Introduction of the Ratio of the Hardness to the Reduced Elastic Modulus for Abrasion [Internet]. Tribology - Fundamentals and Advancements. InTech; 2013. Available from: https://doi.org/10.5772/55470

B. Li, C. Li, Y. Gao, H. Guo, Q. Zheng, Y. Kang and S. Zhao, Influence of Heat Treatment on Corrosion-Wear Behavior of Ni-Based Coating in Artificial Seawater, J. Mater. Eng. Perform., 2019, 28, p 7828–7834.

C. Xu, Y. Peng, L.Y. Chen, T.Y. Zhang, S. He and K.H. Wang, Corrosion Behavior of Wire-Arc Additive Manufactured and as-cast Ni-Al Bronze in 35 wt.% NaCl Solution, Corr Sci., 2023, 215, p 111048.

J.L. del Abra-Arzola, M.A. García-Rentería, V.L. Cruz-Hernández, J. García-Guerra, V.H. Martínez-Landeros, L.A. Falcón-Franco and F.F. Curiel-López, Study of the Effect of Sigma Phase Precipitation on the Sliding Wear and Corrosion Behaviour of Duplex Stainless Steel AISI 2205, Wear, 2018, 400, p 43–51.

K. Abd El-Aziz, K. Zohdy, D. Saber and H.E.M. Sallam, Wear and Corrosion Behavior of High-Cr White Cast Iron Alloys in Different Corrosive Media, J. Bio- Tribo-Corr., 2015, 1, p 1–12.

S. Huth, N. Krasokha and W. Theisen, Development of Wear and Corrosion Resistant Cold-Work Tool Steels Produced by Diffusion Alloying, Wear, 2009, 267(1–4), p 449–457.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boudjit, S., Younes, R., Bradai, M.A. et al. Mechanical, Tribological, and Electrochemical Evaluation of NiCrAlMoFe Thermally Sprayed Coatings Subject to Post-treatments. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09393-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09393-8