Abstract

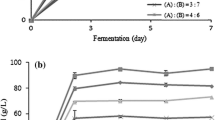

Cassava waste pulp (CWP)–enzymatic hydrolysate was co-fermented with molasses (CWP-EH/molasses mixture) with the aim to optimize ethanol production by Saccharomyces cerevisiae TISTR 5606 (SC 90). The optimal fermentation conditions for ethanol production using this mixture were 245 g/L initial total sugar supplemented with KH2PO4 (8 g/L), at 30 °C for 48 h of fermentation under an oxygen-limited condition with agitation at 100 rpm, producing an ethanol concentration of 70.60 g/L (0.31 g ethanol/g total sugar). The addition of cassava tuber fiber (solid residue of CWP after enzymatic hydrolysis) at 30 g/L dry weight to the CWP-EH/molasses mixture increased ethanol production to 74.36 g/L (0.32 g ethanol/g total sugar). Co-fermentation of CWP-EH with molasses had the advantage of not requiring any supplementation of the fermentation mixture with reduced nitrogen.

Similar content being viewed by others

References

Akaracharanya A, Kesornsit J, Leepipatpiboon N, Srinorakutara T, Kitpreechavanich V, Tolieng V (2011) Evaluation of the waste from cassava starch production as a substrate for ethanol fermentation by Sacharomyces cerevisiae. Ann Microbiol 61:431–436

Association of Official Analytical Chemists (AOAC) (2010) Official methods of analysis. 19th ed. AOAC International, Gaithersburg, MD

Association of Official Analytical Chemists (AOAC) (2012) Official methods of analysis. 18th ed. AOAC International, Gaithersburg, MD

Bai FW, Anderson WA, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Adv 26:89–105

Chotineeranat S, Wansuksri R, Piyachomkwan K, Chatakanonda P, Weerathaworn P, Sriroth K (2010) Effect of calcium ions on ethanol production from molasses by Saccharomyces cerevisiae. Sugar Tech 12(2):120–124

El-Latif MM, Ibrahim AM, El-Kady MF (2010) Adsorption Equilibrium, kinetics and thermodynamics of methylene blue from aqueous solutions using biopolymer oak sawdust composite. J Am Sci 6(6):267–283

Genisheva Z, Mussatto SI, Oliveira JM, Teixeria JA (2011) Evaluating the potential of wine-making residues and corn cobs as support materials for cells immobilization for ethanol production. Indian Crops Prod 34:979–985

Jutakanoke R, Leepipatpiboon N, Tolieng V, Kitpreechavanich V, Srinorakutara T, Akaracharanya A (2012) Sugacane leaves: pretreatment and ethanol fermentation by Saccharomyces cerevisiae. Biomass Bioenergy 39:283–289

Maiorella B, Blanch HW, Wilke CR (1983) By-product inhibition effects on ethanolic fermentation by Saccharomyces cerevisiae. Biotechnol Bioeng 25:103–121

Office of the National Economic and Social Development Board (2006) Final report: Zero waste industry project. Department of Industrial Economic, Ministry of Industry, Thailand

Pradeep P, Reddy OVS (2010) High gravity fermentation of sugarcane molasses to produce ethanol: Effect of nutrients. Indian J Microbiol 50:S82–S87

Puwastien P, Siong TE, Kantasubrata J, Craven G, Feliciano RR, Judprasong K (2011) ASEAN manual of food analysis regional center of ASEAN network of food data system. Institute of Nutrition, Mahidol University, Putthamonthon

Razmovski R, Pejin D (1996) Immobilization of Saccharomyces diastaticus on wood chips for ethanol production. Folia Microbiol 41:201–207

Santos DT, Sarrouh BF, Rivaldi JD, Converti A, Silva SS (2008) Use of sugarcane bagasse as biomaterial for cell immobilization for xylitol production. J Food Eng 86:542–548

Somogyi M (1952) Notes on sugar determination. J Biol Chem 195:19–23

Stehlik-Tomas V, Zetic VG, Stanzer D, Grba S, Vahcic N (2004) Zinc, copper and manganese enrichment in yeast Saccharomyces cerevisiae. Food Technol Biotech 42(2):115–120

Takeshige K, Ouchi K (1995) Factors affecting the ethanol productivity of yeast in molasses. J Ferment Bioeng 79:449–452

Tesfaw A, Assefa F (2014) Current trends in bioethanol production by Saccharomyces cerevisiae: substrate, inhibitor reduction, growth variables, coculture, and immobilization. Int Sch Res Notices. doi:10.1155/2014/532852

Thongchul N, Navankasattusas S, Yang ST (2010) Production of lactic acid and ethanol by Rhizopus oryzae integrated with cassava pulp hydrolysis. Bioprocess Biosyst Eng 30:407–416

Acknowledgments

The authors thank Dr. Robert Butcher for critical reading of this manuscript and the Thai Alcohol Public Company, Thailand for providing the α-amylase and glucoamylase enzymes. This study was financially supported by the Thai Government budget (fiscal year 2015) and Graduate school, Chulalongkorn University to commemorate the 72nd Birthday Anniversary of His Majesty the King Bhumibol Aduladej.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wattanagonniyom, T., Lee, WC., Tolieng, V. et al. Co-fermentation of cassava waste pulp hydrolysate with molasses to ethanol for economic optimization. Ann Microbiol 67, 157–163 (2017). https://doi.org/10.1007/s13213-016-1245-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-016-1245-z