Abstract

Dry (CO2) reforming of methane (DRM) produces syngas with H2/CO ratio of ≤1. In this work, we report the use of pyrochlores (A2B2O7) as catalysts for this reaction. Here, we examine lanthanum zirconate pyrochlores, LZ, with lanthanum and zirconium occupying the A and B sites, respectively. Three catalysts are tested: LZ and two pyrochlores in which the B-site has been isomorphically substituted with (a) Ru (2 wt%) (designated LRuZ) and (b) Pt (3.78 wt%) (designated LPtZ). These levels of substitution by weight correspond to identical atomic levels of substitution at the B-site. The effect of isomorphic substitution of Ru and Pt on the structure and activity of the pyrochlores in DRM is studied in this work. ICP-OES, XRD, H2 and CH4 TPR were used to characterize the structure of the catalysts. XRD results confirmed the formation of the La2Zr2O7 phase in the bulk of the pyrochlores. H2 TPR showed higher reduction temperatures for LPtZ compared to LRuZ, suggesting a less reducible, stable Pt in the pyrochlore structure compared to Ru. Quantitative analysis showed that LRuZ consumed 0.534 mg H2/gcat, whereas LPtZ consumed only 0.161 mg H2/gcat corresponding to much greater extent of reduction for LRuZ compared to LPtZ. CO formation during CH4 TPR showed that both materials have reactive lattice oxygen which helps in reducing carbon formation during DRM. Temperature programmed oxidation studies of the catalyst immediately after CH4 TPR showed greater carbon formation over LPtZ (1.67 gc/gcat) compared to LRuZ (1.17 gc/gcat) suggesting that Pt activates CH4 to a greater extent compared to Ru. Temperature programmed DRM surface reaction showed that the light off temperature for LRuZ was about 45 °C lower than that of LPtZ. These are novel results and constitute the first report of which we are aware for Pt and Ru substituted pyrochlores for DRM.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Dry reforming of methane (DRM) produces commercially important syngas that can be used for chemical processes like Fischer–Tropsch or synthesis of various chemicals [5, 6]. One of the problems associated with DRM is catalyst deactivation due to carbon deposition [3, 5, 8]. In addition to carbon deposition, DRM is highly endothermic reaction (∆H298K = 59.1 kcal mol−1) and requires temperatures approaching 900–1,000 °C to reach high equilibrium syngas yields. These temperatures lead to sintering of conventional supported metal catalysts. Thus, there is a need to develop catalyst that will resist deactivation due to sintering and carbon deposition [2, 11, 20, 28]. Pyrochlores are ternary metal oxides based on the fluorite structure with general formula of A2B2O7 [25]. Large cations like rare earth elements occupy the A-site, whereas the B-site is occupied by a transition metal with a smaller atomic radius [16]. The pyrochlore structure allows limited isomorphic substitution of catalytically active metals like Ru, Rh, Pt at the B-site.

The most preferred metal for the DRM reaction is Ni due to its low cost and availability [8, 10, 17–19]; however, this metal undergoes severe deactivation due to carbon deposition. Noble metals like Ru, Rh, and Pt have greater resistance to carbon deposition, but are not economical [4, 7, 9, 21, 22]. In our previous work, we have studied Ru (on B-site) and Sr (on A-site) substituted pyrochlores for DRM [12]. In the present work, we report a study of Ru and Pt substituted (at the B-site) lanthanum zirconate pyrochlores. Despite their well-known thermal stability and reports of their use for other purposes such as thermal barrier coatings, we are aware of only one study of these materials for DRM, i.e., by Ashcroft et.al [1]. In that paper, Ashcroft et al. studied Eu2Ir2O7 pyrochlores and observed that above 342 °C under DRM conditions, these materials completely decompose to Eu2O3 and Ir metal. However, in one of our previous works, we have used Ru and Sr substituted pyrochlores which have proven to be extremely thermally stable at 850 °C [12].

Here, we perform ICP-OES, XRD, and TPR using H2 and CH4 as reducing gases and study the effect of substitution of Ru and Pt (separately) at the B-site of the pyrochlore structure. Temperature programmed surface reaction (TPSR) was conducted to study the changes in the catalyst light-off temperatures as a result of change in the active metal substituted on the B-site.

Experimental section

Catalyst synthesis

The LZ, LRuZ, and LPtZ pyrochlores were synthesized by modified Pechini method using salts of lanthanum nitrate hexahydrate [La(NO3)3.6H2O], zirconium oxynitrate [ZrO(NO3)2.xH2O], and either ruthenium chloride (RuCl3) or hydro-chloroplatinic acid [H2PtCl6·(H2O)6] salts as precursors, and anhydrous citric acid (C6H8O7) and ethylene glycol (C2H6O2) as complexing and polymerizing agents, respectively. Stoichiometric amounts of metallic precursors were separately dissolved in 50 ml of deionized water, and then combined into a larger beaker with continuous stirring. An aqueous citric acid (CA) solution was then added to the stirring solution in the beaker. The molar ratio between CA and total metal ions was kept at 1.2. The solution was heated to 70 °C while stirring on a hot plate before ethylene glycol (EG) was added. The molar ratio of EG to CA was 1:1. The solution was stirred under isothermal conditions for several hours until a clear viscous gel was obtained. To promote polyesterification reaction between CA and EG, the gel was further heated in a heating mantle at 130 °C. This resulted in an amorphous polyester-type resin. The solid material was then collected and calcined at 1,000 °C for 8 h to form the mixed metal oxide material.

Inductively coupled plasma-optical emission spectroscopy (ICP-OES)

The samples were quantitatively weighed to the nearest 0.00001 g and then transferred to a Teflon digestion sample holder. Four mL of concentrated trace metal grade hydrochloric acid was added to the sample and was loosely covered for 16 h. The sample was then heated in a sand bath for 1 h at 95 °C. After cooling, the samples were sealed and digested in a CEM Mars 5 microwave. After digestion, the Teflon sample holders were heated on a sand bath at ~95 °C until acid was nearly evaporated. Then, 5 mL of freshly prepared aqua regia was added to each sample and loosely covered overnight. The microwave digestion was repeated with holding at 200 °C for 20 min. The samples were then cooled and sat overnight. The so prepared samples were then analyzed on a Perkin Elmer 2000 DV Inductively coupled plasma optical emission spectrometer at wavelengths of 240.272 nm for Ru, 333.749 nm for La, 257.139 nm for Zr, and 214.423 nm for Pt.

X-ray diffraction (XRD)

Crystalline nature of the freshly calcined pyrochlores was studied using X-Ray Diffraction spectra obtained from a Bruker/Siemens D5000 system. The system was composed of a ceramic X-ray tube with Cu Kα radiation operating at a wave length of 1.54184 Å. The X-ray tube operated at a voltage of 40 kV with a current of 30 mA. Angle of divergence slit for the incident X-ray beam was set to 1º and the antiscatter slit was set at 0.5º. For analysis, 2θ was varied from 10º to 80º at a sweep rate of 0.02º/min.

Temperature programmed reduction (TPR)

Temperature programmed reduction by H2

Temperature programmed reduction of the catalysts was conducted in an AMI 200 (Altamira instruments, Pittsburgh, PA, USA) fixed bed reactor. For each run, 50 mg of catalyst was loaded into the 6.5 inch (length) by 6 mm (outer diameter) by 4 mm (inner diameter) quartz tube. The catalyst was packed in place using quartz wool plugs. Thermocouple that ran axially through the tube touching the quartz wool was used to monitor the bed temperature continuously. TPR was performed on LZ, LPtZ and LRuZ pyrochlores. Before starting TPR, samples were oxidized in flowing O2/He at 30 mL/min from ambient (ca. 35° C) to 950 °C at a rate of 5 °C/min. This was done to oxidize the metals on the surface and in the bulk which could then consume H2 during the TPR. The sample was then cooled to room temperature in flowing He at 30 mL/min. This also ensured oxidation and desorption of any adsorbed species on the catalyst surface. Next, the sample was exposed to mixture of 10 % H2/Ar flowing at 30 mL/min with the temperature ramped from 40 to 950 °C at 5 °C/min. The temperature was held at 950 °C for 30 min and then cooled to room temperature.

The amount of metal reduced in pyrochlores was quantified. This estimation of the extent of metal reduction in the catalyst was done using silver oxide (Ag2O) standards. Known quantity of Ag2O was reduced under similar conditions as the catalysts. From stoichiometric calculations, the amount of hydrogen required for reduction of the given amount of Ag2O was determined. Repeating TPR of the Ag2O standard gave a calibration curve relating the area under the TPR profile of the catalyst to the hydrogen consumption of that catalyst during the reduction reaction. The area under the TPR peak of the catalyst was related to the H2 uptake by that catalyst during TPR.

Temperature programmed reduction by CH4

This characterization method was used to study the oxygen conductivity of the pyrochlore structure. For this about 50 mg of catalyst was dried at 500 °C in flowing He at 30 mL/min and cooled to room temperature in flowing He. The catalyst bed was then subjected to reduction by 10 % CH4/He flowing at 30 mL/min and the temperature was ramped from 40 to 950 °C at the ramp rate of 5 °C/min. The conditions were maintained isothermal at 950 °C for 30 min. The product stream during the CH4 TPR was analyzed using the mass spectrometer (MS) that was hooked up with the reactor outlet. The MS was calibrated for known concentration of CO and CO2 and the concentration of CO and CO2 in the product line was determined.

Temperature programmed oxidation (TPO)

After subjecting the catalysts to TPR by CH4, a TPO was conducted for studying quantitatively and qualitatively the oxygen conductivity of the pyrochlores. For conducting the TPO, the catalyst was cooled to room temperature (ca. 35 °C) in flowing He at 20 mL/min. Then, it was oxidized in flowing 5 % O2/He at 30 mL/min from room temperature to 950 °C and the ramp rate was 5 °C/min. The conditions were maintained isothermal at 950° C for 30 min. The CO and CO2 emitted during the TPO were tracked using the mass spectrometer (MS) hooked up to the reactor outlet. The amount of CO and CO2 formed during TPR by CH4 and TPO was calculated using the calibration gases of 5 % CO/He and 10 % CO2/He.

Temperature programmed surface reaction (TPSR)

For carrying out TPSR experiment, 50 mg of catalyst was loaded into the U-tube quartz reactor and was dried at 300 °C in flowing He. After treatment with He, it was cooled to room temperature (ca. 25 °C) and the reactant gases were allowed to flow over the catalysts. The temperature was then programmed to rise from 25 to 900 °C with the ramp rate of 5 °C/min and the gas hourly space velocity (GHSV) was maintained at 48,000 mL g −1cat h−1. The MS signal for the products from the reactor was recorded.

Results and discussions

Inductively coupled plasma-optical emission spectroscopy

Table 1 shows the bulk concentration of the metals in the pyrochlores determined using ICP-OES. These results show similar atomic level substitution for Ru and Pt at the B-site.

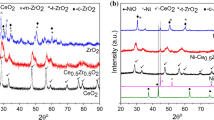

X-ray diffraction (XRD) study of fresh catalyst

XRD pattern of the freshly calcined catalysts (see Fig. 1) showed the formation of the cubic unit cell crystalline La2Zr2O7 phase. The triangle marked peaks denote the angle of diffraction of the X-rays from the La2Zr2O7 phase of the catalyst. The diffraction angles attributed to the La2Zr2O7 phase observed in this work are in accordance with the ones observed in the literature [13, 14]. As expected, the substitution of Pt and Ru on the B-site did not affect the pyrochlore crystalline structure.

Haynes et al. have studied pyrochlores with Sr and Ru substitution on A and B sites, respectively, for other fuel reforming reactions [14–16]. They observed that when substitution of Sr and Ru was beyond a certain limit, a SrZrO3 perovskite phase was formed, which diffracted X-rays at the angle of about 32°. This is in agreement with the fact that there is a limit to the extent of substitution at either A or B sites, beyond which the excess of the substituted metal separates out as a perovskite phase [13]. There was no formation of any such perovskite phase observed in Fig. 1, suggesting that the extent of substitution of Pt and Ru is low enough to avoid the formation of any separate perovskite phase. Comparing the diffraction pattern for LZ with LPtZ and LRuZ shows that there was no shift in the diffraction angle as a result of Pt (3.3 wt%) or Ru (2 wt%) substitution on the Zr+4 site. The substitution of Pt and Ru atoms on the B-site caused no apparent change in the lattice constant of the lanthanum zirconate.

Temperature programmed reduction (TPR)

Temperature programmed reduction (TPR) by H2

The H2 TPR profile for LZ, LPtZ, and LRuZ is shown in Fig. 2. LZ pyrochlore shows reduction at 490 °C and 580 °C and the total consumption of H2 during reduction amounts to 0.155 mg H2/gcat. This suggests that only 0.6 % of the total lanthanum zirconate is reduced during TPR.

Reduction of LPtZ shows a small peak at 343 °C and two peaks at 499 and 558 °C. The 343 °C peak could be due to the reduction of either PtOx in the pyrochlore lattice to Pt metal or of Zr at the Pt–Zr interface [24]. Souza et.al [24] observed similar reduction peaks for Pt/ZrO2 catalysts and attributed it to the Pt-assisted reduction of Zr, possibly by hydrogen spillover, where Pt activates and homolytically dissociates H2 which then reduces the Zr at the Pt–Zr interface. A similar phenomenon could be occurring over LPtZ. However, it is important to consider the fact that the class of catalysts used in the work by Souza and in this work is different.

The reduction peaks at 499 and 558 °C for LPtZ can be attributed to the reduction of lanthanum zirconate as seen in the profile of LZ. The total hydrogen consumption by LPtZ is 0.161 mg H2/gcat which is very close to that consumed by LZ, i.e., 0.155 mg H2/gcat. This indicates that the presence of Pt does not significantly increase the reducibility of the pyrochlore itself. Also, if all of Pt (assuming PtO2 form) in the pyrochlore was reduced during TPR, then the hydrogen consumed by Pt would be 1.3 mg H2/gcat which is much greater than the total hydrogen consumption of LPtZ (0.161 mg H2/gcat). In pyrochlores, most of the metal is substituted in the bulk of the pyrochlore and is inaccessible to H2 during TPR experiment. The extent of reduction of LPtZ during TPR is only 0.64 % of the total metal content, showing that the reduction is limited to the surface atoms, as expected.

TPR of LRuZ, however, shows multiple reduction peaks at 100, 238, 450, and 551 °C. The presence of a low temperature reduction peak at 100 °C suggests that at least a small amount of Ru at the pyrochlore surface is not strongly bound to the pyrochlore structure. Though not detectable by XRD, these small clusters of Ru exhibit a reduction behavior similar to that for RuO2/Al2O3 [16]. This surface Ru appears to be formed by the oxygen pretreatment (to 950 °C; “Temperature programmed reduction by H2”), during which Ru in the pyrochlore is destabilized from the B-site and diffuses to the surface. The peak at 238 °C is assigned to the reduction of Ru substituted in the pyrochlore structure. In one of our earlier work with Ru (at B-site) and Sr (at A-site) substituted pyrochlores, we observe reduction of Ru at 280 °C [12]. The reduction of Ru in the LRuZ is about 40 °C lower than that reported in the earlier study, possibly due to a slightly weaker interaction of Ru in the pyrochlore structure. The similarity of the reduction peaks at 450 and 551 °C for LRuZ and those at 490 and 580 °C for LZ in Fig. 2 suggests that both are attributed to reduction of the lanthanum zirconate pyrochlore. Presumably, the slightly lower peaks for LRuZ suggest that the reduction of LZ is enhanced somewhat by Ru via hydrogen spillover. The amount of hydrogen consumed by LRuZ is 0.534 mg H2/gcat which is much greater than that by LPtZ or LZ, largely due to reducibility of the Ru that appears to be on the pyrochlore surface rather than in the structure. If all the Ru in LRuZ reduces, then the hydrogen consumption by Ru (assuming RuO2 form) alone would be 1.4 mg H2/gcat which is far greater than the total hydrogen consumption of LRuZ of 0.534 mg H2/gcat. This suggests that most of the Ru is still substituted in the pyrochlore structure, which is inaccessible during TPR. The total metal (La, Zr, and Ru together) reduced during LRuZ TPR is 2.12 % of the total metal content, again consistent with the premise that the reduction is limited to the surface of the pyrochlore.

Temperature programmed reduction (TPR) by CH4

Lanthanum zirconate pyrochlores similar to those reported here have been used by Haynes et al. [14–16] for reforming of diesel-range alkanes. They observed that the lattice oxygen of these materials is reactive and helps in resisting carbon formation during reforming reactions. To study lattice oxygen conductivity on the pyrochlores of interest, TPR of these materials using CH4 as a reducing agent was carried out. CH4 is believed to activate on the catalyst to form surface carbon and hydrogen. This surface carbon then must be oxidized to limit the accumulation of carbon deposits. During DRM, CO2 acts as an oxidizing agent and helps in limiting carbon formation over the catalyst. However, during CH4 TPR, there is no CO2 or O2 in the feed or in the pre-treatment of the catalyst. Thus, the only oxygen available for oxidation of surface carbon is the lattice oxygen.

Figure 3a shows the CO and CO2 formation during the CH4 TPR of LZ pyrochlore. The signal for CO2 was very weak and no distinct peak could be identified. CO formation begins at about 560 °C and reaches a first peak at 605 °C. Other peaks at 720 and 920 °C were also observed for CO formation.

Substitution of Pt and Ru on the B-site decreases the temperature at which the lattice oxygen in the pyrochlore begins to react with methane (see Fig. 3b, c). For LPtZ, CH4 TPR resulted in CO formation at 397, 650 and 950 °C. Substantial amounts of CO2 were also formed during CH4 TPR of LPtZ, unlike LZ. For LRuZ (Fig. 3c), the reduction temperatures were much lower compared to LPtZ and LZ. The first peak for CO formation was observed at 283 °C followed by a large peak at 449 °C and small peaks at 582 and 814 °C.

High temperature reduction peaks (720 and 920 °C) were observed for LZ and one similar reduction peak (950 °C) was also observed for LPtZ. This suggests that these high temperature peaks in LPtZ profile is due to the reaction of oxygen associated with the lanthanum zirconate part of LPtZ pyrochlore. The low temperature peaks (397 and 650 °C) are due to the reaction of oxygen associated with Pt in the pyrochlore structure. For LRuZ, the reduction peaks were at very low temperatures (283 and 449 °C) compared to LZ (605 and 720 °C) and LPtZ (397 and 650 °C). This is consistent with the H2 TPR results, which suggested that Ru is not stable within the pyrochlore structure, and migrates from the B-site to the surface. The low temperature reduction peaks for LRuZ (Fig. 2c) could be due to the reaction of oxygen associated with Ru. H2-TPR of LRuZ showed that Ru substitution increases the reducibility of lanthanum zirconate, causing it to reduce at temperatures (450 and 551 °C) lower than LZ (490 and 580 °C) (Fig. 2). A similar phenomenon was observed in CH4-TPR of LRuZ where the reaction of oxygen associated with lanthanum zirconate was observed at 814 °C compared to 920 °C for LZ and 950 °C for LPtZ. Because H2 is a stronger reducing agent than CH4, it reduces the catalyst at much lower temperatures than CH4. A comparison of Fig. 2 (H2 TPR) and Fig. 3 (CH4 TPR) shows this to be true for all the catalysts.

We are not aware of any reports in which CH4-TPR has been used to study the lattice oxygen reactivity of Ru and Pt pyrochlores and in which CH4-TPR and H2-TPR are directly compared.

TPO of catalysts spent for CH4 TPR

The surface carbon formed during CH4 TPR was oxidized and the resultant CO/CO2 profile (TPO) plots for LZ, LPtZ, and LRuZ are shown in Fig. 4a, b, and c, respectively. The major product during TPO was CO2 and very small amounts of CO were formed at the same temperatures as CO2. The oxidizable carbon formed on the surface were then quantified and normalized with respect to the weight of the catalyst.

TPO of the LZ pyrochlore shows a low temperature CO2 peak at 340 °C and CO peak at 335 °C (see Fig. 4a). Verykios et al. [27] in their work on Rh/Al2O3 catalysts observed surface carbon which oxidized at 330 °C and called it (δ) phase of carbon. The peak at 340 °C could be due to the oxidation of this C(δ) phase. Dehydrogenated carbon often oxidizes at higher temperatures compared to the partially hydrogenated surface carbon [23]. A similar dehydrogenated form of carbon could be responsible for the 600 °C TPO peak. The total amount of carbon formed over LZ during CH4 TPR which was later oxidized to CO and CO2 is 0.261 gC/gcat. The carbon formed over the LPtZ was qualitatively found to be more reactive, and presumably more hydrogenated, than the carbon formed on LZ pyrochlores. The low temperature peak was found to be at 260 °C (Fig. 4b). This carbon could be polymeric in nature deposited near the metal (Pt) site in the pyrochlore structure [23]. The high temperature peaks at 503 and 569 °C could be due to the oxidation of more dehydrogenated type of carbon deposited away from the Pt site [16, 23]. The total amount of carbon formed over LPtZ is about 1.67 gc/gcat, which is much greater than that compared to LZ. This suggests that Pt is the active site for activation of CH4 during DRM.

The TPO of the LRuZ pyrochlores after CH4 TPR suggests that the carbon formed was qualitatively different from that observed over LZ and LPtZ pyrochlores. The peak at 516 °C could be due to the oxidation of the same dehydrogenated polymeric carbon found on the LPtZ deposited away from the active metal [16, 23]. A high temperature peak was observed at 776 °C, which was not observed over LZ or LPtZ. This carbon could be graphitic in nature and is extremely stable, requiring a high temperature for oxidation. In one of our earlier studies with Ru and Sr substituted pyrochlores, we observed similar graphitic carbon oxidizing at 790 °C [12]. This carbon could be considered to be progressively formed during CH4 TPR, first starting with hydrogenated polymeric carbon that is further dehydrogenated with increasing temperature.

Table 2 shows the total amount of carbon formed over the three catalysts. Carbon on LRuZ is 1.17 gC/gcat, somewhat less than for LPtZ (1.67 gC/gcat).

Recall from the CH4 TPR spectra in Fig. 3b, c that LRuZ has more reactive lattice oxygen than LPtZ. This is likely the reason for smaller amount of carbon formation over LRuZ. Also, the greater amount of carbon on LPtZ would suggest greater amount of CH4 is activated over Pt. This would mean that Pt is more active towards CH4 activation as compared to Ru in the pyrochlore structure. A significant difference is observed in the reactivity of carbon formed over LRuZ and LPtZ. The reason could be due to the difference in the activation mechanism of CH4. Activation of CH4 occurs by either formate formation or by direct decomposition to form C(s) and H2(g) over the catalyst [26]. As the carbon formed over LPtZ is observed to be more reactive than that over LRuZ; Pt could be activating CH4 via formate formation. Direct decomposition would result in a dehydrogenated form of carbon which could become more graphitic and less reactive, resulting in a higher TPO peak. Thus, the TPO results suggest that Ru could be activating CH4 via direct decomposition.

Temperature programmed surface reaction (TPSR)

TPSR of LZ, LPtZ and LRuZ is shown in Fig. 5a, b, and c, respectively. This experiment was performed to determine the catalyst light-off temperature and to study the effect of metal substitution on the B-site of the pyrochlore. TPSR plot shows that LZ does not convert CH4 or CO2 to any significant extent at any temperature. The initial drop in CO2 signal is due to the experimental error, as it is observed over all catalysts. Lack of any activity on LZ could be attributed to the absence of any active metal in the pyrochlore structure that is needed to activate CH4.

It appears that LPtZ (see Fig. 5b) activates in two stages. It starts to form CO and H2 at about 460 °C, but the rate of product formation increases more rapidly after 615 °C. These catalysts were not reduced during pre-treatment before TPSR. During TPSR, CH4 appears to start in situ reduction of Pt, creating more active sites for DRM with time [1]. Once formed, H2 and CO continue to reduce Pt to a greater extent resulting in faster creation of active sites, autocatalytically increasing reaction rate with temperature. This suggests that metallic Pt in the pyrochlore is the active site for DRM.

Figure 5c shows that LRuZ has a single light-off temperature of 415 °C, which is about 45 °C lower than for LPtZ. As a result of simultaneous occurrence of RWGS, small amount of water was also formed over both the catalysts. The temperature for water formation corresponds to the light-off temperature of each catalyst. In case of LPtZ, water formation began at about 460 °C, but the rate increased at 615 °C. However for LRuZ, water formation started at about 415 °C and was almost constant up to 900 °C.

Conclusion

XRD confirmed the formation of the La2Zr2O7 phase in the freshly calcined pyrochlores. H2 TPR showed that the reduction profile for LPtZ was very similar to that of LZ, suggesting that Pt is strongly bound within the pyrochlore structure. A somewhat lower reduction peak for LPtZ compared to LZ suggests that hydrogen spill-over from Pt reduces Zr ions at a lower temperature than when Pt is not present. For LRuZ, very low TPR peaks were observed suggesting that surface Ru was likely formed during a 950 °C oxygen pretreatment and was reducible at temperatures expected for conventional supported Ru clusters. CH4 TPR suggested that all the pyrochlores, with or without Pt or Ru substitution, have mobile lattice oxygen that is reactive towards carbon formed over the catalyst during CH4 TPR.

Ru substitution also assists in reduction of lanthanum zirconate. Quantitative and qualitative analysis of carbon formed over LRuZ and LPtZ during CH4 TPR suggests a difference in the mechanism of CH4 activation. Ru appears to activate CH4 via direct decomposition resulting in the formation of surface carbon and hydrogen. Pt seems to activate CH4 via formyl or formate group formation. Thus, the carbon formed over LPtZ is more hydrogenated and oxidizes at a lower temperature compared to that formed over LRuZ.

TPSR experiments suggest that the light-off temperature of LRuZ is about 45 °C lower compared to LPtZ. Greater surface coverage of Ru metal due to migration of Ru to surface as a result of unstable substitution on the B-site could be the reason for lower light-off temperature of LRuZ compared to LPtZ.

References

Ashcroft AT, Cheetham AK, Green MLH, Vernon PDF (1991) Partial oxidation of methane to synthesis gas using carbon-dioxide. Nature 352(6332):225–226. doi:10.1038/352225a0

Bitter JH, Seshan K, Lercher JA (2000) On the contribution of X-ray absorption spectroscopy to explore structure and activity relations of Pt/ZrO2 catalysts for CO2/CH4 reforming. Top Catal 10(3–4):295–305. doi:10.1023/a:1019149025242

Bradford MCJ, Vannice MA (1999) CO2 reforming of CH4 over supported Ru catalysts. J Catal 183(1):69–75. doi:10.1006/jcat.1999.2385

Carrara C, Munera J, Lombardo EA, Cornaglia LM (2008) Kinetic and stability studies of Ru/La(2)O(3) used in the dry reforming of methane. Top Catal 51(1–4):98–106. doi:10.1007/s11244-008-9131-y

Choudhary VR, Mondal KC, Mamman AS, Joshi UA (2005) Carbon-free dry reforming of methane to syngas over NdCoO3 perovskite-type mixed metal oxide catalyst. Catal Lett 100(3–4):271–276. doi:10.1007/s10562-004-3467-0

Daza CE, Gallego J, Moreno JA, Mondragon F, Moreno S, Molina R (2008) CO2 reforming of methane over Ni/Mg/Al/Ce mixed oxides. Catal Today 133:357–366. doi:10.1016/j.cattod.2007.12.081

Erdohelyi A, Cserenyi J, Solymosi F (1993) Activation of CH4 and its reaction with CO2 over supported RH catalysts. J Catal 141(1):287–299. doi:10.1006/jcat.1993.1136

Fan M-S, Abdullah AZ, Bhatia S (2009) Catalytic technology for carbon dioxide reforming of methane to synthesis gas. Chemcatchem 1(2):192–208. doi:10.1002/cctc.200900025

Ferreira-Aparicio P, Marquez-Alvarez C, Rodriguez-Ramos I, Schuurman Y, Guerrero-Ruiz A, Mirodatos C (1999) A transient kinetic study of the carbon dioxide reforming of methane over supported Ru catalysts. J Catal 184(1):202–212. doi:10.1006/jcat.1999.2439

Gallego GS, Batiot-Dupeyrat C, Barrault J, Florez E, Mondragon F (2008) Dry reforming of methane over LaNi1-yByO3 ± delta (B = Mg, Co) perovskites used as catalyst precursor. Appl Catal A Gen 334(1–2):251–258. doi:10.1016/j.apcata.2007.10.010

Garcia-Dieguez M, Pieta IS, Herrera MC, Larrubia MA, Malpartida I, Alemany LJ (2010) Transient study of the dry reforming of methane over Pt supported on different gamma-Al(2)O(3). Catal Today 149(3–4):380–387. doi:10.1016/j.cattod.2009.07.099

Gaur S, Pakhare D, Wu HY, Haynes DJ, Spivey JJ (2012) CO2 reforming of CH4 over Ru-substituted pyrochlore catalysts: effects of temperature and reactant feed ratio. Energy Fuels 26(4):1989–1998. doi:10.1021/ef300158y

Hayakawa I, Kamizono H (1993) Durability of an La2Zr2O7 waste form containing various amounts of simulated HLW elements. J Nucl Mater 202(1–2):163–168. doi:10.1016/0022-3115(93)90039-2

Haynes DJ, Berry DA, Shekhawat D, Spivey JJ (2008) Catalytic partial oxidation of n-tetradecane using pyrochlores: effect of Rh and Sr substitution. Catal Today 136(3–4):206–213. doi:10.1016/j.cattod.2008.02.012

Haynes DJ, Berry DA, Shekhawat D, Spivey JJ (2009) Catalytic partial oxidation of n-tetradecane using Rh and Sr substituted pyrochlores: effects of sulfur. Catal Today 145(1–2):121–126. doi:10.1016/j.cattod.2008.05.014

Haynes DJ, Campos A, Berry DA, Shekhawat D, Roy A, Spivey JJ (2010) Catalytic partial oxidation of a diesel surrogate fuel using an Ru-substituted pyrochlore. Catal Today 155(1–2):84–91. doi:10.1016/j.cattod.2009.03.025

Hou ZY, Yokota O, Tanaka T, Yashima T (2003) Characterization of Ca-promoted Ni/alpha-Al2O3 catalyst for CH4 reforming with CO2. Appl Catal A Gen 253(2):381–387. doi:10.1016/s0926-860x(03)00543-x

Hou ZY, Yokota O, Tanaka T, Yashima T (2003) Investigation of CH4 reforming with CO2 on meso-porous Al2O3-supported Ni catalyst. Catal Lett 89(1–2):121–127. doi:10.1023/a:1024787913883

Hu YH, Ruckenstein E (1996) An optimum NiO content in the CO2 reforming of CH4 with NiO/MgO solid solution catalysts. Catal Lett 36(3–4):145–149

Luo JZ, Yu ZL, Ng CF, Au CT (2000) CO2/CH4 reforming over Ni-La2O3/5A: an investigation on carbon deposition and reaction steps. J Catal 194(2):198–210. doi:10.1006/jcat.2000.2941

O’Connor AM, Schuurman Y, Ross JRH, Mirodatos C (2006) Transient studies of carbon dioxide reforming of methane over Pt/ZrO2 and Pt/Al2O3. Catal Today 115(1–4):191–198. doi:10.1016/j.cattod.2006.02.051

Sadykov VA, Gubanova EL, Sazonova NN, Pokrovskaya SA, Chumakova NA, Mezentseva NV, Bobin AS, Gulyaev RV, Ishchenko AV, Krieger TA, Mirodatos C (2011) Dry reforming of methane over Pt/PrCeZrO catalyst: kinetic and mechanistic features by transient studies and their modeling. Catal Today 171(1):140–149. doi:10.1016/j.cattod.2011.04.004

Shamsi A, Baltrus JR, Spivey JJ (2005) Characterization of coke deposited on Pt/alumina catalyst during reforming of liquid hydrocarbons. Appl Catal A Gen 293:145–152. doi:10.1016/j.apcata.2005.07.002

Souza M, Aranda DAG, Schmal M (2001) Reforming of methane with carbon dioxide over Pt/ZrO2/Al2O3 catalysts. J Catal 204(2):498–511. doi:10.1006/jcat.2001.3398

Subramanian MA, Aravamudan G, Rao GVS (1983) Oxide pyrochlores: a review. Prog Solid State Chem 15(2):55–143. doi:10.1016/0079-6786(83)90001-8

vanKeulen ANJ, Seshan K, Hoebink J, Ross JRH (1997) TAP investigations of the CO2 reforming of CH4 over Pt/ZrO2. J Catal 166(2):306–314. doi:10.1006/jcat.1997.1539

Zhang ZL, Tsipouriari VA, Efstathiou AM, Verykios XE (1996) Reforming of methane with carbon dioxide to synthesis gas over supported rhodium catalysts.1. Effects of support and metal crystallite size on reaction activity and deactivation characteristics. J Catal 158 (1):51–63. doi:10.1006/jcat.1996.0005

Zhang ZL, Verykios XE (1996) Mechanistic aspects of carbon dioxide reforming of methane to synthesis gas over Ni catalysts. Catal Lett 38(3–4):175–179. doi:10.1007/bf00806565

Acknowledgments

This material is based upon work supported as part of the Center for Atomic Level Catalyst Design, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under Award Number DE-SC0001058. We thank Ms. Kim Hutchison at North Carolina State University, and Ms. Wanda LeBlanc for helping in getting the ICP, and XRD data, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Pakhare, D., Haynes, D., Shekhawat, D. et al. Role of metal substitution in lanthanum zirconate pyrochlores (La2Zr2O7) for dry (CO2) reforming of methane (DRM). Appl Petrochem Res 2, 27–35 (2012). https://doi.org/10.1007/s13203-012-0014-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-012-0014-6