Abstract

Electrical submersible pumping is the most inflexible of any artificial lift system because a specific ESP pump can only be used in a definite, quite restricted range of pumping rates. If it is used outside the specified range, pump and system efficiencies rapidly deteriorate and eventually mechanical problems leading to a complete system failure develop. When serious deviation from the design production rate is experienced, the possible solutions are (a) running a different pump with the proper recommended operating range, or (b) using a variable speed drive (VSD) unit. However, in case the ESP system produces a higher than desired liquid rate, a simple and frequently used solution is the installation of a wellhead choke. The wellhead choke restricts the pumping rate and forces the ESP pump to operate within its recommended liquid rate range. This solution, of course, is very detrimental to the economy of the production system because of the high hydraulic losses across the choke that cause a considerable waste of energy. The paper utilizes NODAL analysis to investigate the negative effects of surface production chokes on the energy efficiency of ESP systems as compared to the application of VSD drives. The power flow in the ESP system is described and the calculation of energy losses in system components is detailed. Based on these, a calculation model is proposed to evaluate the harmful effects of wellhead choking and to find the proper parameters of the necessary VSD unit. By presenting a detailed calculation on an example well using the proposed model the detrimental effects of wellhead choking are illustrated and the beneficial effects of using a VSD drive are presented. Using data of a group of wells placed on ESP production a detailed investigation is presented on the field-wide effects of choking. The energy flows and the total energy requirements are calculated for current and optimized cases where VSD units providing the required electrical frequencies are used. Final results clearly indicate that substantial electric power savings are possible if production control is executed by VSDs instead of the present practice of using surface chokes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The objective of any artificial lift design is to set up a lift system with a liquid producing capacity that matches the inflow rate from the well it is installed in. Since the mechanical design of the lifting equipment is only possible in the knowledge of the probable liquid rate, the designer needs a precise estimate on the production rate attainable from the given well. Design inaccuracies or improperly assumed well rates can very easily result in a mismatch of the designed and actually produced liquid volumes (Brown 1980; Takacs 2009). The main cause of discrepancies between these rates, assuming proper design procedures are followed, is the improper estimation of possible well rates, i.e. inaccurate data on well inflow performance. The consequences of under-, or over-design of artificial lift systems can lead to the following:

-

If the artificial lift equipment’s capacity is greater than well inflow then the operational efficiency of the system cannot reach the designed levels; mechanical damage may also occur.

-

In case the well’s productivity is greater than the capacity of the lifting system, one loses the profit of the oil not produced.

Over-, and under-design of artificial lift installations happens in the industry very often and professionals know how to deal with them. Some lifting methods such as gas lifting or sucker rod pumping are relatively easy to handle since their lifting capacity can be adjusted in quite broad ranges after installation. ESP installations, however, do not tolerate design inaccuracies because any given ESP pump can only be used in a specific, quite restricted range of pumping rates. If used outside its recommended liquid rate range, the hydraulic efficiency of the pump rapidly deteriorates; efficiencies can go down to almost zero. In addition to the loss of energy and the consequent decrease in profitability the ESP system, when operated under such conditions, soon develops mechanical problems that can lead to a complete system failure. The usual outcome is a workover job and the necessity of running a newly designed ESP system with the proper lifting capacity.

One common solution for over-designed ESP systems is the use of production chokes at the wellhead. Installation of the choke, due to the high pressure drop that develops through it, limits the well’s liquid rate so the ESP pump is forced to operate in its recommended pumping rate range. This solution eliminates the need for running a new ESP system of the proper capacity into the well and saves the costs of pulling and running operations. At the same time, however, the system’s power efficiency decreases considerably due to the high hydraulic losses occurring across the surface choke.

The paper investigates the detrimental effects of surface chokes on the power efficiency of ESP systems and discusses an alternative solution. The analysis is provided for wells producing negligible amounts of free gas and is based on the application of NODAL analysis principles to describe the operation of the ESP system.

The effects of using wellhead chokes

Why use chokes

Most ESP installations are designed to operate using electricity at a fixed frequency, usually 60 or 50 Hz. This implies that the ESP pump runs at a constant speed and develops different heads for different pumping rates as predicted by its published performance curve. When designing for a constant production rate, a pump type with the desired rate inside of its recommended capacity range is selected. The number of the required pump stages is found from detailed calculations of the required total dynamic head (TDH), i.e. the head required to lift well fluids to the surface at the desired pumping rate. Thus, the head versus capacity performance curve of the selected pump can easily be plotted based on the performance of a single stage.

For an ideal design when all the necessary parameters of the well and the reservoir are perfectly known the pump will produce exactly the design liquid rate since it will work against the design TDH (1997; 2001; 2002). In this case the head required to overcome the pressure losses necessary to move well fluids to the separator is covered by the head available from the pump at the given pumping rate. This perfect situation, however, is seldom achieved; very often inaccuracies or lack of information on well inflow performance cause design errors and the well produces a rate different from the initial target.

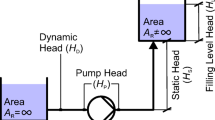

The problem with the conventional design detailed above is that the ESP installation is investigated for a single design rate only and no information is available for cases when well parameters are in doubt. All these problems are easily solved if system (NODAL) analysis principles are used to describe the operation of the production system consisting of the well, the tubing, the ESP unit, and the surface equipment. NODAL analysis permits the calculation of the necessary pump heads for different possible pumping rates and the determination of the liquid rate occurring in the total system, This will be the rate where the required head to produce well fluids to the separator is equal to the head developed by the ESP pump run in the well.

Figure 1 shows a schematic comparison of the conventional design with that provided by NODAL analysis. Conventional design calculates the TDH at the design rate only and selects the type of the ESP pump and the necessary number of stages accordingly. After selecting the rest of the equipment the ESP unit is run in the well and it is only hoped that actual conditions were properly simulated resulting in the well output being equal to the design liquid rate. If well inflow performance data were uncertain or partly/completely missing during the design phase then the ESP system’s stabilized liquid rate is different from the design target. NODAL calculations, however, can predict the required head values for different liquid rates, shown in Fig. 1 by the curve in dashed line. The well’s actual production rate will be found where the required and the available (provided by the pump) heads are equal, at Point 1 in the figure.

In typical cases the actual liquid production rate is greater than the target value. This clearly indicates inaccuracies in the well performance data assumed during the design process. Since the well’s required production is usually dictated by reservoir engineering considerations production of a greater rate is not allowed. The problem is caused, as shown in Fig. 1, by the fact that the actual head requirement (actual TDH) is much less than the calculated design TDH.

The solution of the problem, if pulling the ESP equipment and replacing it with a properly designed one is not desired, is to place a production choke of the proper diameter at the wellhead to restrict the liquid rate to the design target. At this rate, however, the installed pump develops the designed operating head as shown by Point 2. Since the actual head required for lifting the well fluids to the surface, as found from NODAL calculations, is less than this value, a sufficient head loss across the choke is needed. This head loss, found between Points 2 and 3 must be sufficient to supplement the system’s actual TDH to reach the TDH that was used for the original design. As a result, the head requirement of the production system is artificially increased and the ESP pump is forced to produce the desired liquid rate.

Estimating the energy loss across wellhead chokes

The detrimental effect of choking an ESP unit is clearly indicated by the amount of power wasted through the surface choke. This (in HP units) can be calculated from the pumping rate and the amount of head loss across the choke:

where ql is the pumping rate (bpd), ΔHchoke the head loss across surface choke (ft), and γl is the specific gravity of the produced liquid.

The above power, of course, must be supplied by the electric motor to drive the submersible pump that is being subjected to a higher than necessary load. Since this power is wasted, the ESP system’s power efficiency as well as the profitability of fluid production will decrease.

Calculation of the ESP pump’s required head by NODAL methodology

Since choking of the ESP well at the wellhead is clearly detrimental to the lifting performance, proper design and installation of the ESP equipment is highly important. In case sufficiently accurate inflow performance data are available, the use of NODAL analysis techniques allows for an accurate installation design and eliminates the need for using wellhead chokes (Takacs 2009).

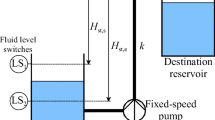

In order to apply systems (NODAL) analysis to the ESP installation, the variation of flowing pressures in the well should be analyzed first. Figure 2 depicts the pressures along the well depth (a) in the tubing string, and (b) in the casing-tubing annulus. The well is assumed to produce incompressible liquids at a stabilized flow rate, found from the well’s inflow performance relationship (IPR) curve. From the depth of the perforations up to the setting depth of the ESP pump, pressure in the casing changes according to the flowing pressure gradient of the well fluid which is approximated by the static liquid gradient. This assumption is acceptable when medium flow rates are produced through large casing sizes; otherwise, a pressure traverse including all pressure losses should be calculated. The calculated casing pressure at the pump setting depth is the pump intake pressure (pintake).

At the depth of the pump discharge (which is practically at the same depth as the intake), the pump develops a pressure increase denoted as Δppump in the figure. The pressure available at the ESP pump’s discharge, therefore, can be calculated as follows:

where pwf is the flowing bottomhole pressure (psi), gradl the liquid gradient (psi/ft), Δppump the pressure increase developed by the pump (psi), Lset = pump setting depth (ft), Lperf is the depth of perforations (ft).

Calculation of the pressure at the pump’s setting depth required to produce the given rate is started from the surface separator. The wellhead pressure pwh is found by adding the flowing pressure losses in the flowline to the separator pressure psep. For the single-phase liquid production case studied in this paper, the pressure distribution in the tubing string starts at the wellhead pressure and changes linearly with tubing length. Tubing pressure has two components: (1) the hydrostatic pressure, and (2) the frictional pressure loss. By proper consideration of the terms described we can define the required discharge pressure of the ESP pump as follows:

where psep is the surface separator pressure (psi), Δpfl the frictional pressure drop in the flowline (psi), Δpfr is the frictional pressure drop in the tubing string (psi).

Since the available and the required pressures must be equal at the ESP pump’s discharge, the simultaneous solution of the two formulas results in the following expression that describes the pressure increase to be developed by the ESP pump:

Since the ESP industry uses head instead of pressure, the previous equation is divided by the liquid gradient to arrive at the necessary head of the pump:

where ΔHfl is the frictional head drop in the flowline (ft), ΔHfr is the frictional head drop in the tubing string (ft).

The previous formula, if evaluated over an appropriate range of liquid flow rates, represents the variation of the necessary head that the pump must develop to produce the possible liquid rates from the given well, see the curve in dashed line in Fig. 1. For an accurate installation design the ESP pump’s operating point must fall on this curve at its intersection with the desired liquid rate. Based on this, the required pump can be properly selected and no wellhead choke will be needed to control the flow rate. This scenario, of course, can only be followed if sufficiently accurate inflow performance data on the given well are available.

Use of variable speed drive (VSD) units to eliminate wellhead chokes

If, for any reason, the installation design is inaccurate and the ESP system, after installation, produces a higher rate than desired the use of wellhead chokes is a common solution to control the well’s production. If a VSD is available, however, the elimination of the choke and its associated disadvantages can be accomplished (Divine 1979). As shown in Fig. 1, by reducing the electrical frequency driving the ESP system to a level where the head developed by the pump is equal to the head required to produce the desired rate (Point 3) the choke is no more needed to adjust the pumping rate.

When a VSD unit is used to control the ESP system’s liquid rate the different components of the system behave differently as the driving frequency is adjusted. The centrifugal pump will develop different head values and will need different brake horsepowers from the electric motor. All these changes are described by the pump performance curves valid at variable frequencies usually available from manufacturers. In case such curves are missing, the Affinity Laws (Takacs 2009; 1997) and the performance curves at a constant frequency may be used to calculate the required parameters at the reduced frequency: heads, efficiencies, and brake horsepowers.

The performance parameters of the ESP motor at variable frequency operation are described by two basic formulae that express the change of (a) the nameplate voltage, and (b) the power developed, both with the changes in the electrical frequency. Actually, nameplate voltage of the motor is adjusted by the surface VSD unit so that the voltage-to-frequency ratio is kept constant. This is to ensure that the motor becomes a constant-torque, variable speed device. The applicable formula is the following:

where f1, f2 are the AC frequencies (Hz), U1, U2 are the output voltages at f1 and f2 (Hz, V).

The power developed by the ESP motor is linearly proportional with the electrical frequency as shown by the next formula:

where f2, f1 are the AC frequencies (Hz), HP1, HP2 are the motor powers available at f1 and f2 (Hz, HP).

As described previously, the use of a VSD unit substantially modifies the power conditions of the ESP pump and the motor. In order to fully understand the changes and to demonstrate the beneficial effects of removing wellhead chokes the next section details the power conditions in the ESP system.

Power conditions in ESP installations

Power flow in the ESP system

The ESP installation’s useful output work is done by the centrifugal pump when it lifts a given amount of liquid from the pump setting depth to the surface. This work is described by the useful hydraulic power, Phydr, and can be calculated from the power consumed for increasing the potential energy of the liquid pumped. The following formula, recommended by Lea et al. (1999), can be applied to any artificial lift installation and gives a standardized way to compare the effectiveness of different installations:

where Phydr is the hydraulic power used for fluid lifting (HP), ql the liquid production rate (bpd), Lpump the pump setting depth (ft) and pintake is the pump suction pressure, called pump intake pressure (psi).

The total power consumed by the system comprises, in addition to the energy required to lift well fluids to the surface (i.e. the hydraulic power Phydr), all the energy losses occurring in downhole and surface components. Thus, the required electrical energy input at the surface is always greater than the useful power; the relation of these powers defines the ESP system’s power efficiency.

Classification of the energy losses in ESP systems can be made according to the place where they occur; one can thus distinguish between downhole and surface losses (Takacs 2010). Another way to group these losses is based on their nature and categorizes them as hydraulic and electrical.

Energy losses in the ESP system

Hydraulic losses

The sources of energy losses of hydraulic nature are the tubing string, the backpressure acting on the well, the ESP pump, and the optional rotary gas separator.

Tubing losses

Flow of the produced fluids to the surface involves frictional pressure losses in the tubing string; the power wasted on this reduces the effectiveness of the ESP installation. In case a single-phase liquid is produced, the frictional loss in the tubing string is determined from the total head loss, ΔHfr, usually taken from charts or appropriate calculation models. The power lost, ΔPfr in HP units, is found from the following formula:

where ΔHfr is the frictional head loss in the tubing (ft).

Backpressure losses

The ESP unit has to work against the well’s surface wellhead pressure and the power consumed by overcoming this backpressure is not included in the useful power. The necessary power to overcome the wellhead pressure (in HP units) is found from:

where ql is the liquid production rate (bpd) and pwh is the wellhead pressure (psi).

Pump losses

Energy losses in the ESP pump are mostly of hydraulic nature, and are represented by published pump efficiency curves. In most cases the pump efficiencies, as given by the manufacturer, include the effect of the additional power required to drive the ESP unit’s protector. Based on the actual pump efficiency, the power lost in the pump (in HP units) is easily found:

where BHP is the pump’s required brake horsepower (HP) and ηpump is the published pump efficiency (%).

Electrical losses

Electrical power losses in the ESP installation occur, starting from the motor and proceeding upward, in the ESP motor, in the power cable, and in the surface equipment.

Motor losses

The ESP motor converts the electrical energy input at its terminals into mechanical work output at its shaft; the energy conversion is characterized by the motor efficiency. Based on published efficiency values, the power lost in the ESP motor (in HP units) is calculated as follows:

where HPnp is the motor’s nameplate power (HP), Load is the motor loading, fraction, and ηmotor is the motor efficiency at the given loading (%).

Cable losses

Since the ESP motor is connected to the power supply through a long power cable, a considerable voltage drop occurs across this cable. The voltage drop creates a power loss proportional to the square of the current flowing through the system, as given here in kW units:

where I is the required motor current (Amps) and RT is the resistance of the power cable at well temperature (Ohms).

Surface electrical losses

The ESP installation’s surface components are very efficient to transmit the required electric power to the downhole unit, their usual efficiencies are around ηsurf = 0.97. The energy wasted in surface equipment can thus be found from:

where P is the sum of the hydraulic power and the power losses, and ηsurf is the power efficiency of the surface equipment.

Example problem

In the following, a detailed calculation model is proposed and illustrated through an example well. Energy flow in the ESP system is determined for current conditions when a surface choke is used to control the well’s liquid flow rate. Then the use of a VSD unit is investigated and the required operational frequency is determined; the energy conditions of the modified installation are compared to the original case.

Well data

Production data of an example well are given in Table 1.

Common calculations

First calculate those parameters that are identical for the original, choked conditions and for the case without the choke.

The flowing bottomhole pressure from the Productivity Index formula is found as:

Now the pump intake pressure is calculated:

Knowledge of these parameters permits the calculation of the system’s useful hydraulic power from Eq. 8

At pump suction conditions there is no free gas present, as can be found from the Standing correlation; the oil’s volume factor at the same pressure is found as Bo = 1.115 bbl/STB. The total liquid volume to be handled by the ESP pump is thus:

In order to find the frictional head loss due to the flow of the current liquid rate through the well tubing the Hazen-Williams formula or the use of the proper graph gives a head loss of 42 ft/1,000 ft of pipe. The total head loss in the tubing is thus:

The energy loss corresponding to tubing frictional losses can be calculated from Eq. 9:

Energy conditions of the current installation

This section contains calculations for the original, choked condition and evaluates the energy conditions of the current ESP installation.

The hydraulic losses due to the backpressure at the wellhead pressure of 745 psi are calculated from Eq. 10 as follows:

From the performance curve of the GN4000 pump operated at 50 Hz, the following parameters of the pump are found at the current liquid rate of 461 m3/day:

Since there are 99 stages in the pump, the pump’s power requirement is:

Based on these parameters the power lost in the pump can be calculated from Eq. 11:

The existing ESP motor’s rated power (see input data) being 104.2 HP, the motor is only 70% loaded by the pump power of 73 BHP. From motor performance data, motor efficiency at that loading is 89%. Now the power loss in the electric motor can be found from Eq. 12:

In order to find the electrical losses in the downhole cable, first the resistance of the well cable has to be found. The installation uses an AWG 2 size electrical cable with an electrical resistance of 0.17 Ohm/1,000 ft. The total resistance of the downhole cable, considering well temperature, is found as 0.658 Ohms.

The actual current flowing through the cable is equal to the motor current found from the motor load and the nameplate current as:

Now the electrical power lost in the cable is calculated from the basic 3-Phase power formula (Eq. 13):

Finally, the power lost in the ESP system’s surface components is to be found from Eq 14 with a surface efficiency of 97%.

Energy conditions of the modified installation

This section presents the calculations required to describe the conditions when a VSD unit is used to control the pumping rate instead of choking the well.

In this case the operating wellhead pressure is reduced to the flowline intake pressure; this was measured downstream of the wellhead choke as 130 psi. The hydraulic losses due to the backpressure are calculated from Eq. 10 as follows:

Next the required electrical frequency is calculated using the head performance curve of the pump for multiple frequencies. Since the current case uses 50 Hz, metric performance curves have to be used.

-

The head developed by the pump at 50 Hz operation is found at the current liquid rate of 461 m3/day and is designated as Point 1.

-

The head drop across the wellhead choke, corrected for one stage, is calculated in metric units:

$$ {\text{Drop}} = 0.3048 \, 2.3 \, \left( {p_{\text{wh}} - P_{\text{downstream}} } \right)/\gamma_{\text{l}} /{\text{no}} . {\text{ of stages}} = 0.3048 \, 2.3 \, \left( {745 - 130} \right)/0.876/99 = 5\;{\text{m}} . $$ -

From Point 1, a vertical is dropped by the calculated distance of 5 m; this defines Point 2.

-

The frequency valid at Point 2 is read; this should be used on the VSD unit to drive the ESP motor.

The process described here resulted in a required frequency of 37 Hz for the example case.

Next the operational parameters of the GN4000 pump at 37 Hz service have to be determined. Since detailed performance curves for this frequency are not available, the use of published 50 Hz curves and the Affinity Laws is required.

The required rate of 461 m3/day at 37 Hz operation corresponds to the following rate at 50 Hz, as found from the Affinity Laws:

The power requirement and the efficiency of the pump at this rate at 50 Hz operation are read from the 50 Hz performance curves as:

From these data and using the Affinity Laws again, the power requirement of the pump at 37 Hz operation is calculated:

The efficiency of the pump remains at 65%.

Now the power needed to drive the 99 pump stages at an electrical frequency of 37 Hz has decreased to:

Based on these parameters the power lost in the pump can be calculated as (Eq. 11):

The operating conditions of the ESP motor change at the modified frequency. Its nameplate power decreases from that at 50 Hz according to Eq. 7:

Motor voltage is adjusted by the VSD unit from the nameplate value valid at 50 Hz to the following voltage, according to Eq. 6:

The ESP motor’s loading is found from the pump power requirement and the modified motor power:

The efficiency of the motor at this loading is 87%, as found from motor performance curves. The power loss in the electric motor can now be found from Eq. 12:

When finding the electrical losses in the downhole cable, the resistance of the cable is identical to the previous case at 0.658 Ohms. Since the nameplate current of the ESP motor at the new frequency does not change the actual motor current is found from the motor load and nameplate current as:

The power loss in the cable is calculated from Eq. 13:

Finally, the power lost in the ESP system’s surface components is to be found from Eq. 14 with a surface efficiency of 97%:

Final results

Table 2 summarizes the energy conditions of the two cases.

As seen, the use of a VSD unit has increased the system efficiency to more than twofold and system power decreased to less than 40% of the original requirement.

Application to a group of wells

In order to evaluate the model proposed in the paper for increasing the efficiency of ESP wells on surface choke control, calculations were performed using the data of several wells from the same field. The wells produced API 40 gravity oil with low water cuts from relatively shallow depths. Original installation designs were far from ideal and most wells had downhole equipment capable of much higher production rates than those permitted by reservoir engineering management and had to be choked back. This is the reason why wellhead pressures are much higher than the required line pressure in the gathering system.

The most important input and calculated data are given in Table 3. Most of the wells indicate quite high pressure drops across the wellhead chokes that obviously involve lots of energy wasted in the ESP system. The surface power requirements for the original cases, of course, include these wasted power components and the overall system efficiencies are accordingly very low.

After re-designing the installations according to the procedure proposed in this paper, application of VSD units was assumed and the required operational frequencies were determined. The modified cases, as seen in Table 3, have much lower total energy requirements mainly due to the removal of the wellhead choke’ harmful effect; overall system efficiencies have substantially increased.

Total electrical power requirement of the well group investigated has decreased to almost one-third of the original, from 606 to 211 kW. This clearly proves that using VSDs to control the production rate of ESP wells is a much superior solution to wellhead choking adopted in field practice.

Conclusions

The paper investigates the power conditions of ESP installations where the pumping rate of oversized ESP units is reduced by placing chokes on the wellhead. Power flow in the system with the description of possible energy losses is presented and system efficiency is evaluated. In order to reduce the harmful effects of wellhead chokes on system efficiency NODAL analysis principles are used to describe the operation of the ESP system. A detailed calculation method is developed and example cases are presented to find the proper frequency setting of a VSD unit to be used. Main conclusions derived are as follows.

-

The practice of controlling the pumping rate of ESP installations by wellhead chokes can very substantially reduce the energy efficiency of the system.

-

NODAL analysis can be used to properly design an ESP installation and/or rectify the situation without a need to change downhole equipment.

-

The proposed calculation model provides a much more energy-efficient solution to production rate control using VSD units.

-

Several field examples are shown to prove that very substantial energy savings can be realized by following the proposed model.

References

Submersible pump handbook (1997) 6th edn. Centrilift-Hughes Inc., Claremore

The 9 step (2001) Baker-Hughes Centrilift, Claremore

Recommended practice for sizing and selection of electric submersible pump installations (2002) API RP 11S4, 3rd edn. American Petroleum Institute

Brown KE (1980) The technology of artificial lift methods, vol 2b. PennWell Books, Tulsa

Divine DL (1979) A variable speed submersible pumping system. In: Paper SPE 8241 presented at the 54th annual technical conference and exhibition held in Las Vegas, September 23–26

Lea JF, Rowlan L, McCoy J (1999) Artificial lift power efficiency. In: Proceedings of 46th Annual Southwestern Petroleum Short Course, Lubbock, pp 52–63

Takacs G (2009) Electrical submersible pumps manual. Gulf Professional Publishing, USA

Takacs G (2010) Ways to obtain optimum power efficiency of artificial lift installations. In: Paper SPE 126544 presented at the SPE oil and gas India conference and exhibition held in Mumbai, 20–22 January

Acknowledgments

This work was carried out as part of the TÁMOP-4.2.1.B-10/2/KONV-2010-0001 project in the framework of the New Hungarian Development Plan. The realization of this project is supported by the European Union, co-financed by the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Takacs, G. How to improve poor system efficiencies of ESP installations controlled by surface chokes. J Petrol Explor Prod Technol 1, 89–97 (2011). https://doi.org/10.1007/s13202-011-0011-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-011-0011-9