Abstract

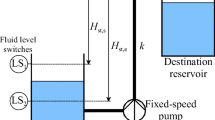

In this present study, energy consumption behavior and performance of the submersible pumping system running at different sites in the Barind Tract of Bangladesh have been investigated and compared with those of the lab test results of new pumps. It is found that the efficiency of the running pumps is 20–40% lower than that of laboratory efficiency. The total operating head of the submersible pump includes a parameter known as “drawdown” which has a significant effect on its performance. The drawdown characteristics of a 15 HP submersible pump have been studied in the laboratory by varying bore well diameter. It is observed that the amount of drawdown, as well as efficiency, decreases significantly with increasing bore well diameter. This work provides new ideas by incorporating three different mechanical devices (plane, bowl, and propeller) attached to the delivery pipe near the pump to achieve higher efficiency as well as lower energy consumption and compared while using no device. It is possible to obtain 55% efficiency by using a bowl type of a mechanical device in an 8-in bore well that is 5% higher while using no device. On the other hand, there is an opportunity to attain 57% efficiency by using all three devices (plane, bowl, and propeller) at a time in 8-in bore well that is 7% higher while using no attachment. By integrating the mechanical devices in the Talaimari pumping site of Rajshahi Water Supply and Sewerage Authority (RWASA), the annual cost and energy savings will be 61,964.52 BDT and 8074.56 kWh, respectively.

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Banglapedia, National Encyclopedia of Bangladesh. (n.d.). Retrieved from https://en.banglapedia.org/index.php/Barind_Tract

Berezin, S. (2007). Wet and dry installation of submersible pumps. World Pumps, 493, 44–48.

BMDA, “Barind Multipurpose Development Authority Activities.” (2019). Retrieved from http://www.bmda.gov.bd/site/page/db57511d-2cd1-4ce3-8678-a7d83423b991/-.%0A

Chhanya, V., & Thoriya, P. (2016). Design and CFD analysis of submersible pump impeller of mixed flow type for performance improvement. International Journal of Advance Engineering and Research Design and CFD Analysis of Submersible Pump Impeller of. International Journal of Advance Engineering and Research Development, 2, 468–475. https://www.researchgate.net/profile/Vishal-Chhaya/publication/286920987_design_and_cfd_analysis_of_submersible_pump_impeller_of_mixed_flow_type_for_performance_improvement/links/5726b53d08ae586b21e04f12/design-and-cfd-analysis-of-submersible-pump-impeller-of-mixed-flow-type-for-performance-improvement.pdf

Dhanasekaran, A., & Kumaraswamy, S. (2017). Pressure pulsation study in the stages of an electric submersible pump at shut-off under various speeds. Imp J Interdiscip Res, 3(4), 1–9.

Emiliawati, A. (2017). A study of water pump efficiency for household water demand at Lubuklinggau. AIP Conference Proceedings, 1903(November 2017). https://doi.org/10.1063/1.5011613

Fiaschi, D., Graniglia, R., & Manfrida, G. (2005). Improving the effectiveness of solar pumping systems by using modular centrifugal pumps with variable rotational speed. Solar Energy, 79(3), 234–244. https://doi.org/10.1016/j.solener.2004.11.005

Gopal, C., Mohanraj, M., Chandramohan, P., & Chandrasekar, P. (2013). Renewable energy source water pumping systems—a literature review. Renew Sustain Energy Rev, 25, 351–370.

Haque, M. E., Islam, M. R., Islam, M. S., Haniu, H., & Akhter, M. S. (2017). Life cycle cost and energy consumption behavior of submersible pumps using in the Barind area of Bangladesh. Energy Procedia, 110, 479–485.

Haque, M. E., Islam, M. S., Islam, M. R., Haniu, H., & Akhter, M. S. (2019). Energy efficiency improvement of submersible pumps using in barind area of Bangladesh. Energy Procedia, 160(2018), 123–130. https://doi.org/10.1016/j.egypro.2019.02.127

Haque ME (2020). Development of an Energy Saving Submersible Pumping System for Barind Tract of Bangladesh. PhD Thesis, Department of Mechanical Engineering, Rajshahi University of Engineering & Technology, RUET.

Hosoy A, Gjerstad S, Smaamo J, & Torbergsen E (2005) Design and development of electric submersible pumps for large capacities. Proceedings of the Twenty-Second International Pump User Symposium, 69–76.

Icier, F., Colak, N., Erbay, Z., Kuzgunkaya, E. H., & Hepbasli, A. (2010). A comparative study on exergetic performance assessment for drying of broccoli florets in three different drying systems. Drying Technol, 28(2), 193–204. https://doi.org/10.1080/07373930903524017

Islam MS, Hoque ME, Islam MR, & Haniu H (2017) Effect of drawdown on submersible pump performance. International Conference on Mechanical Engineering and Renewable Energy, 18–20.

Jokandan, M. J., Aghbashlo, M., & Mohtasebi, S. S. (2015). Comprehensive exergy analysis of an industrial-scale yogurt production plant. Energy, 93, 1832–1851. https://doi.org/10.1016/j.energy.2015.10.003

Karanth, S. (2014). Design, modeling & analysis of a submersible pump and to improve the pump efficiency. Int J Latest Trends Eng Technol, 4(2), 178–190.

Khan T (2016) Performance Investigation of a Submersible Pump under Different Operating Conditions. 0–6.

Kowalczyk, T., Ziólkowski, P., & Badur, J. (2015). Exergy losses in the Szewalski binary vapor cycle. Entropy, 17(10), 7242–7265. https://doi.org/10.3390/e17107242

Kulkarni SJ. (2017). Factors affecting pump performance—an insight into research and investigation.International Journal of Research & Review (Www.Gkpublication.In), 4(8), 39. https://www.ijrrjournal.com/IJRR_Vol.4_Issue.8_Aug2017/IJRR006.pdf

Li, L., Hua, C., & Xu, X. (2018). Condition monitoring and fault diagnosis of electric submersible pump based on wellhead electrical parameters and production parameters. Syst Sci Control Eng, 6(3), 253–261. https://doi.org/10.1080/21642583.2018.1548983

Liang X, & Fleming E (2012) Power Consumption Evaluation for Electrical Submersible Pump Systems. 1–6.

Liang X, & Fleming E (2013) Electrical submersible pump systems: evaluating their power consumption. In IEEE Industry Applications Magazine (19). https://doi.org/10.1109/MIAS.2012.2215660

Liang, X., He, J., & Du, L. (2015). Electrical submersible pump system grounding: Current practice and future trend. IEEE Trans Indus Appl, 51(6), 5030–5037. https://doi.org/10.1109/TIA.2015.2432096

Magnusson B, Näykki T, Hovind H, & Krysell M (2012) Handbook for Calculation of Measurement Uncertainty in Environmental Laboratories. Nordtest Technical Report 537, 537(0170), 1–46. Retrieved from http://ovidsp.ovid.com/ovidweb.cgi?T=JS&PAGE=reference&D=emed17&NEWS=N&AN=71911388

Manoharan, S., Devarajan, N., Deivasahayam, M., & Ranganathan, G. (2011). Enriched efficiency with cost effective manufacturing technique in 3.7 kw submersible pump sets using dcr technology. Int J Elect Eng Inform, 3(3), 360–371.

Minette, R. S., SilvaNeto, S. F., Vaz, L. A., & Monteiro, U. A. (2016). Experimental modal analysis of electrical submersible pumps. Ocean Eng, 124, 168–179. https://doi.org/10.1016/j.oceaneng.2016.07.054

Odeh, I., Yohanis, Y. G., & Norton, B. (2006). Influence of pumping head, insolation and PV array size on PV water pumping system performance. Solar Energy, 80(1), 51–64. https://doi.org/10.1016/j.solener.2005.07.009

Ofuchi, E. M., Stel, H., Sirino, T., Vieira, T. S., Ponce, F. J., Chiva, S., & Morales, R. E. M. (2017). Numerical investigation of the effect of viscosity in a multistage electric submersible pump. Eng Appl Comput Fluid Mech, 11(1), 258–272. https://doi.org/10.1080/19942060.2017.1279079

Prasad, M. B., & Sudha, M. (2016). Automation of submersible pumps and design ( TRIZ ) technology address for correspondence. International Journal of Advanced Engineering Technology, 6(1), 925–927.

Rajput RK (2008). Fluid mechanics. Retrieved from https://qdoc.tips/queue/fluid-mechanics-rk-rajputpdf-pdf-free.html

Rego, A. da G., Santos, A. C. P. A., & Pereira, J. A. R. (2017). Assessment of water pumping system and improvement in hydro-energetic performance. Journal of Urban and Environmental Engineering, 11(1), 42–50. https://doi.org/10.4090/juee.2017.v11n1.042050

RWASA. (2020). Annual report. Retrieved from 2020 website: http://rajshahiwasa.portal.gov.bd/site/page/8e80e771-de6a-4777-8dfc-7b8ef3278393/-

SG. (2020). Electrical submersible pump design in vertical oil wells. Petroleum & Petrochemical Engineering Journal, 4(4), 1–7 https://doi.org/10.23880/ppej-16000237

Shahid Salman Kassem, O. M., Dol, S. S., Gadala, M. S., & Hasan, A. Q. (2021). WSEAS TRASACTIONS ON FLUID MECHANICS. Rev Electr Submersible Pump Head Losses Methods Analyze Two-Phase Perform Curve, 16, 14–31. https://doi.org/10.37394/232013.2021.16.3

Shahid, S., & Hazarika, M. K. (2010). Groundwater drought in the northwestern districts of Bangladesh. Water Resour Manag, 24(10), 1989–2006. https://doi.org/10.1007/s11269-009-9534-y

Strategy 2003–2007: “Improved access to clean energy and water in selected states” –. (2007).

Wei, Q., & Sun, X. (2016). Performance influence in submersible pump with different diffuser inlet widths. Adv Mech Eng, 9(1), 1–8. https://doi.org/10.1177/1687814016683354

Zhang, Q. H., Xu, Y., Xu, Y. H., Shi, W. D., Lu, W. G., & Liu, W. (2013). Study on key technologies of energy-saving and environment-protective pumps. Thermal Sci, 17(5), 1556–1559. https://doi.org/10.2298/TSCI1305556Z

Zhou L (2018) Numerical analysis and performance experiment of electric submersible pump with different diffuser vanes number. J Brazil SocMech Sci Eng 0123456789https://doi.org/10.1007/s40430-018-0986-y

Zhu, J., Banjar, H., Xia, Z., & Zhang, H. Q. (2016). CFD simulation and experimental study of oil viscosity effect on multi-stage electrical submersible pump (ESP) performance. J Petrol Sci Eng, 146, 735–745. https://doi.org/10.1016/j.petrol.2016.07.033

Acknowledgements

The work has been carried out under the project (dre/7/ruet/528 (39)/pro/2021-22/25), financed by the Research & Extension Section, Rajshahi University of Engineering & Technology, Bangladesh. The authors would like to acknowledge the Department of Mechanical Engineering, Rajshahi University of Engineering & Technology, Bangladesh, for supporting the research work. The authors would like to express their sincere gratitude and thanks to the Barind Multipurpose Development Authority (BMDA) and Rajshahi WASA for providing the necessary information and the opportunity to study their different water pumping sites.

Author information

Authors and Affiliations

Contributions

Md. Sanowar Hossain (conceptualization, investigations, and conduction—major activities), Md. Emdadul Haque (review and editing), Mohammad Rofiqul Islam (supervision), and Md. Hasibul Hasan Himel (writing and survey). All authors have read and agreed to the published version of the manuscript.

I/We hereby declare that the research paper mentioned above has not been submitted to any other Proceeding/Journal for publication nor will it be submitted to any other proceeding/journal. I/We also declare that the work contained in the said research paper is my/our original contribution and has not been published anywhere.

I/We further declare that the authors have no competing interests and all the authors listed have read and approved the manuscript. I/We hereby transfer the copyright of my/our paper to Energy efficiency Journal, Springer nature. The sole responsibility in this respect lies with the corresponding author.

I/We give the authority Energy Efficiency journal, Springer nature for the review of my/our research paper for publication in this journal.

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Nomenclature table

Nomenclature table

Formulations/symbols | Description | Ref |

|---|---|---|

\({Y}_{1}+\frac{{P}_{1}}{\rho g}+\frac{{V}_{1}^{2}}{2g}+{H}_{p}={Y}_{2}+\frac{{P}_{2}}{\rho g}+\frac{{V}_{2}^{2}}{2g}+{h}_{ls}+{h}_{fm}+{h}_{lb}+n\times {h}_{lf}+{h}_{lo}\) | The Bernoulli’s equation is applied between point 1 and point 2 in Fig. 5 where P1, V1, and Y1 are the pressure, velocity, and height, respectively, in point 1. Similarly, P2, V2, and Y2 are the pressure, velocity, and height at point 2. Besides, Hp is the pumping head and \({h}_{ls},\) \({h}_{fm}\), \({h}_{lb}\),\({h}_{lf} \mathrm{and} {h}_{lo}\) are various type head loss which are explained in latter | Rajput (2008) |

\({V}_{1}=\frac{{d}_{2}^{2}}{{d}_{1}^{2}}\times ({V}_{2})\) | Applying continuity equation between points 1 and 2. Here, V1 and V2 is the velocity at points 1 and 2 whereas d1 and d2 are the diameter of the well and discharge pipe, respectively | |

\({h}_{ls}=\frac{{V}_{2}^{2}}{2g}\times ({f}_{ls})\) | \({\mathrm{Where }h}_{ls}\) is the head loss at pump inlet including the effect of the screen (m of water) and \({f}_{ls}\) is the effect of screen factor | |

\({h}_{fm}={f}_{m.}\frac{L}{{d}_{2}}\frac{{V}_{2}^{2}}{2g}\) | Where \({h}_{fm}\) is the major head loss due to friction in the discharge pipe (m of water) and \({f}_{m}\) is the friction factor | |

\({h}_{lb}={f}_{lb}\frac{{V}_{2}^{2}}{2g}\) | Where \({h}_{lb}\) is the head loss at the bend (m of water) and \({f}_{lb}\) is the factor due to bend | |

\({h}_{lf}={n\times f}_{lf}.\frac{{V}_{2}^{2}}{2g}\) | Where n is the no. of flange and \({h}_{lf}\) is the head loss in flange joints (m of water) and \({f}_{lf}\) is the flange factor | |

\({h}_{lo}={f}_{lo}.\frac{{V}_{2}^{2}}{2g}\) | Where \({h}_{lo}\) is the head loss at the outlet of discharge pipe (m of water) and \({f}_{lo}\) is the factor at outlet of discharge pipe | |

Y1 = 0 | Y1 = 0, because it is the point at the datum line | |

\(K=\{1-{\left(\frac{{d}_{2}}{{d}_{1}}\right)}^{4}+{f}_{ls}+{f}_{m.}\frac{L}{{d}_{2}}+{f}_{lb}+n{f}_{lf}+{f}_{lo}\}\) | Where k is a constant calculated using this equation | |

\({d}_{1}\) | Diameter of the well (m) | |

\({d}_{2}\) | Diameter of the discharge pipe (m) | |

\(g\) | Gravitational acceleration (m/s2) | |

\({H}_{p}\) | Pump head gain (m of water) | |

\({\mathrm{H}}_{2}\) | Pumping level (m) | |

\({h}_{fm}\) | Major head loss due to friction in the discharge pipe (m of water) | |

\({h}_{ls}\) | Head loss at pump inlet including the effect of the screen (m of water) | |

\({h}_{lb}\) | Head loss at the bend (m of water) | |

\({h}_{lf}\) | Head loss in flange joints (m of water) | |

\({h}_{lo}\) | Head loss at the outlet of discharge pipe (m of water) | |

\(L\) | Length of discharge pipe (m) | |

\(n\) | The number of flange joints | |

\(P\) | Electricity consumption (watt) | |

\({P}_{1}\) | Suction pressure at datum line (m of water) | |

\({P}_{2}\) | Delivery pressure in water distribution line (m of water) | |

\(Q\) | Discharge (m3/h) | |

\(S\) | The specific gravity of water | |

\({V}_{2}\) | The velocity of water at the delivery pipe (m/s) | |

\(\rho\) | The density of water (kg/m3) | |

\({\eta }_{c}\) | Combined efficiency (%) |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hossain, M.S., Haque, M.E., Islam, M.R. et al. Energy consumption behavior analysis and experimental investigation of a novel technique for energy-efficient operation of submersible pumping system used in Barind Tract of Bangladesh. Energy Efficiency 16, 5 (2023). https://doi.org/10.1007/s12053-022-10082-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12053-022-10082-5