Abstract

The Nickel oxide nanoparticles (NiO NPs) and Nickel oxide/Nanoclay nanocomposite (NiO/Nc NC) were synthesized by chemical reduction method and used for the photodegradation of Orange II dyes in aqueous solution. The synthesized samples were characterized through SEM, EDX, FTIR and TGA. The SEM analysis presented that the NiO NPs are spherical with irregular shapes and sizes. The size of particles is in the range of 100–400 nm. It was also observed that the NiO NPs are deposited on the surface of Nanoclay. The EDX study confirmed the formation of metal NPs and verify and purity. The FT-IR spectra of NiO and NiO/Nc NC presented peaks at 432 cm−1 and 504 cm−1, which correspond to NiO while peak at 1090–940 cm−1 is due to Si–O stretching vibration of orthosilicate anions and Si–O–Al groups. The photodegradation study illustrated that the NiO NPs and NiO/Nc NC degraded about 93 and 96% Orange II in aqueous medium, respectively within 20 min. The effect of various parameters like initial concentration of dyes, pH, recycled catalysts, and catalyst dosage were also studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dyes have wide range of applications in various industries like textile, paper and pulp, food and, dye industries. It is reported that the textile industries consume about 10×103 various dyes and pigments and worldwide more than 0.7 million tons of dyes are synthesized annually (Naderpour et al. 2012; Khan et al. 2022). The discharge of effluents from these industries causes considerable water pollution. It is predicted that about 1–15% of dyes are released during the processing or manufacturing operations into wastewater stream, which are toxic, carcinogenic, and non-biodegradable due to their large size and complex structures (Zhu et al. 2009; Saeed et al. 2015). Water contamination by these coloring materials is a serious life-threatening and harmful to the surrounding environment, aquatic life, and particularly to human beings (Khan et al. 2020d). Such types of organic coloring compounds can be removed by different methods such as precipitation, adsorption, ozonation, flocculation, reverse osmosis, and ultrafiltration (Santhanalakshmi and Komalavalli 2012; Khan et al. 2020b). These conventional treatment methods were found ineffective in handling wastewater containing synthetic dyes. Each conventional method of treatment has its disadvantages, which limit their practical employing not only in terms of cost but also in terms of feasibility, efficiency, reliability, sludge production, practicability, environmental impact, operation difficulty, pre-treatment requirements, and the generation of toxic byproducts (Khan et al. 2020d). Recently, semiconductor photocatalysis attained great attention due to its advantages over traditional techniques because of their efficiency during the photodegradation of organic compounds into simple and nontoxic species like CO2 and H2O (Solomon et al. 2012). During the photocatalytic process, the semiconducting materials /nanoparticles absorb photon equal to or more than energy gap, which produces the positive holes and electrons. The positive holes can react with water molecules and generate hydroxyl radicals (•OH). While the electrons are trapped by O2 molecules and as a result, the formation of reactive superoxide radical (•O2) occurs. Both •OH and •O2 − radicals are highly reactive and cause degradation of organic dyes (N et al. 2013; Gao et al. 2013). Several metals and metal oxides NPs like Silver (Sinha et al. 2014), ZnO (Yu et al. 2004), Fe2O3 (Abhilash et al. 2019), MnO2 NPs (Khan et al. 2019), SnO2 (Khan et al. 2020a), etc. were used as photocatalysts for the photodegradation of organic pollutants.

In the present study, NiO NPs and NiO/Nc NC were synthesized by chemical reduction method, where Nanoclay is used as a supporting material for NiO NPs. Ni was selected due to its excellent electronic, optical, magnetic, chemical, and catalytic properties (Barakat et al. 2013; Hashemi et al. 2017). NiO NPs were reported for synthesis of organic compound (Sachdeva et al. 2013; Nasseri et al. 2015), catalytic transfer hydrogenation (He et al. 2018), water splitting (Wang et al. 2017), photocatalytic degradation of dyes (Jayakumar et al. 2017; Akbari et al. 2020), etc. The NiO NPs and NiO/Nc NC were then used as a photocatalyst for the photodegradation of Orange II (O II) dye in aqueous medium under UV-light irradiation. O II is monoazo anionic and acidic textile dye and its chemical name is 4-(2-hydroxy-1 naphthyl) azobenzene sulfonic acid. Their stability is valuable in the textile manufacturing industry but makes its removal difficult, such as in wastewater treatment plants, where it does not undergo biological degradation. It shows resistance to degradation through light, common acids or bases, and the action of O2 (Khan et al. 2020a). The effect of irradiation time, initial concentration of dye, pH of the medium, catalysts sustainability, and catalyst dosage were evaluated. The photodegradation of Orange II dye was monitored by using UV–Vis spectrophotometer.

Materials and methods

Materials

Nickel chloride hexahydrate was purchased from BDH Company (England). The analytical grade sodium hydroxide and hydrochloric acid were purchased from Riedel–de Haen Company. Orange II dye was purchased from Sigma-Aldrich.

Preparation of NiO nanoparticles and NiO/nanoclay nanocomposite

About 11.9 g of nickel chloride hexahydrate was dissolved in 250 mL double distilled water and then NaOH (2 M) was added to it dropwise until the pH became basic. After basification of the solution, 0.5 g of Nanoclay were added and dispersed in the basified solution through sonication. The obtained mixture was continuously stirred and heated at 80 °C for 3 h. The NiO/Nc NC were cooled, filtered, and washed with double distilled water until the particles became neutral. The NiO/Nc NC was dried in an oven for overnight and stored for further use. Similarly, NiO NPs were also synthesized through the same protocol without adding nanoclay.

Photodegradation of orange II dye

The NiO NPs and NiO/Nc NC were used as photocatalysts for the photodegradation of orange II (O II). In degradation reaction, 10 mL OII (90 ppm) dye solution and known amount of photocatalyst was taken in 25 mL beaker and placed in dark for 20 min in order to achieve adsorption–desorption equilibrium. The mixture was kept under the UV light for specified time. After completion of degradation reaction time, the photocatalyst was separated from the reaction mixture via centrifugation (time = 10 min, rpm = 1200). The photodegradation study was carried out by UV/VIS spectrophotometer and the percent degradation of O II in aqueous media was calculated by the following equation:

where “Ao” represents the initial absorbance and “A” represents the dye absorbance after UV irradiation.

Characterization

The morphological study of NiO NPs and NiO/Nc NC was carried out by JEOL, JSM-5910 SEM. The EDX analyses of NiO NPs and NiO/Nc NC were performed on EDX (Model INCA 200/Oxford Instruments, UK, company oxford). The FT-IR study was performed by FT-IR spectrometer (Perkin Elmer, serial number 95120). The TGA analysis was carried out through Perkin Elmer USA in inert atmosphere. The photodegradation study of OII was monitored through UV–VIS spectrophotometer (UV-1800, Shimadzu, Japan).

Results and discussion

SEM analysis of NiO NPs and NiO/Nc NC

Figure 1 shows the morphological study of NiO NPs and NiO/Nc NC. Figure 1a shows the morphology of NiO NPs. The NPs are found to be spherical with irregular shape and the size are in nano range. The NPs are mostly found in agglomerated and bulky forms. Figure 1b illustrates the SEM image of NiO/Nc NC. The image clearly shows that the NiO NPs are spherical and present both in dispersed and aggregated form on the surface of the nanoclay. The images confirmed that the average particle size of NiO/Nc NC is below 100 nm.

Elemental composition analysis of NiO and NiO/nanoclay

Figure 2a illustrates the EDX pattern of NiO NPs which reveals the presence of both Ni and O peaks. The weight% and atomic% of Ni t is 77.41% and 48.29% respectively, while the weight% of oxygen is 22.59% and atomic% is 51.71%. Figure 2b represents the EDX spectrum of NiO/Nc NC, which showed high concentration of Ni, O, Si, C, and Al and minute quantity of other constituent elements. The presence of elements other than Ni and O such as Mg, Al, Si, Cl, and Fe is due to the skeleton of nanoclay (Shahid Nazir et al. 2016). Si is the main constituent of nanoclay as reported in the literature (Khan et al. 2020c). The %elemental composition of NiO NPs and NiO/Nc NC are also represented in tabulated form in their respective EDX spectra.

FTIR analysis of NiO NPs and NiO/Nc NC

The FT-IR spectra of NiO NPs and NiO/Nc NC which showed several absorption peaks as shown in Fig. 3. The spectra show strong, narrow band of the OH stretching vibration at 3640 cm−1 and which is the characteristic of Ni (OH)2 (El-Kemary et al. 2013). The absorption at 1635 cm−1 is assigned to the weak band of H–O–H vibrations in bending mode, which might be caused due to adsorption of water molecules from air (QiaoHongxia et al. 2009). The various bands in the region of 1000–1500 cm−1 are assigned to the O–C=O symmetric and asymmetric and C–O stretching vibration the stretching vibrations. While the characteristic peaks at 432 cm−1 and 504 cm−1 correspond to the vibration of Ni–O bond (Khansari et al. 2013). Furthermore, the NiO/Nc NC spectrum presented high-intensity band at 1090–940 cm−1 is due to Si–O stretching vibration of orthosilicate anions and Si–O–Al groups (Calabi-Floody et al. 2011).

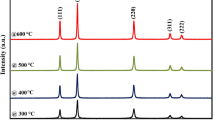

Thermal analysis of NiO NPs and NiO/Nc NC

The TG analysis of NiO NPs and NiO/Nc NC were carried out from room temperature to 600 °C. The TG thermograms of NiO NPs and NiO/Nc NC are shown in Fig. 4. The TGA of NiO and NiO/Nc NC curve shows different steps of weight loss. The TG curve show weight loss in the range of 50–100 °C, which might be due to the attached water on the surface of NPs. The loss of weight in the range from 100 to 400 °C is because of the removal of one water molecule that occurs in the range of 210–400 °C, which results due to the thermal decomposition of Ni(OH)2 to NiO nanoparticles. When temperature is above 400 °C, weight loss becomes fairly slight indicating the formation of NiO NPs is nearly completed. The TGA result verifies that the Ni(OH)2 NPs are calcinated at 400 °C. Above 400 °C obviously, there is no change in the weight of the precursor in the TG curve as previously reported (El-Kemary et al. 2013). The TGA curve of the NiO/Nc NC is shown in Fig. 4b. The material loses weight quite gradually at 120 °C because of the vaporization of residual water loss. After this stage, an abrupt decomposition occurs under these conditions all the organic fraction present in the nanoclay is destroyed.

Photodegradation of orange II Dye using NiO NPs and NiO/Nc NC

The NiO NPs and NiO/Nc NC were utilized for the photodegradation of O II dye under UV-light irradiation. Figure 5a, b shows the UV/VIS spectra of O II dye before and after photodegradation in the presence NiO NPs and NiO/Nc NC respectively. The degradation of O II dye was calculated by the relative intensity of the UV/ VIS spectra that gave highest absorbance peak at 482 nm. Figure shows that the degradation of O II dye gradually increased with increasing the irradiation time. Figure 5c demonstrates the %degradation of O II dye photodegraded by NiO NPs and NiO/Nc NC. The results presented that the NiO NPs and NiO/Nc NC degraded about 59 and 70% of O II dye within 5 min, which increased up to 93 and 96%, respectively as the irradiation time increased to 20 min. Figure 6a, b shows the digital photograph of O II dye before and after degradation reaction under UV-light photodegraded by NiO NPs and NiO/Nc NC respectively, as a function of irradiation time. The figure clearly displays that the dye degradation increases with increase in the irradiation time.

Sustainability of catalyst

The photodegradation of O II was also carried out by recycled catalysts in order to check their sustainability. The NiO and NiO/Nc NC catalysts were recovered from the reaction mixture, washed thoroughly with double distilled water, and dried overnight before the next run. Figure 7a, b represent the comparison of %degradation of O II dye photodegraded by fresh and recovered NiO NPs and NiO/Nc NC respectively. The figures clearly demonstrate that the recycled catalysts show less degradation as compared to fresh catalyst, which might be due to blockage of some active part of the catalyst by any attached chemical. The result showed that the fresh NiO NPs and NiO/Nc NC degraded about 93 and 96% dye while the recovered NiO NPs and NiO/Nc NC degraded about 65% and 69% within 20 min.

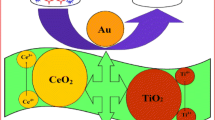

In the semiconductor photocatalysis, the photon having greater or equal energy to the energy of bandgap of photocatalyst is required. As the light energy falls on the NPs, the electron (e−) of the valence band (VB) are excited to conduction band (CB) and create a positive charged holes (h+) in the valence band. The conduction band electron (e−) react with O2 species as an electron acceptor and result in the formation of strong oxidizing agent superoxide anion radical (.O2−). Similarly, the h+ of the VB reacts with H2O molecule and generates hydroxyl radical (.OH). Both radical are liable for the degradation of dyes. These steps are summarized in the following reaction equations and can be easily understood from Fig. 8.

Effect of photo catalyst dosage

The effect of amount of photocatalyst on the photodegradation of OII dye was also checked by adding various dosage of catalyst (0.01, 0.015, 0.02, 0.025, 0.03 g) applying constant irradiation time (5 min) and initial dye concentration (90 ppm). Figure 9a, b demonstrate the UV/Vis spectra of OII dye using different dosages of NiO NPs and NiO/Nc NC, respectively. Figure 9c represents %degradation of O II dye employing different dosages of NiO and NiO/Nc NC. The results revealed that 0.01 g of NiO NPs and NiO/Nanoclay NPs degraded about 34% and 36%, respectively. Increasing the photocatalyst dosage causes an increase in %degradation and it was observed that 0.03 g of NiO NPs and NiO/Nc NC degraded 76% and 90%, respectively. It was observed that with an increase in catalyst amount, the rate of degradation of dye was improved due to the increase in the number of active sites for dye degradation reaction (Reuterg̊ardh and Iangphasuk 1997).

Effect of initial dye concentration

The effect of initial dye concentration on dye degradation was evaluated by degrading O II dye at various initial concentration (30, 60, 90, 120 ppm) keeping photocatalysts amount (0.02 g) and irradiation time (5 min) constant. Figure 10 represents the % degradation of OII dye photodegraded at various initial concentration of O II dye in the presence of NiO NPs and NiO/Nc NC. The results clearly demonstrate that the %degradation of O II dye decrease as initial concentration of O II dye increases. The decrease in photodegradation of dye with increasing initial dye concentration might be due to the color intensity which decreases light penetration and results in generation of less number of radicals (Sauer et al. 2002).

Effect of pH of the medium

Different industries like cosmetics, pharmaceuticals, paper, paint, etc. discharge their effluents at various pH and thus pH of the medium is very important parameter and is necessary to investigate the effect of pH on photodegradation of dyes (Siddique et al. 2014; Rache et al. 2014). The effect of pH of the medium was evaluated by degrading O II dye in different pH medium (2, 4, 6, 8 and 10) keeping dye concentration (90 ppm), irradiation time (5 min) and photocatalyst dosage (0.02 g) constant. Figure 11 represents the %degradation of O II dye photodegraded in different pH medium in the presence of NiO NPs and NiO/Nc NC. The results revealed that at pH 2, NiO NPs and NiO/Nc NC degraded about 89 and 97% O II dye, while at pH 10, NiO NPs and NiO/Nc NC degraded about 22 and 35% O II dye, respectively. It was clearly observed that as pH of the medium increases from 2 to 10 the photodegradation of O II dye decreases in a regular pattern. It means that the acidic conditions are more favorable for the photodegradation of O II dye than basic condition. In an acidic medium, reduction by electrons in the conduction band is essential in the degradation of dyes because of the reductive cleavage of azo bonds (Min et al. 2015).

Conclusion

Metal NPs are were successfully synthesized through chemical reduction techniques. The NPs are well supported on the surface of nanoclay. The NiO NPs are mostly agglomerated and nanoclay supported NiO NPs are mostly in dispersed form. The photodegradation study showed that both catalyst significantly degraded the Orange II dye in aqueous solutions. It was also found that NiO NPs and NiO/Nc NC are more efficient for the degradation of dye, which degraded about 93 and 96% Orange II dye within 20 min, respectively. It was also reported that the recycled catalyst is significantly degraded the dye. The enhanced photodegradation of O II dye by NiO/Nc NC than neat NiO NPs is due to the uniform distribution of NiO on the surface of nanoclay which increases its surface area for dye adsorption followed by photodegradation. The photodegradation of dye increases with increasing irradiation time, photocatalysts dosage and decreases with increasing initial dye concentration and pH of the medium.

References

Abhilash MR, Akshatha G, Srikantaswamy S (2019) Photocatalytic dye degradation and biological activities of the Fe2O3/Cu2O nanocomposite. RSC Adv 9:8557–8568. https://doi.org/10.1039/c8ra09929d

Akbari A, Sabouri Z, Hosseini HA et al (2020) Effect of nickel oxide nanoparticles as a photocatalyst in dyes degradation and evaluation of effective parameters in their removal from aqueous environments. Inorg Chem Commun 115:107867. https://doi.org/10.1016/J.INOCHE.2020.107867

Barakat A, Al-Noaimi M, Suleiman M et al (2013) One step synthesis of NiO nanoparticles via solid-state thermal decomposition at low-temperature of novel aqua(2,9-dimethyl-1,10-phenanthroline)NiCl2 complex. Int J Mol Sci 14:23941–23954. https://doi.org/10.3390/IJMS141223941

Calabi-Floody M, Bendall JS, Jara AA et al (2011) Nanoclays from an andisol: extraction, properties and carbon stabilization. Geoderma 161:159–167. https://doi.org/10.1016/J.GEODERMA.2010.12.013

El-Kemary M, Nagy N, El-Mehasseb I (2013) Nickel oxide nanoparticles: synthesis and spectral studies of interactions with glucose. Mater Sci Semicond Process 16:1747–1752. https://doi.org/10.1016/J.MSSP.2013.05.018

Gao P, Liu J, Sun DD, Ng W (2013) Graphene oxide–CdS composite with high photocatalytic degradation and disinfection activities under visible light irradiation. J Hazard Mater 250–251:412–420. https://doi.org/10.1016/J.JHAZMAT.2013.02.003

Hashemi M, Amin MM, Sadeghi S et al (2017) Coupling adsorption by NiO nanopowder with UV/H2O2 process for Cr(VI) removal. J Adv Environ Heal Res 5:210–219. https://doi.org/10.22102/JAEHR.2018.104101.1046

He J, Schill L, Yang S, Riisager A (2018) Catalytic transfer hydrogenation of bio-based furfural with NiO nanoparticles. ACS Sustain Chem Eng 6:17220–17229. https://doi.org/10.1021/ACSSUSCHEMENG.8B04579/SUPPL_FILE/SC8B04579_SI_001.PDF

Jayakumar G, Albert Irudayaraj A, Dhayal Raj A (2017) Photocatalytic degradation of methylene blue by nickel oxide nanoparticles. Mater Today Proc 4:11690–11695. https://doi.org/10.1016/J.MATPR.2017.09.083

Khan I, Sadiq M, Khan I, Saeed K (2019) Manganese dioxide nanoparticles/activated carbon composite as efficient UV and visible-light photocatalyst. Environ Sci Pollut Res 26:5140–5154. https://doi.org/10.1007/s11356-018-4055-y

Khan I, Khan AA, Khan I et al (2020a) Investigation of the photocatalytic potential enhancement of silica monolith decorated tin oxide nanoparticles through experimental and theoretical studies. New J Chem 44:13330–13343. https://doi.org/10.1039/d0nj00996b

Khan I, Khan I, Usman M et al (2020b) Nanoclay-mediated photocatalytic activity enhancement of copper oxide nanoparticles for enhanced methyl orange photodegradation. J Mater Sci Mater Electron. https://doi.org/10.1007/s10854-020-03431-6

Khan I, Khan I, Usman M et al (2020c) Nanoclay-mediated photocatalytic activity enhancement of copper oxide nanoparticles for enhanced methyl orange photodegradation. J Mater Sci Mater Electron 31:8971–8985. https://doi.org/10.1007/s10854-020-03431-6

Khan I, Saeed K, Ali N et al (2020d) Heterogeneous photodegradation of industrial dyes: an insight to different mechanisms and rate affecting parameters. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.104364

Khan I, Saeed K, Zekker I et al (2022) Review on methylene blue: its properties, uses toxicity and photodegradation. Water 14:242. https://doi.org/10.3390/W14020242

Khansari A, Enhessari M, Salavati-Niasari M (2013) Synthesis and characterization of nickel oxide nanoparticles from Ni(salen) as precursor. J Clust Sci 24(1):289–297. https://doi.org/10.1007/S10876-012-0521-8

Min O-M, Ho L-N, Ong S-A, Wong Y-S (2015) Comparison between the photocatalytic degradation of single and binary azo dyes in TiO2 suspensions under solar light irradiation. J Water Reuse Desalin 5:579–591. https://doi.org/10.2166/WRD.2015.022

Lu N, Lu Y, Liu F et al (2013) H3PW12O40/TiO2 catalyst-induced photodegradation of bisphenol A (BPA): kinetics, toxicity and degradation pathways. Chemosphere 91:1266–1272. https://doi.org/10.1016/J.CHEMOSPHERE.2013.02.023

Naderpour H, Noroozifar M, Khorasani-Motlagh M (2012) Photodegradation of methyl orange catalyzed by nanoscale zerovalent iron particles supported on natural zeolite. J Iran Chem Soc 10(3):471–479. https://doi.org/10.1007/S13738-012-0181-5

Nasseri MA, Kamali F, Zakerinasab B (2015) Catalytic activity of reusable nickel oxide nanoparticles in the synthesis of spirooxindoles. RSC Adv 5:26517–26520. https://doi.org/10.1039/C5RA02825F

Qiao H, Wei Z, Yang H et al (2009) Preparation and characterization of NiO nanoparticles by anodic arc plasma method. J Nanomater. https://doi.org/10.1155/2009/795928

Rache ML, García AR, Zea HR et al (2014) Azo-dye orange II degradation by the heterogeneous Fenton-like process using a zeolite Y-Fe catalyst—kinetics with a model based on the Fermi’s equation. Appl Catal B Environ 146:192–200. https://doi.org/10.1016/J.APCATB.2013.04.028

Reutergardh LB, Iangphasuk M (1997) Photocatalytic decolourization of reactive azo dye: a comparison between TiO2 and us photocatalysis. Chemosphere 35:585–596. https://doi.org/10.1016/S0045-6535(97)00122-7

Sachdeva H, Dwivedi D, Bhattacharjee RR et al (2013) Nio nanoparticles: an efficient catalyst for the multicomponent one-pot synthesis of novel spiro and condensed indole derivatives. J Chem. https://doi.org/10.1155/2013/606259

Saeed K, Khan I, Park S-Y (2015) TiO2/amidoxime-modified polyacrylonitrile nanofibers and its application for the photodegradation of methyl blue in aqueous medium. Desalin Water Treat. https://doi.org/10.1080/19443994.2014.912157

Santhanalakshmi J, Komalavalli R (2012) Nano TiO2 assisted degradation of textile dyes in H2O2 aqueous solution: kinetic studies with pH and mass effects. Chem Sci Trans 1:522–529. https://doi.org/10.7598/CST2012.158

Sauer T, Cesconeto Neto G, José HJ, Moreira RFPM (2002) Kinetics of photocatalytic degradation of reactive dyes in a TiO2 slurry reactor. J Photochem Photobiol A Chem 149:147–154. https://doi.org/10.1016/S1010-6030(02)00015-1

Shahid Nazir M, Haafiz Mohamad Kassim M, Mohapatra L et al (2016) Characteristic properties of nanoclays and characterization of nanoparticulates and nanocomposites. Eng Mater. https://doi.org/10.1007/978-981-10-1953-1_2

Siddique M, Khan R, Khan AF, Farooq R (2014) Improved photocatalytic activity of TiO2 coupling ultrasound for reactive blue 19 degradation. J Chem Soc Pak 36:37

Sinha T, Ahmaruzzaman M, Bhattacharjee A (2014) A simple approach for the synthesis of silver nanoparticles and their application as a catalyst for the photodegradation of methyl violet 6B dye under solar irradiation. J Environ Chem Eng 2:2269–2279. https://doi.org/10.1016/J.JECE.2014.10.001

Solomon RV, Lydia IS, Merlin JP, Venuvanalingam P (2012) Enhanced photocatalytic degradation of azo dyes using nano Fe3O4. J Iran Chem Soc 9(2):101–109. https://doi.org/10.1007/S13738-011-0033-8

Wang J, Xie Y, Yao Y et al (2017) Ni/NiO nanoparticles on a phosphorous oxide/graphene hybrid for efficient electrocatalytic water splitting. J Mater Chem A 5:14758–14762. https://doi.org/10.1039/C7TA03628K

Yu D, Cai R, Liu Z (2004) Studies on the photodegradation of Rhodamine dyes on nanometer-sized zinc oxide. Spectrochim Acta Part A Mol Biomol Spectrosc 60:1617–1624. https://doi.org/10.1016/J.SAA.2003.09.003

Zhu H, Jiang R, Xiao L et al (2009) Photocatalytic decolorization and degradation of Congo Red on innovative crosslinked chitosan/nano-CdS composite catalyst under visible light irradiation. J Hazard Mater 169:933–940. https://doi.org/10.1016/J.JHAZMAT.2009.04.037

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All the authors contributed equally to the compilation of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khan, N.A., Saeed, K., Khan, I. et al. Efficient photodegradation of orange II dye by nickel oxide nanoparticles and nanoclay supported nickel oxide nanocomposite. Appl Water Sci 12, 131 (2022). https://doi.org/10.1007/s13201-022-01647-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01647-x