Abstract

Proper treatment of heavy metal ions present in wastewaters is a major concern. With extensive usage in various industries, Cr(VI) contamination has become threatening for the environment. Biosorption is a favorable technique for heavy metals removal. In the present study, dried cyanobacterial consortium of Dinophysis caudata and Dinophysis acuminata were used to assess its biosorption capability. The surface texture and morphology of the biosorbent were obtained through scanning electron microscopy. The presence of different chemical bonds, namely hydroxyl, C–H and C–N, was confirmed through FTIR study. Pseudo-second-order Mckay-Ho model was found to perform best to fit the kinetic data. Temkin adsorption isotherm model fit best to the equilibrium data. Response surface methodology (RSM) was employed to optimize Cr(VI) abatement. Effect of initial concentration (IC) of metal ion, temperature, pH variation and amount of adsorbent (AD) were studied during batch study. Maximum Cr(VI) abatement after 5 min contact time was 80.77% for an IC of Cr(VI) of 25 mg/L, at pH 11 and 45 °C with the AD of 2.5 g/L. The optimum removal conditions as shown by RSM study were IC of Cr(VI): 15 mg/L, AD: 1 g/L, pH: 11, and the removal was predicted as 81.72%. Artificial neural network-based model was further developed based on experimental points which indicated that the model can predict abatement of Cr(VI) for various operating conditions with reasonably high accuracy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since the dawn of industrialization, water pollution is a critical environmental issue as the industrial wastewater containing various pollutants is directly or indirectly released into the water bodies that undoubtedly interrupt the aquatic biota. Among the various pollutants such as organic or inorganic chemicals, dyes and pesticides, heavy metals in wastewater play a crucial role due to their toxic and carcinogenic nature (Sen et al. 2017). Furthermore, they cannot be biodegraded rather bioaccumulated in the living body causing serious health hazards and even death (Tangahu et al. 2011). The atomic weights of heavy metals vary between 63.5 and 200.6, and their specific gravities are five times higher than that of water (Shanab et al. 2012). Chromium is commonly found in wastewater of tannery, textile, paint, ink, aluminum, galvanometry and electric, dyes and pigments, metal cleaning, plating and electroplating, film and photography, mining, leather industries, and its concentration can range from tens to hundreds of mg/L (Han et al. 2008). Cr(III) and Cr(VI) are the most stable form of chromium (Gupta and Rastogi 2009). Though Cr(III) is used as an important nutrient to animals, the toxicity of Cr(VI) is near about 300 times more than Cr(III) because of its profound carcinogenic, mutagenic and teratogenic effects (Qu et al. 2014). Adverse health effects of chromium depend on its dose, exposure duration and the nature of compound. As per World Health Organization (WHO), the maximum allowable limit of hexavalent chromium is 0.05 mg/L in drinking water (Gupta and Rastogi 2009). Thus, chromium removal from wastewater is mandatory before releasing into the environment.

Several conventional treatment process, such as chemical precipitation (Karale et al. 2007; Ramakrishnaiah and Prathima 2012), membrane separation (Rad et al. 2009; Zargar 2012), ion exchange (Dharnaik and Ghosh 2014; Dima et al. 2015) and solvent extraction (Sahu et al. 2008; Mane et al. 2012), have been used for abatement of chromium from wastewater. However, conventional techniques are having the limitations of high chemical or energy requirements, formation of secondary pollutants, high cost, toxic sludge generation, etc. (Rizzuti et al. 2015). Furthermore, they cannot be used effectively for the metal concentration below 100 mg/L (Anjana et al. 2007; Gupta and Rastogi 2009). It will always be beneficial if some low-cost adsorbents can be synthesized from waste biomass or agricultural residue (Pangeni et al. 2014). Therefore, the researchers are now trending toward alternate environment-friendly, low-cost and technically viable process.

About 7000 algal species are found in the world. The reasons behind the choice of microalgae as pollutant removal agent are numerous. Some of them are: (1) microalgae are capable of biofixing CO2 from waste gas/atmosphere; (2) they can utilize low-quality water, such as agricultural and municipal run-off, industrial wastewater containing toxic metals, organic matters; (3) algal bodies can live in natural weather condition; (4) they provide much higher yields of biomass when grown in wastewater; and (5) high-quality agricultural land is not required to grow the algal cells (Ramanan et al. 2010; Sen et al. 2017). Cyanobacteria, a photoautotrophic bacteria, also known as blue green algae, are recommended to have some additional advantages such as higher mucilage volume, greater binding affinity, simple nutrient requirements and larger surface area which leads to a better treatment in combating pollution over other microorganisms (Sen et al. 2017). Though several researches have been done on abatement of Cr(VI) using microalgal/cyanobacterial biomass, only a very few paper addresses the detailed mathematical analysis substantiated with experimental findings.

In the present article, cyanobacterial consortium of Dinophysis caudata and Dinophysis acuminata has been employed for the Cr(VI) abatement. ANN (artificial neural network) model has been developed to predict the bioremediation of Cr(VI) using said consortium, and RSM (response surface methodology) has been implemented for optimizing the removal condition. Thus, the effect of operating variables on biosorption process has been ascertained using these two highly sophisticated mathematical tools.

Materials and methods

Collection, identification, culture condition and preparation of biosorbents

Cyanobacterial consortium of Dinophysis caudata and Dinophysis acuminata, collected from East Kolkata Wetland (EKW), was used for the study. The details of collection and identification were described by Sen et al. (2017). The consortium was cultured in BG-11 media and incubated inside an algal incubator at 25 ± 2 °C under light intensity of 2500 lx with dark to light period of 8:16. For the preparation of the biosorbent, the well-grown consortium was first harvested by centrifugation (Eltek TC 8100 F) at 5000 rpm, followed by washing 2–3 times using distilled water (Gupta and Rastogi 2009). The biomass was then dried naturally under sunlight. The prepared biomass was then grinded in mortar pestle to make it fine dust particles.

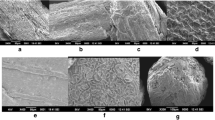

Characterization of biosorbent

Scanning electron microscopy (SEM) study of both dry cyanobacterial biomass and Cr(VI)-loaded sample was done to obtain the topographical characteristics using SEM (Hitachi-S-3000N, Japan). To get Cr(VI)-loaded sample, dried cyanobacterial biomass (2.5 g/L) was contacted with 10 mL solution of Cr(VI) with IC of 25 mg/L. Batch experiment was done inside a BOD incubator (Modern Instrument) at 25 °C and under constant agitation speed of 120 rpm for 5 min. After that, the centrifugation was done for 10 min at 5000 rpm. The biomass was then collected, dried and used for characterization. To get the elemental analysis, energy-dispersive spectroscopy (EDS) (Hitachi-S-3000N, Japan) study was also performed for both native and Cr(VI)-treated biomass. Fourier transform infrared (FTIR) study was done using (FTIR) spectrometer (Model No. Spectrum 100, Perkin-Elmer, USA) to determine the presence of different chemical bonds in the cell wall which are responsible for biosorption.

Preparation and analysis of Cr(VI) solution

To make a 100 mg/L stock solution of Cr(VI), 0.1414 g K2Cr2O7 was dissolved in 500 mL distilled water. The preparation of desired concentration of Cr(VI) was done by diluting the proper amount of stock solution. All the chemicals of analytical grade were used throughout this study and procured from MERCK, India. To maintain the initial solution pH at the start of the each experiments, 0.1N NaOH and 0.1N HCL were used. Batch experimentations were conducted to investigate the biosorption of Cr(VI) using dried algal biomass in Erlenmeyer flasks. In each flask, proper amount of biomass was added and flasks were kept inside the BOD incubator at 120 rpm agitation speed and 25 °C, until the equilibrium was reached. Finally, 1.0 mL sample was collected followed by the centrifugation. The supernatant was collected and analyzed for residual Cr(VI) concentration spectrophotometrically at 540 nm using a VIS spectrophotometer (Thermo Fisher Scientific, Genesys 20) after adding 1,5 diphenylcarbazide in acidic medium following the standard protocol (Clesceri et al. 1996).

Cr(VI) removal study

Batch study

The batch experiments were studied with synthetic solution of Cr(VI). To see the effect of various input variables, namely IC of Cr(VI) ion, initial pH of solution, temperature and AD on percentage abatement of Cr(VI), they were varied in the range of 2.5–25 mg/L, 5–11, 25–45 °C and 0.5–2.5 g/L, respectively. Instead of following one-factor-at-a-time (OFAT) methodology, IC of Cr(VI) was varied along with individual variation of other three variables, namely pH, AD and temperature. The solutions of all the experiments were thoroughly stirred at 120 rpm for 5 min. At first, initial pH was varied in the range of 5–11 for various ICs of Cr(VI) when AD and temperature of the system were kept fixed at 2.5 mg/L and 25 °C, respectively. The pH value for which the biomass gave the maximum metal removal was chosen for the next set of experiments where effect of biomass dosage was studied on Cr(VI) abatement. Similarly to see the effect of temperature, initial pH of solution and biomass dose was kept constant at their optimum values which were obtained through previous sets of experiments. Three sets of each experiment were done, and the mean value of these data was reported with standard deviation.

Equilibrium study

Equilibrium study was performed by changing IC in the range of 2.5–25 mg/L at three temperatures (25 °C, 35 °C and 45 °C). Other parameters such as AD, volume of solution and pH were kept constant at 2.5 g/L, 10 mL and 11, respectively. Samples were collected after 5 min and analyzed for Cr(VI) concentration. The amount of Cr(VI) uptake in each flask was calculated as follows:

where \(q_{\text{e}}\) is the solid-phase concentration of Cr(VI) at equilibrium (mg/g) and \(C_{\text{e}}\) is the equilibrium or final ion concentration (mg/L).

Kinetic study

Kinetics of abatement of Cr(VI) was investigated in batch mode for different ICs (2.5–25 mg/L) and ADs (0.5–2.5 g/L) at pH 11 and temperature 25 °C. When AD was varied, IC was kept constant at 25 mg/L, and when IC was varied, AD was kept 2.5 g/L. Samples were collected from the flasks at a fixed time interval of 1 min, and Cr(VI) concentration was measured.

Optimization of abatement of Cr(VI) using cyanobacterial biomass using response surface methodology

Design of experiment

Application of RSM is sequential in nature, and optimization is done through three successive major steps such as (1) designing of experiments, (2) analyzing the responses with prediction of model and (3) finding out optimum condition (Myers and Montgomery 1995; Chatterjee et al. 2012). RSM tells us the relationship between different input factors and the response. Mathematically, it can be shown as follows:

where \(Y^{{\prime }}\) is the response and \(X_{1}^{{\prime }} ,X_{2}^{{\prime }} , \ldots ,X_{n}^{{\prime }}\) are the independent variables called the numeric factors.

Central composite design (CCD), the most familiar class of second-order design, was used in the present study (Myers and Montgomery 1995).

Thus, for \(n\) number of variables, total number of tests required is:

For the three input variables used in this study, the total number of tests required is:

To avoid aliased terms present in the higher-order models, a second-degree polynomial equation is selected to analyze the responses as a function of numeric factors. The equation is as follows:

where \(\beta_{0}\) = the constant coefficient, \(\beta_{i}\) = the slope or linear effect of the input factor \(X_{i}^{{\prime }}\), \(\beta_{ii}\) = the quadratic effect of input factor \(X_{i}^{{\prime }}\), \(\beta_{ij}\) = the linear-by-linear interaction effect between the input factors \(X_{i}^{{\prime }}\) and \(X_{j}^{{\prime }}\) (Myers and Montgomery 1995; Sen et al. 2017).

Experimentation

Three input variables, viz. IC of Cr(VI), initial pH and AD, were independent factors, whereas percentage abatement of Cr(VI) was dependent variable. The minimum (− 1) and maximum (+ 1) values of IC of Cr(VI), initial pH and AD were kept as 8.125 g/L and 19.375 g/L, 6.5 and 9.5 and 0.1 g/L and 0.2 g/L, respectively. Design Expert software (version 8.0.7.1; Stat-Ease, Inc., Minneapolis, USA) was used for such purpose. Test cyanobacterial biomass was added in Erlenmeyer flasks containing synthetic wastewater of Cr(VI). The pH, AD and concentration of Cr(VI) were varied according to the design. The volume of wastewater was kept at 10 mL. Since equilibrium was obtained within 5 min as seen from equilibrium and kinetic studies, time was not considered as input variables and all the experiments were performed for 5 min. After experimentation, sample broth was analyzed for residual Cr(VI) concentration.

Theoretical analysis

Artificial neural network (ANN)

The development of empirical model using artificial neural network (ANN) is very much promising technique for the prediction of behavior of a biosorption system. ANN can be considered as a powerful tool and can be applied in the situations where there is an existence of inherent nonlinearity between the process inputs and the corresponding dependent variables. The idea of artificial intelligence that formulates the relation between human brain and nervous system was used for the development of ANN (Rumelhart et al. 1986; Nandi et al. 2001). A number of mathematical correlations are used in ANN which model learning and memorizing processes. There are several advantages of ANN models over traditional mathematical models such as detailed process understanding of the process which may not be needed, and it can be developed fast based on process input and outputs in relatively lesser time as compared to rigorous phenomenological models. The other important benefit of ANN model is its lesser simulation time which enables it to use extensively for the online process control applications (Himmelblau 2000; Kumar et al. 2014). Nodes of the input layers are used for feeding of all process input data, and the output layer has equal number of nodes (neurons) as that of output variables. The numbers of nodes in the hidden layer are chosen heuristically as depicted in Fig. 1. The nonlinear transformation carried out at the hidden nodes improves the performance of ANN to model difficult problems. The number of such nodes varies; however, the key parameter is the level of complication of the function. Neural network acts as a means in which input information is fed to the input nodes, and finally, after all the processing, the predicted outcome is received at the output layer to an external receiver. The main important parameters for network training are setting the number of hidden nodes and the nonlinear transformation to be used. The actual number of neurons in the hidden layer is calculated based on minimum value of mean squared error (MSE). For training of network, two parameters, namely momentum rate and learning coefficients, are used. However, for better generalization capability, the slow learning rate with little momentum coefficients is generally preferred. Initially, assigned weights connecting inputs to hidden nodes and hidden nodes to outputs layer are getting updated through backpropagation strategy (Kumar et al. 2014; Nandi et al. 2001).

In order to estimate the model applicability, the mean square error (MSE) is employed as a function of error.

Here N denotes number of experimental data points, \(y_{{i,{\text{pred}}}}^{{\prime }}\) denotes predicted output for ith experimental data point, and \(y_{i,\exp }^{{\prime }}\) denotes the experimentally determined output for ith data point.

Results and discussions

Characterization of cyanobacterial biomass

Surface texture of native cyanobacterial biomass and biomass after biosorption of Cr(VI) has been examined by SEM study as shown in Fig. 2a, b. From both the figures, irregular shaped cluster has been seen and no clear distinction for loading of Cr(VI) has been observed. To get the elemental analysis, EDS study has been performed. EDS spectra (Fig. 3a, b) show that for native sample, no traces of Cr(VI) are present in the sample; however, for treated biomass 35.24 weight % Cr(VI) has been found which clearly ascertains the binding of Cr(VI) onto the surface of cyanobacterial biomass. Conversely, all the other elements found in the treated biomass are comparatively lower than that in native cyanobacterial biomass (C: reduces from 28.39 to 14.15%, N: reduces from 7.81 to 5.24%, O: reduces from 49.57 to 33.68% and Na: reduces from 10.01 to 7.25%). Figure 4a, b shows the FTIR spectra of native cyanobacterial biomass and chromium-loaded biomass when wave number varies in the range of 400–4000 cm−1. The characteristics groups present in the native cyanobacterial biomass are –C–N bond, –C=C bond, C≡N bond, –C–H bond and –O–H bond at the wave numbers of 1045 cm−1, 1659 cm−1, 2357 cm−1, 2928 cm−1 and 3431 cm−1, respectively. For chromium-loaded biomass, –C–N stretch shifts to the wave number 1053 cm−1. C≡N bond and –C–H bond have not been found in the chromium-loaded biomass, whereas the –C=C bond and –O–H bond remain same as that of native cyanobacterial biomass. The changes or shift of these bonds may be due to the interaction between the cell wall and metal ions for which the binding of Cr(VI) occurs onto the cell wall.

Effect of operating variables on abatement of Cr(VI) using cyanobacterial biomass

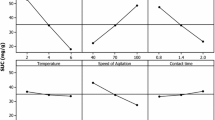

Combined effect of IC and pH

The effect of pH has been studied for different initial pHs of the solution in the range of 5–11 at varying ICs of Cr(VI) from 2.5 to 25 mg/L keeping other variables such as AD, temperature, shaking speed and time constant at 2.5 g/L, 25 °C, 120 rpm and 5 min, respectively (Fig. 5). From the figure, it is seen that higher abatement of Cr(VI) occurs at higher pH and IC. At pH 5.0, when IC of Cr(VI) is varying from 2.5 to 25 g/L, the percentage abatement of Cr(VI) is minutely increased from 10.12 to 35.01%. However, higher pH of the medium facilitates the biosorption process which leads to higher abatement of Cr(VI). Biosorption is the only mechanism for abatement of Cr(VI) using dried cyanobacterial biomass. As seen from FTIR study, the major bonds responsible for the biosorption process are –C–N bond, C≡N bond and –C–H bond. At higher pH, the net negative charge present in the cyanobacterial biomass is comparatively higher which facilitates the binding of positive Cr(VI) ion onto the cell surface. At pH 11, cyanobacterial consortium shows maximum abatement of Cr(VI), and under such condition, when IC of Cr(VI) is varied from 2.5 to 25 g/L, the corresponding removal has significantly increased from 35.01 to 80.36%. From the figure, it is seen that for a particular pH, higher the IC, higher is the percentage abatement of Cr(VI). Again, maximum removal has been obtained at IC of 25 mg/L irrespective of pH of solution. When solution pH increases from 5 to 11, the abatement of Cr(VI) increases from 27.23 to 80.36% at 25 mg/L IC. The increase in percentage removal with increasing IC of Cr(VI) was observed by Sibi 2016. When IC of Cr(VI) increased from 24.5 to 147 mg/L, the removal efficiency increased from 17.4 to 63.2 mg/g at pH 2 and from 16.9 to 58.1 mg/g at pH 1(Sibi 2016).

Combined effect of IC and AD

To examine the effect of AD on abatement of Cr(VI), the cyanobacterial biomass has been varied in the range of 0.5–2.5 g/L for different ICs of the solution ranging from 2.5 to 25 g/L keeping other parameters such as initial pH of the solution (11), temperature (25 °C), shaking speed (120 rpm) and time (5 min) constant (Fig. 6). From the figure, it is evident that the biosorption process depends significantly on the AD. For a particular concentration of 2.5 mg/L, when AD increases from 0.5 to 2.5 g/L the corresponding percentage removal increases from 10.64 to 35.01%. However, at higher IC of Cr(VI) (25 mg/L), increasing AD in the same range (0.5–2.5 g/L), percentage removal increases from 32.63 to 80.36%, respectively. The higher removal at higher AD is quite obvious because of availability of more adsorption site (Gupta and Rastogi 2009). In addition, it can also be seen that for same AD, the removal is more at higher IC. This may be caused by higher driving force of mass transfer at higher IC. Thus, it can be stated that the present system may be mass transfer-driven process instead of kinetically controlled one. Furthermore, at higher AD, the removal is almost same for 15 mg/L (78.11%), 20 mg/L (79.86%) and 25 mg/L (80.36%) solution. This is because of the reduction in available surface area for biosorption due to the formation of biomass aggregates.

Effect of IC at varying temperatures

Results on the effect of temperature at different ICs of Cr(VI) are depicted in Fig. 7. Though the enhanced temperature increases the percentage abatement of Cr(VI), the influence of temperature on the abatement of Cr(VI) is not significant at higher IC range. The higher the temperature of the solution, the higher will be the diffusion rate of Cr(VI) to the surface of biosorbent. At lower concentration, the mass transfer driving force is less, and thus, the effect of temperature on the removal process becomes significant. However, at higher IC, mass transfer driving force, i.e., the difference between concentration at solution and concentration at interface, is higher and biosorption rate will solely be dependent on such factor and effect of temperature becomes insignificant. Maximum percentage removal (80.77%) of Cr(VI) is obtained at 25 mg/L IC of Cr(VI), at pH 11.0, AD 2.5 g/L, temperature 45 °C after 5 min contact time.

Equilibrium study

Various equilibrium models have been used for fitting the experimental data for examining the relationship between solid- and liquid-phase concentrations of Cr(VI) at equilibrium. For each isotherm study, IC of Cr(VI) has been varied at different temperatures, while the other parameters have been kept constant. The values of isotherm constants and corresponding correlation coefficients are presented in Table 1. From the table, it is seen that Langmuir isotherm is not apt for the present study. Temkin isotherm model has been fitted best in comparison with other isotherm models with a maximum \(R^{2}\) value of 0.9553.

To understand the impact of temperature, and feasibility of the biosorption process, the various thermodynamic parameters, such as Gibbs free energy \((\Delta G^{0} )\), enthalpy \((\Delta H^{0} )\) and entropy \((\Delta S^{0} )\), were evaluated using the following equations:

where \(K_{\text{e}}\) is the equilibrium constant, \(T\) is temperature and \(R\) is the universal gas constant.

Based on the van’t Hoff plot of \(\ln K_{\text{e}}\) versus \(1/T\), the values of \(\Delta H^{0}\) and \(\Delta S^{0}\) were determined from the slope and intercept. From the thermodynamic plot, the parameters such as \(\Delta G^{0}\), \(\Delta H^{0}\) and \(\Delta S^{0}\) for the biosorption of Cr(VI) on cyanobacterial strain were calculated (Table 2). The value of \(\Delta G^{0}\) was found negative at the temperatures ranging from 25 to 45 °C, indicating the favorable and spontaneity of the process. The positive value of \(\Delta H^{0}\) indicates that the biosorption reaction is endothermic.

Kinetic study

Kinetic studies on abatement of Cr(VI) have been done by varying two variables, viz. AD (0.5–2.5 g/L) and IC (2.5–25 g/L) separately, and are shown in Figs. 8 and 9, respectively. From Figs. 8 and 9, it can be stated that higher values of both AD and IC of Cr(VI) enhance the abatement of Cr(VI). In all the cases, major removal has been obtained within 1 min, and after that, a minute increase in removal is seen. For ADs of 0.5 g/L and 2.5 g/L, the abatement of Cr(VI) has been obtained as 31.61% and 76.34% after 1 min and then increases to 32.63% and 80.36% after 5 min, respectively. Similarly, the percentage abatement of Cr(VI) increases from 34.48 to 35.01% with the increase in time of operation from 1 to 5 min at IC of Cr(VI) of 2.5 mg/L.

To examine the kinetics of the biosorption process using cyanobacterial biomass, various kinetic models, namely Lagergren first-order, pseudo-second-order (PSOM) and Morris–Weber (MB) kinetic models, have been used to fit the experimental data obtained during kinetic study. The values of the constants of different kinetic models are presented in Tables 3 and 4 considering AD and IC of Cr(VI) as varying parameters, respectively. From the tables, it can be stated that PSOM holds good to interpret the kinetic data of the biosorption process.

Determination of optimum conditions for abatement of Cr(VI) using RSM

RSM is employed for the optimization of Cr(VI) removal using the biomass of cyanobacterial consortium. IC of Cr(VI) (\(A^{{\prime }}\), mg/L); initial solution pH (\(B^{{\prime }}\)); AD (\(C^{{\prime }}\), g/L) are taken as input factors or independent variable, whereas abatement of Cr(VI) (\(R_{1}^{{\prime }}\), %) is taken as a response. The experimental design along with responses is shown in Table 5. Since the maximum (95%)-to-minimum (64.78%) ratio of the response is 1.47, less than 10, the transformation is not required. To avoid aliased terms present in higher-order models, a quadratic order equation is used as suggested by the software for analyzing the responses and the final equation is as follows:

The results of ANOVA for response surface quadratic model are shown in Table 6. The values of “Prob > F” lower than 0.05 designate the significance of the model terms. Analysis by ANOVA (Table 6) reveals that IC of Cr(VI), pH and AD have major effect on biosorptive abatement of Cr(VI) using cyanobacterial biomass. The combined effect of IC of Cr(VI) and pH and interactive effect of IC of Cr(VI) and AD are found significant. The diagram of the interactive effect of these two parameters is discussed in the present article.

The values of correlation coefficients have been found as \(R^{2}\): 0.9872, \(R_{\text{adj}}^{2}\): 0.9692 and \(R_{\text{pred}}^{2}\): 0.8998. Since the values of correlation coefficients are much higher, it can be stated that the predicted data match quite well with experimental one.

Figure 10a shows conjugate effect of both IC of Cr(VI) and pH on the abatement of Cr(VI). For constant IC of Cr(VI) of 7.06 mg/L, when the pH increases from 6.22 to 9.78, the percentage abatement of Cr(VI) increases from 72.41 to 81.96%. Similarly for a constant pH of 6.22 when IC of Cr(VI) increases from 7.06 to 20.44 mg/L, the percentage abatement of Cr(VI) increases from 72.41 to 80.46%. Figure 10b represents the interactive effect of AD and IC of Cr(VI) on removal process. From the figure, it is seen that higher AD facilitates the removal process. At constant IC of 7.06 mg/L and 20.44 mg/L, when AD increases from 0.91 to 2.09 g/L, the abatement of Cr(VI) increases from 74.53 to 80.09% and from 78.57 to 87.79%, respectively. Similar trend of abatement of Cr(VI) with varying ICs of Cr(VI), AD and pH has been described in the section “Effect of operating variables on abatement of Cr(VI) using cyanobacterial biomass.” To acquire the optimum abatement of Cr(VI), the criteria are as follows: IC: “in range”; pH: equal to “11”; AD: “minimize”; the response: “maximize.” The optimum condition obtained as: IC of Cr(VI): 15 mg/L; pH: 11.00; adsorbent dosage: 1 g/L, and at this condition, the removal has been predicted as 81.72%.

ANN modeling

In the present study, neural network is used for prediction of percentage abatement of Cr(VI) due to biosorption based on key governing parameters, namely IC of the heavy metal mg/L, pH of the medium, AD used in g/L and temperature in °C. Altogether 77 data points were available based on experimentation, and those are classified into learning or training, testing and validation set. Majority of data (70%) have been chosen for training of the model, whereas rest data were analyzed for validation purpose (15%) and the model was further tested with unseen test set (15%). Hence, the ANN model is developed (trained) based on 54 data points (70% of total data points), 12 data points were utilized for validating the model, and remaining 11 unseen data points were utilized for the testing the model performance. Based on some trial and error, it has been observed that network architecture comprises of four nodes in input—four nodes in the hidden layer, and 1 output node possesses maximum generalization capability. All the output and input data were first normalized, and the hyperbolic tangent sigmoid transfer function was used as the nonlinear transformation for all hidden and output nodes. Levenberg–Marquardt optimization method was utilized to minimize the mean squared error of the output through backpropagation strategy. As evident from Fig. 11a, the ANN model predicts the percentage removal quite accurately for the training set data points, and the percentage error in model prediction is well within 10% for all the 54 data points for training set. Similarly, the developed model fares reasonably well for the validation set as well, as shown in Fig. 11c, d for the actual performance. Subsequently, the developed neural network model was tested with unseen data and the performance of the model was really superb as evident from perfect fit in Fig. 11e and very low error in model prediction (much below 0.05%, refer to Fig. 11f). These clearly indicate true generalization capability of the model.

a Comparison of ANN prediction for training data set (54 points), b percentage error in ANN prediction for training data set (54 points), c comparison of ANN prediction for validation data set (12 points), d percentage error in ANN prediction for validation data set (12 points), e comparison of ANN prediction for unseen data test data set (11 points) and f percentage error in ANN prediction for unseen data test data set (11 points)

Conclusion

In the present study, cyanobacterial consortium consisting of Dinophysis caudata and Dinophysis acuminata, collected from EKW, has been proved efficient for the abatement of Cr(VI) from wastewater. The presence of chromium in the treated cyanobacterial biomass has been confirmed through EDS study. Different input variables, namely IC of Cr(VI), pH, AD and time, have significant effect on the removal process. From batch study, optimum Cr(VI) removal has been obtained as 80.77% with an IC of Cr(VI) of 25 mg/L, pH 11, AD 2.5 g/L, at temperature 45 °C after 5 min of operation, whereas the optimum removal conditions during RSM study are IC of Cr(VI): 15 mg/L; pH: 11.00; AD: 1 g/L, and at this condition, the removal has been predicted as 81.72%. Temkin adsorption isotherm fits the best for equilibrium data; however, kinetic data match quite well with pseudo-second-order model. Finally, an ANN model has been developed for biosorption based on part of the experimental data, and the model has sufficient generalization ability as evident from prediction of the unseen experimental data with reasonable accuracy.

Abbreviations

- A′:

-

Initial Cr(VI) conc. (mg/L)

- b :

-

Langmuir constant (L/mg)

- b′:

-

Variation of sorption energy (J/mol)

- B′:

-

Initial solution pH

- C′:

-

Amount of adsorbent (g/L)

- C 0 :

-

Initial ion conc. (mg/L)

- C e :

-

Equilibrium or final ion conc. (mg/L)

- C″ :

-

Constant (mg/g)

- k 1 :

-

First-order reaction rate constant (min−1)

- k 2 :

-

Second-order reaction rate constant (g/(mg min))

- k m :

-

Rate constant of Morris–Weber model (mg/(g min1/2))

- K f :

-

Freundlich adsorption constant ((mg/g) (L/mg)1/n′)

- K T :

-

Equilibrium binding constant corresponding to maximum binding energy (L/mg)

- M :

-

Biomass dry weight (g)

- n :

-

Total number of variables

- n c :

-

Number of central run

- n′:

-

Empirical parameter relating the sorption intensity

- N :

-

Total number of data

- q e :

-

Biomass biosorption equilibrium ions uptake capacity (mg/g)

- q max :

-

Maximum biosorption capacity (mg/g)

- q t :

-

Mass of metal adsorbed at time t (mg/g)

- R :

-

Universal gas constant = 8.314 × 10−3 (J/mol K)

- R′1 :

-

Percentage removal of Cr(VI) (%)

- t :

-

Time (min)

- T :

-

Temperature (K)

- V :

-

Sample volume (L)

- X′i :

-

Independent variables

- y′i,exp :

-

Response obtained from experiments

- y′i,pred :

-

Predicted response obtained from ANN

- Y′:

-

Response

- β :

-

Activity coefficient related to sorption mean energy (mol2/KJ2)

- β 0 :

-

The constant coefficient

- β ij :

-

The linear-by-linear interaction effect between the input factors Xi and Xj

- β ii :

-

The quadratic effect of input factor Xi

- β i :

-

The slope or linear effect of the input factor Xi

- ɛ :

-

Polanyi potential (KJ/mol)

- ΔG 0 :

-

Gibbs free energy (KJ/mol)

- ΔH 0 :

-

Enthalpy (KJ/mol)

- ΔS 0 :

-

Entropy (KJ/mol K)

References

Anjana K, Kaushik A, Kiran B, Nisha R (2007) Biosorption of Cr(VI) by immobilized biomass of two indigenous strains of cyanobacteria isolated from metal contaminated soil. J Hazard Mater 148:383–386

Chatterjee S, Kumar A, Basu S, Dutta S (2012) Application of response surface methodology for methylene blue dye removal from aqueous solution using low cost adsorbent. Chem Eng J 181–182:289–299

Clesceri LS, Greenberg AE, Trussell RR (1996) Standard methods for the examination of water and wastewater. APHA, AWWA, WPCF, Washington

Dharnaik AS, Ghosh PK (2014) Hexavalent chromium [Cr(VI)] removal by the electrochemical ion-exchange process. Environ Technol 35(18):2272–2279

Dima JB, Sequeiros C, Zaritzky NE (2015) Hexavalent chromium removal in contaminated water using reticulated chitosan micro/nanoparticles from seafood processing wastes. Chemosphere 141:100–111

Gupta VK, Rastogi A (2009) Biosorption of hexavalent chromium by raw and acid-treated green alga Oedogonium hatei from aqueous solutions. J Hazard Mater 163:396–402

Han X, Wong YS, Wong MH, Tam NFY (2008) Effects of anion species and concentration on the removal of Cr(VI) by a microalgal isolate, Chlorella miniata. J Hazard Mater 158:615–620

Himmelblau DM (2000) Applications of artificial neural networks in chemical engineering. Korean J Chem Eng 17(4):373–392

Karale RS, Wadkar DV, Nangare PB (2007) Removal and recovery of hexavalent chromium from industrial waste water by precipitation with due consideration to cost optimization. J Environ Res Dev 2(2):209–216

Kumar A, Dutta S, Bhattacharjee C, Datta S (2014) Artificial neural network modelling for removal of chromium(VI) from wastewater using physisorption onto powdered activated carbon. Desalin Water Treat. https://doi.org/10.1080/19443994.2014.987172

Mane CP, Mahamuni SV, Kolekar SS, Han SH, Anuse MA (2012) Hexavalent chromium recovery by liquid–liquid extraction with 2-octylaminopyridine from acidic chloride media and its sequential separation from other heavy toxic metal ions. Arab J Chem 9:S1420–S1427

Myers RH, Montgomery DC (1995) Response surface methodology: process and product optimization using designed experiments, 1st edn. Wiley, New York

Nandi S, Ghosh S, Tambe SS, Kulkarni BD (2001) Artificial neural-network-assisted stochastic process optimization strategies. AIChE J 47(1):126–141

Pangeni B, Paudyal H, Inoue K, Kawakita H, Ohto K, Gurung M, Alam S (2014) Development of low cost adsorbents from agricultural waste biomass for the removal of Sr(II) and Cs (I) from wastewater. Waste Biomass Valor 5:1019–1028

Qu Y, Zhang X, Xu J, Zhang W, Guo Y (2014) Removal of hexavalent chromium from wastewater using magnetotactic bacteria. Sep Purif Technol 136:10–17

Rad SAM, Mirbagheri SA, Mohammadi T (2009) Using reverse osmosis membrane for chromium removal from aqueous solution. Int J Chem Mol Nucl Mater Metall Eng 3(9):505–509

Ramakrishnaiah CR, Prathima B (2012) Hexavalent chromium removal from industrial watsewater by chemical precipitation method. Int J Eng Res Appl 2(2):599–603

Ramanan R, Kannan K, Deshkar A, Yadav R, Chakrabarti T (2010) Enhanced algal CO2 sequestration through calcite deposition by Chlorella sp. and Spirulina platensis in a mini-raceway pond. Biores Technol 101:2616–2622

Rizzuti AM, Ellis FL, Cosme LW (2015) Biosorption of mercury from dilute aqueous solutions using soybean hulls and rice hulls. Waste Biomass Valor 6:561–568

Rumelhart D, Hinton G, Williams R (1986) Learning representations by back propagating errors. Nature 323:533

Sahu SK, Verma VK, Bagchi D, Kumar V, Pandey BD (2008) Recovery of chromium(VI) from electroplating effluent by solvent extraction with tri-n-butyl phosphate. Indian J Chem Technol 15:397–402

Sen S, Dutta S, Guhathakurta S, Chakrabarty J, Nandi S, Dutta A (2017) Removal of Cr(VI) using a cyanobacterial consortium and assessment of biofuel production. Int Biodeterior Biodegrad 119:211–224

Shanab S, Essa A, Shalaby E (2012) Bioremoval capacity of three heavy metals by some microalgae species (Egyptian Isolates). Plant Signal Behav 7(3):1–8

Sibi G (2016) Biosorption of chromium from electroplating and galvanizing industrial effluents under extreme conditions using Chlorella vulgaris. Green Energy Environ 1:172–177

Tangahu BV, Abdullah SRS, Basri H, Idris M, Anuar N, Mukhlisin M (2011) A review on heavy metals (As, Pb and Hg) uptake by plants through phytoremediation. Int J Chem Eng. https://doi.org/10.1155/2011/939161

Zargar FH (2012) Separation of hexavalent chromium from water using nanofiltration. In: International conference on trade, tourism and management (ICTTM’2012)

Acknowledgement

Authors are grateful to the Department of Chemical Engineering, National Institute of Technology Durgapur, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sen, S., Nandi, S. & Dutta, S. Application of RSM and ANN for optimization and modeling of biosorption of chromium(VI) using cyanobacterial biomass. Appl Water Sci 8, 148 (2018). https://doi.org/10.1007/s13201-018-0790-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0790-y