Abstract

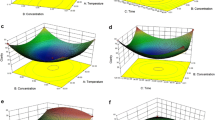

Banana juice extraction was optimized using central composite rotatable design with four numerical factors was employed to design the experiments. The numerical factors were incubation temperature (30–50 °C), and incubation time (20–60 min), cellulase concentration (0–0.4 g/100 g banana) and pectinase concentration (0–0.4 g/100 g banana). The optimum condition for extraction of banana juice were incubation temperature of 36.5 °C, incubation time of 29.33 min, cellulase concentration of 0.34% and pectinase concentration of 0.35%. The corresponding values of yield, viscosity, lightness, acidity, reducing sugar content and total soluble solids at the optimum condition were 74.15%, 101.14 mPa s, 30.06, 2.72%, 171.28 mg/100 g juice and 12.10 °Brix, respectively. Response surface analysis showed that yield increased with incubation time, and cellulase and pectinase concentration, and with temperature it initially increased and then decreased. The processing parameters had an opposite effect on viscosity. Reducing sugar content was also affected by all processing parameters.

Similar content being viewed by others

References

AOAC (2000) Official method no. 942.15 acidity (titrable), official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington

Barman S, Sit N, Badwaik LS, Deka SC (2015) Pectinase production by Aspergillus niger using banana (Musa balbisiana) peel as substrate and its effect on clarification of banana juice. J Food Sci Technol 52(6):3579–3589

Corzo O, Bracho N, Vásquez A, Pereira A (2008) Optimization of a thin layer drying process for coroba slices. J Food Eng 85(3):372–380

Demir N, Acar J, Sarıoğlu K, Mutlu M (2001) The use of commercial pectinase in fruit juice industry. Part 3: immobilized pectinase for mash treatment. J Food Eng 47(4):275–280

Egwim EC, Ogudoro AC, Folashade G (2013) The effect of pectinase on the yield and organoleptic evaluation of juice and wine from banana and paw-paw. Ann Food Sci Technol 14(2):206–211

Erbay Z, Icier F (2009) Optimization of hot air drying of olive leaves using response surface methodology. J Food Eng 91(4):533–541

FAOSTAT (2017) UN Food and Agriculture Organization, corporate statistical database (FAOSTAT)

Ibarra-Junquera V, Escalante-Minakata P, Chávez-Rodríguez AM, Comparan-Dueñas IA, Osuna-Castro JA, de Jesús Ornelas-Paz J, Pérez-Martínez JD, Aguilar CN (2014) Optimization, modeling, and online monitoring of the enzymatic extraction of banana juice. Food Bioprocess Technol 7(1):71–83

Kasozi G, Kasisira LL (2005) Design and performance of a banana juice extractor. In: African crop science conference proceedings, vol 7, no. pt. 03 of 03, pp 1381–1384

Kyamuhangire W, Myhre H, Sørensen HT, Pehrson R (2002) Yield, characteristics and composition of banana juice extracted by the enzymatic and mechanical methods. J Sci Food Agric 82(4):478–482

Lee WC, Yusof S, Hamid NSA, Baharin BS (2006) Optimizing conditions for hot water extraction of banana juice using response surface methodology (RSM). J Food Eng 75(4):473–479

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Mohapatra D, Mishra S, Sutar N (2010) Banana and its by-product utilization: an overview. J Sci Ind Res 69(5):323–329

Monitor S (2007) The presidential initiative for banana industrial development (PIBID). Poverty Alleviation Department-State House, Kampala, p 17

Park SH, Park JU (1997) Simultaneous optimization of multiple response using weighted desirability function. J Korean Soc Qual Manag 25:56–68

Qi B, Chen X, Shen F, Su Y, Wan Y (2009) Optimization of enzymatic hydrolysis of wheat straw pretreated by alkaline peroxide using response surface methodology. Ind Eng Chem Res 48(15):7346–7353

Rai P, Majumdar GC, Dasgupta SDES, De S (2004) Optimizing pectinase usage in pretreatment of mosambi juice for clarification by response surface methodology. J Food Eng 64(3):397–403

Sagu ST, Nso EJ, Karmakar S, De S (2014) Optimisation of low temperature extraction of banana juice using commercial pectinase. Food Chem 151:182–190

Sandri IG, Fontana RC, Barfknecht DM, da Silveira MM (2011) Clarification of fruit juices by fungal pectinases. LWT Food Sci Technol 44(10):2217–2222

Sharma HP, Patel H, Sugandha (2017) Enzymatic added extraction and clarification of fruit juices—a review. Crit Rev Food Sci Nutr 57(6):1215–1227

Sit N, Deka SC, Misra S (2015) Optimization of starch isolation from taro using combination of enzymes and comparison of properties of starches isolated by enzymatic and conventional methods. J Food Sci Technol 52(7):4324–4332

Sreekantiah KR (1975) Nature and application of pectinases with special reference to fruit and vegetable processing industry. Indian Food Pack 29(4):22–36

Tadakittisarn S, Haruthaithanasan V, Chompreeda P, Suwonsichon T (2007) Optimization of pectinase enzyme liquefaction of banana ‘Gros Michel’for banana syrup production. Kasetsart J (Nat Sci) 41:740–750

Tapre AK, Jain RK (2014) Optimization of an enzyme assisted banana pulp clarification process. Int Food Res J 21(5):2043–2048

Wanasundara UN, Shahidi F (1998) Concentration of ω-3 polyunsaturated fatty acids of marine oils using Candida cylindracea lipase: optimization of reaction conditions. J Am Oil Chem Soc 75(12):1767–1774

Zaker MA, Syed KA, Harkal RS (2014) Pre-treatment of pectinase and amylase on production of banana based wine. Int J Process Post Harvest Technol 5(2):145–150

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Handique, J., Bora, S.J. & Sit, N. Optimization of banana juice extraction using combination of enzymes. J Food Sci Technol 56, 3732–3743 (2019). https://doi.org/10.1007/s13197-019-03845-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03845-z