Abstract

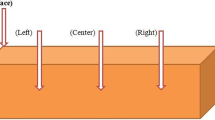

In the present work, temperature distribution within an industrial blast chiller with pork leg for Protected Designation of Origin Parma ham production was studied and the slowest cooling zone and the fastest cooling zone were recognized. Moreover, apparent heat transfer coefficients in both positions were calculated and resulted equal to 27.1 and 15.6 W m−2 °C−1, respectively. A finite element method model by distinguishing the three main components (skin, lean meat and bone) of the leg for the unsteady heat transfer during cooling was developed and validated against industrial chiller data. Good agreement between experimental and simulated data was obtained with RMSE value for thermal centre equal to 0.81 °C. Furthermore, in order to introduce CCP limit in the HACCP plan, a microbial growth model of the most important pathogens in meat was developed starting from the heat transfer model results. Temperature as well as pathogen growth were estimated in the case of different plant breakdowns. Defined CCP limit was represented by reaching 11 °C at 5 mm of depth within 2 h from the beginning of the cooling process, moreover a different cooling program was simulated and established as the alternative one.

Similar content being viewed by others

References

Adzitey F, Nurul H (2011) Pale soft exudative (PSE) and dark firm dry (DFD) meats: causes and measures to reduce these incidences—a mini review. Int Food Res J 18:11–20

ASHRAE (2010) Thermal properties of foods. In: 2010 ASHRAE handbook refrigeration, chapter 19. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA

Bergman TL, Lavine AS, Incropera FP, DeWitt DP (2011) Fundamentals of heat and mass transfer. Wiley, New York

EC Regulation No. 852/2004 of the European Parliament & of the Council of 29 April 2004

EC Regulation No. 853/2004 of the European parliament & of the Council of 29 April 2004

James SJ, James CB (2002) Meat refrigeration. CRC Press, Boca Raton, pp 273–275

Karakolev R (2009) Incidence of Listeria monocytogenes in beef, pork, raw-dried and raw-smoked sausages in Bulgaria. Food Control 20:953–955. doi:10.1016/j.foodcont.2009.02.013

Kondjoyan A (2006) A review on surface heat and mass transfer coefficients during air chilling and storage of food products. Int J Refrig 29:863–875. doi:10.1016/j.ijrefrig.2006.02.005

Kondjoyan A, Daudin JD (1997) Heat and mass transfer coefficients at the surface of a pork hindquarter. J Food Eng 32:225–240. doi:10.1016/S0260-8774(97)00005-8

Kuffi KD, Defraeye T, Nicolai BM, De Smet S, Geeraerd A, Verboven P (2016) CFD modelling of industrial cooling of large beef carcasses. Int J Refrig 69:324–339. doi:10.1016/j.ijrefrig.2016.06.013

Kuitche A, Letang G, Daudin JD (1996) Modelling of temperature and weight loss kinetics during meat chilling for time-variable conditions using an analytical-based method—II. Calculations versus measurements on wet plaster cylinders and cast. J Food Eng 28:85–107. doi:10.1016/0260-8774(95)00029-1

Ministerial Decree No. 253 of 15/02/1993 published on “Gazzetta Ufficiale della Repubblica Italiana” No. 173 of 26/07/1993

Ministerial Provision of 03/03/2014 published on “Gazzetta Ufficiale della Repubblica Italiana” No. 64 of 18/03/2014

Pham QT, Trujillo FJ, McPhail N (2009) Finite element model for beef chilling using CFD-generated heat transfer coefficients. Int J Refrig 32:102–113. doi:10.1016/j.ijrefrig.2008.04.007

Ramírez CA, Patel M, Blok K (2006) How much energy to process one pound of meat? A comparison of energy use and specific energy consumption in the meat industry of four European countries. Energy 31:2047–2063. doi:10.1016/j.energy.2005.08.007

Rinaldi M, Chiavaro M, Massini R (2014) Mathematical modelling of heat transfer in Mortadella Bologna PGI during evaporative pre-cooling. Int J Food Eng 10:233–241. doi:10.1515/ijfe-2014-0023

Trujillo FJ, Pham QT (2003) Modelling the chilling of the leg, loin and shoulder of beef carcasses using an evolutionary method. Int J Refrig 26:224–231. doi:10.1016/S0140-7007(02)00036-1

World Health Organization (1988) Foodborne listeriosis. World Health Organization, Geneva

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rinaldi, M., Cordioli, M. & Barbanti, D. Investigation on temperature fields in industrial chilling of pork legs for PDO Parma ham production and coupled temperature/microbial growth simulation. J Food Sci Technol 54, 18–25 (2017). https://doi.org/10.1007/s13197-016-2397-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2397-3