Abstract

The aim of this study was to investigate the effect of cold plasma treatment on the inactivation of microorganisms on meat surface and its influence on colour of meat and pH value. Nitrogen, argon and helium plasma were generated by high voltage discharge in a vacuum chamber (final 0.8 MPa) with exposure times of 5 and 10 min. Total number of microorganisms, psychrotrophs and number of yeast and mould were determined using plate method. Instrumental evaluation of colour parameters L* a* b* was performed by colorimeter Minolta Cr 400. Psychrotroph bacteria counts and total number of microorganisms exposed to helium and argon plasma for 10 min were reduced about 3 log cfu/cm2 and 2 log cfu/cm2, respectively. Increasing reductions of yeasts and moulds were also obtained and were about 3 cfu/cm2 (helium) and 2,6 cfu/cm2 (argon). The usage of nitrogen plasma has not resulted in any significant reduction of counts of psychrotrophs and total. number of microorganisms. Yeasts and moulds were little affected by nitrogen plasma and their numbers decrease about 1 log cfu/cm2. after 10 min of treatment. No significant differences in colour parameters and pH value after cold plasma treatment were observed. These results demonstrated that cold plasma has antimicrobial activity and could be a promising method of biodecontamination, but further investigations focusing on meat quality have to be determinate.

Similar content being viewed by others

Introduction

Fresh, unprocessed meat is highly prone to microbial contamination, resulting in loss of quality and/or food spoilage and consequently food-borne illness. Conventional preservation methods base on control by temperature, moisture and inhibitory processes like ionizing radiation and packaging. Scalding and singeing, chilling, water spraying, steams, ultraviolet light are commonly used as a physical treatments in food industry for decontamination of pig carcasses. Chemical decontamination treatments comprise a wide variety of substances such as organic acids (acetic acid, lactic acid)electrolyzed water, potassium sorbate, sodium hypochlorite(NaClO), trisodium phosphate (TSP) (Loretz et al. 2011). Many of them result in chemical and physical changes involving colour, odour, and texture of meat. Taking into consideration demands of consumers, which expect high quality, microbial safety, ecological products with normal flavor and taste, researchers have focused more on alternative decontamination methods such as non-thermal technologies (Aymerich et al. 2008, Zhou et al. 2010). One of them, novel method is gamma irradiation. This treatment is effective but poorly accepted by consumers, thus application in food industry is limited in contrast to the cold plasma technology (Moreau et al. 2008).

The cold plasma is defined as a partially ionized gas containing molecules, charged particles in the form of positive ions, negative ions, free radicals, electrons and photons. Those plasma species can interact with the bacterial cells and can effectively inactivate a wide range of microorganisms including spores and viruses (Misra et al. 2011). The most common method for plasma generation is by use of electrical discharges. Cold plasma is obtained at lower pressures and is characterized by thermodynamic disequilibrium between the electrons and the heavy species, thus the temperature of plasma is about 30–60 °C (Misra et al. 2011). Those properties make cold plasma technology a potential method of decontamination in the food industry, especially in treatment of thermolabile food products (Moreau et al. 2008). Plasma techniques have also advantages like: environmentally friendly, clean, safe for operators and allow treatment of wide range of materials with different properties (Bazaka et al. 2011).

The combination of various types of treatments improve the microbial stability and/or food quality. That hurdle technology has been defined by Leistner (2000) as an intelligent combination of food preservation food methods. For example, cold plasma treatment combined with edible films could provide a great opportunity for decontamination system in the future.

The objective of this study was to determine antimicrobial efficiency of helium, nitrogen and argon cold plasma treatment on surface microflora of meat as well as to observe changes in colour parameters and pH values.

Materials and methods

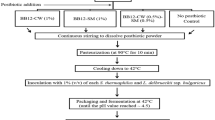

The pork longissimus dorsi muscle was obtained from Meat Industry “Dworeccy” plant. The surface layers of muscle (thickness 2 cm, length 7 cm, width 7 cm) were cut out and were exposed to helium, argon and nitrogen cold plasma for 5 and 10 min at low pressure (0.8 MPa). These samples were compared to samples not subjected to cold plasma treatment. The prototype pulsed plasma reactor (Ertec Poland) for this research was used (Fig. 1). Cold plasma was generated by high voltage discharge in a vacuum chamber (diameter 250 mm, height 500 mm, vacuum under 1 mbar) between the electrodes of the discharge condenser located on high voltage table, where the meat sample was placed. The frequencies used for the alternating voltages were between 20 and 100 kHz and reactive power was 1.2 kVA.

Sampling was started immediately after cold plasma exposure. Sterile cotton swabs were used for surface sampling in accordance with ISO 18593:2004. The swab head was moistened with sterile saline solution and excessive solution was pressed out against the interior wall of the vial with a rotating motion. A template with a 5 cm × 5 cm opening was used to sample the same surface area each time. After the area has been swabbed, the swab head was placed in the vial and series of dilutions were prepared (ISO 17604:2003). Determination of total number of microorganisms was done using plate method described in ISO 2293:1988. Colonies were counted after 72 h of incubation in 30 °C on culture medium containting tryptone, yeast extract, glucose and agar. Psychrotrophs were determined on PCA plates (hydrolyzed casein, yeast extract, glucose, agar) incubated at 6 °C for 10 days (ISO 17410:2001). For the determination of total numer of yeast and mould culture medium supplemented with antibiotic (chloramphenicol) was used. Other components, which were used to prepare medium, were yeast extract, glucose and agar. Plates were icubated for 5 days at 25 °C (ISO 21527-1:2008). The results are expressed as log cfu/cm2.

Colour was measured on the fresh meat surface and immediately after cold plasma treatment using colorimeter Minolta Cr400. The results were expressed in CIE LAB colour scale, where L* determines lightness, a* redness, b*yellowness. L* value is in the range of 0–100, where 0 represents black and 100 represents perfect reflecting diffuser. The a* and b* indicate colour directions, where +a* is red; −a* is green; +b* is yellow; −b* is blue. pH values were determined by using pH-meter.

The experiment was done in triplicate and plate count analyses were made in duplicate of each sample (three independent experiments analyzed in duplicate). Data were analyzed by one-way factor analysis of variance (Anova) using Statistica 9. Differences between means were established with Duncan Test with 5 % significance.

Results and discussion

The effect of helium plasma treatment on reduction of microorganisms is shown in Fig. 2. Total numer of microorganisms and yeasts and moulds were reduced about 2 log cfu/cm2. A longer time of exposure caused greater inactivation of microbes on meat surface. After 10 min treatment, helium plasma reduces those microbes about 3 log (Fig. 3). A significant reduction in the log counts of psychrotrophs was noted and was 1.9 and 2.7 log cfu/cm2 respectively after 5 and 10 min of exposure. The usage of argon plasma treatment results in significant reduction of psychrotrophs, total bacteria, and yeast and mould respectively about 1,1 log cfu/cm2; 1,3 log cfu/cm2; 1,15 log cfu/cm2 (Fig. 4). It was also observed that those microbes were reduced about 2,1 log cfu/cm2; 2,3 log cfu/cm2; 2,6 log cfu/cm2when the time of exposure was increased to 10 min.

The lower antimicrobial efficiency was observed for nitrogen plasma treatment (Fig. 5). Reduction of total number of yeasts and moulds on meat treated this type of plasma was obtained and was about 0.5 and 1.0 log cfu/cm2 lower compared to control sample. No significant differences of psychrotrophs and total numer of microorganisms were observed between control sample and sample treated with nitrogen plasma for 5 and 10 min of exposure. The results suggest that the usage of argon and helium as a process gas may provide more efficient decontamination.

Antimicrobial activity of cold plasma treatment on meat and meat products has been shown in various studies (Kim et al. 2011; Moon et al. 2009; Noriega et al. 2011; Song et al. 2009). Depending on the time of exposure, type of used gas, plasma sources or treated product, influence of cold plasma treatment on inactivation of microorganism is different. Kim et al. (2011) found that helium and helium/oxygen mixture reduce growth of Listeria monocytogenes, Escherichia coli and Salmonella Typhimurium on sliced bacon respectively about 1–2 log cycle and 2–3 log cycle, which indicate that gas mixture is more efficient. Song et al. (2009) observed that Listeria monocytogenes log reduction increased with increases of input power and plasma exposure time. More than 8 log reductions in sliced cheese and 1.7 log reduction in sliced ham can be achieved in 2 min at 150 W (Song et al. 2009). In Noriega et al.’s study (2011) it has been demonstrated that cold atmospheric gas plasmas could be employed for biodecontamination of chicken tissue, because an 8 min treatment gave 1 log reduction of Listeria innocua on skin, and a 4 min treatment gave >3 log reductions on muscle . Sterilization efficiency of helium plasmas generated in atmospheric pressure was confirmed by Moon et al. (2009), where the reduction of Escherichia coli inoculated on pork surface was comparable with that of a conventional UV sterilizer. UV radiation, charged particles and reactive species are responsible for plasma sterilization, because they can interact with the bacterial cells. Inactivation of microorganisms may be due to destruction by UV irradiation of the DNA of microorganism, erosion of the microorganism, atom by atom, through intrinsic photodesorption or etching (Moisan et al. 2002). Mentioned antimicrobial agents are produced in dependence on the adjusted parameters like gas composition, flow rate, moisture, temperature and excitation properties as a consequence of physical and chemical processes inside cold plasma (Ehlbeck et al. 2011). Therefore effect of plasma sterilization could be different.

Colour changes of meat samples treated with nitrogen and helium cold plasma are shown in Table 1.

No significant differences in the L*-, a*-, and b*-values between any of the plasma treated samples and control were found. Similar results were obtained by Moon et al. (2009). There were no significant changes in colour of pork surface after atmospheric pressure plasma treatment for 1 min at an input power of 150 W (Moon et al. 2009). On the other hand Fröhling et al. (2012) found that longer indirect plasma treatment led to lighter meat samples. Increase of a* values and decrease of b* values of pork meat after plasma treatment in comparison to untreated meat samples was observed. Rod et al. (2009) indicate that plasma treatment increases lipid oxidation depending on plasma power, treatment time and storage. Kim et al. (2011) observed fluctuating concentrations of thiobarbituric acid reactive substances (TBARS) in sample treated cold plasma. They suggest oxidation may constitute an issue in some products.

No significant changes in pH values were observed for all plasma treatment and control sample (Fig. 6). Similar results were obtained by Kim et al. (2011). Adler et al. (1998) compared the cost of different sterilization techniques—plasma, ethylene oxide and formaldehyde—for sterilizing thermolabile products. They indicated that plasma sterilization is cheaper than other techniques (even steam sterilization) due to its relatively shorter time of exposure. Besides other benefits after implementing the plasma technology are: avoided payments for air pollution, less personnel and monitoring cost. Low-pressure technology has some limitations connected with costly vacuum chamber, but it depends on application scale in the future.

Conclusion

The results of the present study have shown that usage of argon and helium cold plasma to inactivation of microorganism is a promising method of biodecontamination. In spite of great potential there are still a lot of issues that need to be further investigated. Optimization of cold plasma parameters is required to enhance significant reduction of microorganism after nitrogen plasma treatment. Moreover the effects of cold plasma treatment on quality of meat, especially oxidation process, have to be determinate. Taking into consideration that colour is known to play an important role in acceptability of meat, positive aspect of cold plasma treatment is lack of changes in that quality attribute.

References

Adler S, Scherrer M, Daschner FD (1998) Cost of low-temperature plasma sterilization compared with other sterilization methods. J Hosp Infect 40:125–134

Aymerich T, Picouet PA, Monfort JM (2008) Decontamination technologies for meat products. Meat Science 78:114–129

Bazaka K, Mohan JV, Crawford RJ, Ivanova EP (2011) Plasma assisted surface modification of organic biopolymers. Acta Biomater 7:2015–2028

Ehlbeck J, Schnabel U, Polak M, Winter J, von Woedtke T, Brandenburg R, von dem Hagen T, Weltmann KD (2011) Low temperature atmospheric pressure plasma sources for microbial decontamination. J Phys D Appl Phys. doi:10.1088/0022-3727/44/1/013002

Fröhling A, Durek J, Schnabel U, Ehlbeck J, Bolling J, Schlüter O (2012) Indirect plasma treatment of fresh pork: decontamination efficiency and effects on quality attributes. Innov Food Sci Emerg Technol 16:381–390

ISO 2293:1988 Meat and meat products. Enumeration of micro-organisms. Colony count technique at 30 degrees C

ISO 17410:2001 Microbiology of food and animal feeding stuffs. Horizontal method for the enumeration of psychrotrophic microorganisms

ISO 17604:2003 Microbiology of food and animal feeding stuffs. Carcass sampling for microbiological analysis

ISO 18593:2004. Microbiology of food and animal feeding stuffs. Horizontal methods for sampling techniques from surfaces using contact plates and swabs

ISO 21527-1:2008 Microbiology of food and animal feeding stuffs. Horizontal method for the enumeration of yeasts and moulds. Part 1: colony count technique in products with water activity greater than 0,95

Kim B, Yun H, Jung S, Jung Y, Jung H, Choe W, Jo C (2011) Effect of atmospheric pressure plasma on inactivation of pathogens inoculated onto bacon using two different gas compositions. Food Microbiol 28:9–13

Leistner L (2000) Basics aspects of food preservation by hurdle technology. Int J Food Microbiol 55:181–186

Loretz M, Stephan R, Zweifel C (2011) Antibacterial activity of decontamination treatments for pig carcasses. Food Control 22:1121–1125

Misra NN, Tiwari BK, Raghavarao KSMS, Cullen PJ (2011) Nonthermal plasma inactivation of food-borne pathogens. Food Eng Rev 3:59–170

Moisan M, Barbeau J, Crevier MC, Pelletier J, Philip N, Saoudi B (2002) Plasma sterilization. Methods and mechanisms. Pure Appl Chem 3:349–358

Moon SY, Kim DB, Gweon B, Choe W, Song HP, Yo C (2009) Feasibility study of the sterilization of pork and human skin surfaces by atmospheric pressure plasmas. Thin Solid Films 14:4272–4275

Moreau M, Orange N, Feuilloley MGJ (2008) Non-thermal plasma technologies: New tools for bio-decontamination. Biotechnol Adv 26:610–617

Noriega E, Shama G, Laca A, Díaz M, Kong MG (2011) Cold atmospheric gas plasma disinfection of chicken meat and chicken skin contaminated with Listeria innocua. Food Microbiol 28:1293–1300

Rod S, Hansen F, Leipold F, Knochel S (2009) Cold atmospheric pressure plasma treatment of ready-to-eat meat: inactivation of Listeria innocua and changes in product quality. Food Microbiol 30:233–238

Song HP, Kim B, Choe JH, Jung S, Moon SY, Choe W, Jo C (2009) Evaluation of atmospheric pressure plasma to improve the safety of sliced cheese and ham inoculated by 3-strain cocktail Listeria monocytogenes. Food Microbiol 26:432–436

Zhou GH, Xu XL, Liu Y (2010) Preservation technologies for fresh meat – A review. Meat Science 86:119–128

Acknowledgments

The experiment was done in the development project No N R12 0079 06/2009 “Development of methods to improve the quality and safety of refrigerated and stored meat” funded by Scientific Research and Development Center.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ulbin-Figlewicz, N., Brychcy, E. & Jarmoluk, A. Effect of low-pressure cold plasma on surface microflora of meat and quality attributes. J Food Sci Technol 52, 1228–1232 (2015). https://doi.org/10.1007/s13197-013-1108-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-1108-6