Abstract

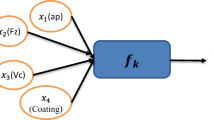

The mechanism behind the formation of surface finish is very complicated and process dependent, therefore it is very difficult to calculate the value of surface roughness through analytical formula. In this paper, a study is presented to model surface roughness in end milling process. Three types of intelligent networks have been considered to numerically identify the end milling process. They are (i) radial basis function neural networks (RBFN) (ii) adaptive neuro-fuzzy inference systems (ANFIS), and (iii) genetically evolved fuzzy inference systems (G-FIS). The machining parameters, namely, the spindle speed, feed rate and depth of cut have been used as inputs to model the workpiece surface roughness. The contribution of this work is to investigate different methodologies which could be used to get the best prediction accuracy. The procedure is illustrated using experimental data of end-milling 6,061 aluminum alloy. The three networks have been trained using experimental training data. After training, they have been examined using another set of data, i.e. validation data. Results are compared with previously published results. It is concluded that ANFIS networks may suffer the local minima problem and genetic tuning of fuzzy networks cannot insure perfect optimality unless suitable parameter setting (population size, number of generations … etc.) and tuning range for the fuzzy inference systems (FIS) parameters are used which can be hardly satisfied. It is shown that the RBFN model has the best performance (prediction accuracy) in this particular case.

Similar content being viewed by others

References

Agarwal S, Rao PV (2010) Modeling and prediction of surface roughness in ceramic grinding. Int J Mach Tools Manuf 50:1065–1076

Asilturk I, Cunkas M (2011) Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst Appl 38:5826–5832

Benardos PG, Vosniakos G-C (2003) Predicting surface roughness in machining: a review. Intern J Mach Tools Manuf 43:833–844

Billings SA, Wei H-L, Balikhin MA (2007) Generalized multiscale radial basis function networks. Neural Netw 20:1081–1094

Bouacha K, Yallese MA, Mabrouki T, Rigal J-F (2010) Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int J Refract Metal Hard Mater 28:349–361

Briceno JF, El-Mounayri H, Mukhopadhyay S (2002) Selecting an artificial neural network for efficient modeling and accurate simulation of the milling process. Int J Mach Tools Manuf 42:663–674

Chavoshi SZ, Tajdari M (2010) Surface roughness modeling in hard turning operation of AISI 4140 using CBN cutting tool. IntJ Mater Form 3:233–239

Chen S, Hong X, Harris CJ, Sharkey PM (2004) Sparse modeling using orthogonal forward regression with PRESS statistic and regulation. IEEE Trans Syst Man Cybern Part B (Cybern) 34(2):898–911

Cheng CT, Wang WC, Xu DM, Chau KW (2008) Optimizing hydropower reservoir operation using hybrid genetic algorithm and chaos. Water Resour Manag 22(7):895–909

Colak O, Kurbanoglu C, Kayacan MC (2007) Milling surface roughness prediction using evolutionary programming methods. Mater Des 28:657–666

Dong M, Wang N (2011) Adaptive network-based fuzzy inference system with leave-one-out cross-validation approach for prediction of surface roughness. Appl Math Model 35:1024–1035

Gupta MM, Jin L, Homma N (2003) Static and Dynamic Neural Networks: From Fundamental to Advanced Theory. Wiley, Hoboken

Haykin S (1999) “Neural Networks: A Comprehensive Foundation,” 2nd edn, Prentice Hall International, Inc., New Jersey

Ho W-H, Tsai J-T, Lin B-T, Chou J-H (2009) “Adaptive network-based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm”, Expert Systems with Applications, 36(2). Part 2:3216–3222

Jang J-SR (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23:3

Jang J-SR, Sun CT, Mizutani E (1997) “Neuro-fuzzy and soft computing: a computational approach to learning and machine intelligence,” Printice-Hall International, Inc., New Jersey

Karayel D (2009) Prediction and control of surface roughness in CNC lathe using artificial neural network. J Mat Proc Technol 209:3125–3137

Lo S-P (2003) An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling. J Mat Proc Technol 142:665–675

Lu C (2008) Study on prediction of surface quality in machining process. J Mat Proc Technol 205:439–450

Mitchell M (1999) An introduction to genetic algorithms. MIT Press, Cambridge

Nandi AK, Pratihar DK (2004) Automatic design of fuzzy logic controller using genetic algorithm to predict power requirement and surface finish in grinding. J Mater Proc Technol 148:288–300

Oktem H, Erzurumlu T, Erzincanli F (2006) Prediction of minimum surface roughness in end milling mold parts using neural network and genetic algorithm. Mat Des 27:735–744

Rao GKM, Rangajanardhaa G, Rao DH, Rao MS (2009) Development of Hybrid model and optimization of surface roughness in electric discharge machining using artificial neural networks and genetic algorithm. J Mater Process Technol 209:1512–1520

Rashid MFF, Lani MRA (2010) “Surface roughness prediction for CNC milling process using artificial neural network,” In: Proceedings of the World Congress on Engineering 2010, vol III, WCE 2010, London, June 30–July 2, 2010

Razfar MR, Zinati RF, Haghshenas M (2011) Optimum surface roughness prediction in face milling by using neural netwok and harmony search algorithm. Int J Adv Manuf Technol 52:487–495

Roy SS (2006) Design of genetic-fuzzy expert system for predicting surface finish in ultra-precision diamond turning of metal matrix composite. J Mater Process Technol 173:337–344

Sharkawy AB (2010) Genetic fuzzy self-tuning PID controllers for antilock braking systems. Eng Appl Artif Intell 23(7):1041–1052

Shieh H-L, Yang Y-K, Chang P-L, Jeng J-T (2009) Robust neural-fuzzy method for function approximation. Expert Syst Appl 36:6903–6913

Singh D, Rao PV (2007) A surface roughness prediction model for hard turning process. Int J Adv Manuf Technol 32:1115–1124

Topla ES (2009) The role of stepover ratio in prediction of surface roughness in flat end milling. Int J Mech Sci 51:782–789

Tsourveloudis NC (2010) Predictive modeling of the Ti6A14V alloy surface roughness. J Intell Robot Syst 60:513–530

Wang M, Chang H (2004) Experimental study of surface roughness in slot end milling AL2014-T6. Interna J Mach Tools Manuf 44:51–57

Wasserman PD (1993) Advanced methods in neural computing. Van Nostrand, New York

Wu Jun, Wang Shitong, Fu-lai Chung (2011) Positive and negative fuzzy rule system, extreme learning machine and image classification. Intern J Mach Learn Cybern 2(4): 261–271

Wu CL, Chau KW, Li YS (2009) “Predicting monthly stream flow using data-driven models coupled with data-preprocessing techniques,” Water Resour Res 45: W08432, doi:10.1029/2007WR006737

Yuhua Qian, Jiye Liang and Wei Wei (2012) Consistency-preserving attribute reduction in fuzzy rough set framework. Intern J Mach Learn Cybern doi: 10.1007/s13042-012-0090-z

Zain AM, Haron H, Sharif S (2010) Prediction of surface roughness in the end milling machining using artificial neural network. Expert Syst Appl 37:1755–1768

Zanaganeh M, Mousavi SJ, Shahidi AFE (2009) A hybrid genetic algorithm-adaptive network-based fuzzy inference system in prediction of wave parameters. Eng Appl Artif Intell 22:1194–1202

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharkawy, A.B., El-Sharief, M.A. & Soliman, ME.S. Surface roughness prediction in end milling process using intelligent systems. Int. J. Mach. Learn. & Cyber. 5, 135–150 (2014). https://doi.org/10.1007/s13042-013-0155-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13042-013-0155-7