Abstract

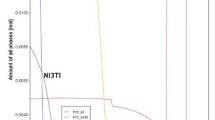

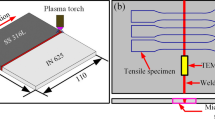

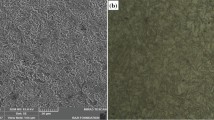

The solid solution strengthened Inconel 625, a Ni-based alloy is known for its excellent strength and good corrosion resistance at extreme environments used in thermal plants, boiler tubes, petrochemical industry and power plant. The presence of Cr content (~ 20 wt%) along with Mo-rich, Nb and Fe makes Ni–Cr–Mo–Nb austenitic alloy called as Inconel 625 to achieve excellent corrosion resistance property. Using cold metal arc transfer (CMT) cladding, the metallurgical, mechanical and corrosion properties of Inconel 625 on 316L is evaluated. The process parameters selected includes welding current, torch angle and travel speed with a constant voltage. From the results of microstructural and EDS inferences, the formation of cellular dendritic structure with secondary phases like Laves phase, complex nitrides along with the interdendritic segregation of Mo and Nb as well as microsegregation of Cr, Ni and Fe. In case of Ni–Cr–Mo alloy, Ni and Cr contribute to resistance to corrosion in NaCl environments. The formation of Cr2O3 and the passivation action of the clad zone is due to the presence of Cr. The solid solution effect in Ni–Cr matrix is contributed by the presence of Nb and Mo. Apart from that the strengthening action happens due to the precipitation of Ni3 (Al, Ti, Nb) commonly known as γ′, γ″ and MC carbides confirmed through XRD. Uni-axial tensile tests and Vickers-micro hardness indentation tests were performed on Inconel 625 cladded over 316L. Based on the fractographic results fatigue striations, tear rigdes with river markings, dimples with fibrous structure and cleavages are observed. Unlike other studies, unique type of cuboidal precipitates are seen, which is due to the presence of Ti, which form carbonitrides containing Ti, which are further characterised as NbC. The potentiodynamic polarisation tests is performed on 3.5% NaCl solution. The results suggest that Ni–Cr–Mo alloy protects the substrate from corrosion.

Graphical Abstract

Similar content being viewed by others

References

P. Varghese, E. Vetrivendan, M.K. Dash, S. Ningshen, M. Kamaraj, U.K. Mudali, Weld overlay coating of Inconel 617 M on type 316 L stainless steel by cold metal transfer process. Surf. Coat. Technol. 357, 1004–1013 (2019)

O.H. Madsen, New technologies for waste to energy plants, in 4th International Symposium on Waste Treatment Technologies, Babcock & Wilcox Vølund, Sheffield (2003)

T. Baldridge, G. Poling, E. Foroozmehr, R. Kovacevic, T. Metz, V. Kadekar, M.C. Gupta, Laser cladding of Inconel 690 on Inconel 600 superalloy for corrosion protection in nuclear applications. Opt. Lasers Eng. 51(2), 180–184 (2013)

S. Selvi, A. Vishvaksenan, E. Rajasekar, Cold metal transfer (CMT) technology—an overview. Def. Technol. 14(1), 28–44 (2018)

H.T. Zhang, J.C. Feng, P. He, B.B. Zhang, J.M. Chen, L. Wang, The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater. Sci. Eng. A 499(1–2), 111–113 (2009)

P. Kah, M. Shrestha, J. Martikainen, Trends in joining dissimilar metals by welding, in Applied Mechanics and Materials, vol. 440, ed. by D. Yang, T. Zhang, Q. Lu (Trans Tech Publications, Zurich, 2014), pp. 269–276

A. Schierl, The CMT process a revolution in welding technology. Weld. World Lond. 49(I), 38 (2005)

C.G. Pickin, S.W. Williams, M. Lunt, Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 211(3), 496–502 (2011)

J. Feng, H. Zhang, P. He, The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 30(5), 1850–1852 (2009)

M. Solecka, P. Petrzak, A. Radziszewska, The microstructure of weld overlay Ni-base alloy deposited on carbon steel by CMT method, in Solid State Phenomena, vol. 231, ed. by B. Dubiel, T. Moskalewicz (Trans Tech Publications, Zurich, 2015), pp. 119–124

M. Rozmus-Górnikowska, M. Blicharski, J. Kusiński, Influence of weld overlaying methods on microstructure and chemical composition of Inconel 625 boiler pipe coatings. Met. Mater. 52(3), 1–7 (2014)

J. Tuominen, J. Näkki, H. Pajukoski, T. Nyyssönen, T. Ristonen, T. Peltola, P. Vuoristo, High performance wear and corrosion resistant coatings by novel cladding techniques. Surf. Modif. Technol. XXVIII, 13 (2014)

A. Evangeline, P. Sathiya, Cold metal arc transfer (CMT) metal deposition of Inconel 625 superalloy on 316L austenitic stainless steel: microstructural evaluation, corrosion and wear resistance properties. Mater. Res. Express 6(6), 066516 (2019)

A. Evangeline, S. Paulraj, Structure–property relationships of Inconel 625 cladding on AISI 316L substrate produced by hot wire (HW) TIG metal deposition technique. Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/ab350f

Q.Y. Wang, Y.F. Zhang, S.L. Bai, Z.D. Liu, Microstructures, mechanical properties and corrosion resistance of Hastelloy C22 coating produced by laser cladding. J. Alloys Compd. 553, 253–258 (2013)

Y. Liang, S. Hu, J. Shen, H. Zhang, P. Wang, Geometrical and microstructural characteristics of the TIG-CMT hybrid welding in 6061 aluminum alloy cladding. J. Mater. Process. Technol. 239, 18–30 (2017)

R.A. Miller, Oxidation-based model for thermal barrier coating life. J. Am. Ceram. Soc. 67(8), 517–521 (1984)

T.E. Abioye, J. Folkes, A.T. Clare, A parametric study of Inconel 625 wire laser deposition. J. Mater. Process. Technol. 213(12), 2145–2151 (2013)

S. Bhattacharya, G.P. Dinda, A.K. Dasgupta, J. Mazumder, Microstructural evolution of AISI 4340 steel during direct metal deposition process. Mater. Sci. Eng. A 528(6), 2309–2318 (2011)

X. Xu, G. Mi, L. Chen, L. Xiong, P. Jiang, X. Shao, C. Wang, Research on microstructures and properties of Inconel 625 coatings obtained by laser cladding with wire. J. Alloys Compd. 715, 362–373 (2017)

S. Saroj, C.K. Sahoo, M. Masanta, Microstructure and mechanical performance of TiC-Inconel825 composite coating deposited on AISI 304 steel by TIG cladding process. J. Mater. Process. Technol. 249, 490–501 (2017)

D. Verdi, M.A. Garrido, C.J. Múnez, P. Poza, Mechanical properties of Inconel 625 laser cladded coatings: depth sensing indentation analysis. Mater. Sci. Eng. A 598, 15–21 (2014)

S.W. Banovic, J.N. DuPont, A.R. Marder, Dilution and microsegregation in dissimilar metal welds between super austenitic stainless steel and nickel base alloys. Sci. Technol. Weld. Join. 7(6), 374–383 (2002)

J.N. DuPont, A.R. Marder, M.R. Notis, C.V. Robino, Solidification of Nb-bearing superalloys: part II. Pseudoternary solidification surfaces. Metall. Mater. Trans. A 29(11), 2797–2806 (1998)

L. Shepeleva, B. Medres, W.D. Kaplan, M. Bamberger, A. Weisheit, Laser cladding of turbine blades. Surf. Coat. Technol. 125(1–3), 45–48 (2000)

G. Longlong, Z. Hualin, L. Shaohu, L. Yueqin, X. Xiaodong, F. Chunyu, Formation quality optimization and corrosion performance of Inconel 625 weld overlay using hot wire pulsed TIG. Rare Met. Mater. Eng. 45(9), 2219–2226 (2016)

T.E. Abioye, P.K. Farayibi, D.G. McCartney, A.T. Clare, Effect of carbide dissolution on the corrosion performance of tungsten carbide reinforced Inconel 625 wire laser coating. J. Mater. Process. Technol. 231, 89–99 (2016)

C.C. Silva, H.C. De Miranda, M.F. Motta, J.P. Farias, C.R.M. Afonso, A.J. Ramirez, New insight on the solidification path of an alloy 625 weld overlay. J. Mater. Res. Technol. 2(3), 228–237 (2013)

R.F. Allen, N.C. Baldini, P.E. Donofrio, E.L. Gutman, E. Keefe, J.G. Kramer et al., Annual Book of ASTM Standards (ASTM, West Conshohocken, 1998), p. 188

N.V. Rao, G.M. Reddy, S. Nagarjuna, Weld overlay cladding of high strength low alloy steel with austenitic stainless steel–structure and properties. Mater. Des. 32(4), 2496–2506 (2011)

O.T. Ola, F.E. Doern, A study of cold metal transfer clads in nickel-base INCONEL 718 superalloy. Mater. Des. 57, 51–59 (2014)

Y. Kaya, N. Kahraman, An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel. Mater. Des. 1980–2015(52), 367–372 (2013)

H.N. Moosavy, M.R. Aboutalebi, S.H. Seyedein, An analytical algorithm to predict weldability of precipitation-strengthened nickel-base superalloys. J. Mater. Process. Technol. 212(11), 2210–2218 (2012)

C. Fink, M. Zinke, Welding of nickel-based alloy 617 using modified dip arc processes. Weld. World 57(3), 323–333 (2013)

D. Janicki, Laser cladding of Inconel 625-based composite coatings reinforced by porous chromium carbide particles. Opt. Laser Technol. 94, 6–14 (2017)

L.Y. Xu, M. Li, H.Y. Jing, Y.D. Han, Electrochemical behavior of corrosion resistance of X65/Inconel 625 welded joints. Int. J. Electrochem. Sci. 8, 2069–2079 (2013)

K.Y. Chiu, F.T. Cheng, H.C. Man, Corrosion behavior of AISI 316L stainless steel surface-modified with NiTi. Surf. Coat. Technol. 200(20–21), 6054–6061 (2006)

H.Z. Rajani, S.A. Mousavi, F.M. Sani, Comparison of corrosion behavior between fusion cladded and explosive cladded Inconel 625/plain carbon steel bimetal plates. Mater. Des. 43, 467–474 (2013)

X. Xu, G. Mi, L. Xiong, P. Jiang, X. Shao, C. Wang, Morphologies, microstructures and properties of TiC particle reinforced Inconel 625 coatings obtained by laser cladding with wire. J. Alloys Compd. 740, 16–27 (2018)

J. De Damborenea, A.J. Vázquez, B. Fernández, Laser-clad 316 stainless steel with Ni-Cr powder mixtures. Mater. Des. 15(1), 41–44 (1994)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Evangeline, A., Sathiya, P. Dissimilar Cladding of Ni–Cr–Mo Superalloy over 316L Austenitic Stainless Steel: Morphologies and Mechanical Properties. Met. Mater. Int. 27, 1155–1172 (2021). https://doi.org/10.1007/s12540-019-00440-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00440-x