Abstract

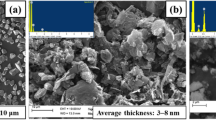

In the present investigation, Al7010/B4C/BN hybrid metal matrix nanocomposites with varying weight percents (wt%) of 0, 0.5, 1.0, 1.5, 2.0 and 2.5 of B4C and BN nanoparticles were prepared by ultrasonic-assisted stir casting technique. For the prepared composites, the microhardness and the tribological characteristics were reported. The wear behavior was determined under normal loads of 10, 20, 30 and 40 N and at sliding speeds of 0.5, 1.0 and 1.5 m/s, respectively. The results showed an increase in wear resistance and decrease in friction coefficient with the addition of the nanoparticles. The wear rate and friction coefficient increased with increase in normal load and sliding speed. The scanning electron microscope (SEM) images revealed uniform dispersion of the reinforcement particles in the composite. The wear specimens showed adhesion and plowing behavior at lower loads and delamination at higher load.

Similar content being viewed by others

References

Siddesh Kumar N G, Ram Prabhu T, Shiva Shankar G S, and Basavarajappa S, Tribol Mater Surf Interfaces 10 (2016) 138.

Arivukkarasan S, Dhanalakshmi V, Stalin B, and Ravichandran, M, Part Sci Technol 36 (2018) 967.

Haq M I U, and Anand A, Silicon 10 (2018) 1819.

Canakci A, Varol T, and Erdemir F, Arab J Sci Eng 41 (2016) 1781.

Chen C, Guo L, Luo J, Hao J, Guo Z, and Volinsky A A Mater Sci Eng: A 646 (2015) 306.

Rao R N, and Das S, Mater Des 31 (2010) 1200.

Suresh S, Gowd G H, and Kumar M D, Adv Compos Hybrid Mater 1 (2018) 819.

Kumar S, and Sood P K A, Mater Res Express (2018).

Kaushik N C, and Rao R N, Tribol Int 96 (2016) 184.

Abdollahi A, Alizadeh A, and Baharvandi H R, Mater Des 55 (2014) 471.

Kannan C, and Ramanujam R, J Adv Res 8 (2017) 309.

Sharifi E M, Karimzadeh F, and Enayati, Mater Des 32 (2011) 3263.

Gostariani R, Ebrahimi R, Asadabad M A, and Paydar M H, Acta Metall Sin (Engl Lett) 31 (2018) 245.

Firestein K L, Steinman A E, Golovin I S, Cifre J, Obraztsova E A, Matveev A T, and Golberg D, Mater Sci Eng A 642 (2015) 104.

Poovazhagan L, Kalaichelvan K, and Sornakumar T, Mater Manuf Process 31 (2016) 1275.

Soy U, Demir A, and Findik F, Ind Lubr Tribol 63 (2011) 387.

Manivannan I, Ranganathan S, Gopalakannan S, and Suresh S, Trans Indian Inst Met 71 (2018) 1897.

Kannan C, and Ramanujam R, J Alloys Compd, 751 (2018) 183.

Reddy A P, Krishna P V, and Rao R N, Trans Indian Inst Met 72 (2019) 2533.

Harichandran R, and Selvakumar N, Int J Mech Sci 144 (2018) 814.

Thirumalai Kumaran S, Uthayakumar M, Aravindan S, and Rajesh S, Proc Inst Mech Eng Part L: J Mater Des Appl 230 (2016) 484.

Moghadam A D, Omrani E, Lopez H, Zhou L, Sohn Y, and Rohatgi P K, Mater Sci Eng: A 702 (2017) 312.

Prasad Reddy A, Vamsi Krishna P, and Rao R N, J Compos Mater 53 (2019) 2165.

Moghadam A D, Omrani E, Menezes P L, and Rohatgi P K, Tribol Lett 62 (2016) 25.

Harichandran R, and Selvakumar N, Arch Civ Mech Eng 16 (2016) 147.

Reddy S, Chandrasekhara Rao P, and Kolli M, J Test Eval 48 (2020) 955.

Pal A, Poria S, Sutradhar G, and Sahoo P, Mater Res Express 5 (2018) 036521.

Murthy I N, Rao D V, and Rao J B, Mater Des 35 (2012) 55.

Baradeswaran A, and Perumal A E Compos Part B: Eng 54 (2013) 146.

Singh G, and Goyal S, Part Sci Technol 36 (2018) 154.

Archard, J, J Appl Phys 24 (1953) 981.

Das S, Samanta S, and Kayaroganam P, Ind Lubr Tribol 71 (2019) 83.

Suresh S, Gowd G H, and Kumar M D, J Inst Eng (India): Ser D (2018) 1.

David Raja Selvam J, Dinaharan I, Rai R S, and Mashinini P M, Tribol Mater Surf Interfaces 13 (2019) 1.

Reddy A P, Krishna P V, and Rao R N, Silicon (2019) 1.

Singh R, Shadab M, Dash A, and Rai R N, J Braz Soc Mech Sci Eng 41 (2019) 98.

Jojith R, and Radhika N, Part Sci Technol (2018) 1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dirisenapu, G., Dumpala, L. & Reddy, S.P. Dry Sliding Tribological Behavior of Al7010/B4C/BN Hybrid Metal Matrix Nanocomposites Prepared by Ultrasonic-Assisted Stir Casting. Trans Indian Inst Met 74, 149–158 (2021). https://doi.org/10.1007/s12666-020-02128-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02128-y