Abstract

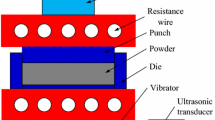

Al6061 alloy-based hybrid nanocomposites reinforced with 2wt% SiC and x wt% of graphite (x = 0, 0.5, 1, 1.5, 2 and 3) nanoparticles are fabricated through ultrasonically assisted casting technique. Microstructure, phases, grain size and fracture surfaces of the hybrid nanocomposites are studied to understand the mechanical properties. Microstructural studies revealed the uniform distribution of SiC and graphite nano-reinforcements in the matrix. The small-scale clusters appeared in the microstructure with the increase in graphite nanoparticles. The grain size, density, hardness and ultimate tensile strength of hybrid nanocomposites decreased with the rise of graphite in the composite material. The yield strength of the hybrid nanocomposites increased with increase in graphite up to 2 wt% and then decreased. SiC and graphite dual phase nanoparticles’ strengthening effect on yield strength was theoretically evaluated using various strengthening mechanisms including porosity effect. Enhancement of yield strength in hybrid nanocomposite due to strengthening mechanisms followed the trend \(\Delta \sigma_{{\Delta {\text{CTE}}}} > \Delta \sigma_{\text{Orowan}} > \Delta \sigma_{\text{HP}} > \Delta \sigma_{\text{load}}\). The predicted yield strength of hybrid nanocomposites obtained using the modified Clyne model and quadratic summation model were close to the experimental values. Fracture surfaces of hybrid nanocomposites exhibited brittle fracture with interdendritic cracking, stepwise facets and particle pull out with the increase in graphite content in the matrix.

Similar content being viewed by others

References

Srivastava N, Chaudhari G P, Mater Sci Eng A 724 (2018) 207.

Zeng X, Yu J, Fu D, Zhang H, Teng J, Vacuum 155 (2018) 375.

Boostani A F, Tahamtan S, Jiang Z Y, Wei D, Yazdani S, Azari R K, Mousavian R T, Xu J, Zhang X, Gong D, Compos Part A Appl Sci Manuf 68 (2015) 163.

Fathy A, Oqail A A, Wagih A, Ceram Int (2018).

Ravindran P, Manisekar K, Kumar S V, Rathika P, Mater Des 51 (2013) 456.

Alexander R, Murthy T S R C, Ravikanth K V, Prakash J, Mahata T, Bakshi S R, Krishnan M, Dasgupta K, Ceram Int 44 (2018) 9838.

Balci Ö, Aǧaoǧullari D, Gökçe H, Duman I, Öveçoǧlu M L, J Alloys Compd 586 (2014) 32.

Reddy A P, Krishna P V, Rao R N, Proc Inst Mech Eng Part N J Nanomater Nanoeng Nanosyst 231(4) (2017) 172.

Govender G, Ivanchev L, Burger H, Mulaba A, Chikwande H, J Compos Mat (2012) 53.

Li Q, Qiu F, Dong B X, Geng R, Lv M M, Zhao Q L, Jiang Q C, Mater Sci Eng A 735 (2018) 317.

Harichandran R, Selvakumar N, Int J Mech Sci 144 (2018) 826.

Harichandran R, Selvakumar N, Arch Civ Mech Eng 16 (2016) 158.

Moghadam A D, Omrani E, Lopez H, Zhou L, Sohn Y, Rohatgi P K, Mater Sci Eng A 702 (2017) 321.

Kannan C, Ramanujam R, J Alloys Compd 751 (2018) 193.

Lü S, Xiao P, Yuan D, Hu K, Wu S, J. Mater. Sci. Technol. 34 (2018) 1617.

Mavhungu S T, Akinlabi E T, Onitiri M A, Varachia F M, Procedia Manuf 7 (2017) 182.

Reddy M P, Shakoor R A, Parande G, Manakari V, Ubaid F, Mohamed A M A, Gupta M, Prog Nat Sci Mater Int 27 (2017) 614.

Gupta R, Chaudhari G P, Daniel B S S, Compos Part B Eng 140 (2018) 34.

Eskin G I, Eskin D G, Ultrason Sonochem 10 (2003) 301.

Khandelwal A, Mani K, Srivastava N, Gupta R, Chaudhari G P, Compos Part B Eng 123 (2017) 73.

Sharma P, Sharma S, Khanduja D, Part Sci Technol 34 (2016) 22.

Reddy A P, Krishna P V, Rao R N, Proc Inst Mech Eng Part N J Nanomater Nanoeng. Nanosyst 231 (2017) 172.

Zhang X, Li S, Pan B, Pan D, Zhou S, Yang S, Jia L, Kondoh K, J Alloys Compd 764 (2018) 288.

Aghdam M K H, Mahmoodi M J, Ansari R, J Alloys Compd 739 (2018) 177.

Bisht A, Srivastava M, Kumar R M, Lahiri I, Lahiri D, Mater Sci Eng A 695 (2017) 28.

Xiao P, Gao Y, Yang C, Liu Z, Li Y, Xu F, Mater Sci Eng A 710 (2018) 259.

Mirza F A, Chen D L, Materials (Basel) 8 (2015) 5153.

Chen B, Shen J, Ye X, Jia L, Li S, Umeda J, Takahashi M, Kondoh K, Acta Mater 140 (2017) 325.

Srivastava N, Chaudhari G P, Mater Sci Eng A 651 (2016) 247.

Zhang Z, Chen D L, Mater Sci Eng A 483–484 (2008) 152.

Deng K, Shi J, Wang C, Wang X, Wu Y, Nie K, Wu K, Compos Part A Appl Sci Manuf 43 (2012) 1284.

Park J G, Keum D H, Lee Y H, Carbon N Y 95 (2015) 698.

Talwar D N, Mater Sci Eng B Solid State Mater Adv Technol 226 (2017) 9.

Tsang D K L, Marsden B J, Fok S L, Hall G, Carbon N Y 43 (2005) 2906.

Ramakrishnan N, Acta Mater 44 (1996) 77.

Alizadeh M, Beni H A, Mater Res Bull 59 (2014) 294.

Zadeh A S, Mater Sci Eng A 531 (2012) 118.

Wang M, Chen D, Chen Z, Wu Y, Wang F, Ma N, Wang H, Mater Sci Eng A 590 (2014) 254.

Kim C S, Sohn I, Nezafati M, Ferguson J B, Schultz B F, Gohari Z B, Rohatgi P K, Cho K, J Mater Sci 48 (2013) 4204.

Yao X, Zhang Z, Zheng Y F, Kong C, Quadir M Z, Liang J M, Chen Y H, Munroe P, Zhang D L, J Mater Sci Technol 33 (2017) 1030.

Ramkumar K R, Sivasankaran S, Alaboodi A S, J Alloys Compd 709 (2017) 141.

Ozkaya S, Canakci A, Powder Technol 297 (2016) 16.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Reddy, A.P., Krishna, P.V. & Rao, R.N. Strengthening and Mechanical Properties of SiC and Graphite Reinforced Al6061 Hybrid Nanocomposites Processed Through Ultrasonically Assisted Casting Technique. Trans Indian Inst Met 72, 2533–2546 (2019). https://doi.org/10.1007/s12666-019-01723-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01723-y