Abstract

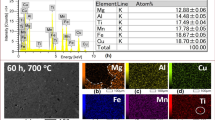

Equiatomic AlCuTaVW high-entropy alloy (HEA) composition have resulted in a single-phase solid solution with a bcc crystal structure after 25 h of ball milling. Two fcc phases and an ordered B2 phase have evolved during spark plasma sintering at 1523 K. The morphology of sintered disc contains a continuous bright phase and a discontinuous dark phase. The dark phase is detected to be Al-rich. Microhardness of the sintered product is 13 ± 1 GPa, and it is very high compared to other HEAs, conventional ceramics and cermets. A fracture toughness of 8.36 MPa m1/2 is measured from the cracks generated along the edges of Vickers indentation.

Similar content being viewed by others

References

Jones D R H, and Ashby M F, Engineering Materials 1: An Introduction to Properties, Applications and Design. 4th Ed., Butterworth-Heinemann, Amsterdam (2009).

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsua C H, and Chang S Y, Adv Eng Mater6 (2004) 299.

Murty B S, Yeh J W, and Ranganathan S, High-Entropy Alloys, Butterworth-Heinemann, Boston (2014).

Miracle D B, and Senkov O N, Acta Mater122 (2017) 488.

Gao M C, Yeh J W, Liaw P K, and Zhang Y, High-Entropy Alloys Fundamentals and Applications, Springer International, Switzerland (2016).

Ganji R S, Sai Karthik P, Bhanu Sankara Rao K, and Rajulapati K V, Acta Mater125 (2017) 58.

Li Z, Tasan C C, Springer H, Gault B, and Raabe D, Sci Rep7 (2017) 40704.

Hsu W -L, Yang Y -C, Chen C -Y, and Yeh J -W, Intermetallics89 (2017) 105.

Gludovatz B, Hohenwarter A, Catoor D, Chang E H, George E P, and Ritchie R O, Science345 (2014) 1153.

Mallik M, Pan S, and Roy H, Int J Curr Eng Tech3 (2013) 1647.

Seifi M, Li D, Yong Z, Liaw P K, and Lewandowski J J, Jom67 (2015) 2288.

Zhang H, He Y, and Pan Y, Scr Mater69 (2013) 342.

Gludovatz B, George E P, and Ritchie R O, Jom67 (2015) 2262.

Senkov O N, Wilks G B, Miracle D B, Chuang C P, and Liaw P K, Intermetallics18 (2010) 1758.

Senkov O N, and Woodward C F, Mater Sci Eng A529 (2011) 311.

Senkov O, Isheim D, Seidman D, and Pilchak A, Entropy18 (2016) 102.

Couzinié J P, Dirras G, Perrière L, Chauveau T, Leroy E, Champion Y, and Guillot I, Mater Lett126 (2014) 285.

Zhang A, Han J, Su B, Li P, and Meng J, Mater Des114 (2017) 253.

Strecker K, Ribeiroa S, and Hoffmannb M -J, Mater Res8 (2005) 121.

Bouteghmes D, Hamidouche M, and Bouaouadja N, Int Rev Mech Eng6 (2012) 803.

Shetty D K, Wright I G, Mincer P N, and Clauer A H, J Mater Sci20 (1985) 1873.

Spiegler R, Schmauder S, and Sigl L S, J Hard Mater1 (1990) 147.

Medeiros E E, and Dias A M S, Int J Recent Res Appl Stud17 (2013) 9.

Lenka K, Duszová A, Kašiarová M, Dorčáková F, Dusza J, and Balázsi C, Acta Metall Slovaca3 (2013) 213.

Sedlák R, Kovalčíková A, Tatarková M, Rutkowski P, and Dusza J, Defect Diffus Forum368 (2016) 166.

Abbas S Z, Khalid F A, and Zaigham H, J Non-Cryst Solids457 (2017) 86.

Gilbert C J, Ritchie R O, and Johnson W L, Appl Phys Lett71 (1997) 476.

Madge S V, Metals5 (2015) 1279.

Ćorić D, Ćurković L, Renjo M M, and Famena T, Transactions of Femena XLI-2 (2017) 1.

Andrejovská J, Mihalik J, Kovaľ V, Bruncková H, and Dusza J, Acta Metall Slovaca15 (2009) 112.

Min K S, Ardell A J, Eck S J, and Chen F C, J Mater Sci30 (1995) 5479.

Balog M, Hric L, Křesťan J, Bača L, and Šajgalík P, Powder Metall Prog6 (2006) 137.

Pramanick A K, Int J Res Eng Tech4 (2015) 334.

Ballóková B, and Besterci M, Powder Metall Prog8 (2008) 270.

Rios C T, Contieri R J, Souza S A, Cremasco A, Hayama A O F, and Caram R, Mater Des33 (2012) 563.

Anstis G R, Chantikul P, Lawn B R, and Marshall D B, J Am Ceram Soc64 (1981) 533.

Quinn G D, and Bradt R C, J Am Ceram Soc90 (2007) 673.

Acknowledgements

DST-PURSE and DST-FIST programs of School of Engineering Sciences and Technology, University of Hyderabad are gratefully acknowledged for supporting this research work. The authors are thankful to Mr. PVV Srinivas of the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad 500005, India, for assisting with spark plasma sintering.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ganji, R.S., Rajulapati, K.V. & Rao, K.B.S. Development of a Multi-phase AlCuTaVW High-Entropy Alloy Using Powder Metallurgy Route and its Mechanical Properties. Trans Indian Inst Met 73, 613–618 (2020). https://doi.org/10.1007/s12666-020-01875-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01875-2