Abstract

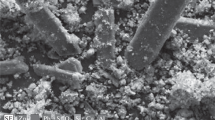

Zinc plant residue is a secondary metal source because it has precious metals such as zinc and lead. However, since this residue contains partial ferrite structure, there is no large-scale recovery in metallurgy industry. The aim of this study is to investigate the effect of mechanical activation of zinc plant residue in sodium hydroxide leaching. The results showed that mechanical activation obtained from high-energy mill had positive effect on the leaching of metals under condition of limited grinding time. Mechanical activation over 1 min caused the increase in particle size. It was also determined that specific surface area decreased due to onset of agglomeration of fine particles on the surface. Leaching efficiency of long-time milled residue was lower than short-time milled material’s leaching. It was determined that lead dissolution from zinc plant residue was higher than zinc dissolution in all experiments due to the presence of zinc in ferrite structure as franklinite form. Furthermore, sodium hydroxide leaching of this residue could be considered as a selective leach, since no iron was present in the solution.

Similar content being viewed by others

References

Baláž P, Extractive metallurgy of activated minerals, Elseiver, Amsterdam (2000) p 4.

Fattahi A, Rashchi F, Abkhoshk E, Hydrometallurgy 161 (2016) 185.

Feng L, Yang X, Shen Q, Xu M, Jin B, Hydrometallurgy 89 (2007) 305.

Langová S, Leško J, Matýsek D, Hydrometallurgy 95 (2009) 179.

Souza A D, Pina P S, Leão V A, Silva C A, Siqueira P F, Hydrometallurgy 89 (2007) 72.

Souza A D, Pina P S, Lima E V O, Silva C A, Leão V A, Hydrometallurgy 89 (2007) 337.

Turan M D, Altundoğan H S, Tümen F, Hydrometallurgy 75 (2004) 169.

Turan M D, Safarzadeh M S, Hydrometallurgy 119–120 (2012) 1.

Wang X, Yang D, Ju U, Peng J, Duan X, Trans Nonferrous Metals Soc China 23 (2013) 3808.

Xia D K, Pickles C A, Miner Eng 12 (1999) 693.

Youcai Z, Stanforth R, Miner Eng 13(2000) 1417.

Zhang Y, Deng J, Chen J, Yu R, Xing X, Hydrometallurgy 146 (2014) 59.

Acknowledgements

This work was financially supported by the Scientific and Technological Research Council of Turkey (TUBITAK, No. 112M285). The authors would like to thank TUBITAK for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Turan, M.D., Altundoğan, H.S., Boyrazlı, M. et al. Basic Leaching Behavior of Mechanically Activated Zinc Plant Residue. Trans Indian Inst Met 72, 2359–2364 (2019). https://doi.org/10.1007/s12666-019-01687-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01687-z