Abstract

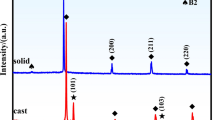

Mg–11Gd–2Y–xSm–0.6Al (x = 0, 1, 3, 5) alloys were prepared in electromagnetic induction furnace by gas protection. The crystal structure, microstructure and mechanical properties of as-cast Mg–11Gd–2Y–xSm–0.6Al alloys were studied by X-ray diffraction, metallographic microscope, scanning electron microscopy and tensile testing. The results show that the main phases of Mg–11Gd–2Y–xSm–0.6Al alloys are α-Mg matrix, Mg5Gd, Mg24Y5 and Mg41Sm5. The addition of Sm refines the microstructure and increases the number of second phase in the grain boundary. The diffraction peaks of the cylindrical plane (100)α-Mg, base plane (002)α-Mg and conical plane (101)α-Mg are shifted to a low angle. The offset of diffraction peak and the lattice constant of α-Mg increase with the increase in Sm content. The crystal axis ratio decreases with the increase in Sm content. When the addition of Sm is 3%, the ultimate tensile strength reaches to 240 MPa, which increases by 17.07%. The improvement in mechanical properties is mainly attributed to the grain refinement and the decrease in the crystal axis ratio of α-Mg.

Similar content being viewed by others

References

Darham W, Anis A L, Arif I A M, Babu N K, Harun M K, and Talari M K, Trans Indian Inst Met 70 (2017) 649.

Che C J, Cheng L R, Tong L B, Cai Z Y, and Zhang H J, J Alloys Compd 706 (2017) 526.

Sing L K, Srinivasan A, Pillai U T S, Joseph M A, and Pai B C, Trans Indian Inst Met 68 (2015) 331.

Nayyeri M J, Ganjkhanlou Y, Kolahi A, Jamili A M, Trans Indian Inst Met 67 (2014) 469.

Wang Q, Xiao L, Liu W C, Zhang H H, Cui W D, Li Z Q, and Wu G H, Mater Sci Eng A 705 (2017) 402.

Meng Y, Li Q, Tang Y, and Sugiyama S, Vacuum 150 (2018) 173.

Chen J, Zhang Q, and Li Q A, J Alloys Compd 686 (2016) 375.

Li J Q, Liu Y, Zhao X L, and Wu R Z, Appl Sci Technol 38 (2011) 55.

Li Z R, Ma C L, Tian S G, Chen L Q, and Liu X H, Chin J Rare Met 38 (2014) 786.

Seyed A H, Seyed M A, Karim Z M, and Mohammad K Y, Mater Chem Phys 211 (2018) 302.

Xu J, Li P F, and Guo F, Trans Mater Heat Treat 32 (2011) 30.

Li K J, Li Q A, Jing X T, Chen J, Zhang X Y, and Zhang Q, Scr Mater 60 (2009) 1101.

Gotoh M, Kitagawa K, Dobatkin S V, and Hirose Y, Mater Sci Forum 561 (2007) 917.

Wang M G, Tian S G, Yu X F, and Qian B J, Rare Met Mater Eng 39 (2010) 268.

Wang Z L, Zhang T, Li L, Zhou Y B, Wang H W, and Wei Z J, Chin J Nonferrous Met 22 (2012) 1006.

Yang X H, Peng L M, Yang C H, Jia B, and An J, Trans Mater Heat Treat 36 (2015) 39.

Lyu S Y, Li G D, Hu T, Zheng R X, Xiao W L, and Ma C L, Mater Lett 217 (2018) 79.

Zhang Q, Sun L C, Lu F, Hu W X, Liu S F, Li H, and Wang X Q, Mater Rev 29 (2015) 105.

Hu Y B, Deng J, Zhao C, Wang J F, and Pan F S, Trans Nonferrous Metal Soc 21 (2011) 732.

Wan D Q, Wang J C, and Yang G C, Mater Sci Eng A 517 (2009) 114.

Li K Y, and Xue D F, J Phys Chem A 110 (2006) 11332.

Zhang J X, Gao A H, and Guo X F, Rare Met Mater Eng 41 (2012) 459.

Yuan W, Panigrahi S K, Su J Q, and Mishra R S, Scr Mater 65 (2011) 994.

Acknowledgements

This project is sponsored by the National Natural Science Foundation of China (Nos. 51571084 and 51171059).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Li, Q., Zhu, L. et al. Effect of Sm on Microstructure, Mechanical Property and Lattice Constant of As-Cast Mg–11Gd–2Y–0.6Al Alloy. Trans Indian Inst Met 72, 1783–1789 (2019). https://doi.org/10.1007/s12666-019-01650-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01650-y