Abstract

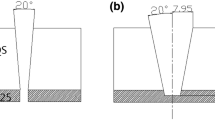

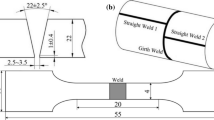

In this paper, a novel process welding for composite pipe, firstly overlaid by SMAW in composite pipe end and subsequently butted by TIG, can greatly improve the joints' comprehensive properties. Mechanical, corrosion tests and microstructure observation were carried out on welded joints. The results show that base X65 is composed of pearlite and ferrite and the weld is composed of dendritic austenite. The microstructure of HAZ in X65 has an upper bainite with coarse grains. The overlaying layer contains single-phase dendritic austenite, which has an apparent phenomenon of competitive growth similar to the weld, with solid subgrain boundary, solidified grain boundary and migrated grain boundary. By comparing the conventional welding process with the novel welding process, the welded joint shows better properties in mechanics and corrosion, showing the advantages in composite pipe.

Similar content being viewed by others

References

Reformatskaya I I, Zav’Yalov V V, Rodionova I G, Podobaev A N, and Ashcheulova I I, Prot Met Phys Chem + 36 (2000) 46.

Spencc M A, and Roscoe C V, Oil Gas J 97 (1999) 80.

Li F G, Wei B, Zhao X H, Shao X D, and Cai R, in International Conference on Pipelines and Trenchless Technology (2013), p 935.

Chen Z C, Ikeda K, Murakami T, Takeda T, and Xie J X, J Mater Process Tech 137 (2003) 10.

Zhang Z P, Xu W C, and Shan D B, Procedia Engineering 81 (2014) 2024.

Bahadori A, in Essentials of Coating, Painting, and Lining for the Oil, Gas, and Petrochemical Industries (2015), p 227.

Hou J, Peng Q J, Takeda Y, Kuniya J, Shoji T, Wang J Q, Han E-H, and Ke W, J Mater Sci 45 (2010) 5332.

Lundin C D, Weld J 61 (1982) S58.

Deng H D, and Zeng S P, Anti-Corros Method M 61 (2014) 380.

Chen H, Ma H Z, Chen X M, Jiang S F, and Wang H J, J Fail Anal Prev 15 (2015) 563.

Huang B S, Chen P, Zhang F R, Gong C L, Yuan P, Dai L, and Hu M D, Mater Rev 30 (2016) 101.

Rao N V, Reddy G M, and Nagarjuna S, Mater Design 32 (2011) 2496.

Rozmus górnikowska M, Cieniek Ł, Blicharski M, and Kusiński J, Arch Metall Mater 59 (2014) 1081.

Zahrani E M, and Alfantazi A M, Metall Mater Trans A 44A (2013) 4674.

El-Danaf E, Baig M, Almajid A, Alshalfan W, Al-Mojil M, and Al-Shahrani S, Mater Design 47 (2013) 529.

Sadeghian M, Shamanian M, and Shafyei A, Mater Design 60 (2014) 678.

Mendoza B I, Maldonado Z C, Albiter HA, Robles P E, Ocean Eng 2 (2010) 520.

Nelson D E, Iii W A B, and Lippold J C, Metallography 18 (1985) 215.

Kim S, Kang S Y, Lee S, Oh S, Kwon S J, Kim O H, and Hong J H, Metall Mater Trans A 31 (2000) 1107.

Ming H L, Zhang Z M, Wang J Q, Han E-H, and Ke W, Mater Charact 97 (2014) 101.

Hajiannia I, Shamanian M, and Kasiri M, Mater Design 50 (2013) 566.

Naffakh H, Shamanian M, and Ashrafizadeh F, J Mater Process Tech 209 (2009) 3628.

Zhao X, Liu Y, Zha X D, Cheng L M, Ma Y C, and Liu K, Acta MetallL Sin-Engl 50 (2014) 1377.

Glover A G, Mcgrath J T, Tinkler M J, and Weatherly G C, Weld J 56 (1977) 225.

Kou S, Welding Metallurgy, Second edition, Wiley, Hoboken (2003).

Lippold J C, Clark W A T, and Tumuluru M, An Investigation of Weld Metal Interfaces, The Metal Science of Joining, The Metals, Minerals and Materials Society, Warrendale (1992), p 141.

Dupont J N, Lippold J C, and Kiser S D, Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiley, Hoboken (2009), p 73.

Øien V, Effect of Electron Beam Welding on the Microstructure and Mechanical Properties of Nickel Alloys, Master’s Thesis, University of Stavanger (2014).

ASM International, ASM Handbook: Volume 3 alloy phase diagrams. The material international company (1992).

Naffakh H, Shamanian M, and Ashrafizadeh F, J Mater Process Tech 209 (2009) 3628.

Arivazhagan N, Singh S, Prakash S, and Reddy G M, Mater Design 32 (2011) 3036.

Zaczek Z, and Cwiek J, Weld J 72 (1993) S37.

Hall E O, Nature 173 (1954) 948.

Ram G D J, Reddy A V, Rao K P, Reddy G M, and Sundar J K S, J Mater Process Tech 167 (2005) 73.

Ahmad Z, Principles of Corrosion Engineering and Corrosion Control, Butterworth-Heinemann, Oxford (2006).

Acknowledgements

This study was financially supported by the Key Laboratory of Ministry of Education of Oil & Gas Equipment (Fund Number OGE201402-02) and Key Laboratory of Material of Oil & Gas of Sichuan Provincial Education Department (Project Number X151516KCL01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, B., Chen, Q., Zhao, X. et al. Microstructure, Properties and Corrosion Characterization of Welded Joint for Composite Pipe Using a Novel Welding Process. Trans Indian Inst Met 71, 2933–2944 (2018). https://doi.org/10.1007/s12666-018-1393-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1393-x